Car fuel injectors are a crucial component of modern vehicle engines, responsible for delivering fuel to the engine's cylinders in a precise and efficient manner. These injectors play a vital role in optimizing engine performance, fuel economy, and emissions. Understanding how fuel injectors work is essential for car owners and mechanics alike, as it helps in maintaining the engine's health and ensuring optimal performance. This paragraph will delve into the inner workings of fuel injectors, explaining their function, design, and the process by which they inject fuel into the engine, ultimately contributing to the overall efficiency and power of the vehicle.

What You'll Learn

- Fuel Delivery: Injectors receive pressurized fuel from the pump and deliver it to the engine

- Spray Pattern: Injectors create a precise spray pattern to ensure optimal combustion

- Timing: Injectors open and close at specific engine speeds and loads

- Pressure Regulation: Injectors maintain precise fuel pressure to control flow rate

- Electronic Control: Injectors are controlled by the engine's computer for optimal performance

Fuel Delivery: Injectors receive pressurized fuel from the pump and deliver it to the engine

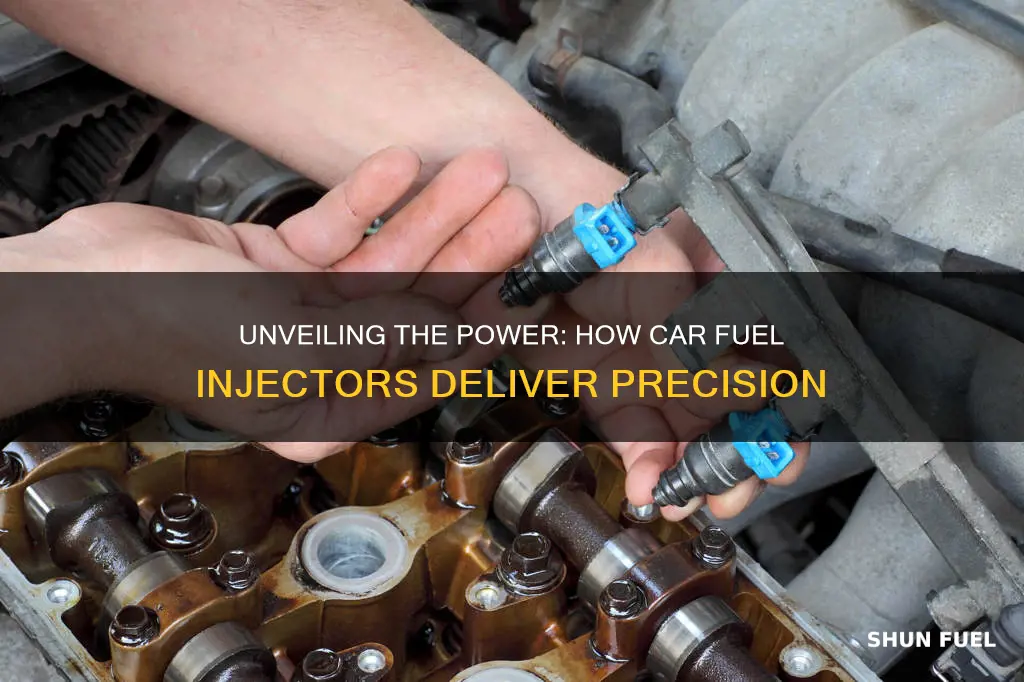

Fuel injectors are a crucial component of a car's fuel system, responsible for delivering the precise amount of fuel required for optimal engine performance. The process begins with the fuel pump, which is designed to maintain a consistent pressure to ensure efficient fuel delivery. When the engine is running, the fuel pump operates continuously, drawing fuel from the fuel tank and sending it through a network of fuel lines to the injectors. This pressurized fuel is then ready for injection into the engine's cylinders.

The injectors are strategically positioned along the fuel lines, often near the intake manifold or directly into the cylinders. Each injector is designed to spray a fine mist of fuel into a specific area of the engine's combustion chamber. This mist is created by the injector's nozzle, which atomizes the fuel, ensuring it mixes thoroughly with the air for efficient combustion. The pressure within the fuel lines is carefully regulated to ensure that the fuel is delivered at the right pressure and volume for each injector.

As the fuel pump sends pressurized fuel to the injectors, the injectors open and close rapidly, releasing the fuel in a controlled manner. This process is highly precise, with the injector's solenoid valve controlling the timing and amount of fuel delivered. The solenoid valve is an electromagnetic component that responds to signals from the engine's electronic control unit (ECU). The ECU calculates the optimal fuel-air mixture based on various engine parameters and sends the appropriate signal to the solenoid valve, ensuring the correct amount of fuel is injected at the right time.

The fuel delivery process is a delicate balance of pressure, timing, and precision. Injectors must deliver the fuel at the right pressure to ensure proper atomization and mixing with air. If the pressure is too low, the fuel may not atomize effectively, leading to poor engine performance and potential fuel leaks. Conversely, excessive pressure can cause fuel to spray in the wrong direction or at the wrong time, resulting in inefficient combustion.

Modern fuel injectors are designed to optimize engine performance and fuel efficiency. They can adjust the fuel spray pattern, spray angle, and injection timing based on engine load and speed. This adaptability ensures that the engine receives the correct amount of fuel for various driving conditions, from low-speed city driving to high-speed highway cruising. By delivering fuel precisely where and when it's needed, fuel injectors play a vital role in maintaining engine performance, fuel economy, and overall vehicle efficiency.

Glow Plug RC Car Fuel: Powering Your Next Adventure

You may want to see also

Spray Pattern: Injectors create a precise spray pattern to ensure optimal combustion

The spray pattern created by fuel injectors is a critical aspect of the combustion process in an internal combustion engine. When a fuel injector opens, it releases a high-pressure stream of fuel into the engine's intake manifold or directly into the combustion chamber. The design of the injector nozzles and the pressure at which the fuel is released determine the shape and characteristics of the spray.

A precise spray pattern is essential for efficient combustion. The fuel must be atomized to a fine mist, ensuring that each droplet is small enough to evaporate quickly and mix thoroughly with the air-fuel mixture. This process is crucial for complete combustion, as it allows for better fuel-air mixture distribution, leading to more efficient power generation and reduced emissions.

The spray pattern also affects the timing and distribution of the fuel injection. A well-designed spray pattern ensures that the fuel is injected at the optimal point in the engine's compression stroke. This timing is critical because it allows the fuel to be mixed with the incoming air and ignited at the right moment, maximizing power output and minimizing engine knock.

Engineers and manufacturers carefully design injector nozzles to create a specific spray angle and penetration. The spray angle determines how far the fuel droplets travel before they start to evaporate and mix with the surrounding air. A wider spray angle can provide better coverage of the combustion chamber, ensuring that all areas receive an adequate fuel supply. However, a too-wide angle might lead to fuel droplets missing the combustion chamber and being expelled through the exhaust.

Additionally, the spray pattern's uniformity is vital. A consistent spray pattern ensures that the fuel is distributed evenly across the combustion chamber, promoting complete combustion and reducing the formation of harmful pollutants. This uniformity is achieved through precise nozzle design, which includes the size, shape, and arrangement of the nozzles, as well as the pressure and flow rate of the fuel.

Turbocharged Engine Maintenance: Can Fuel Injector Cleaner Be Used?

You may want to see also

Timing: Injectors open and close at specific engine speeds and loads

The timing of fuel injector operation is a critical aspect of engine performance and efficiency. Car fuel injectors are designed to precisely control the amount of fuel delivered to the engine's cylinders, and this control is achieved through careful timing. When the engine operates at different speeds and under various loads, the fuel injectors must adjust their operation accordingly to ensure optimal performance.

Engine speed, often referred to as RPM (revolutions per minute), plays a significant role in determining the timing of injector activation. As the engine speed increases, the demand for more fuel to meet the higher power requirements also rises. Fuel injectors are programmed to open at specific RPM thresholds, ensuring that the engine receives the necessary fuel at the right time. For example, at low engine speeds, the injectors might open at a lower RPM range to provide a steady amount of fuel for idling or cruising. As the engine revs increase, the injectors activate at higher RPMs to support the additional power demands.

Engine load, which refers to the amount of power the engine is producing, is another crucial factor in timing. When the engine is under a heavy load, such as during acceleration or climbing a steep hill, more fuel is required to maintain the desired power output. Fuel injectors are calibrated to open at specific load levels, ensuring that the engine receives the additional fuel needed to meet the increased power demands. During light-load conditions, such as driving at a constant speed on a flat road, the injectors might open at a lower load threshold to optimize fuel efficiency while still providing sufficient power.

The timing of injector operation is not just about engine speed and load but also considers the engine's operating conditions. For instance, during cold engine starts, the fuel injectors may open at a lower speed and load to facilitate easier starting and warm-up. As the engine warms up, the timing can be adjusted to match the optimal fuel-air mixture and power delivery. This dynamic timing ensures that the engine operates efficiently and effectively across various driving scenarios.

In summary, the timing of fuel injector operation is a complex process that ensures the engine receives the right amount of fuel at the right time. By adjusting the injector opening based on engine speed and load, modern vehicles can optimize performance, fuel efficiency, and power delivery, providing a smooth and responsive driving experience. This precise control over fuel injection timing is a key factor in the overall functionality and reliability of a car's engine.

Defective Fuel Injector: Why Your Car Won't Start

You may want to see also

Pressure Regulation: Injectors maintain precise fuel pressure to control flow rate

Car fuel injectors are a crucial component of modern engines, responsible for delivering the precise amount of fuel required for efficient combustion. One of the key functions of fuel injectors is pressure regulation, which ensures that the fuel is supplied at the right pressure to control the flow rate into the engine's cylinders. This process is essential for maintaining optimal engine performance, fuel efficiency, and emissions control.

Pressure regulation in fuel injectors is achieved through a sophisticated design that incorporates various components. At the heart of this system is the injector nozzle, which is designed to atomize the fuel into a fine mist. The nozzle's internal structure, including the orifice and the spray guide, plays a critical role in controlling the fuel's exit velocity and spray pattern. By precisely regulating the fuel's exit velocity, the injector ensures that the fuel droplets are small enough to facilitate efficient combustion.

The fuel pressure within the injector is carefully controlled by a pressure regulator, often located within the injector body. This regulator maintains a consistent pressure by adjusting the fuel flow rate based on engine load and speed. When the engine demands more power, the pressure regulator increases the fuel pressure to provide a higher flow rate, ensuring that the engine receives the necessary fuel for optimal performance. Conversely, during lighter loads, the regulator reduces the pressure to maintain efficiency and prevent excessive fuel consumption.

To achieve precise pressure regulation, fuel injectors employ a feedback control system. This system continuously monitors the fuel pressure and makes adjustments to maintain the desired pressure level. Sensors within the injector measure the actual fuel pressure and compare it to a reference value. If there is a deviation from the target pressure, the control system activates solenoid valves to modulate the fuel flow, thus regulating the pressure. This dynamic control ensures that the fuel pressure remains stable and accurate, even under varying operating conditions.

Additionally, fuel injectors often feature pressure relief mechanisms to prevent over-pressurization. These mechanisms are designed to release excess pressure when the fuel system operates beyond its specified limits. By incorporating pressure relief valves or pressure-sensitive components, the injectors safeguard against potential damage caused by excessive fuel pressure. This safety feature is vital for the longevity and reliability of the fuel injection system.

Navigating Deductions: Unlocking Fuel Expense Secrets for Rental Cars

You may want to see also

Electronic Control: Injectors are controlled by the engine's computer for optimal performance

The electronic control unit (ECU) plays a pivotal role in managing the fuel injection system, ensuring that the engine operates at its peak efficiency. This sophisticated computer system is the brain behind the operation, making real-time decisions to optimize fuel delivery. When you start your car, the ECU receives input from various sensors, including the crankshaft position sensor, which monitors the engine's rotation, and the camshaft position sensor, which tracks the valve timing. This data is crucial for the ECU to understand the engine's current state and make precise adjustments.

The ECU's primary task is to calculate the ideal fuel-air mixture required for combustion. It considers factors such as engine speed, load, and temperature to determine the exact amount of fuel needed. This calculation is based on a complex algorithm that takes into account the engine's performance characteristics and the driver's input, such as throttle position. By doing so, the ECU ensures that the engine receives the right amount of fuel at the right time, promoting efficient combustion and power generation.

One of the key advantages of electronic control is the ability to adapt to changing conditions. The ECU continuously monitors the engine's performance and makes adjustments accordingly. For instance, if the engine is running rich (with an excess of fuel), the ECU will reduce the fuel injection to lean out the mixture, improving fuel economy and reducing emissions. Conversely, if the engine is running lean, the ECU will increase the fuel injection to enrich the mixture, preventing engine knock and maintaining optimal performance.

This technology also enables advanced features like idle control and cruise control. When the engine is idling, the ECU ensures a precise fuel-air mixture to maintain a stable and smooth operation. During cruising, it optimizes fuel delivery to balance power and fuel efficiency. The ECU's control over the injectors allows for rapid responses to changes in driving conditions, ensuring a seamless and responsive driving experience.

In summary, the electronic control of fuel injectors is a sophisticated process that maximizes engine performance and efficiency. By utilizing real-time data and advanced algorithms, the ECU makes precise decisions, adjusting fuel injection to match the engine's needs. This technology has revolutionized modern vehicles, providing better fuel economy, reduced emissions, and improved overall engine management.

Fuel Pumps: A Universal Car Component?

You may want to see also

Frequently asked questions

Fuel injectors are responsible for delivering the precise amount of fuel required for combustion in the engine's cylinders. They ensure efficient and accurate fuel delivery, optimizing engine performance and fuel economy.

Unlike carburetors, which mix air and fuel in a single process, fuel injectors spray fuel directly into the engine's intake manifold or directly into the cylinders. This results in better fuel atomization, improved power, and reduced emissions.

Electronic fuel injection (EFI) uses sensors and a computer to control fuel delivery. It offers precise control, faster response times, and the ability to adapt to varying engine conditions. EFI provides better performance, especially at high altitudes or during rapid acceleration.

Fuel injectors adjust the fuel spray pattern and quantity based on engine load, temperature, and speed. They can deliver more fuel during high-demand situations, such as acceleration, and reduce the amount when the engine is idling, ensuring a balanced fuel-air mixture for efficient combustion.

Yes, fuel injectors can significantly enhance engine performance by providing a more efficient and precise fuel-air mixture. This results in increased power, better throttle response, and improved fuel economy. Well-maintained fuel injectors can also extend the engine's lifespan.