Inserting 2-cycle fuel lines into a tank can seem daunting, but with the right tools and a bit of patience, it's a manageable task. This process involves carefully routing the fuel lines through the tank, ensuring they are secure and properly sealed to prevent any leaks. It's crucial to follow the manufacturer's instructions and take the necessary safety precautions to avoid any potential hazards. With the right preparation and technique, you can successfully insert the fuel lines and ensure your engine runs smoothly.

What You'll Learn

- Preparation: Clean and inspect the tank, ensuring it's dry and free of debris

- Fuel Line Material: Choose the right fuel line material for your engine's requirements

- Routing: Plan the route of the fuel line, considering engine placement and accessibility

- Clamps and Fittings: Secure the line with appropriate clamps and fittings for a tight seal

- Testing: Run a test to ensure the fuel line is leak-free and functioning properly

Preparation: Clean and inspect the tank, ensuring it's dry and free of debris

Before you begin the process of inserting 2-cycle fuel lines into the tank, it is crucial to ensure that the tank is in optimal condition. Start by thoroughly cleaning the tank to remove any dirt, grime, or debris that might interfere with the installation process. Use a mild detergent or a specialized cleaner designed for fuel tanks to avoid any damage to the tank's interior. Rinse the tank thoroughly to eliminate any residue and ensure it is completely clean.

Once the tank is clean, it is essential to check for any existing damage or leaks. Inspect the tank's interior and exterior for any signs of corrosion, cracks, or holes. Pay close attention to the areas where the fuel lines will be inserted. Ensure that the tank is dry and free of any moisture, as water can cause corrosion and damage the fuel lines. Use a dry cloth or a shop towel to wipe down the tank's interior and exterior, removing any excess moisture.

Additionally, check the tank's capacity and ensure it is compatible with the fuel lines you are using. Different tanks may have varying dimensions and fuel capacities, so it is important to verify the compatibility to ensure a proper fit. This step is crucial to avoid any issues during the installation process.

By taking the time to clean and inspect the tank, you create a safe and suitable environment for inserting the 2-cycle fuel lines. This preparation process ensures that the tank is ready for the installation, reducing the risk of any complications or issues during the procedure. It is a vital step to guarantee a successful and efficient fuel line installation.

Mastering the Quick Connect Swap: Nylon Fuel Line Guide

You may want to see also

Fuel Line Material: Choose the right fuel line material for your engine's requirements

When it comes to choosing the right fuel line material for your two-stroke engine, it's crucial to consider the specific requirements of your engine to ensure optimal performance and longevity. The material you select will directly impact the fuel's flow, the engine's efficiency, and its overall reliability. Here's a detailed guide to help you make the right choice:

Engine Type and Fuel: Different two-stroke engines may have unique fuel requirements. Some engines use a mixture of gasoline and oil, while others might require pure gasoline. For instance, a 2-stroke outboard boat engine typically needs a specific ratio of gasoline and synthetic oil, whereas a small 2-stroke lawnmower engine might use a different blend. Understanding your engine's fuel needs is essential to select the appropriate fuel line material.

Flexibility and Durability: Fuel lines should be flexible enough to navigate the engine's layout and any potential obstacles. However, they also need to be durable to withstand the engine's operating conditions, including heat, vibration, and chemical exposure from the fuel. Common materials for fuel lines include rubber, vinyl, and braided materials like nylon or stainless steel. Rubber and vinyl are lightweight and flexible, making them suitable for most applications. Braided lines offer excellent heat resistance and are often used in high-performance engines.

Temperature Resistance: Consider the operating temperature range of your engine. If your engine operates in extreme temperatures, you'll need a fuel line material that can handle those conditions without compromising its integrity. For high-temperature applications, materials like silicone or high-temperature rubber are ideal. These materials maintain their flexibility and strength even when exposed to intense heat.

Chemical Compatibility: The fuel line should be compatible with the type of fuel it carries. Different fuels can have varying chemical compositions, and some materials may degrade or become brittle when exposed to certain fuels. For example, some rubber fuel lines may not be suitable for engines using ethanol-blended fuels due to potential swelling or degradation. Always check the compatibility of the fuel line material with your engine's fuel type.

Installation and Maintenance: Proper installation and regular maintenance are essential to ensure the fuel lines function correctly. When choosing the material, consider how easy it is to install and maintain. Some materials might require specific tools or techniques for a secure fit. Additionally, regular inspection for any signs of wear, cracks, or damage is crucial to prevent fuel leaks and maintain engine performance.

E85 Fuel's Impact: Does It Cause Dry Rot in Fuel Lines?

You may want to see also

Routing: Plan the route of the fuel line, considering engine placement and accessibility

When inserting a 2-cycle fuel line into the tank, proper routing is crucial to ensure optimal performance and longevity of the engine. The first step is to carefully plan the route, taking into account the engine's placement and the available space. Start by identifying the fuel tank's location and the engine's position. Typically, the fuel tank is mounted near the engine, often on the side or rear of the machine. Understanding the engine's layout will help you determine the most efficient path for the fuel line.

Consider the engine's components and any obstacles that might hinder the fuel line's placement. For example, if the engine has a large air filter or a complex wiring harness, you may need to route the fuel line around these areas to avoid interference. Take measurements and sketch out a rough plan to visualize the path. Ensure that the fuel line has enough clearance to move freely without being pinched or damaged.

Accessibility is another critical factor. The fuel line should be easily accessible for maintenance and repairs. Avoid routing it in areas where it might get caught or damaged during regular use. For instance, if the engine has a side panel that can be removed for servicing, consider running the fuel line along the inside of the panel to keep it out of the way. Proper routing also includes using appropriate bends and angles to avoid sharp turns that could lead to kinks or stress on the line.

When planning the route, aim for a straight and smooth path whenever possible. This reduces the risk of fuel line damage and ensures consistent fuel flow. If the engine has a specific mounting position for the fuel line, make sure to follow the manufacturer's guidelines. Proper routing will also help prevent fuel leaks and ensure that the engine receives the correct amount of fuel at the right time.

In summary, routing the 2-cycle fuel line requires careful consideration of the engine's layout, accessibility, and potential obstacles. By planning the route in advance, you can ensure a clean and efficient installation, promoting the overall performance and reliability of your 2-cycle engine. Remember to measure, visualize, and adjust the route as needed to accommodate the specific requirements of your engine and fuel system.

Clean Fuel: Tips for Removing Excess Carbon from Your Lines

You may want to see also

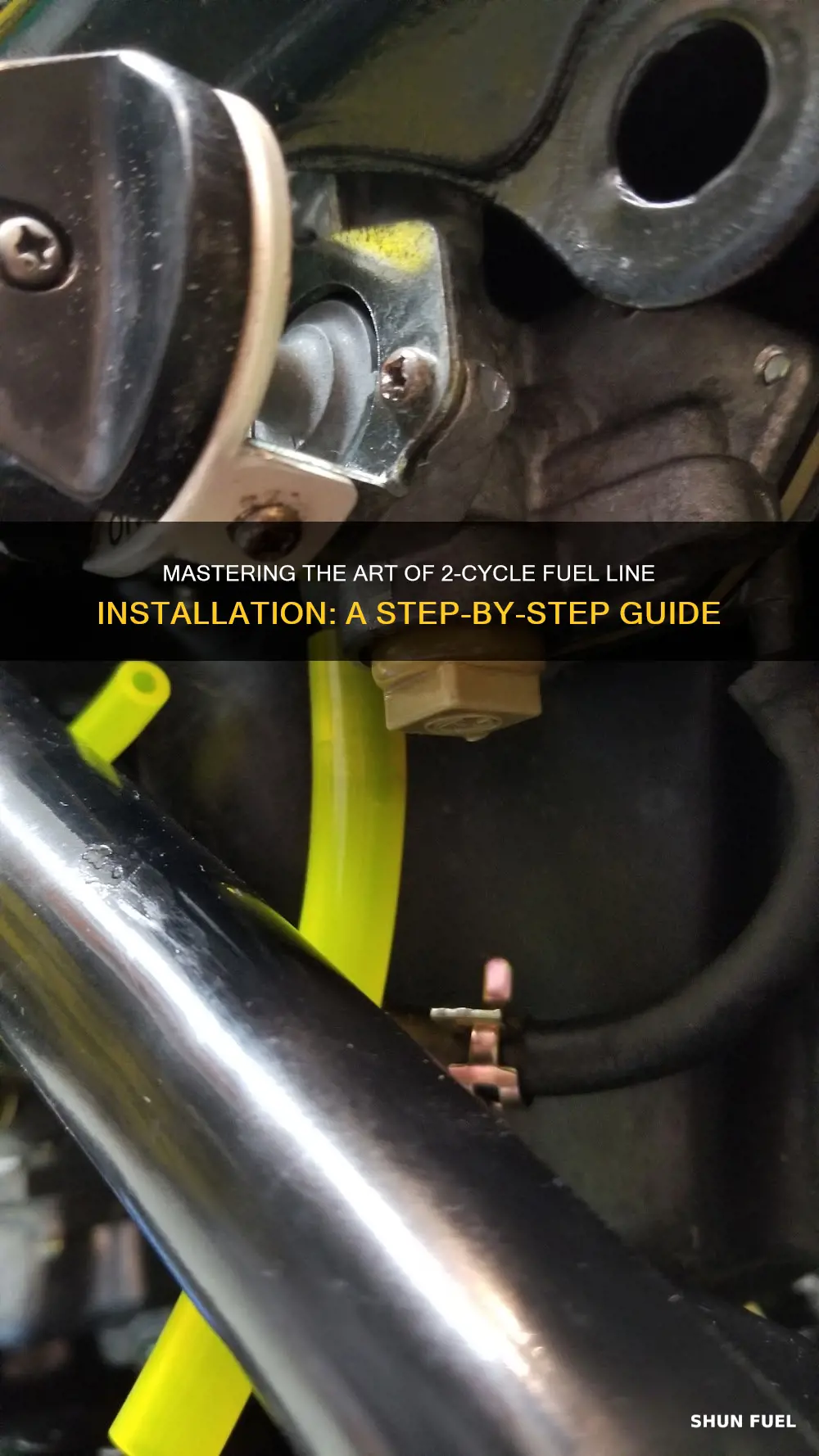

Clamps and Fittings: Secure the line with appropriate clamps and fittings for a tight seal

When inserting a 2-cycle fuel line into a tank, ensuring a secure and tight seal is crucial to prevent fuel leaks and maintain optimal engine performance. The process involves using specific clamps and fittings designed for this purpose. Here's a step-by-step guide on how to secure the fuel line effectively:

Start by selecting the right clamps and fittings. For 2-cycle fuel lines, you typically need a fuel line clamp and a fitting that matches the fuel line's diameter. These components are usually made of durable materials like metal or high-quality plastic to withstand fuel pressure and temperature changes. Ensure that the clamps are designed for the specific fuel line you are using to avoid any compatibility issues.

Once you have the necessary clamps and fittings, it's time to secure the fuel line. Begin by positioning the fitting onto the fuel line, ensuring it is aligned correctly. Then, apply the clamp over the fitting and fuel line, tightening it securely. The clamp should be tight enough to create a snug fit but not so tight that it restricts fuel flow or causes damage to the line. A good rule of thumb is to use your hand to tighten the clamp by hand, and then use a wrench or a pair of pliers to ensure it is secure without being overly tight.

After tightening the clamp, inspect the connection to ensure it is leak-free. You can do this by applying a small amount of fuel near the connection and observing if there are any signs of leakage. If no fuel is visible, the seal is likely secure. However, if you notice any leaks, carefully loosen the clamp slightly and re-tighten it to achieve a tighter seal.

Remember, the goal is to create a tight, leak-resistant connection without causing any damage to the fuel line. Using the right clamps and fittings, and ensuring a proper installation, will contribute to a reliable and efficient 2-cycle engine system. Always refer to the manufacturer's guidelines for specific recommendations regarding the fuel line and clamps to ensure compatibility and optimal performance.

Understanding Rag Fuel Lines: A Comprehensive Guide

You may want to see also

Testing: Run a test to ensure the fuel line is leak-free and functioning properly

Before you can test the fuel line, it's important to ensure that the engine is not running, as this could cause fuel to spray out and create a hazardous situation. Once you've confirmed the engine is off, you can proceed with the test.

The first step is to locate the fuel line and identify the areas where it connects to the tank and the engine. You should also check for any existing connections or fittings that might need to be tightened or replaced. Make sure to have a supply of fuel nearby, as you'll need to fill the line to perform the test.

Now, you can start the process of testing for leaks. Begin by removing the fuel line from the tank, being careful not to pull it too tightly, as this could damage the line. Once the line is removed, you can use a soapy water solution to coat the interior of the line and the connections. Take a small brush or a cloth and apply the soapy water mixture to the entire length of the fuel line, ensuring that you cover all the connections and fittings. Allow the soap to sit for a few minutes, then rinse the line thoroughly with water to remove any excess soap.

After rinsing, inspect the line for any bubbles or soapy residue. If you notice any, this indicates a potential leak. If there are no leaks, you can proceed to the next step. Start the engine and allow it to run for a few minutes. During this time, you should continue to monitor the fuel line for any signs of leaks. If you notice any, you may need to re-test the line or investigate further to identify the source of the leak.

Once you've confirmed that the fuel line is leak-free, you can test its functionality. This involves starting the engine and checking for proper fuel flow. You should hear the engine start smoothly, and it should run without any issues related to fuel delivery. If the engine starts and runs without any problems, you can be confident that the fuel line has been successfully installed and is functioning as intended.

Unveiling the Car Fuel Line: Visual Guide

You may want to see also

Frequently asked questions

Before inserting the fuel lines, ensure they are clean and free from any debris or contaminants. Use a fuel line cleaner or a mild detergent to wash the lines, then rinse and dry them thoroughly. This step is crucial to prevent any impurities from affecting the engine's performance.

Insert the fuel lines into the tank's fuel inlet port, ensuring they are aligned properly. Use a fuel line adapter or a specialized tool to push the lines in smoothly. Take care not to force the lines, as this can damage the tank or the lines themselves.

Yes, you'll need a fuel line adapter or a fuel line insertion tool to ensure a proper and secure fit. These tools help guide the lines into the tank and prevent any potential damage during the insertion process.

Tighten the fuel line connections securely using the appropriate size of fuel line clamps or fittings. Ensure the connections are tight enough to create a seal but not so tight that it causes damage to the lines. Regularly check and tighten the connections as needed.

If you encounter difficulty inserting the fuel lines, double-check the alignment and ensure the lines are the correct size for your tank. If the issue persists, consider consulting a professional mechanic who can provide assistance and ensure the correct installation.