Alcohol, particularly ethanol, has been explored as a renewable fuel source for vehicles, offering an alternative to traditional gasoline. The process involves the fermentation of sugars derived from crops like corn, wheat, or sugarcane, producing ethanol through a process known as fermentation. This ethanol can then be blended with gasoline to create a fuel known as E10 or used alone in flexible-fuel vehicles designed to run on a range of ethanol blends, from E85 to pure ethanol. The use of alcohol as a car fuel is seen as a potential solution to environmental concerns and the depletion of fossil fuels, although challenges such as land use, water consumption, and the energy balance of the production process need to be addressed.

What You'll Learn

- Fermentation: Yeast converts sugar in ethanol, a key component in biofuel

- Ethanol Production: From corn, wheat, or sugar cane, a sustainable fuel source

- Engine Adaptations: Special engines can run on ethanol, requiring modifications

- Performance: Ethanol blends can improve engine performance and reduce emissions

- Environmental Impact: Biofuels reduce carbon footprint compared to traditional gasoline

Fermentation: Yeast converts sugar in ethanol, a key component in biofuel

The process of fermentation is a crucial step in the production of bioethanol, a renewable biofuel that is derived from renewable biomass sources. This process involves the use of a microorganism called yeast, which plays a vital role in converting sugars into ethanol. Here's an overview of how fermentation works in the context of biofuel production:

In the first stage of bioethanol production, biomass, such as corn, wheat, or even switchgrass, is harvested and processed to extract the sugars. These sugars are primarily in the form of glucose and can be present in various concentrations depending on the feedstock. The extracted sugars are then fed into a fermentation vessel, where the magic of yeast comes into play. Yeast, specifically ethanol-producing yeast strains, is added to the sugary solution. These yeast cells have the unique ability to metabolize glucose and other sugars through a process called fermentation. During this process, yeast enzymes break down glucose molecules into simpler sugars, such as fructose and glucose-6-phosphate. This is a critical step as it prepares the sugars for further conversion.

The yeast then proceeds to convert these simpler sugars into ethanol and carbon dioxide through a series of biochemical reactions. This fermentation process is highly efficient and can be optimized by controlling factors like temperature, pH, and oxygen levels. Typically, the fermentation is carried out in an oxygen-limited environment, which encourages the yeast to produce ethanol instead of other byproducts. As the yeast consumes the sugars, ethanol accumulates in the fermentation broth, making it a key component in the biofuel mixture.

The ethanol produced through fermentation is then separated from the yeast and other impurities through various distillation processes. This ethanol can be further refined and blended with gasoline to create a biofuel suitable for use in conventional internal combustion engines. The beauty of this process lies in its sustainability; by utilizing agricultural residues, dedicated energy crops, or even waste materials, bioethanol production can significantly reduce our reliance on fossil fuels and contribute to a more sustainable energy future.

In summary, fermentation is a critical biological process that harnesses the power of yeast to convert sugars into ethanol, a vital component in the production of biofuel. This renewable energy source has the potential to reduce greenhouse gas emissions and provide a cleaner alternative to traditional fossil fuels. Understanding and optimizing fermentation processes are essential steps in the development of efficient and sustainable biofuel technologies.

The Evolution of Fuel Systems: A 1920s Perspective

You may want to see also

Ethanol Production: From corn, wheat, or sugar cane, a sustainable fuel source

Ethanol, a renewable biofuel, is produced from various agricultural feedstocks, including corn, wheat, and sugarcane. This process not only contributes to a more sustainable energy landscape but also offers a viable alternative to traditional fossil fuels. The production of ethanol from these crops involves several key steps, each designed to maximize efficiency and minimize environmental impact.

The first step in ethanol production is the selection and preparation of the feedstock. Corn, for instance, is a popular choice due to its high starch content. The corn is first dried and then ground to separate the starch from the fiber. This starch is then converted into sugars through a process called enzymatic hydrolysis, where enzymes break down the starch into simpler sugars. Alternatively, wheat and sugarcane can be used, with their own unique preprocessing steps. Wheat, for example, requires a process called wet milling to extract the starch, while sugarcane can be directly processed due to its naturally high sugar content.

Once the feedstock is prepared, the next stage involves the fermentation process. Yeast is added to the sugars, and through fermentation, it converts the sugars into ethanol and carbon dioxide. This is a crucial step as it determines the quality and yield of the ethanol. After fermentation, the mixture is distilled to separate the ethanol from the water and other byproducts. The ethanol is then purified and dried to meet the required standards for fuel use.

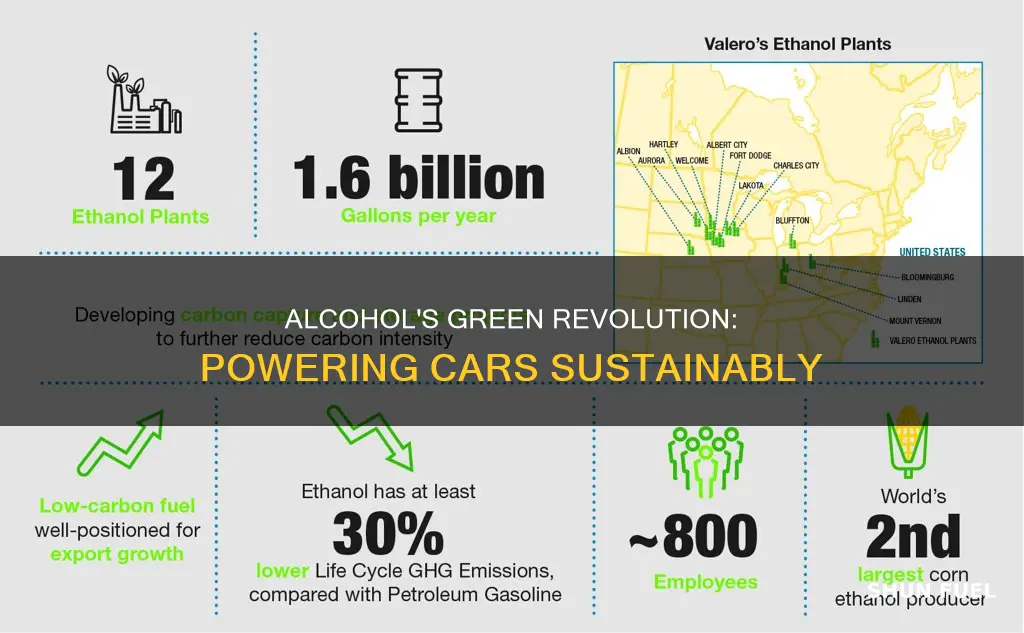

The environmental sustainability of ethanol production is a significant advantage. The use of agricultural feedstocks means that the fuel is derived from renewable resources, reducing the reliance on finite fossil fuels. Additionally, the process can help reduce greenhouse gas emissions compared to gasoline. Ethanol production also supports local agriculture and can provide economic benefits to farming communities.

In summary, the production of ethanol from corn, wheat, or sugarcane is a well-established process that offers a sustainable alternative to conventional fuels. It involves the careful selection and preprocessing of feedstocks, followed by fermentation and distillation to produce high-quality ethanol. This renewable energy source not only contributes to a greener economy but also provides a practical solution to the world's growing energy demands.

Fuel Door Placement: A Global Standard for Car Safety and Convenience

You may want to see also

Engine Adaptations: Special engines can run on ethanol, requiring modifications

The concept of using alcohol as a fuel source for vehicles is not entirely new and has been explored for several decades. One of the primary methods of utilizing alcohol in automotive applications is through the use of ethanol, a type of alcohol derived from plant materials such as corn, sugarcane, or wheat. Ethanol has gained popularity as a renewable and cleaner alternative to traditional gasoline.

To accommodate the use of ethanol, engines need to be specifically designed or modified to handle this different fuel. One of the key adaptations involves the engine's ability to manage the higher octane levels of ethanol. Ethanol has a higher octane rating compared to gasoline, which means it can withstand higher compression ratios without pre-ignition or engine knock. This requires engine modifications such as using different piston materials, altering the combustion chamber design, and optimizing the fuel injection system to ensure efficient and controlled combustion.

Engineers often focus on the fuel injection system as a critical component for ethanol-compatible engines. The system must be capable of delivering the precise amount of ethanol and gasoline mixture required for optimal performance. This involves using advanced fuel injectors that can handle the higher vapor pressure of ethanol and ensuring accurate fuel metering to maintain the correct air-fuel ratio. The injection timing and spray patterns may also need to be adjusted to account for the different combustion characteristics of ethanol.

Another essential aspect of engine adaptations is the use of specialized lubricants. Ethanol can have a diluting effect on engine oils, which may lead to reduced lubrication and increased wear on engine components. To mitigate this, engineers often recommend using ethanol-compatible engine oils that provide adequate protection and maintain the necessary viscosity levels. Additionally, the engine's cooling system might require modifications to handle the different heat transfer characteristics of ethanol-based fuels.

Furthermore, the use of ethanol in vehicles often involves the implementation of electronic controls and sensors. These systems monitor and adjust various engine parameters to optimize performance and efficiency. For example, sensors can measure the ethanol content in the fuel and adjust the engine's operation accordingly, ensuring it runs smoothly and efficiently on the alternative fuel. Such adaptations allow for a seamless transition from conventional gasoline to ethanol-based fuels, providing vehicle owners with the flexibility to choose more sustainable energy sources.

VP Fuel in Nitro Cars: Unleash the Power!

You may want to see also

Performance: Ethanol blends can improve engine performance and reduce emissions

Ethanol, a renewable biofuel derived from plant materials, has gained significant attention as an alternative fuel for vehicles. When blended with gasoline, it offers several performance benefits and contributes to a more environmentally friendly driving experience. One of the key advantages of ethanol blends is their ability to enhance engine performance. Ethanol contains a higher octane rating compared to gasoline, which means it can withstand higher compression ratios in the engine without pre-ignition or engine knocking. This results in a more efficient combustion process, allowing the engine to produce more power and torque. As a result, vehicles with ethanol blends often experience improved acceleration and overall performance.

The increased power output is particularly noticeable in high-performance engines. Ethanol's higher octane can enable engine designers to optimize combustion, leading to a more responsive and powerful driving experience. This is especially beneficial for sports cars and high-performance vehicles, where maximizing engine performance is a primary goal. Additionally, ethanol blends can contribute to reduced emissions, making them an environmentally friendly choice. The combustion of ethanol in engines produces fewer harmful pollutants compared to traditional gasoline. It leads to lower emissions of carbon monoxide, a toxic gas harmful to human health, and unburned hydrocarbons, which contribute to smog formation.

The use of ethanol in fuel blends also results in lower emissions of particulate matter, which is a mixture of tiny particles and liquid droplets. These particles can be harmful to human health and the environment. By reducing the emission of these pollutants, ethanol blends help improve air quality and contribute to a cleaner, healthier environment. Furthermore, ethanol's oxygen content plays a crucial role in reducing emissions. The oxygen in ethanol acts as a catalyst during combustion, promoting the complete burning of other hydrocarbons in the fuel mixture. This complete combustion process ensures that fewer carbon-based compounds are released into the atmosphere, further reducing emissions.

In addition to performance and emission benefits, ethanol blends offer other advantages. Ethanol is a renewable resource, meaning it can be produced from sustainable sources such as corn, sugarcane, and even cellulosic materials. This renewability aspect makes it an attractive alternative to finite fossil fuels. Moreover, ethanol blends can contribute to energy security by diversifying the fuel supply and reducing dependence on imported oil. The use of ethanol in fuel blends has been a subject of extensive research and development, leading to various blend levels and engine modifications to optimize performance and emissions. Common ethanol blends include E10 (10% ethanol, 90% gasoline) and E85 (85% ethanol, 15% gasoline), each offering unique advantages and suitable for different vehicle types and driving conditions.

In summary, ethanol blends have a significant impact on engine performance and emissions. The higher octane rating of ethanol allows for improved power output and reduced engine knocking, resulting in a more responsive and powerful driving experience. Simultaneously, the combustion of ethanol produces fewer harmful pollutants, leading to reduced emissions of carbon monoxide, unburned hydrocarbons, and particulate matter. With its renewability and potential for energy security, ethanol is a valuable component in the transition towards a more sustainable and environmentally friendly transportation system.

Car Fuel Tank Drain: A Step-by-Step Guide

You may want to see also

Environmental Impact: Biofuels reduce carbon footprint compared to traditional gasoline

The environmental benefits of biofuels, particularly those derived from alcohol, are significant when compared to traditional gasoline. One of the primary advantages is the reduction in carbon footprint. Biofuels, such as ethanol and biodiesel, are produced from renewable biomass sources, which means they release fewer greenhouse gases when burned. This is in stark contrast to conventional gasoline, which is derived from fossil fuels and contributes significantly to global warming and climate change.

The carbon footprint of a fuel source is a measure of the total greenhouse gas emissions caused by its production, processing, transportation, and combustion. When biofuels are used, the carbon dioxide released during their combustion is typically offset by the carbon dioxide absorbed by the plants during their growth. This process is often referred to as 'carbon sequestration'. For example, ethanol, produced from corn or sugarcane, and biodiesel, made from vegetable oils or animal fats, both have lower lifecycle greenhouse gas emissions compared to gasoline.

The environmental impact of biofuels is further enhanced by their potential to reduce air pollution. Ethanol, for instance, is a cleaner-burning fuel than gasoline, leading to lower emissions of harmful pollutants such as carbon monoxide, volatile organic compounds (VOCs), and particulate matter. These pollutants contribute to smog formation and have adverse effects on human health and the environment. By using biofuels, we can significantly improve air quality, especially in urban areas where vehicle emissions are a major concern.

Additionally, the production and use of biofuels can contribute to the conservation of natural resources. Unlike fossil fuels, which are finite and non-renewable, biofuels can be produced from agricultural waste, residues, and dedicated energy crops. This means that biofuel production can be designed to have a minimal impact on food production and land use. For example, waste materials from the corn or sugarcane industry can be used to produce ethanol, ensuring that food crops are not diverted for fuel production.

In summary, biofuels, including those derived from alcohol, offer a more environmentally friendly alternative to traditional gasoline. Their production and use result in a reduced carbon footprint, lower air pollution, and more sustainable resource management. As the world seeks to mitigate the impacts of climate change and transition towards a more sustainable energy future, the adoption of biofuels can play a crucial role in achieving these goals.

Jump-Starting a Car: Fuel Pump Issues and Solutions

You may want to see also

Frequently asked questions

Alcohol, typically ethanol or methanol, is blended with gasoline to create a fuel known as a gasoline-alcohol blend. This blend is then used to power internal combustion engines. The alcohol acts as an oxygenate, increasing the oxygen content in the fuel, which improves combustion and reduces the amount of harmful emissions.

The primary advantage is the potential for reduced greenhouse gas emissions and improved engine performance. Ethanol, for example, has a higher octane rating than gasoline, which can lead to more efficient combustion and increased power output. Additionally, the use of bioethanol, derived from renewable sources like corn or sugarcane, can contribute to a more sustainable and environmentally friendly energy system.

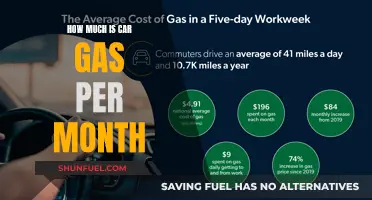

One significant challenge is the potential for reduced fuel economy. Ethanol has a lower energy content per gallon compared to gasoline, which means vehicles may need to use larger volumes of fuel to achieve the same distance. This can result in higher fuel costs for consumers. Furthermore, the infrastructure for distributing and storing alcohol-based fuels may require significant investments.

The production process varies depending on the type of alcohol used. For ethanol, common methods include fermentation of sugars from crops like corn or sugarcane, followed by distillation to separate the ethanol from the remaining liquid. Methanol can be produced through various processes, including steam reforming of natural gas or the gasification of coal. These methods ensure the alcohol meets the required purity standards for automotive applications.

While it is technically possible, it is not common for vehicles to run exclusively on alcohol-based fuels. Most cars are designed to use a blend of gasoline and alcohol, ensuring optimal performance and engine compatibility. However, some vehicles, particularly those used in racing or specialized applications, may be modified to run on pure alcohol fuel, but this requires significant engine modifications and careful tuning.