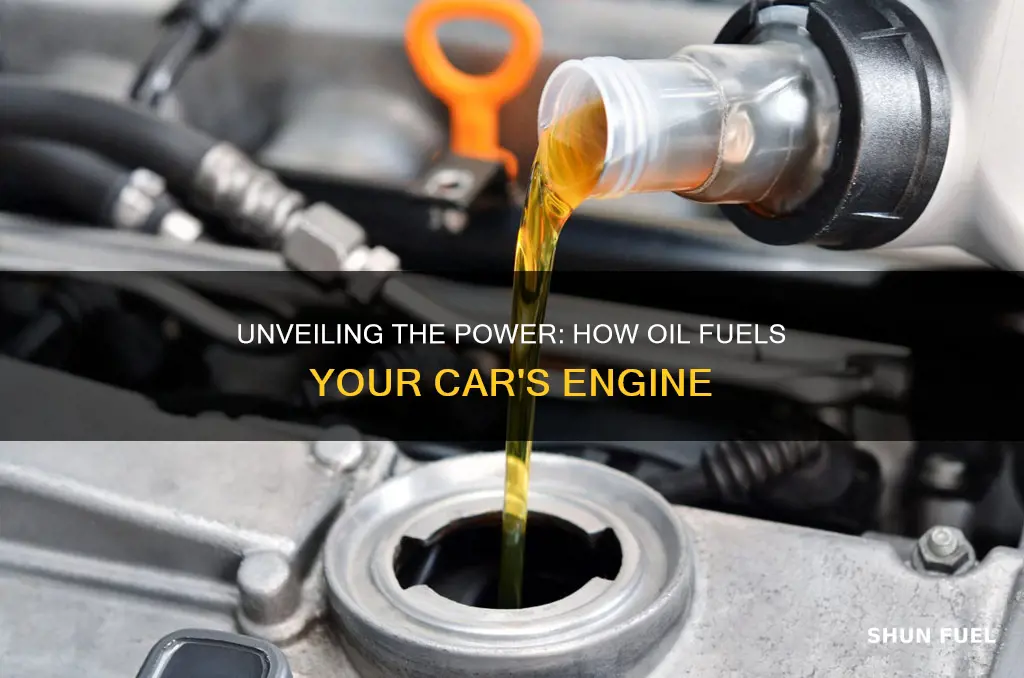

Oil is a crucial component in the operation of cars, serving as the primary fuel source for internal combustion engines. When oil is refined, it is transformed into gasoline, diesel, or other petroleum-based fuels, which are then used to power vehicles. The process begins with the extraction of crude oil from the ground, which is then sent to refineries to be processed and separated into various components. These refined products, such as gasoline and diesel, are what ultimately power the engines of cars, trucks, and other vehicles. The combustion of these fuels in the engine's cylinders generates the energy needed to propel the vehicle forward. Understanding the role of oil in car fuel is essential to grasp the complex relationship between energy resources and transportation.

What You'll Learn

- Extraction: Crude oil is extracted from the ground using drilling techniques

- Refining: Oil undergoes a complex process to produce gasoline and diesel

- Combustion: Gasoline ignites in the engine, driving the pistons and propelling the car

- Engine Mechanics: Engines convert chemical energy into mechanical motion for vehicle movement

- Emissions: Oil combustion releases pollutants, requiring catalytic converters for cleaner exhaust

Extraction: Crude oil is extracted from the ground using drilling techniques

The process of extracting crude oil from the earth is a complex and specialized task, primarily carried out by the oil and gas industry. This extraction process begins with the identification of potential oil reserves, which are often found beneath the Earth's surface in areas known as oil fields. Once a field is identified, the next step is to employ drilling techniques to access the oil-bearing formations.

Drilling operations typically start with the construction of a wellbore, a cylindrical hole drilled into the ground. This wellbore serves as a pathway to the oil-rich layers below. The drilling process can be vertical, horizontal, or directional, depending on the geological structure and the location of the oil reserves. Advanced drilling rigs, often mounted on mobile platforms, are used to create these wells. These rigs can be fixed or mobile, allowing for flexibility in various drilling environments.

Once the wellbore is drilled, it must be completed to ensure the safe and efficient extraction of crude oil. This involves several steps, including casing the well, which means inserting a steel pipe into the wellbore to prevent collapse and provide structural support. The casing is then cemented in place to create a barrier between the oil and any potential water or gas-bearing formations. After casing, the well is tested to ensure it is intact and capable of producing oil.

After the well is ready, the extraction process begins. Crude oil is extracted through a process called primary recovery, which relies on the natural pressure of the oil reservoir to push the oil up the wellbore. This method is often effective in the initial stages of production. However, as the pressure decreases, more advanced techniques are employed. Secondary recovery methods, such as water flooding or gas injection, are used to maintain and enhance oil production. These processes involve injecting fluids into the reservoir to displace oil and facilitate its flow towards the well.

In some cases, enhanced oil recovery (EOR) techniques are utilized when conventional methods become less effective. EOR methods include thermal, chemical, and gas injection processes designed to improve oil recovery from challenging reservoirs. These advanced techniques are crucial in maximizing the extraction of crude oil, ensuring a steady supply for the transportation and refining processes that ultimately lead to the production of gasoline and other petroleum products used to fuel cars and other vehicles.

E87 Flex Fuel: Can I Use It?

You may want to see also

Refining: Oil undergoes a complex process to produce gasoline and diesel

The process of refining crude oil is a crucial step in transforming it into the fuels that power our vehicles. This intricate procedure involves several stages, each designed to extract and purify specific components from the raw material. When crude oil is first received at a refinery, it is typically in a semi-solid state, often referred to as 'crude oil' or 'petroleum'. The initial step is to heat the oil to a specific temperature, which varies depending on the type of crude oil and the desired end product. This heating process is known as 'distillation' and is carried out in large, tall towers called fractional distillation columns.

During distillation, the crude oil is heated to a point where its various components start to vaporize. These vaporized fractions are then separated based on their different boiling points. Lighter fractions, such as gasoline, have lower boiling points and vaporize at lower temperatures, while heavier fractions like diesel and lubricating oils require higher temperatures to vaporize. This separation is achieved through a series of condensers and collectors, which cool the vaporized fractions, causing them to condense back into liquid form.

The separated fractions are then sent to different processing units for further purification. One of the key processes is 'cracking', which is used to convert heavier, less valuable fractions into lighter, more valuable ones. This is done by exposing the fractions to high temperatures and pressures in the presence of a catalyst. The cracking process breaks down large hydrocarbon molecules into smaller ones, creating a range of lighter products, including gasoline, diesel, and jet fuel.

After cracking, the refined products are further processed to meet specific quality standards. For example, gasoline undergoes a process called 'reforming' to improve its octane rating and reduce harmful emissions. This involves treating the gasoline with catalysts and high temperatures to rearrange its molecular structure. Similarly, diesel fuel is treated with catalysts to remove impurities and improve its performance.

The final stage of refining involves blending and adding various additives to the refined products. For instance, gasoline is blended with ethanol and other oxygenates to enhance its combustion properties and reduce pollution. Diesel fuel is often blended with biofuels or other additives to improve its lubricity and reduce emissions. These final touches ensure that the refined oil products meet the required specifications for vehicle fuel.

Engine Efficiency: 4 vs. 6 Cylinders, Fuel Consumption Compared

You may want to see also

Combustion: Gasoline ignites in the engine, driving the pistons and propelling the car

The process of combustion is at the heart of how oil fuels cars. When gasoline is injected into the engine's cylinders, it is carefully timed to coincide with the upward movement of the pistons, creating a precise and powerful mechanism. This timing is crucial as it ensures that the gasoline is ignited at the optimal moment, maximizing efficiency and power. The spark plugs play a vital role here, as they deliver a high-voltage spark to the air-fuel mixture, causing it to ignite and rapidly expand. This expansion exerts immense force on the pistons, pushing them downward with great force.

As the pistons move downward, they drive the crankshaft, which converts the reciprocating motion into rotational energy. This rotational motion is then transferred to the wheels through the transmission, enabling the car to move forward. The combustion process is a complex interplay of various components, all working in harmony to convert chemical energy from gasoline into mechanical energy, which ultimately powers the vehicle.

The engine's design is critical to this process. Modern engines are engineered to optimize combustion, ensuring that the air-fuel mixture is precisely controlled and ignited at the right moment. This involves intricate timing mechanisms and carefully designed combustion chambers that promote efficient burning. The engine's ability to manage combustion directly impacts the car's performance, fuel efficiency, and overall driving experience.

In the combustion chamber, the air-fuel mixture is compressed, creating a high-pressure environment. This compression further enhances the combustion process, allowing for more complete burning of the fuel. The design of the chamber and the engine's ability to maintain optimal temperatures and pressures are essential factors in ensuring efficient combustion. This intricate dance of combustion and mechanical motion is what makes it possible for oil to fuel cars and propel them forward with remarkable efficiency.

The combustion process is a delicate balance of timing, pressure, and temperature, all working in unison to convert chemical energy into the mechanical force that drives the car. It is a testament to the ingenuity of automotive engineering and the continuous pursuit of optimizing performance and efficiency in the world of automobiles.

Bad Fuel Damper: A Hidden Cause of Car Starting Issues

You may want to see also

Engine Mechanics: Engines convert chemical energy into mechanical motion for vehicle movement

The process of how oil fuels cars is a fascinating interplay of engine mechanics and chemical reactions. At its core, the engine is a sophisticated machine designed to convert the chemical energy stored in fuel into mechanical motion, which propels the vehicle forward. This intricate dance begins with the combustion of gasoline or diesel, both derived from crude oil, within the engine's cylinders.

In a gasoline engine, the fuel-air mixture is ignited by a spark plug, creating a rapid combustion process. This combustion generates a significant amount of heat and pressure, which is harnessed to drive the engine's pistons. These pistons are connected to a crankshaft, which converts the linear motion into rotational motion, ultimately powering the vehicle's wheels. The precision engineering of these components is crucial, as it ensures efficient energy transfer and optimal performance.

Diesel engines operate on a slightly different principle. Here, the fuel is injected into the cylinder at high pressure, where it is ignited by the heat of compression. This process, known as compression ignition, results in a more controlled and efficient combustion. The expanded gases push the pistons, which, like in a gasoline engine, drive the crankshaft and transmit power to the wheels. The key difference lies in the fuel injection and combustion timing, which are finely tuned to optimize performance and fuel efficiency.

The mechanics of these engines are intricate and highly engineered. For instance, the timing of fuel injection and spark ignition must be precise to ensure optimal combustion and power output. Modern engines employ advanced technologies such as electronic fuel injection and engine control units to manage these processes, ensuring that the engine operates efficiently and responds promptly to driver inputs.

Furthermore, the design of the engine's cylinders, pistons, and crankshaft plays a vital role in energy conversion. The shape and size of the cylinders influence the volume and pressure changes during combustion, while the piston's surface area and material affect heat transfer and engine friction. These factors collectively contribute to the engine's overall performance, fuel efficiency, and longevity. Understanding these engine mechanics is essential for optimizing vehicle performance and maintaining the efficiency of the combustion process.

Speeding: The Fuel-Consuming Truth: How Fast Driving Affects Your Car's Fuel Efficiency

You may want to see also

Emissions: Oil combustion releases pollutants, requiring catalytic converters for cleaner exhaust

The combustion of oil in car engines is a complex process that, while efficient, has significant environmental implications, particularly in terms of emissions. When oil is burned, it releases a variety of pollutants into the atmosphere, many of which are harmful to both human health and the environment. These emissions are a major concern for public health and environmental protection.

One of the primary pollutants released during oil combustion is nitrogen oxides (NOx). These gases are produced when nitrogen in the air combines with oxygen at high temperatures in the engine. NOx contributes to the formation of smog and is a key component in the creation of ground-level ozone, a major component of smog. Ground-level ozone is a harmful pollutant that can cause respiratory issues and damage crops and other vegetation.

Carbon monoxide (CO) is another significant pollutant. It is produced when the oil combustion process is incomplete, meaning that not all the carbon in the fuel is fully burned. CO is a toxic gas that can be deadly in high concentrations and is also a major contributor to the formation of ground-level ozone.

Particulate matter, or PM, is a complex mixture of extremely small particles and liquid droplets. These particles can be composed of various chemicals, including acids, metals, and organic compounds. PM is emitted as a result of incomplete combustion and can be directly inhaled, causing serious health issues, especially for individuals with respiratory conditions.

To mitigate these emissions, modern vehicles are equipped with catalytic converters. These devices are designed to reduce the harmful effects of exhaust gases by converting them into less harmful substances. The catalytic converter uses a catalyst, typically made of precious metals like platinum and palladium, to facilitate chemical reactions that transform harmful pollutants into less toxic ones. For example, it converts NOx into nitrogen (N2) and oxygen (O2), and carbon monoxide into carbon dioxide (CO2) and water (H2O).

In summary, the combustion of oil in car engines releases a range of pollutants, including NOx, CO, and PM, which have detrimental effects on the environment and human health. Catalytic converters are an essential technology that helps to significantly reduce these emissions, making modern vehicles more environmentally friendly. While the use of oil as a fuel has its drawbacks, the continuous development and implementation of technologies like catalytic converters are crucial steps towards minimizing the environmental impact of the automotive industry.

Fuel Additives: Friend or Foe for Your Car?

You may want to see also

Frequently asked questions

Oil, also known as petroleum, is a complex mixture of hydrocarbons and other organic compounds. When refined, it can be transformed into various products, including gasoline (petrol) and diesel, which are commonly used as fuels for internal combustion engines in vehicles. The process involves distillation, cracking, and other refining techniques to separate the different components of crude oil. Gasoline is then used to power the engine's cylinders, which drives the car's wheels through a series of mechanical components.

Crude oil is a dark, viscous liquid extracted from underground reservoirs. The refining process begins with distillation, where the oil is heated and separated into various fractions based on their boiling points. Lighter fractions, such as naphtha, are used to produce gasoline, while heavier fractions can be converted into diesel or other products. Further refining processes like cracking and reforming are used to improve the quality and performance of the fuel.

In an internal combustion engine, gasoline is injected into the engine's cylinders, where it is mixed with air. A spark plug ignites the mixture, causing a small explosion. This explosion creates rapid pressure, which pushes the pistons down, rotating the crankshaft and ultimately turning the wheels of the car. The exhaust gases are then expelled through the tailpipe after the combustion process.

Yes, there are several alternative fuels and technologies that aim to reduce or eliminate the use of oil-based fuels. Some common alternatives include:

- Electric Vehicles (EVs): EVs use electric motors powered by batteries or fuel cells, eliminating the need for gasoline or diesel.

- Biofuels: These are derived from renewable biological materials, such as plant oils, animal fats, or agricultural waste, and can be used in modified internal combustion engines.

- Hydrogen Fuel Cells: Hydrogen gas is used to generate electricity through a chemical reaction with oxygen, producing only water as a byproduct.