Are you ready to unleash the power of your car's engine? Look no further than the ultimate DIY project: building your own fuel-injected car exhaust flame thrower! This innovative system not only boosts your vehicle's performance but also adds a thrilling visual element to your ride. With a few simple modifications and some clever engineering, you can transform your car into a powerful beast that leaves a lasting impression. Get ready to embark on a thrilling journey of customization and performance enhancement as we explore the world of DIY fuel-injected car exhaust systems.

What You'll Learn

- Fuel Injection Tuning: Adjusting fuel injectors for optimal performance and efficiency

- Exhaust System Design: Crafting custom exhaust systems for enhanced power and sound

- Flame Thrower Safety: Understanding and implementing safety measures for flame thrower operation

- Performance Testing: Evaluating exhaust system performance through dyno testing and track days

- Maintenance and Upkeep: Regular care and maintenance to ensure longevity and reliability

Fuel Injection Tuning: Adjusting fuel injectors for optimal performance and efficiency

Fuel injection tuning is a process that allows car enthusiasts to optimize their vehicle's performance and efficiency by adjusting the fuel injectors. This technique is particularly useful for fuel-injected engines, where precise control of fuel delivery is essential for achieving the best power output and fuel economy. By fine-tuning the fuel injectors, you can ensure that your engine receives the right amount of fuel at the right time, resulting in improved performance and reduced emissions.

The process begins with a thorough understanding of your vehicle's fuel injection system. Each car's setup is unique, and factors such as engine size, compression ratio, and desired performance levels play a crucial role in determining the ideal fuel-air mixture. You'll need to consult your vehicle's manual or seek professional advice to gather specific information about your engine's requirements. This knowledge will guide you in making the necessary adjustments to the fuel injectors.

One common method of fuel injection tuning is the use of a fuel pressure gauge and a fuel flow meter. These tools allow you to measure the fuel pressure and flow rate, respectively, which are critical parameters for optimizing performance. By adjusting the fuel pressure, you can control the amount of fuel entering the engine, ensuring it receives the precise amount needed for efficient combustion. Fine-tuning the fuel pressure also helps in achieving a balanced air-fuel mixture, which is essential for power and efficiency.

Another aspect of fuel injection tuning involves adjusting the injector pulse width and duty cycle. The pulse width determines the duration of the fuel injection pulse, while the duty cycle represents the proportion of the cycle during which the fuel is injected. By modifying these parameters, you can control the fuel-air mixture's richness or leaness, directly impacting engine performance. A leaner mixture can improve power and fuel efficiency but may require careful calibration to avoid engine knock.

When performing fuel injection tuning, it's crucial to make small adjustments and monitor the engine's response. This iterative process allows you to fine-tune the fuel injectors to achieve the desired performance characteristics. Remember that each engine is unique, and finding the perfect balance may require some experimentation. Additionally, regular maintenance and monitoring of fuel system components, such as fuel filters and injectors, are essential to ensure long-term reliability and optimal performance.

Higher-Grade Fuel: Friend or Foe for Your Car?

You may want to see also

Exhaust System Design: Crafting custom exhaust systems for enhanced power and sound

The exhaust system of a vehicle is a critical component that significantly influences performance, sound, and overall driving experience. For enthusiasts seeking to unlock their car's full potential, designing and building a custom exhaust system can be a rewarding endeavor. This process involves careful consideration of various factors to achieve the desired balance between power gain and the unique sound that enthusiasts often crave.

When crafting a custom exhaust system, the first step is to assess the vehicle's current setup and identify areas for improvement. This includes examining the existing exhaust pipes, mufflers, and tailpipes. For those aiming to create a 'do-it-yourself fuel-injected car exhaust flame thrower,' the goal is to maximize power output while maintaining control over the sound produced. One approach is to start with a high-performance exhaust manifold, which directs exhaust gases more efficiently, allowing for increased power and improved throttle response.

Designing the exhaust system requires a meticulous approach to ensure optimal performance. The layout should consider the vehicle's engine configuration, ensuring that the exhaust pipes are routed correctly to accommodate the engine's layout. For instance, in an inline-six engine, the exhaust pipes can be arranged in a symmetrical pattern, while V8 engines may require a more complex layout to manage the exhaust flow from multiple cylinders. The use of mandrel bending techniques can help create smooth curves, ensuring minimal restriction and maximizing flow.

In addition to power and sound, the material choice is crucial. Stainless steel is a popular option due to its durability, corrosion resistance, and ability to withstand high temperatures. It provides a balance between weight and strength, ensuring the exhaust system can handle increased power without compromising structural integrity. Some enthusiasts might also consider using mandrel-bent stainless steel tubing, which offers improved flow characteristics compared to standard exhaust pipes.

The final touches involve selecting the right mufflers and tailpipes. For a flame-thrower-like exhaust, performance mufflers with minimal restriction can be used to retain sound while still providing some noise reduction. Tailpipes can be customized with different diameters and lengths to influence the sound further. It's essential to test the exhaust system thoroughly, ensuring it meets the desired performance and sound goals while adhering to local noise regulations.

Can a Car Fuel Pump Be Fixed? Repair Tips

You may want to see also

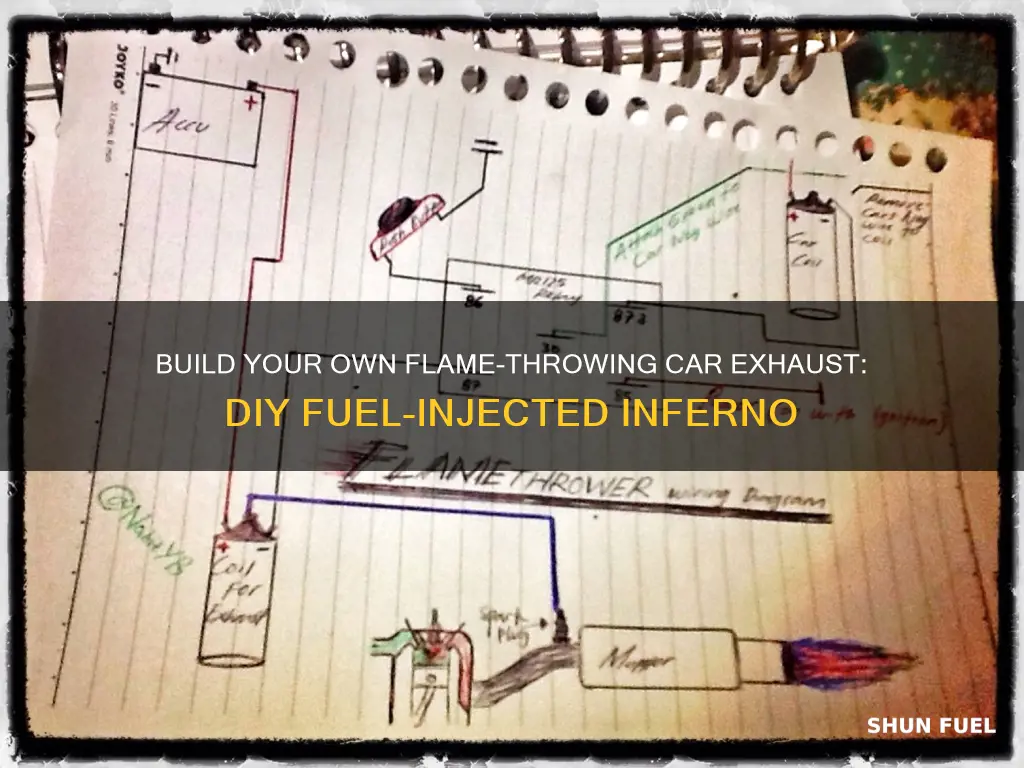

Flame Thrower Safety: Understanding and implementing safety measures for flame thrower operation

The concept of a "do-it-yourself fuel-injected car exhaust flame thrower" is an intriguing but potentially dangerous project. While it might seem like a thrilling idea to create a powerful flamethrower from scratch, it is crucial to prioritize safety throughout the process. Operating a flame thrower, especially one designed for automotive exhaust, can be extremely hazardous if proper precautions are not taken. This guide aims to provide an overview of the essential safety measures to consider when embarking on such a project.

Before beginning, it is imperative to understand the potential risks associated with flame throwers. These devices can produce intense heat, high-pressure flames, and potentially explosive gases. The combustion of fuel and air mixture in an engine's exhaust system can lead to dangerous conditions if not handled correctly. The first step in ensuring safety is to thoroughly research and understand the specific components and materials you will be working with. Online resources, technical manuals, and expert advice can provide valuable insights into the potential hazards and best practices for construction and operation.

Safety gear is a critical aspect of flame thrower operation. When building your DIY flame thrower, consider investing in personal protective equipment (PPE) such as heat-resistant gloves, goggles, and a full-face shield to protect your eyes and face from potential burns and flying debris. Additionally, ensure you have a well-ventilated workspace to minimize the inhalation of harmful fumes. It is also advisable to wear appropriate clothing, such as long sleeves and pants, to cover your skin and prevent direct contact with flames.

During the construction process, follow a step-by-step approach, ensuring that all components are securely assembled and properly sealed to prevent fuel and air leaks. Use high-quality materials and fittings to maintain structural integrity. Regularly inspect your work for any signs of damage or wear, especially when dealing with high-pressure systems. It is essential to test the flame thrower in a controlled environment before attempting to use it in an open space. Start with a small-scale test to verify the functionality and adjust the settings accordingly.

When operating the flame thrower, maintain a safe distance from any flammable materials or structures. Always have a clear understanding of the target area and ensure it is clear of any potential hazards. Keep a fire extinguisher nearby and be familiar with its use. Regular maintenance and inspections are vital to ensure the long-term safety of your flame thrower. Check for any blockages, leaks, or damage to the fuel system, igniter, and nozzle regularly. Keep a record of your maintenance activities to track the flame thrower's performance and identify any potential issues.

In conclusion, building a DIY fuel-injected car exhaust flame thrower can be an exciting project, but it demands a strong emphasis on safety. By understanding the risks, wearing appropriate protective gear, following construction guidelines, and implementing regular maintenance, you can significantly reduce the potential dangers associated with flame thrower operation. Always prioritize safety and seek professional advice when needed to ensure a successful and secure outcome.

The Fuel That Powers Our Cars: A Deep Dive

You may want to see also

Performance Testing: Evaluating exhaust system performance through dyno testing and track days

Performance testing is an essential step in evaluating the effectiveness of your DIY exhaust system, especially when aiming to create a powerful flame-throwing exhaust for your fuel-injected car. This process involves both controlled laboratory settings and real-world track conditions to ensure optimal performance and safety. Here's a detailed guide on how to approach this:

Dyno Testing:

This is a controlled environment where you can simulate various driving conditions and measure the exhaust system's performance. Here's how you can utilize dyno testing:

- Setup: Find a local dyno tuning facility or use a portable dyno if you prefer home testing. Ensure the dyno is calibrated and suitable for your vehicle's power output.

- Calibration: Calibrate the dyno to match your vehicle's engine management system. This step is crucial for accurate data interpretation.

- Testing: Run the engine through a series of tests, including wide-open throttle (WOT) tests, to measure horsepower, torque, and exhaust backpressure. Note the differences between stock and modified settings.

- Data Analysis: Compare the test results with your expectations and previous dyno runs. Identify areas where the exhaust system can be improved, such as flow restrictions or backpressure.

Track Days:

Taking your modified car to a track provides a more realistic and challenging environment to test exhaust performance:

- Circuit Selection: Choose a track that allows for high-speed driving and acceleration. Ensure it has a variety of corners and straights to simulate different driving conditions.

- Warm-Up and Practice: Start with a warm-up lap to get a feel for the car's behavior. Practice different driving techniques to understand how the exhaust system responds under various loads.

- Performance Evaluation: During track sessions, focus on acceleration, top speed, and cornering performance. Pay attention to how the exhaust note changes and its impact on the car's overall performance.

- Driver Feedback: Collect feedback from yourself and other drivers (if testing with a co-driver or a test group). Note any unusual noises, changes in drivability, and overall driving experience.

Combining Results:

By combining dyno test data and track day experiences, you can make informed decisions about exhaust system modifications. Look for areas of improvement identified in both tests and consider the following:

- Adjusting the exhaust pipe diameter to optimize flow.

- Upgrading catalysts or adding resonators for a balanced performance.

- Fine-tuning the exhaust note to match your driving preferences.

Remember, performance testing is an iterative process. You may need to repeat these tests after making modifications to ensure the exhaust system performs as expected and meets your desired flame-throwing capabilities while maintaining drivability and safety.

Flex Fuel or Not? Signs to Identify Your Car's Flexibility

You may want to see also

Maintenance and Upkeep: Regular care and maintenance to ensure longevity and reliability

The 'Do-It-Yourself Fuel-Injected Car Exhaust Flame Thrower' is an ambitious project that requires careful maintenance and regular upkeep to ensure it operates safely and effectively. This powerful device, while exciting, demands attention to detail and a methodical approach to maintenance to avoid potential issues and ensure its longevity. Here's a comprehensive guide to keeping your flame thrower in top condition:

Routine Inspection and Cleaning: Begin by establishing a regular inspection routine. Before each use, inspect the exhaust flame thrower for any signs of wear and tear. Check for cracks, corrosion, or damage to the fuel lines and injectors. A thorough inspection will help identify potential issues early on. Additionally, regular cleaning is essential. Use a mild detergent and water solution to clean the exterior and interior components, ensuring no residue or buildup that could affect performance. Pay close attention to the fuel injection system, as any blockages or contamination can lead to inefficient operation.

Fuel System Maintenance: The fuel injection system is the heart of your flame thrower, and its proper maintenance is crucial. Start by regularly replacing the fuel filter to prevent contaminants from entering the system. Check the fuel pump for any signs of wear and ensure it delivers the required pressure. Inspect the fuel injectors for clogs and consider using a fuel injection cleaner to maintain optimal performance. Keep the fuel tank clean and consider using a fuel stabilizer to prevent fuel degradation over time.

Engine and Exhaust Care: Focus on the engine and exhaust system for optimal performance. Regularly check the engine's compression and spark plug condition. Replace spark plugs at the recommended intervals to ensure efficient combustion. Inspect the exhaust manifold and pipes for any signs of damage or corrosion, especially if the flame thrower is used in harsh environments. Proper exhaust maintenance will prevent backfires and ensure the flame thrower operates safely and efficiently.

Safety Checks: Safety should always be a priority. Regularly inspect the safety mechanisms, such as pressure relief valves and flame arrestors, to ensure they are functioning correctly. Test the flame thrower's performance and adjust the fuel-air mixture if necessary. Always follow the manufacturer's guidelines for safe operation and consider having a professional inspect the device periodically, especially if modifications are made.

Storage and Winter Care: Proper storage is essential, especially if you live in a region with harsh winters. After each use, ensure the flame thrower is clean and dry. Store it in a cool, dry place, and consider using a protective cover to prevent rust and corrosion. During winter, consider draining the fuel system to prevent freezing. Regular maintenance and care will ensure your flame thrower is ready for action when needed.

Electric Car Charging: The Fossil Fuel Connection

You may want to see also

Frequently asked questions

This is a custom car modification project that involves creating a powerful exhaust system for a fuel-injected vehicle. It's a DIY enthusiast's dream, allowing them to build a high-performance exhaust that can produce a loud, aggressive sound and even a visible flame when the engine is revved.

Begin by researching the specific requirements of your car's engine and exhaust system. You'll need to purchase a high-flow exhaust manifold, a performance exhaust pipe, and a suitable muffler or silencer to control noise. Ensure you have the necessary tools and safety equipment, and consider seeking guidance from online forums or experienced mechanics.

Yes, it's important to check local laws and regulations regarding vehicle modifications. Some areas have strict noise ordinances, and you may need permits or approvals to install a loud exhaust system. Always ensure your modifications comply with legal requirements to avoid any issues with law enforcement.

Yes, the DIY fuel-injected car exhaust flame thrower is designed to work with standard fuel injection systems. However, you may need to make some adjustments to ensure proper fuel delivery and engine performance. Consulting the manufacturer's guidelines and seeking expert advice is recommended.

This exhaust system offers several advantages, including increased horsepower and torque, improved engine response, and a unique, aggressive sound. The visible flame effect can also be a fun visual feature. Additionally, it provides an opportunity to customize your vehicle and stand out from the crowd.