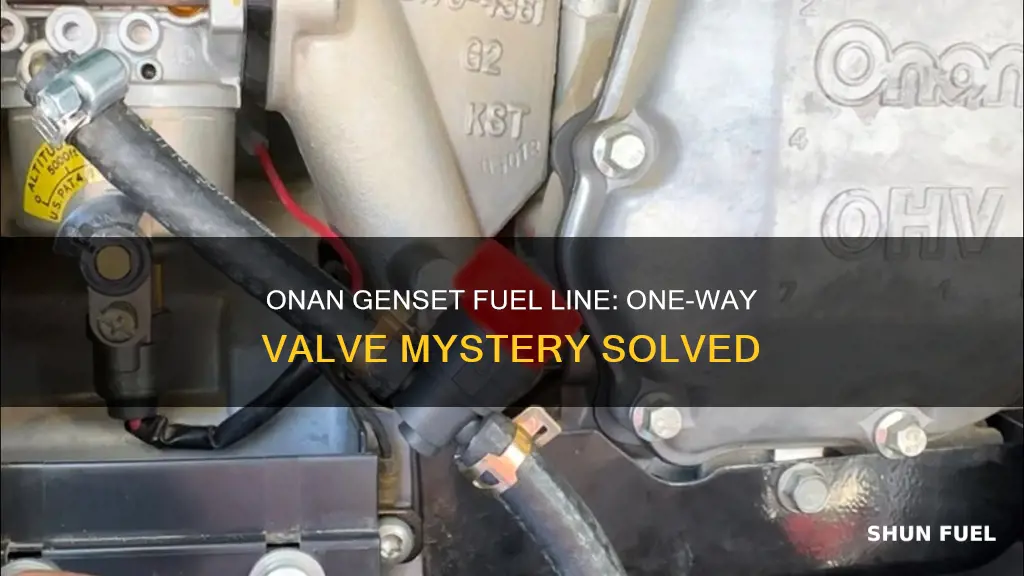

The Onan Genset fuel line is a critical component in the operation of a generator set, and its design includes a one-way valve to ensure efficient and safe fuel flow. This valve is a crucial safety feature that prevents fuel from flowing backward, which could lead to engine damage or performance issues. Understanding the role and placement of this valve is essential for proper maintenance and troubleshooting of the generator set.

| Characteristics | Values |

|---|---|

| Onan Genset Model | Not specified |

| Fuel Line Material | Typically rubber or plastic |

| One-Way Valve Function | Allows fuel flow in one direction, preventing backflow |

| Location | Usually near the fuel tank or pump |

| Purpose | To ensure fuel flows only when the genset is running and to prevent airlock or contamination |

| Common Issues | Clogging, leaks, or failure to close properly |

| Maintenance | Regular inspection and replacement as needed |

| Compatibility | Specific to the genset model and fuel system |

What You'll Learn

- Valve Location: Onan genset fuel lines typically have one-way valves near the fuel tank and pump

- Fuel Flow: One-way valves prevent backflow, ensuring fuel flows in the correct direction

- Pressure Relief: These valves can also act as pressure relief mechanisms to prevent damage

- Maintenance: Regular inspection of one-way valves is crucial for genset maintenance and longevity

- Troubleshooting: Common issues include valve blockages or damage, requiring professional diagnosis and repair

Valve Location: Onan genset fuel lines typically have one-way valves near the fuel tank and pump

Onan gensets, a popular brand of portable generators, rely on a fuel system that includes a fuel line to deliver gasoline from the tank to the engine. This fuel line is an essential component to ensure the generator's efficient operation and longevity. One critical aspect of this system is the inclusion of one-way valves, which are strategically placed to prevent fuel backflow and maintain optimal performance.

The location of these one-way valves is crucial and typically follows a standard design. Onan genset fuel lines usually incorporate a one-way valve near the fuel tank and another near the fuel pump. This placement is intentional and serves a specific purpose. By positioning the valve close to the fuel tank, it acts as a barrier to any potential air or water intrusion during the fueling process. This is essential as air and water can contaminate the fuel, leading to performance issues and potential damage to the generator's engine.

The valve near the fuel pump is equally important. It ensures that the fuel flows in the correct direction, from the tank to the pump, and prevents any backpressure that could cause fuel to flow backward. This is a critical safety feature, as it protects the pump from potential damage caused by reverse flow.

Additionally, the proximity of these valves to their respective components allows for easier maintenance and potential replacements if needed. This accessibility is a significant advantage when performing routine checks or addressing any fuel-related issues that may arise during the genset's operation.

In summary, Onan genset fuel lines are designed with one-way valves strategically placed near the fuel tank and pump. This design choice ensures optimal performance, prevents contamination, and safeguards the generator's fuel system from potential damage. Understanding the location and function of these valves is essential for anyone maintaining or troubleshooting an Onan genset.

Optimizing Performance: Choosing the Right Fuel Line for Your HMSK80

You may want to see also

Fuel Flow: One-way valves prevent backflow, ensuring fuel flows in the correct direction

One-way valves are an essential component in fuel systems, especially in generators like the Onan genset, to ensure efficient and safe fuel flow. These valves are strategically placed in the fuel lines to regulate the direction of fuel movement, preventing backflow and potential issues. The primary function of a one-way valve is to allow fuel to flow in a single direction, from the fuel source to the engine, while blocking any reverse flow. This is crucial as it helps maintain the integrity of the fuel system and prevents air from entering the fuel lines, which could lead to engine misfires and reduced performance.

In the context of an Onan genset, the fuel line is designed with a one-way valve to ensure that the fuel pump delivers fuel to the engine in the correct sequence. When the engine is running, the fuel pump creates a pressure that pushes fuel through the line. The one-way valve opens to allow this flow, ensuring a continuous supply of fuel to the engine. However, if the valve were to malfunction and allow backflow, it could result in air entering the fuel system. Air bubbles in the fuel can cause erratic engine behavior, such as stalling or difficulty starting.

The design of these valves is critical to their functionality. They are typically made of durable materials like brass or plastic, ensuring they can withstand the pressure and temperature changes within the fuel system. The valve's structure includes a flexible flap or diaphragm that opens when fuel flows in the correct direction and closes tightly when fuel attempts to flow backward. This mechanism is designed to be reliable and long-lasting, providing consistent performance over extended periods.

In addition to preventing backflow, one-way valves also contribute to the overall efficiency of the fuel system. By ensuring a one-way flow, these valves minimize fuel wastage and reduce the risk of fuel contamination. Properly functioning one-way valves can also extend the lifespan of the fuel pump and other engine components, as they prevent excessive wear caused by reverse fuel flow.

In summary, one-way valves are a vital part of the Onan genset's fuel system, ensuring that fuel flows in the correct direction and preventing backflow-related issues. Their presence guarantees a reliable and efficient fuel supply to the engine, contributing to the overall performance and longevity of the genset. Regular maintenance and inspection of these valves are recommended to ensure their continued effectiveness.

Understanding Impulse Fuel Lines: Powering Chainsaws Efficiently

You may want to see also

Pressure Relief: These valves can also act as pressure relief mechanisms to prevent damage

When it comes to Onan gensets, the fuel lines are an essential component that requires careful consideration. One crucial aspect to explore is the presence of one-way valves in these fuel lines, which can significantly impact the system's performance and longevity. By understanding the role of these valves, particularly in relation to pressure relief, we can ensure the optimal functioning of the genset.

The fuel lines in an Onan genset are designed to transport fuel efficiently from the tank to the engine. Over time, fuel lines can experience pressure fluctuations, especially during operation and when starting the genset. This is where one-way valves come into play. These valves are strategically placed within the fuel lines to allow fuel flow in one direction while preventing backflow. This directional control is vital to maintain the proper fuel supply and ensure the genset operates smoothly.

One of the primary functions of one-way valves in the fuel lines is to provide pressure relief. Fuel systems can experience rapid pressure changes, especially when the genset is started or when the engine load varies. Without proper pressure management, these fluctuations can lead to potential damage to the fuel lines, engine components, and even the genset itself. One-way valves act as a safety mechanism by allowing excess pressure to be released, preventing the buildup that could cause harm. This pressure relief capability is crucial for the long-term reliability and performance of the Onan genset.

In addition to their role in pressure relief, one-way valves also contribute to efficient fuel flow. By ensuring that fuel moves in the correct direction, these valves prevent air from entering the system, which could lead to engine misfires and reduced performance. Properly functioning one-way valves guarantee that the genset receives a consistent and clean fuel supply, optimizing its output and overall efficiency.

In summary, the inclusion of one-way valves in Onan genset fuel lines serves a critical purpose, particularly in pressure relief. These valves safeguard the genset's components by managing pressure fluctuations, preventing damage, and ensuring a steady fuel supply. Understanding the importance of these valves highlights the need for regular maintenance and inspection to guarantee their effectiveness and, consequently, the overall performance and longevity of the genset.

Unveiling the Standard Fuel Line Size: A Comprehensive Guide

You may want to see also

Maintenance: Regular inspection of one-way valves is crucial for genset maintenance and longevity

One-way valves are essential components in the fuel system of Onan gensets, ensuring that the fuel flows in the correct direction and preventing backflow. These valves are designed to allow fuel to pass in one direction while blocking its return flow. Regular maintenance and inspection of these valves are critical to the genset's performance and longevity. Over time, these valves can become worn or damaged, leading to potential issues with fuel flow and system efficiency.

During routine maintenance, it is imperative to inspect the one-way valves for any signs of damage or malfunction. This inspection should include checking for leaks, ensuring the valve's proper seating, and verifying its functionality. A simple yet effective method to test the valve is to temporarily block the fuel supply and observe if the valve closes tightly, preventing any fuel from flowing backward. If the valve fails to close properly, it may need to be replaced to maintain the genset's optimal performance.

The fuel lines in an Onan genset are typically equipped with one-way valves to prevent airlock and ensure fuel delivery. These valves are often located near the fuel tank and the engine, providing a critical barrier against backpressure and potential engine damage. Regularly checking these valves for any signs of corrosion, debris buildup, or damage is essential, as it can lead to reduced performance and potential fuel system failures.

In addition to visual inspections, it is beneficial to listen for any unusual sounds during the maintenance process. A properly functioning one-way valve should operate silently, allowing fuel to flow freely in one direction. Any abnormal noises, such as hissing or whistling, could indicate a faulty valve, requiring immediate attention and potential replacement.

By incorporating regular one-way valve inspections into the maintenance routine, operators can significantly extend the lifespan of their Onan gensets. This proactive approach ensures that the fuel system remains efficient, reliable, and capable of delivering consistent performance when it is needed the most. Proper maintenance not only prevents costly repairs but also ensures the genset's availability during critical power-generating situations.

Mastering the Quick Connect Swap: Nylon Fuel Line Guide

You may want to see also

Troubleshooting: Common issues include valve blockages or damage, requiring professional diagnosis and repair

When dealing with the fuel lines of an Onan genset, it's important to understand the role of the one-way valve, which is designed to prevent fuel from flowing back into the tank when the generator is running. However, over time, this valve can become blocked or damaged, leading to a range of issues. One common problem is fuel starvation, where the generator doesn't receive enough fuel to operate efficiently or at all. This can be caused by a blocked or damaged one-way valve, which restricts the flow of fuel. Another issue is the potential for fuel to backflow into the tank, which can contaminate the fuel system and cause further problems.

Valve blockages are a frequent occurrence and can be caused by various factors. Accumulated debris, such as dirt, rust, or even small particles of fuel, can restrict the valve's opening, preventing it from allowing fuel to pass through. This issue is often more prevalent in older gensets or those that have been used in dirty environments. In some cases, the valve may become damaged due to mechanical wear and tear, especially if the genset has been subjected to frequent starting and stopping cycles.

If you suspect that the one-way valve is the source of your genset's problems, it is crucial to address the issue promptly. Attempting to repair or replace the valve yourself can be challenging due to its location and the specialized tools required. It is highly recommended to consult a professional technician who has experience with Onan gensets. They can provide an accurate diagnosis, ensuring that the valve is properly assessed for blockages or damage.

Professional repair or replacement of the one-way valve is often necessary to ensure the genset's optimal performance. A qualified technician will have the expertise to identify the root cause of the valve's failure and recommend the appropriate solution. They may also advise on preventative measures to avoid future issues, such as regular maintenance and fuel system cleaning. Remember, proper maintenance and timely repairs are essential to keeping your Onan genset reliable and efficient.

Chevy Fuel Pump Lines: A Step-by-Step Removal Guide

You may want to see also

Frequently asked questions

A one-way valve, also known as a check valve, is an essential component in the fuel line of a Onan genset. Its primary function is to prevent fuel from flowing back into the tank when the generator is running. This ensures that the fuel system operates efficiently and maintains a consistent fuel supply to the engine.

When the genset is operating, the engine's pressure creates a force that opens the one-way valve, allowing fuel to flow from the tank to the engine. Once the engine stops, the pressure dissipates, and the valve closes automatically, preventing any backflow of fuel. This mechanism ensures that the fuel system remains sealed and protects against potential contamination or damage.

Yes, like any mechanical component, one-way valves can malfunction over time due to wear and tear, debris accumulation, or damage. If a valve fails, it may not close properly, leading to fuel leakage or backflow. This can result in engine performance issues, fuel wastage, and potential safety hazards. Regular maintenance and inspection of the fuel system, including the one-way valve, are crucial to prevent such malfunctions.

The manufacturer's guidelines and maintenance schedule should be followed for the genset. Typically, the fuel system, including the one-way valve, should be inspected during routine maintenance checks. The frequency of replacement depends on usage, environmental factors, and the genset's age. It is recommended to consult the Onan genset's manual or seek professional advice for specific maintenance intervals to ensure optimal performance and longevity of the fuel system components.