Scotch, a beloved spirit known for its rich flavor and cultural significance, has sparked curiosity among enthusiasts and scientists alike regarding its potential as an alternative fuel source. While it may not be the most practical or efficient option for powering vehicles, the idea of using Scotch to fuel a car has gained attention. This paragraph explores the feasibility and implications of this unconventional approach, examining the chemical composition of Scotch and its potential energy content, while also considering the challenges and benefits associated with this unique concept.

What You'll Learn

- Scotch Production Process: Fermentation and distillation of barley produce alcohol, a key component in fuel

- Alcohol as Fuel: Ethanol, derived from scotch, can be blended with gasoline to power vehicles

- Biofuel Potential: Scotch's byproducts can be converted into bioethanol, a renewable fuel source

- Environmental Impact: Producing scotch from organic materials may offer a more sustainable fuel alternative

- Engine Modifications: Cars require adaptations to run on ethanol blends, ensuring efficient combustion

Scotch Production Process: Fermentation and distillation of barley produce alcohol, a key component in fuel

The production of Scotch, a renowned spirit, involves a meticulous process that begins with the fermentation and distillation of barley, which is a crucial step in creating the alcohol used in various applications, including fuel. This traditional method has been refined over centuries, ensuring the unique flavor and quality that Scotch is renowned for.

Barley, a staple grain in Scotland, is carefully selected and prepared for the brewing process. It is first malted, a process where the barley is soaked in water and allowed to germinate, activating enzymes that break down starches into sugars. This step is vital as it provides the necessary sugar content for fermentation. After malting, the barley is dried and then ground to create a fine grist.

Fermentation is the next critical phase. The ground barley, along with water, is mixed and heated to create a sweet liquid known as 'wash.' Yeast is then added to initiate the fermentation process, where sugars are converted into alcohol and carbon dioxide. This process typically takes several days, during which the temperature and conditions are carefully controlled to encourage the growth of specific yeast strains, resulting in the desired alcohol content and flavor profile.

Following fermentation, the liquid is separated from the solids, and this is where distillation comes into play. Distillation is an essential step in Scotch production, as it increases the alcohol concentration and contributes to the spirit's unique character. The wash is heated, and as it vaporizes, it is captured and cooled, causing the alcohol to condense. This process is repeated in a series of distillation columns, gradually purifying the alcohol and separating it from impurities.

The resulting spirit, now with a higher alcohol content, is the base for Scotch. Further aging in oak casks can enhance flavor and color, but the initial alcohol produced through fermentation and distillation is the foundation of this beloved spirit. While the idea of using Scotch as fuel might seem unconventional, the alcohol produced during the fermentation and distillation process can indeed be utilized for various purposes, including as a biofuel, showcasing the versatility of this ancient craft.

Tesla's Hydrogen Fuel Cell Cars: A Revolutionary Concept or a Misstep?

You may want to see also

Alcohol as Fuel: Ethanol, derived from scotch, can be blended with gasoline to power vehicles

The concept of using alcohol, particularly ethanol, as a fuel source for vehicles is not a new idea. In fact, it has been explored and utilized in various forms for many years. One interesting aspect of this is the potential to derive ethanol from grains, such as barley, which is commonly used in the production of alcoholic beverages like Scotch. While it might seem unconventional, the idea of using alcohol as a fuel source has gained traction due to its potential environmental benefits and the availability of the raw materials.

Ethanol, a type of alcohol, can be produced through the fermentation of sugars and starches present in grains. When barley is used, the process involves breaking down the starches into sugars and then fermenting these sugars to create ethanol. This method of ethanol production is similar to the way alcohol is made in the brewing and distillation processes used to create Scotch. The key difference is the purification and concentration of the ethanol for fuel use.

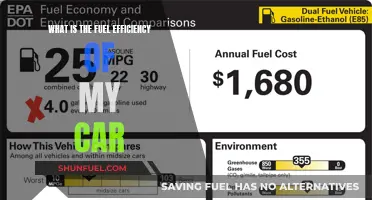

Blending ethanol with gasoline is a common practice in many countries to improve the performance and reduce the environmental impact of vehicles. Ethanol-gasoline blends, often referred to as E10 or E85, can be used in conventional gasoline engines with minor modifications. These blends offer several advantages, including increased octane, improved engine performance, and a reduction in carbon emissions compared to pure gasoline. By using a blend, drivers can contribute to a cleaner environment while still enjoying the convenience of using gasoline at their local stations.

The process of blending ethanol with gasoline is straightforward. Ethanol is added to gasoline in specific proportions, depending on the desired blend level. For example, E10 contains 10% ethanol and 90% gasoline, while E85 has a higher ethanol content of 85%. These blends can be used in most modern vehicles without any modifications, making it accessible to a wide range of drivers. The flexibility of these blends allows for a gradual transition to a more sustainable fuel source while ensuring compatibility with existing infrastructure.

In summary, the idea of using alcohol derived from grains, such as barley used in Scotch production, as a fuel source for vehicles is a viable and environmentally friendly option. Ethanol, produced through fermentation, can be blended with gasoline to create E10 or E85 fuels, offering improved performance and reduced emissions. This approach not only provides an alternative to traditional gasoline but also contributes to a more sustainable and greener future for the automotive industry.

Winter's Chill: Unveiling the Fuel Efficiency Mystery

You may want to see also

Biofuel Potential: Scotch's byproducts can be converted into bioethanol, a renewable fuel source

The idea of using Scotch, a beloved spirit, as a fuel source might seem unconventional, but it opens up an interesting avenue for exploring renewable energy. While Scotch itself is not typically used as a direct fuel, its byproducts can be harnessed to create a valuable resource: bioethanol. This process not only offers a potential solution to the world's growing energy demands but also presents an opportunity to reduce waste and promote sustainability in the alcohol industry.

Scotch, like many alcoholic beverages, is produced through a fermentation process that primarily uses grains, such as barley. After the distillation and aging processes, the remaining stillage, a liquid byproduct, can be utilized for biofuel production. This stillage contains a variety of organic materials, including sugars, proteins, and lipids, which can be converted into bioethanol through a process known as fermentation. The key to this process is the use of specific enzymes and microorganisms that break down these complex organic compounds into simpler sugars, which can then be fermented to produce ethanol.

The conversion of Scotch's byproducts into bioethanol involves several steps. Firstly, the stillage is treated to remove any impurities and to separate it into different fractions. The most valuable fraction for bioethanol production is the one containing the sugars. These sugars are then subjected to a fermentation process using yeast or other microorganisms. During fermentation, the sugars are converted into ethanol and carbon dioxide. The ethanol can be further refined and purified to meet the required standards for fuel use.

Bioethanol produced from Scotch's byproducts offers several advantages. Firstly, it is a renewable fuel source, as it is derived from organic materials that can be replenished. This contrasts with fossil fuels, which are finite resources. Secondly, the process helps to reduce waste. The alcohol industry generates significant amounts of stillage, and converting this into bioethanol provides a valuable outlet for this byproduct, potentially reducing environmental impact. Additionally, the production of bioethanol can stimulate local economies, creating jobs in the biofuel industry and providing an alternative revenue stream for alcohol producers.

In summary, while Scotch itself may not be used as a direct fuel, its byproducts hold significant potential for biofuel production. The conversion of stillage into bioethanol is a promising process that can contribute to a more sustainable and renewable energy future. This approach not only explores innovative ways to utilize waste but also highlights the versatility of organic materials in creating alternative fuel sources. With further research and development, the biofuel potential of Scotch's byproducts could become a significant contributor to the global transition towards cleaner and more sustainable energy solutions.

Flex-Fuel Misstep: What Happens When You Fill Up a Regular Car

You may want to see also

Environmental Impact: Producing scotch from organic materials may offer a more sustainable fuel alternative

The idea of using scotch, a beloved spirit, as a fuel source might seem unconventional, but it opens up an intriguing avenue for exploring sustainable energy alternatives. While the concept of using scotch as a direct fuel for cars may not be a practical reality, the process of producing it from organic materials could have a significant positive environmental impact. Here's how:

Organic Feedstocks and Sustainability: Scotch, typically made from grains like barley, can be produced using organic farming practices. Organic agriculture focuses on sustainable methods, avoiding synthetic pesticides and fertilizers, which often have detrimental effects on the environment. By utilizing organic feedstocks, the production of scotch can reduce the carbon footprint associated with agriculture. This is especially important in the context of fuel production, as the agricultural sector is known to contribute significantly to greenhouse gas emissions.

Ethanol Extraction and Biodiesel Production: The key to making scotch a potential fuel alternative lies in the extraction of ethanol from the grains. Ethanol, a renewable biofuel, can be produced through fermentation, a process that breaks down organic matter. This ethanol can then be used as a biofuel, offering a cleaner-burning alternative to traditional gasoline or diesel. Additionally, the remaining organic by-products can be further processed to create biodiesel, another sustainable fuel source. This dual-purpose approach ensures that the entire production process is environmentally friendly.

Reducing Fossil Fuel Dependency: One of the most significant environmental benefits of producing scotch from organic materials is the potential to reduce our reliance on fossil fuels. Fossil fuels, such as coal, oil, and natural gas, are finite resources and their extraction and combustion contribute to air pollution and climate change. By utilizing organic feedstocks and converting them into biofuels, we can diversify our energy sources and decrease the demand for non-renewable resources. This shift can lead to a more sustainable and environmentally friendly energy landscape.

Waste Management and Recycling: The production of scotch and subsequent biofuel creation can also contribute to waste management and recycling efforts. The organic waste generated during the fermentation process can be utilized as animal feed or compost, reducing the need for synthetic fertilizers. Furthermore, the spent grain, a byproduct of ethanol production, can be used for animal feed or in the production of animal bedding, providing an eco-friendly alternative to traditional waste management practices.

In summary, while the idea of using scotch as a car fuel might be more of a creative concept, the process of producing it from organic materials has the potential to offer a more sustainable and environmentally friendly approach to fuel production. By focusing on organic agriculture, ethanol extraction, and biodiesel creation, we can explore a greener path towards energy alternatives, reducing our impact on the planet and moving towards a more sustainable future. This innovative approach to fuel production highlights the importance of thinking outside the box while prioritizing environmental conservation.

Can You Jump-Start a Car Without Fuel?

You may want to see also

Engine Modifications: Cars require adaptations to run on ethanol blends, ensuring efficient combustion

The idea of using Scotch, or any alcohol-based beverage, as a fuel source for cars is an intriguing concept, but it is not a practical or efficient method for powering vehicles. While it might be tempting to explore unconventional fuel sources, it's essential to understand the challenges and limitations of using ethanol blends, which are more commonly associated with biofuels.

Ethanol, a type of alcohol, is a renewable biofuel that can be derived from various sources, including corn, sugarcane, and even cellulosic materials. When blended with gasoline, it can be used to power conventional internal combustion engines. However, to run efficiently and effectively, engines require specific modifications to accommodate the unique properties of ethanol-based fuels.

One of the primary modifications involves the engine's fuel injection system. Ethanol has a higher energy content and a lower volatility compared to gasoline, which means it requires a different fuel-air mixture for optimal combustion. The fuel injectors must be calibrated to deliver the precise amount of ethanol and gasoline mixture required for efficient burning. This adjustment ensures that the engine operates within the optimal combustion range, providing better performance and fuel efficiency.

Additionally, the engine's intake and exhaust systems may need modifications. Ethanol has a higher octane rating, which can lead to increased engine knock if not properly managed. The intake valves and piston crowns might require special coatings or materials to withstand the higher temperatures and pressures associated with ethanol combustion. Moreover, the exhaust system should be designed to handle the byproducts of ethanol combustion, ensuring that emissions meet environmental standards.

Another critical aspect is the engine's ability to manage the higher moisture content in ethanol. Ethanol blends can contain up to 10% water, which can lead to condensation and potential issues with engine performance, especially in colder climates. Engineers often implement systems to manage this moisture, such as using fuel heaters or adding drying agents to the fuel system. These modifications ensure that the engine operates reliably and efficiently, even with the presence of ethanol.

In summary, while Scotch or ethanol-based fuels might be an interesting concept, powering cars with them requires significant engine modifications. These adaptations include adjusting fuel injection systems, modifying intake and exhaust components, and implementing measures to manage moisture content. Such modifications aim to optimize combustion, improve engine performance, and ensure that vehicles can run efficiently on ethanol blends without compromising reliability or safety.

Fuel Filter Failure: When Your Car Suddenly Shuts Down

You may want to see also

Frequently asked questions

While it might seem like a creative solution, using alcohol like Scotch as a fuel for a car is not practical or efficient. Alcoholic beverages are not designed or optimized for combustion in an internal combustion engine. The combustion process requires specific fuel-air mixtures, and Scotch, being a beverage, lacks the necessary properties to function as a viable fuel source.

Attempting to use Scotch as fuel can lead to several issues. Firstly, it may cause engine misfires and reduced performance due to its lower energy content compared to conventional fuels. Additionally, alcohol can dissolve engine gaskets and seals, leading to potential engine damage over time. The corrosive nature of alcohol can also accelerate the degradation of engine components, making it a risky and unreliable choice for powering a vehicle.

Scotch can be used in small quantities as a lubricant or cleaner for certain car parts, but it should never be used as a primary fuel source. Some car enthusiasts might experiment with using it as a fuel additive to enhance performance, but this is not recommended as it can lead to engine issues. It's always best to use approved and tested fuels and additives to ensure the longevity and reliability of your vehicle.

Yes, there is ongoing research and development in the field of alternative fuels and energy sources for vehicles. Scientists and engineers are exploring various options, such as biofuels, hydrogen, and electric power, to reduce the reliance on traditional gasoline and diesel. These alternative fuels aim to provide cleaner and more sustainable energy solutions for the automotive industry.