Fuel-efficient cars are designed to optimize performance while minimizing fuel consumption, offering an eco-friendly and cost-effective driving experience. These vehicles employ various technologies and engineering principles to achieve improved fuel economy. One key aspect is the use of advanced engines that burn fuel more efficiently, often through direct fuel injection and improved combustion processes. Additionally, lightweight materials and aerodynamic designs reduce drag, allowing the vehicle to move more smoothly through the air. Efficient transmission systems also play a crucial role, optimizing gear ratios to match engine power with driving conditions. Other features, such as regenerative braking systems that capture and reuse energy, further enhance fuel efficiency. Understanding these mechanisms can help drivers appreciate the technology behind these vehicles and make informed choices when considering fuel-efficient options.

What You'll Learn

- Engine Design: Optimized combustion chambers and fuel injectors enhance efficiency

- Aerodynamics: Streamlined body shapes reduce drag, improving fuel economy

- Lightweight Materials: Using alloys and composites lowers vehicle weight without compromising strength

- Hybrid Technology: Combining electric motors with traditional engines boosts efficiency and reduces emissions

- Regenerative Braking: Energy recovery systems convert kinetic energy back into usable power

Engine Design: Optimized combustion chambers and fuel injectors enhance efficiency

Engine design plays a pivotal role in achieving fuel efficiency, and one of the key aspects is the optimization of combustion chambers and fuel injectors. These components work in harmony to ensure efficient fuel combustion, thereby maximizing power output while minimizing fuel consumption.

Combustion chambers, also known as combustion spaces or cylinders, are the heart of the engine's power generation. In modern fuel-efficient engines, these chambers are meticulously designed to promote efficient fuel-air mixing and combustion. The shape and volume of the chamber are critical factors. Engineers aim to create a combustion chamber with a specific geometry that allows for a precise and controlled fuel-air mixture. This mixture is carefully designed to have the right air-fuel ratio, ensuring complete combustion with minimal unburned fuel. By optimizing the chamber's dimensions, engineers can reduce the volume of the mixture, leading to faster combustion and improved power output. This design approach also helps in reducing the engine's overall size and weight, contributing to overall fuel efficiency.

Fuel injectors are another essential component in this process. They are responsible for delivering the precise amount of fuel required for efficient combustion. Modern fuel injectors are highly accurate and can spray fuel in a fine mist form, ensuring optimal mixing with the air-fuel mixture. The design of the fuel injectors involves careful consideration of the spray pattern, nozzle design, and injection timing. By optimizing these factors, engineers can ensure that the fuel is injected at the right moment and with the correct pressure, allowing for complete combustion. This precision in fuel delivery is crucial for achieving the desired air-fuel ratio, which is essential for maximum efficiency.

The integration of these optimized combustion chambers and fuel injectors results in a more efficient engine. The carefully controlled combustion process ensures that the engine operates at its peak performance while consuming less fuel. This design approach not only improves fuel efficiency but also contributes to reduced emissions, making it an environmentally friendly choice. Additionally, the use of advanced materials and manufacturing techniques allows for the creation of lightweight, compact engines, further enhancing overall vehicle efficiency.

In summary, engine design, specifically the optimization of combustion chambers and fuel injectors, is a critical aspect of developing fuel-efficient cars. This meticulous attention to detail ensures that the engine operates with maximum efficiency, delivering power while minimizing fuel consumption and environmental impact.

Lincoln Town Car's Throttle Body Fuel Injection: A Deep Dive

You may want to see also

Aerodynamics: Streamlined body shapes reduce drag, improving fuel economy

Aerodynamics plays a crucial role in enhancing fuel efficiency in automobiles. The design of a car's body is a critical factor in reducing drag, which is the force that opposes the motion of the vehicle as it moves through the air. This force increases with the square of the vehicle's speed and the density of the air, making it a significant factor in fuel consumption. By optimizing the car's shape, engineers can minimize this drag, leading to improved fuel economy.

Streamlined body shapes are a key element in achieving this goal. The design aims to create a smooth, continuous surface that reduces the separation of airflow, which is a primary cause of drag. This is achieved through careful consideration of the car's front end, sides, and rear. The front of the vehicle, for instance, is designed with a sharp, angular shape that helps to direct airflow efficiently around the car, reducing the formation of turbulent eddies that create drag.

The side profile of the car is also crucial. Designers often use a technique called 'underbody shielding' where the underbody of the car is designed to be as smooth as possible, with no protruding elements. This ensures that the airflow remains attached to the car's surface, reducing drag. Additionally, the use of smooth, curved surfaces along the sides can help to minimize the disruption of airflow, further decreasing drag.

At the rear of the vehicle, the design often incorporates a spoiler or a small wing. These elements are strategically placed to create a downward force, which helps to keep the car firmly attached to the road, improving stability and reducing drag. The spoiler also helps to redirect airflow, ensuring a smooth transition over the rear of the car, which is a critical area for minimizing drag.

By implementing these aerodynamic principles, car manufacturers can significantly reduce the drag force acting on their vehicles. This results in improved fuel efficiency, as less energy is required to overcome the drag, allowing the engine to operate more efficiently. Aerodynamic design is a powerful tool in the pursuit of fuel-efficient automobiles, offering a practical and effective solution to the challenge of reducing fuel consumption.

Fuel Tank Size: Does It Affect How Often You Need to Refuel?

You may want to see also

Lightweight Materials: Using alloys and composites lowers vehicle weight without compromising strength

Lightweight materials play a crucial role in enhancing fuel efficiency in modern vehicles. By utilizing alloys and composites, engineers can significantly reduce a car's weight while maintaining its structural integrity. This approach is a strategic move towards achieving better fuel economy and reducing environmental impact.

The primary benefit of employing lightweight materials is the reduction in vehicle weight. Traditional cars often use heavy materials like steel, which contributes to increased fuel consumption. By substituting steel with alloys and composites, engineers can make the vehicle lighter without sacrificing its strength. Alloys, such as aluminum, magnesium, and titanium, offer improved strength-to-weight ratios compared to conventional materials. For instance, aluminum alloys provide excellent corrosion resistance and a lower density, making them ideal for structural components like body panels and engine components. Magnesium alloys, known for their high strength and low weight, can be used in critical areas like the engine block and transmission, further reducing overall weight.

Composites, on the other hand, are a combination of two or more materials, often including fibers and resins. These materials offer exceptional strength and stiffness while being significantly lighter than traditional metals. Carbon fiber composites, for example, have gained popularity in high-performance vehicles due to their remarkable strength-to-weight ratio. These composites can be used in structural elements like the chassis and body, providing excellent rigidity without adding excessive weight. By strategically placing these lightweight materials, engineers can optimize the vehicle's design, ensuring that structural integrity is maintained while minimizing weight.

The use of lightweight alloys and composites also contributes to improved fuel efficiency through better aerodynamics. Lighter vehicles experience less drag, which is the force that opposes the motion of the car through the air. Reduced drag means less energy is required to overcome air resistance, resulting in better fuel economy. Additionally, the improved strength of these materials allows for more efficient design, enabling engineers to create streamlined shapes that further enhance aerodynamics.

In summary, the adoption of lightweight materials, particularly alloys and composites, is a key strategy in the pursuit of fuel-efficient vehicles. These materials enable engineers to reduce vehicle weight significantly while ensuring structural strength and integrity. By utilizing alloys like aluminum and magnesium, and composites such as carbon fiber, manufacturers can create vehicles that are not only more efficient but also environmentally friendly, contributing to a greener and more sustainable future for the automotive industry.

Speeding: The Fuel-Consuming Truth: How Fast Driving Affects Your Car's Fuel Efficiency

You may want to see also

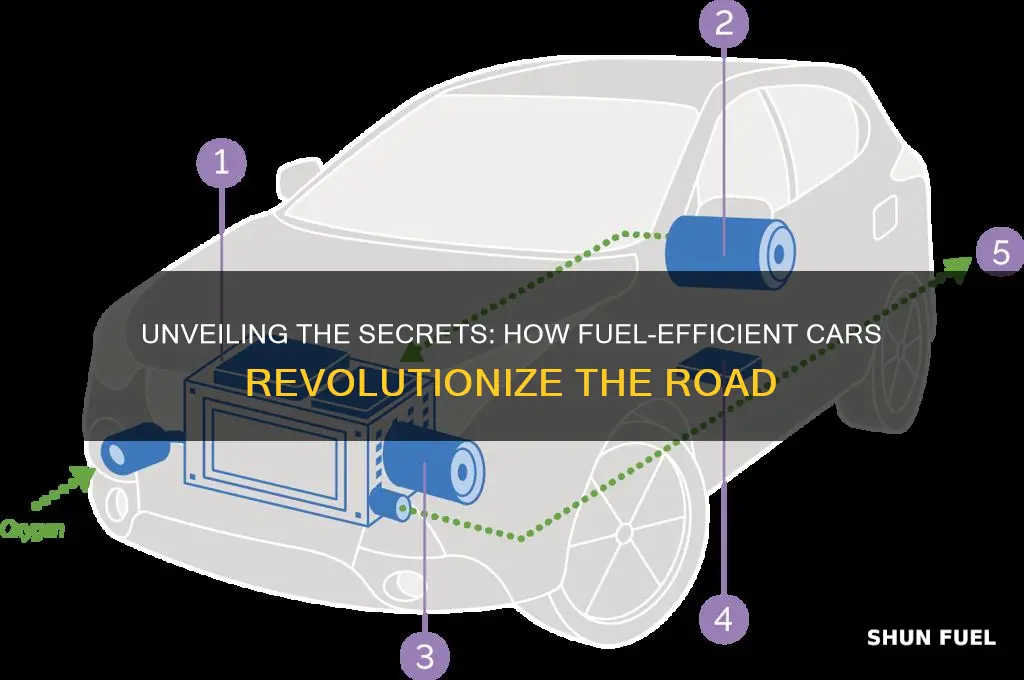

Hybrid Technology: Combining electric motors with traditional engines boosts efficiency and reduces emissions

Hybrid technology is a groundbreaking innovation in the automotive industry, revolutionizing the way we drive by combining the strengths of electric motors and traditional internal combustion engines. This innovative approach aims to significantly enhance fuel efficiency and minimize environmental impact, making it an attractive choice for environmentally conscious consumers.

At its core, a hybrid vehicle utilizes two distinct power sources: an electric motor and a conventional engine. The electric motor, typically smaller and more efficient, provides the initial burst of power, especially during acceleration. This instant torque delivery gives hybrids a responsive and smooth driving experience, often surpassing the performance of their non-hybrid counterparts. When the vehicle reaches a steady speed, the traditional engine takes over, ensuring a continuous and reliable power supply. This dual-power system allows hybrids to offer the best of both worlds, combining the efficiency of electric power with the reliability and range of a conventional engine.

One of the key advantages of hybrid technology is its ability to optimize fuel consumption. During city driving, where frequent stop-and-go traffic is common, the electric motor often takes the lead. It seamlessly powers the vehicle, eliminating the need for constant gear changes and reducing fuel wastage. This 'stop-and-go' driving mode is where hybrids truly shine, as the electric motor's efficiency comes into play, resulting in significant fuel savings. In contrast, during highway driving, the traditional engine takes over, providing a continuous and powerful driving experience while maintaining a steady fuel supply.

The hybrid system also excels in regenerative braking, a feature that captures and stores energy that would otherwise be lost during braking. This energy is then reused to power the electric motor, further enhancing efficiency. As a result, hybrids can achieve impressive fuel economy figures, often surpassing 40 miles per gallon in combined city and highway driving. Moreover, the reduced reliance on the traditional engine leads to lower emissions, making hybrids an environmentally friendly choice.

In summary, hybrid technology represents a significant advancement in automotive engineering, offering a practical and sustainable solution to the challenges of fuel efficiency and emissions. By combining electric motors and traditional engines, hybrids provide a seamless driving experience, excellent fuel economy, and reduced environmental impact. This innovative approach is a testament to the industry's commitment to sustainability and the future of clean, efficient transportation.

Hydrogen's Future: Unraveling the Fossil Fuel Connection

You may want to see also

Regenerative Braking: Energy recovery systems convert kinetic energy back into usable power

Regenerative braking is a revolutionary technology that plays a pivotal role in enhancing the fuel efficiency of modern vehicles. This innovative system harnesses the kinetic energy that is typically lost during braking and transforms it into a valuable resource, effectively improving overall efficiency. When a conventional car brakes, the kinetic energy is dissipated as heat through the brake pads and rotors, resulting in a significant waste of potential energy. However, regenerative braking systems offer a sustainable solution by capturing and reusing this energy.

At its core, regenerative braking operates on a simple principle: when the driver applies the brakes, the electric motor in the vehicle switches to generator mode. This motor, which is often part of the electric drive system, converts the kinetic energy of the moving car into electrical energy. The process begins with the rotation of the wheels, which turns the motor's internal components, generating electricity in the process. This electricity is then directed back to the vehicle's battery, where it can be stored for later use.

The beauty of this energy recovery system lies in its ability to recharge the battery while the car is in motion. Unlike traditional braking methods, regenerative braking does not rely on friction to slow down the vehicle. Instead, it utilizes the electric motor's inherent properties to capture and store energy, reducing the strain on the conventional braking system. As a result, the car's overall efficiency is improved, and the driver benefits from a smoother and more responsive braking experience.

This technology is particularly advantageous for electric vehicles (EVs) and hybrid cars, where energy conservation is crucial. In these vehicles, the regenerative braking system contributes significantly to extending the range and improving the overall performance. When the driver lifts their foot off the accelerator or applies the brakes, the electric motor acts as a generator, converting the vehicle's kinetic energy into electrical power. This power is then fed back into the battery, ensuring that the car's electric components remain charged and ready for use.

The impact of regenerative braking extends beyond energy conservation. It also contributes to a quieter and more comfortable driving experience. By reducing the reliance on traditional friction brakes, the system minimizes the noise and vibrations associated with conventional braking. This not only enhances the overall driving experience but also contributes to improved safety, as the braking system becomes more responsive and efficient.

Fuel, Fire, and Crank: Troubleshooting Engine Start Issues

You may want to see also

Frequently asked questions

Fuel-efficient cars employ various technologies to optimize fuel usage, such as advanced engines with improved combustion processes, direct fuel injection, and turbocharging or supercharging. These designs ensure that the engine operates at its most efficient power output, minimizing fuel wastage. Additionally, lightweight materials and aerodynamic designs reduce drag, allowing the vehicle to move more efficiently through the air, which indirectly contributes to better fuel economy.

Engine technology is a key factor in achieving fuel efficiency. Modern engines use advanced materials and designs to reduce friction, improve combustion efficiency, and minimize heat loss. For instance, direct fuel injection ensures precise fuel delivery to the engine's cylinders, allowing for more efficient combustion. Turbochargers and superchargers increase power output without significantly increasing fuel consumption, as they force more air into the engine, enabling it to burn fuel more effectively.

Electric vehicles are a prime example of fuel-efficient transportation. EVs use electric motors powered by batteries, eliminating the need for traditional internal combustion engines. This results in zero direct fuel consumption and significantly lower emissions. The efficiency of electric motors is higher than that of internal combustion engines, and the use of regenerative braking systems allows EVs to recover energy that would otherwise be lost during braking, further enhancing their fuel efficiency.

Absolutely. Many fuel-efficient cars are designed with environmental sustainability in mind. By reducing fuel consumption, these vehicles lower the amount of greenhouse gas emissions and air pollutants released into the atmosphere. Additionally, some fuel-efficient cars, like hybrid electric vehicles, can run on electricity for short distances, further reducing emissions. This combination of fuel efficiency and environmental considerations makes these vehicles an attractive choice for eco-conscious consumers.