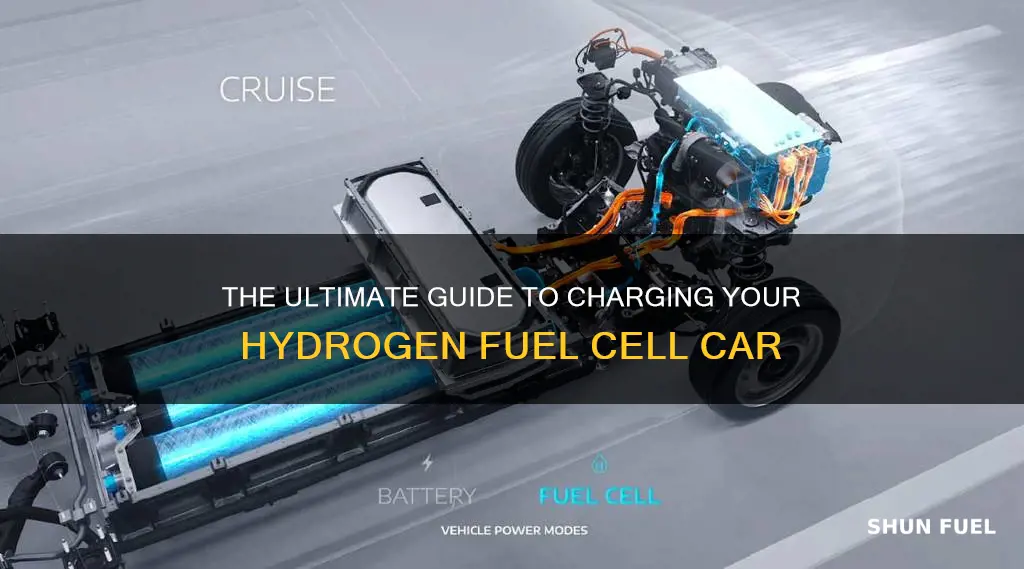

Hydrogen fuel cell cars are an innovative and sustainable mode of transportation, but understanding how to charge them is essential for their widespread adoption. Unlike traditional electric vehicles that rely on batteries, hydrogen fuel cell cars convert hydrogen gas into electricity through a chemical reaction, producing only water as a byproduct. The charging process involves supplying compressed hydrogen gas to the fuel cell, where it combines with oxygen from the air to generate electricity, heat, and water. This efficient and clean energy conversion makes hydrogen fuel cell cars a promising alternative to conventional vehicles, but the infrastructure for refueling stations is still developing. This paragraph introduces the topic of charging hydrogen fuel cell cars, highlighting the unique process and the importance of infrastructure development for their successful integration into the transportation ecosystem.

What You'll Learn

- Power Source: Hydrogen fuel cells convert hydrogen and oxygen into electricity, water, and heat

- Fuel Storage: High-pressure tanks store hydrogen at up to 3,500 psi

- Stack Operation: Electrochemical cells generate electricity through a redox reaction

- Air Intake: Oxygen from the air is supplied to the stack for the reaction

- Regulation: Systems regulate pressure and temperature to ensure safe and efficient operation

Power Source: Hydrogen fuel cells convert hydrogen and oxygen into electricity, water, and heat

The power source of a hydrogen fuel cell car is a fascinating and innovative technology that enables clean and efficient transportation. Hydrogen fuel cells are the heart of this system, and they operate on a simple yet powerful principle. These cells convert hydrogen gas and oxygen from the air into electricity, water, and heat through a chemical reaction. This process is the key to understanding how these vehicles are powered and refueled.

When hydrogen enters the fuel cell, it undergoes a reaction with oxygen, which is supplied from the air through a catalyst. This catalyst, typically made of a precious metal like platinum, facilitates the reaction by lowering the activation energy required. The reaction produces electricity, which is then used to power the car's electric motor. The byproducts of this reaction are water and a small amount of heat, which are harmless and can be safely expelled from the vehicle.

The efficiency of this process is remarkable. Hydrogen fuel cells can convert over 60% of the chemical energy in hydrogen to electricity, which is significantly higher than the efficiency of traditional internal combustion engines. This high efficiency means that hydrogen fuel cell cars can travel longer distances on a single 'charge' compared to battery-electric vehicles.

The charging process for hydrogen fuel cell cars is unique. Instead of plugging into an electrical outlet, these vehicles are 'refueled' by filling a hydrogen tank with compressed hydrogen gas. This process is similar to refueling a conventional gasoline or diesel vehicle. The hydrogen is then directed to the fuel cell stack, where it undergoes the electrochemical reaction, producing electricity and water.

This technology offers a promising solution to the challenges of sustainable transportation. Hydrogen fuel cell cars produce zero direct emissions, making them environmentally friendly. They also have the potential to provide fast refueling times, similar to those of gasoline vehicles, which can address range anxiety concerns. Additionally, the hydrogen infrastructure is already being developed in many regions, making it more accessible for potential adopters.

Siphoning Fuel: Can It Still Work on Modern Cars?

You may want to see also

Fuel Storage: High-pressure tanks store hydrogen at up to 3,500 psi

High-pressure tanks are a critical component of hydrogen fuel cell vehicles, designed to store the hydrogen gas at extremely high pressures, typically up to 3,500 pounds per square inch (psi). This storage method is essential to accommodate the relatively low density of hydrogen compared to other fuels, ensuring that the vehicle has sufficient range and performance. The high-pressure tanks are typically made of advanced materials such as carbon fiber composites or aluminum alloys, which can withstand the immense stress and temperature variations associated with hydrogen storage.

The design and construction of these tanks are highly regulated and standardized to ensure safety and reliability. They are often cylindrical in shape, with a robust and lightweight structure to minimize the overall weight of the vehicle. The tanks are usually located in the vehicle's underbody or behind the rear seats, providing a low center of gravity, which enhances stability and handling.

To ensure the safety of hydrogen storage, the tanks are equipped with various safety mechanisms. These include pressure relief valves, which automatically release excess pressure if it exceeds a safe threshold, and pressure sensors that monitor the tank's condition in real-time. Additionally, the tanks are often designed with a double-wall structure, providing an extra layer of protection against potential leaks or damage.

The high-pressure nature of hydrogen storage requires specialized fueling infrastructure. Hydrogen fuel stations are equipped with high-pressure pumps and dispensing nozzles to transfer hydrogen gas into the vehicle's tank. These stations are designed to handle the extreme pressures and are often located in dedicated areas to ensure the safety of both the vehicles and the fueling process.

Despite the challenges, high-pressure tank technology has enabled hydrogen fuel cell vehicles to achieve impressive range and performance. This storage method allows for efficient energy utilization and provides a practical solution for powering vehicles with a clean and renewable energy source. As hydrogen fuel cell technology continues to advance, the development of even more compact and efficient storage solutions will further enhance the viability of hydrogen-powered transportation.

Prepaying Fuel: A Smart Choice for Rental Cars?

You may want to see also

Stack Operation: Electrochemical cells generate electricity through a redox reaction

The operation of a hydrogen fuel cell stack is a fascinating process that involves the conversion of chemical energy into electrical energy through an electrochemical reaction. This technology is at the heart of hydrogen fuel cell vehicles, offering a clean and efficient alternative to traditional internal combustion engines. Here's a detailed explanation of the stack operation:

In a hydrogen fuel cell, the stack is the core component responsible for generating electricity. It consists of multiple layers, or cells, stacked together to increase the overall power output. Each cell is an electrochemical device, utilizing the principles of redox (reduction-oxidation) reactions to produce electricity. The basic structure of a fuel cell includes an anode, a cathode, and an electrolyte membrane. When hydrogen gas (H₂) is supplied to the anode and oxygen (O₂) from the air is provided to the cathode, the electrochemical reaction begins.

The redox reaction in a fuel cell involves the transfer of electrons between the reactants. At the anode, hydrogen molecules (H₂) are split into protons (H⁺) and electrons (e⁻). The protons pass through the electrolyte membrane, while the electrons are directed through an external circuit, creating an electric current. This process is known as the anode reaction. Simultaneously, at the cathode, oxygen molecules (O₂) react with the protons and electrons from the anode, forming water (H₂O) and releasing additional electrons. The cathode reaction completes the circuit, allowing the flow of electrons back to the anode, thus generating electricity.

The key to the stack's operation lies in the efficient management of these reactions. The electrolyte membrane acts as a selective barrier, allowing only protons to pass through while blocking electrons. This design ensures that the electrons flow through the external circuit, creating a continuous electric current. The stack's design also includes catalysts, typically made of precious metals like platinum, to facilitate the redox reactions and lower the activation energy required for the reactions to occur.

As the reactions proceed, the fuel cell stack continuously produces electricity. The efficiency of this process is remarkable, as it directly converts chemical energy into electrical energy without the need for combustion. This makes hydrogen fuel cell vehicles highly efficient and environmentally friendly. The stack's operation is a delicate balance of chemical reactions, and optimizing this process is crucial for the widespread adoption of hydrogen fuel cell technology.

Powering the Future: The Rise of Fuel Cell Cars

You may want to see also

Air Intake: Oxygen from the air is supplied to the stack for the reaction

The air intake system plays a crucial role in the operation of a hydrogen fuel cell vehicle, as it provides the necessary oxygen for the electrochemical reaction that generates electricity. When a hydrogen fuel cell car is in operation, it requires a continuous supply of oxygen to sustain the chemical reaction between hydrogen and oxygen, which produces electricity, water, and heat.

The process begins with the intake of air through a dedicated air intake system, often located at the front of the vehicle. This system is designed to efficiently capture and filter the air, ensuring a steady supply of clean oxygen to the fuel cell stack. The air is drawn into the vehicle's engine compartment and passes through a series of filters to remove impurities such as dust, pollen, and other particulate matter. This filtration process is essential to maintain the performance and longevity of the fuel cell stack.

Once the air is filtered, it is directed towards the fuel cell stack, which is the heart of the hydrogen fuel cell system. The stack consists of multiple layers of thin, catalyst-coated membranes, typically made of a polymer such as Nafion. These membranes are designed to facilitate the electrochemical reaction between hydrogen and oxygen. As the filtered air enters the stack, it is carefully controlled to ensure a precise oxygen concentration. The oxygen molecules in the air are attracted to the anode side of the fuel cell, where they react with the hydrogen gas supplied from the fuel tank.

The air intake system is designed to optimize the oxygen supply, ensuring that the fuel cell stack receives the required amount of oxygen for efficient operation. This involves precise control of the air flow rate and pressure to match the demands of the fuel cell. Advanced sensors and control mechanisms are employed to monitor the oxygen concentration and adjust the air intake accordingly, ensuring a steady and efficient reaction within the fuel cell.

In summary, the air intake system is a critical component in the charging process of a hydrogen fuel cell car. It provides the essential oxygen required for the electrochemical reaction, enabling the vehicle to generate electricity and power its operations. Efficient air intake and filtration ensure the longevity and performance of the fuel cell stack, contributing to the overall efficiency and reliability of hydrogen fuel cell technology.

Ethanol Fuel: Friend or Foe for Your Car?

You may want to see also

Regulation: Systems regulate pressure and temperature to ensure safe and efficient operation

The regulation of pressure and temperature is a critical aspect of hydrogen fuel cell technology, ensuring the safe and efficient operation of these vehicles. Hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, producing water as a byproduct. This process requires precise control to optimize performance and prevent potential hazards.

Pressure regulation is essential in fuel cell systems. Hydrogen fuel is stored at high pressures, typically ranging from 350 to 700 bars (5,000 to 10,000 psi), to maximize energy density. However, maintaining such high pressures requires sophisticated regulation mechanisms. Pressure regulators are employed to control the flow of hydrogen, ensuring it is delivered at the optimal pressure for the fuel cell stack. These regulators monitor the pressure and adjust it accordingly to prevent overpressure, which could lead to safety risks, or underpressure, which might reduce efficiency.

Temperature regulation is another vital component of fuel cell operation. Fuel cells operate optimally within a specific temperature range, typically between 40°C and 90°C (104°F and 194°F). Excessive heat can degrade the fuel cell's performance and potentially cause damage, while insufficient temperature can hinder the electrochemical reaction. Temperature control systems are designed to maintain the desired operating temperature. These systems may include heating elements to warm the fuel cell stack during cold start-ups or in low-temperature environments, and cooling mechanisms to dissipate heat generated during operation, ensuring the fuel cell operates within the optimal temperature range.

Advanced fuel cell systems often incorporate feedback control loops to continuously monitor and adjust pressure and temperature. These loops use sensors to measure the actual values and compare them to the desired setpoints. If deviations occur, the system automatically makes adjustments to maintain the required conditions. For instance, if the temperature rises above the setpoint, the cooling system may activate to lower the temperature, ensuring safe and efficient operation.

In summary, the regulation of pressure and temperature is integral to the proper functioning of hydrogen fuel cell vehicles. Pressure regulators control the flow of hydrogen, ensuring it is delivered at the right pressure for optimal performance. Temperature control systems maintain the fuel cell stack within the ideal operating range, preventing overheating or underperformance. Through these regulatory mechanisms, fuel cell vehicles can operate safely and efficiently, contributing to the widespread adoption of hydrogen as a clean energy source.

Scotch: A Fuel Alternative? Exploring the Potential of Whisky as a Car Fuel

You may want to see also

Frequently asked questions

Hydrogen fuel cell cars are unique in that they are not typically "charged" in the traditional sense like electric vehicles (EVs) with a plug. Instead, they are refueled with hydrogen gas. The process involves filling the vehicle's fuel tank with compressed hydrogen gas, similar to how you would fill a car's gasoline or diesel tank. This hydrogen is then used in the fuel cell, where it reacts with oxygen from the air to produce electricity, which powers the vehicle's electric motor.

The infrastructure for hydrogen refueling stations is still developing, but you can find them at various locations. These stations are often located near highways, rest stops, or in areas with a high concentration of fuel cell vehicle owners. You can use apps or online maps specifically designed for fuel cell vehicles to locate the nearest hydrogen fueling station. Some cities and regions are also investing in the construction of hydrogen refueling networks to support the growing number of fuel cell cars on the road.

Yes, the refueling process is quite different. Hydrogen fuel cell cars require high-pressure hydrogen gas, typically compressed to 5,000-10,000 psi, which is much higher than the pressure in a conventional car's fuel tank. Refueling usually takes just a few minutes, and the process is similar to filling a bicycle tire with air. The hydrogen is delivered to the vehicle through a specialized nozzle, and the fuel cell then converts this hydrogen into electricity, providing power to the vehicle.