Electric cars are often seen as a cleaner, more sustainable alternative to traditional gasoline vehicles, but they still rely on fossil fuels in various ways. Despite their zero-emission nature at the tailpipe, the production and distribution of electricity used to power these vehicles often involve the burning of fossil fuels, such as coal, natural gas, or oil. This process generates greenhouse gases and other pollutants, contributing to environmental degradation. Additionally, the manufacturing of electric car batteries and the extraction of raw materials, such as lithium and cobalt, can also have significant environmental impacts, often associated with fossil fuel use and mining activities. Understanding these interconnected processes is crucial for a comprehensive assessment of electric cars' sustainability and their role in the transition towards a more environmentally friendly transportation system.

What You'll Learn

- Battery Production: Mining and refining materials for batteries require fossil fuels

- Charging Infrastructure: Powering charging stations, often from fossil fuel-based grids

- Manufacturing: Car assembly and component production rely on fossil fuel-derived materials

- Recycling: Recycling processes for end-of-life batteries and materials can use fossil fuels

- Grid Energy: Charging electric cars from grids powered by fossil fuels

Battery Production: Mining and refining materials for batteries require fossil fuels

The production of batteries for electric vehicles (EVs) is a complex process that relies on various materials, and the extraction and refinement of these materials often involve the use of fossil fuels. This is an important aspect to consider when understanding the environmental impact of electric cars.

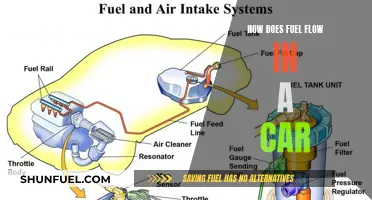

Battery manufacturing begins with mining, which is the initial step in obtaining the raw materials. For lithium-ion batteries, commonly used in EVs, the primary materials include lithium, cobalt, nickel, and manganese. These elements are extracted from the earth through mining operations, often located in regions with abundant mineral resources. The mining process itself can be energy-intensive, requiring significant amounts of electricity, which is frequently generated by burning fossil fuels. Coal, natural gas, and oil are commonly used to power the machinery and equipment needed for mining and processing.

Once the raw materials are mined, they undergo a series of refining processes to transform them into usable components for batteries. Refining involves chemical processes that require heat and energy, typically supplied by fossil fuels. For instance, lithium extraction often utilizes a process called lithium leaching, where lithium-rich solutions are separated from the ore using various solvents and chemicals. This separation process demands substantial energy input, often derived from non-renewable sources. Similarly, the refining of cobalt and nickel involves complex processes like hydrometallurgy and electrolysis, which also rely on fossil fuel-based energy sources.

The environmental implications of these processes are significant. The burning of fossil fuels releases greenhouse gases, contributing to climate change and air pollution. Additionally, the extraction and refining of materials can lead to habitat destruction, water pollution, and soil degradation if not managed sustainably. As the demand for electric vehicles increases, so does the need for batteries, putting further pressure on these finite resources and the ecosystems they support.

In summary, the production of batteries for electric cars is a resource-intensive process that directly links to the use of fossil fuels. From mining to refining, the extraction and transformation of materials require substantial energy, often derived from non-renewable sources. This highlights the importance of exploring and implementing more sustainable practices in the battery production sector to reduce the environmental impact of electric vehicles.

Driving with a Fuel Leak: Risks and Solutions

You may want to see also

Charging Infrastructure: Powering charging stations, often from fossil fuel-based grids

The charging infrastructure for electric vehicles (EVs) plays a crucial role in the overall environmental impact of these cars, especially when it comes to their reliance on fossil fuels. While electric cars themselves produce zero tailpipe emissions, the process of charging them often involves the use of electricity generated from fossil fuel-based power plants. This is a critical aspect that many people overlook when discussing the sustainability of electric vehicles.

Charging stations are typically connected to the electrical grid, which, in many regions, is predominantly powered by non-renewable sources. For instance, coal, natural gas, and oil-fired power plants still contribute significantly to the energy mix in many countries. When an electric car is plugged into a charging station, it draws power from this grid, and the source of that electricity can vary widely. In areas heavily reliant on fossil fuels, the carbon footprint of charging an EV can be substantial.

The process of charging an electric car is similar to plugging any other electrical device into a power outlet. However, the scale and power requirements are much higher for EVs. Charging stations can provide power at various levels, from slow (1-5 kW) to fast (20-40 kW) and rapid (up to 350 kW) charging. The higher the power output, the faster the car can be charged, but this also means a higher energy demand, which is often met by the existing power grid.

The challenge lies in the fact that the electricity grid's capacity and the timing of charging sessions can vary. During peak hours, the grid's demand can exceed its supply, leading to increased reliance on less environmentally friendly power sources. This is where the concept of smart charging comes into play, which aims to optimize charging times to match the grid's availability of renewable energy. However, until the grid's energy mix is entirely renewable, the environmental impact of charging EVs will remain a concern.

To address this issue, some regions are investing in renewable energy sources to power their grids, ensuring that the electricity used to charge EVs is as clean as possible. Additionally, vehicle-to-grid (V2G) technology is being explored, which could allow EVs to feed power back into the grid during periods of high demand, potentially reducing the strain on the grid and the need for additional fossil fuel-based power generation. These solutions are crucial in minimizing the environmental impact of electric cars and making them a truly sustainable transportation option.

Manual Transmission: The Fuel Efficiency Advantage

You may want to see also

Manufacturing: Car assembly and component production rely on fossil fuel-derived materials

The manufacturing process of electric vehicles (EVs) is an intricate one, and it's important to understand that even these environmentally friendly cars still have a significant reliance on fossil fuels. While electric cars themselves do not burn fossil fuels to operate, the production and assembly of these vehicles often involve processes that are heavily dependent on these non-renewable resources.

One of the primary reasons for this is the materials used in the construction of electric cars. Many components, such as batteries, motors, and even the plastics used in the interior, require fossil fuel-derived materials. For instance, lithium-ion batteries, a common power source for EVs, are produced using lithium, which is often sourced from fossil fuel-intensive mining operations. The extraction and processing of these materials involve energy-intensive processes that rely on fossil fuels, contributing to the carbon footprint of EV manufacturing.

The production of electric motors, another crucial component, also utilizes fossil fuel-derived materials. These motors often require rare earth metals, such as neodymium and dysprosium, which are extracted through mining processes that can be energy-intensive and dependent on fossil fuels. Additionally, the manufacturing of these motors involves various stages of processing and assembly, each of which may require energy-intensive steps, further emphasizing the need for fossil fuels.

Furthermore, the assembly of electric cars itself is a complex process that relies on a vast array of components. From the wiring harnesses to the electronic control units, each part is carefully constructed and assembled. This assembly line process often involves the use of fossil fuel-derived plastics, rubbers, and other materials, which are essential for the structural integrity and functionality of the vehicle. The manufacturing facilities and machinery used in this process also require energy, often supplied by fossil fuel-based power sources.

In summary, while electric cars are designed to reduce environmental impact, the manufacturing and production processes still have a significant environmental cost. The reliance on fossil fuels in the extraction, processing, and assembly of various components highlights the complex relationship between electric vehicles and traditional energy sources. As the demand for EVs continues to grow, it is crucial to explore and implement more sustainable practices in the manufacturing sector to minimize the environmental footprint of the automotive industry.

Unleash Your Engine's Potential: Banging on the Fuel Pump Works!

You may want to see also

Recycling: Recycling processes for end-of-life batteries and materials can use fossil fuels

The recycling of end-of-life batteries and materials from electric vehicles (EVs) is an important process, but it does have some environmental implications, including the potential use of fossil fuels. As the demand for electric cars rises, so does the need for efficient and sustainable recycling methods to handle the increasing number of batteries that will eventually reach the end of their useful life.

The recycling process for EV batteries typically involves several stages. Firstly, the batteries are disassembled to separate the various components, including the cathode, anode, electrolyte, and housing. This step often requires energy-intensive processes, such as mechanical shredding or chemical dissolution, which can be powered by fossil fuels. For example, the shredding process might utilize electricity generated from coal or natural gas power plants, contributing to greenhouse gas emissions.

Once the components are separated, further processing is needed to extract valuable materials like lithium, cobalt, nickel, and manganese. These metals are then refined and purified to meet the standards required for reuse in new batteries or other products. The refining process can be energy-intensive and may rely on fossil fuel-based industrial processes, especially in the initial stages of extraction and purification.

However, it's important to note that the environmental impact of recycling EV batteries is not solely dependent on fossil fuel usage. Many recycling facilities are exploring and implementing more sustainable practices. For instance, some companies are developing advanced recycling technologies that use less energy, such as hydrometallurgical processes that employ water-based solutions instead of harsh chemicals. These methods can reduce the reliance on fossil fuels and minimize the carbon footprint of the recycling process.

Additionally, the recycling industry is focusing on closing the loop by ensuring that recycled materials are reused in the production of new batteries and other products. This circular economy approach aims to minimize the need for virgin resources and further reduce the environmental impact associated with extraction and processing. While the recycling of EV batteries does involve the use of fossil fuels in certain stages, ongoing innovations and sustainable practices are being adopted to mitigate these effects and make the process more environmentally friendly.

Mazda's Fuel Efficiency: A Comprehensive Guide to Eco-Friendly Driving

You may want to see also

Grid Energy: Charging electric cars from grids powered by fossil fuels

The concept of electric cars is often associated with a more sustainable and environmentally friendly approach to transportation, but it's important to understand the full picture, especially when considering the energy sources that power these vehicles. While electric cars themselves produce zero tailpipe emissions, their operation is still dependent on energy generation, and in many cases, this energy is derived from fossil fuels. This is particularly relevant when discussing the charging infrastructure, known as the grid, that supports electric vehicles.

When an electric car is plugged into a charging station, it draws power from the electrical grid. The grid, in turn, can be powered by various sources, including renewable energy, nuclear power, and, most commonly, fossil fuels. Fossil fuel-based power plants, such as coal, natural gas, and oil, are prevalent in many regions and contribute significantly to the electricity supply. These power plants generate electricity through combustion, which is then transmitted to the charging stations.

The process of charging an electric car from a grid powered by fossil fuels involves several steps. Firstly, the electricity is produced at a power plant, often through the burning of fossil fuels. This process releases greenhouse gases and other pollutants, contributing to environmental degradation. The generated electricity is then transmitted through power lines to the charging infrastructure. When an electric vehicle is connected to a charging station, it draws this electricity, which is then used to recharge the car's battery.

It is essential to recognize that the environmental impact of electric cars is not solely determined by their driving emissions but also by the energy used to power them. If the grid is predominantly supplied by fossil fuels, the overall carbon footprint of an electric car can be higher compared to conventional vehicles, especially during the initial years of the car's lifecycle. However, as the grid transitions towards renewable energy sources, the environmental benefits of electric cars become more pronounced.

To address this concern, many regions are actively working on improving the sustainability of the grid by integrating renewable energy sources like solar, wind, and hydropower. Governments and energy companies are investing in renewable infrastructure to reduce the reliance on fossil fuels for electricity generation. As a result, the environmental impact of charging electric cars from grids powered by fossil fuels is being mitigated, making electric vehicles an increasingly attractive and eco-friendly transportation option.

New Car Fuel: Initial Usage and Efficiency

You may want to see also

Frequently asked questions

No, electric cars do not directly use fossil fuels like gasoline or diesel. They are powered by electricity, which can be generated from various sources, including renewable options.

EVs can be charged using electricity from the grid, which can be produced from a range of sources. These sources include renewable energy like solar and wind power, as well as non-renewable but cleaner options such as hydropower and nuclear energy.

While electric cars themselves don't burn fossil fuels, they can indirectly use them during the charging process if the electricity comes from fossil fuel-based power plants. However, this is not the primary or intended way of operating an electric vehicle.

The environmental benefits of electric cars are significant. By reducing reliance on fossil fuels, EVs help decrease greenhouse gas emissions and air pollution. The overall carbon footprint of an electric car depends on the energy mix used for charging, but they still offer a more sustainable transportation option compared to traditional internal combustion engine vehicles.

Absolutely! The automotive industry is continuously working towards improving EV technology and infrastructure. The goal is to make electric cars more efficient and accessible, ensuring that they can be charged using only renewable energy sources, thus eliminating the need for fossil fuels in their operation.