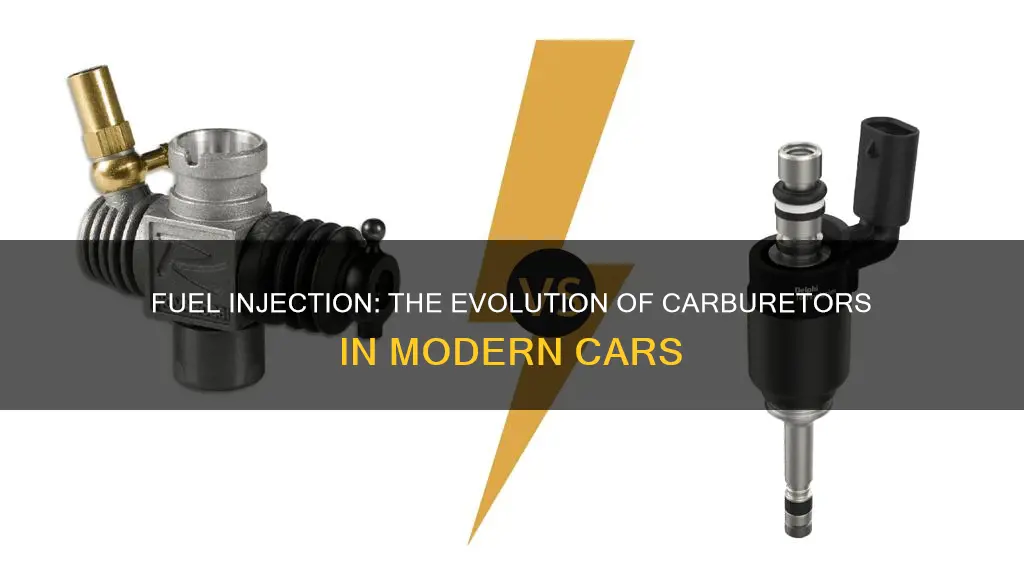

Fuel-injected cars have revolutionized the automotive industry, offering improved performance and fuel efficiency compared to their carbureted counterparts. The question of whether these modern vehicles still use carburetors is an interesting one. While fuel injection has become the standard in recent decades, it's important to understand the differences between these two systems and how they impact engine performance. Carburetors, once a common feature in internal combustion engines, have largely been replaced by fuel injection systems. This transition has been driven by the need for more precise fuel delivery, better performance, and increased fuel efficiency. In this paragraph, we will explore the relationship between fuel-injected cars and carburetors, highlighting the advantages and disadvantages of each system.

| Characteristics | Values |

|---|---|

| Fuel Injection vs Carburetor | Fuel injection systems are more modern and efficient compared to carburetors. They deliver fuel to the engine more precisely, resulting in better performance and fuel economy. |

| Engine Control Unit (ECU) | The ECU is a key component in fuel-injected engines. It controls the fuel injection process, adjusting the fuel-air mixture based on engine speed, load, and temperature. |

| Performance | Fuel-injected engines generally offer higher performance due to precise fuel delivery, resulting in more power and better throttle response. |

| Fuel Efficiency | These engines are known for their improved fuel efficiency, as they can optimize the fuel-air mixture, reducing waste and improving mileage. |

| Emissions | Modern fuel injection systems contribute to lower emissions, meeting stricter environmental regulations. |

| Reliability | The reliability of fuel-injected engines is often higher due to their electronic control, which can detect and correct issues more effectively. |

| Maintenance | Carburetors require periodic adjustments and maintenance, while fuel-injected systems are generally lower maintenance, as they have fewer moving parts and don't need regular tuning. |

| Adaptability | Fuel injection systems can adapt to various driving conditions and loads, providing a consistent performance across different environments. |

| Cost | Initially, fuel-injected engines might be more expensive to purchase, but their long-term cost-effectiveness and improved performance make them a popular choice. |

| Common in Modern Vehicles | Most modern cars and motorcycles use fuel injection systems, making carburetors less common in new vehicles. |

What You'll Learn

- Fuel Injection Technology: Direct fuel injection systems replace carburetors in modern cars

- Performance Benefits: Fuel injection enhances engine performance and efficiency

- Emission Control: These systems reduce emissions and improve air quality

- Maintenance: Less maintenance is required compared to carburetors

- Cost: Initial costs are higher, but long-term savings are possible

Fuel Injection Technology: Direct fuel injection systems replace carburetors in modern cars

The evolution of fuel injection technology has significantly transformed the automotive industry, marking a shift from traditional carburetors to more efficient and precise direct fuel injection systems. This transition is a pivotal moment in the history of internal combustion engines, offering a myriad of benefits that have become essential in modern vehicles.

Direct fuel injection systems, as the name suggests, inject fuel directly into the engine's cylinders, bypassing the carburetor. This method offers a more controlled and efficient way of delivering fuel compared to the mechanical mixing and atomization processes of carburetors. By eliminating the carburetor, these systems provide a more straightforward and reliable fuel delivery mechanism.

One of the key advantages of direct fuel injection is improved performance and efficiency. The precise control over fuel delivery allows for better combustion, resulting in increased power output and improved fuel economy. Modern cars equipped with direct fuel injection can achieve higher torque and horsepower while consuming less fuel, making them more environmentally friendly. This technology is particularly beneficial for vehicles with smaller engines, where the direct injection system can optimize performance without the need for a large carburetor.

In terms of maintenance, direct fuel injection systems offer a more convenient and cost-effective approach. Without the complexity of a carburetor, these systems are less prone to mechanical failures and require fewer routine services. The absence of a carburetor also means that drivers no longer need to worry about adjusting the carburetor's jetting or replacing worn-out parts, reducing the overall maintenance burden.

Furthermore, direct fuel injection technology contributes to better emissions control. The precise fuel-air mixture delivered directly to the cylinders results in more complete combustion, reducing the release of harmful pollutants. This is a crucial aspect of modern environmental regulations, as it helps vehicles meet stricter emission standards. The technology's ability to optimize fuel usage also contributes to reduced carbon emissions, making it an essential component in the development of greener transportation solutions.

Green Machines: Do Fuel-Efficient Cars Sell Faster?

You may want to see also

Performance Benefits: Fuel injection enhances engine performance and efficiency

Fuel injection is a revolutionary technology that has transformed the automotive industry, offering a myriad of performance advantages over traditional carburetors. One of the most significant benefits is the precise control it provides over the fuel-air mixture, which is crucial for optimal engine performance. In a fuel-injected engine, the fuel is injected directly into the combustion chamber, ensuring that the air and fuel are mixed at the exact ratio required for efficient combustion. This precision is achieved through sophisticated electronic controls, which monitor various engine parameters and adjust the fuel injection accordingly. As a result, the engine receives the perfect amount of fuel at every revolution, leading to improved power output and a more responsive driving experience.

The efficiency gains of fuel injection are substantial. By delivering fuel directly to the combustion chamber, the engine can burn it more completely, resulting in higher energy extraction from each drop of fuel. This process, known as complete combustion, produces more power and reduces the amount of unburned fuel that exits the exhaust, leading to better fuel economy. Additionally, the electronic controls can optimize the fuel injection timing, ensuring that the engine operates at its most efficient point, further enhancing overall performance and reducing emissions.

One of the key advantages of fuel injection is its ability to provide a consistent and stable fuel supply to the engine. Unlike carburetors, which can struggle with maintaining a precise fuel-air mixture at high speeds or during rapid acceleration, fuel injectors deliver a precise amount of fuel regardless of engine speed or load. This results in a more powerful and responsive engine, capable of delivering its maximum potential in various driving conditions. The improved throttle response and reduced lag time are particularly noticeable during acceleration, making the vehicle more agile and enjoyable to drive.

The performance benefits of fuel injection extend beyond just power and efficiency. The technology also contributes to a smoother and quieter engine operation. With precise fuel control, the engine can run at optimal conditions, reducing vibrations and noise. This is especially beneficial for high-performance vehicles, where a smooth and responsive power delivery is essential for a premium driving experience. Moreover, the electronic controls can adapt to different driving styles and conditions, ensuring that the engine always performs at its best, whether it's a gentle cruise or a high-speed sprint.

In summary, fuel injection technology offers a comprehensive performance enhancement package for modern vehicles. Its ability to precisely control the fuel-air mixture, ensure efficient combustion, and maintain a stable fuel supply results in increased power, improved fuel economy, and a more responsive driving experience. The technology's adaptability and electronic controls make it a superior choice for engine management, elevating the overall performance and driving pleasure of fuel-injected vehicles.

Fuel Pump Facts: Do Cars Have Two Pumps?

You may want to see also

Emission Control: These systems reduce emissions and improve air quality

The evolution of internal combustion engines has been marked by a continuous quest for improved performance and reduced environmental impact. One of the key innovations in this journey is the development of emission control systems, which play a crucial role in minimizing the harmful effects of vehicle exhaust on the environment. These systems are designed to reduce the emission of pollutants, such as carbon monoxide, nitrogen oxides, and particulate matter, thereby contributing to cleaner air and a healthier environment.

Emission control systems operate through a combination of technologies and strategies. One of the primary methods is the use of catalytic converters, which are devices that convert harmful pollutants into less harmful substances before they are released into the atmosphere. These converters are typically positioned in the exhaust system and contain a catalyst, often made of platinum or palladium, that facilitates the chemical reactions necessary for pollutant reduction. For instance, a three-way catalyst can simultaneously reduce carbon monoxide, nitrogen oxides, and volatile organic compounds.

Another critical component of emission control is the precise management of fuel injection. Fuel-injected engines, as the name suggests, deliver fuel directly to the engine's cylinders through injectors, bypassing the traditional carburetor. This system allows for more accurate control over the fuel-air mixture, enabling the engine to operate at optimal conditions for reduced emissions. By ensuring that the correct amount of fuel is injected at the right time, fuel-injected engines can minimize the release of unburned hydrocarbons and carbon monoxide, which are major contributors to air pollution.

Additionally, modern vehicles are equipped with advanced sensors and control units that monitor and adjust engine performance in real-time. These systems can optimize fuel injection, combustion, and exhaust processes, further enhancing emission control. For example, some engines use oxygen sensors to monitor the exhaust gas temperature and composition, providing feedback to the engine control unit (ECU) to adjust fuel injection accordingly. This real-time feedback loop ensures that the engine operates at the most efficient and environmentally friendly settings.

In summary, emission control systems are integral to modern vehicles, aiming to minimize the environmental impact of transportation. Through the use of catalytic converters, precise fuel injection management, and advanced sensor technology, these systems reduce the emission of harmful pollutants, contributing to improved air quality and a more sustainable future. As engine technology continues to advance, the focus on emission control will remain a critical aspect of automotive engineering.

F1 Fuel Strategy: Do Pit Stops Require Refueling?

You may want to see also

Maintenance: Less maintenance is required compared to carburetors

Fuel injection systems in modern vehicles have revolutionized the automotive industry by offering a more efficient and reliable method of fuel delivery compared to traditional carburetor systems. One of the significant advantages of fuel injection is the reduced maintenance it requires, which sets it apart from its predecessor. Carburetors, while still widely used in some applications, have a reputation for being more prone to wear and tear, which can lead to increased maintenance needs.

The primary reason for the lower maintenance requirement of fuel injection systems is their precision and simplicity. Fuel injectors deliver fuel directly to the engine's intake valves, ensuring a more accurate and consistent fuel-air mixture. This precision reduces the chances of engine misfires, which were a common issue with carburetors. Misfires occur when the engine doesn't burn fuel efficiently, often due to incorrect fuel-air ratios. With fuel injection, the engine's computer controls the injection timing and amount, minimizing these problems.

In a carburetor system, the carburetor itself is a complex component that requires regular adjustments to maintain optimal performance. Over time, carburetors can develop issues such as float bowl leaks, jet blockages, or needle and seat wear, all of which can lead to poor engine performance and increased maintenance. Fuel injection systems, on the other hand, have fewer moving parts, making them less susceptible to mechanical failures. This simplicity translates to less frequent servicing and a reduced risk of unexpected breakdowns.

Additionally, fuel injection systems often incorporate self-diagnostics, which can detect and alert the driver to potential issues before they become major problems. This proactive approach to maintenance ensures that any minor issues are addressed promptly, preventing them from escalating. Regular maintenance tasks for fuel injection systems typically include filter changes and occasional fuel system cleaning, which are generally less time-consuming and costly compared to the maintenance required for carburetors.

For vehicle owners, the reduced maintenance aspect of fuel injection systems translates to significant cost savings over the long term. With fewer components to worry about and less frequent servicing, owners can enjoy a more reliable and trouble-free driving experience. This is particularly beneficial for high-performance vehicles or those used in demanding conditions, where reliability and longevity are crucial.

Petroleum Fuel Flexibility: Can Cars Run on Gas?

You may want to see also

Cost: Initial costs are higher, but long-term savings are possible

The initial cost of a fuel-injected engine can be higher compared to a traditional carbureted engine, primarily due to the complexity of the fuel injection system. This system involves precise fuel metering and injection, which requires specialized components such as injectors, sensors, and an engine control unit (ECU). These components can be more expensive to purchase and install, especially for older or classic car models that may not have been designed with fuel injection in mind. However, it's important to consider the long-term benefits that come with this higher initial investment.

One of the key advantages of fuel injection is its ability to optimize fuel usage, leading to improved fuel efficiency. Modern fuel injection systems can precisely control the amount of fuel delivered to the engine, ensuring that it runs at the most efficient combustion levels. This results in better mileage, which translates to significant long-term savings at the pump. Over time, the fuel savings can easily offset the higher initial costs, making fuel-injected vehicles more economical in the long run.

Additionally, fuel-injected engines often have improved performance and power output. The precise fuel delivery allows for more efficient combustion, resulting in increased horsepower and torque. This enhanced performance can make the vehicle more responsive and enjoyable to drive. While the initial purchase price might be higher, the long-term benefits in terms of performance and fuel efficiency can be substantial.

Maintenance costs can also be a factor to consider. Fuel-injected systems generally require less frequent maintenance compared to carbureted engines. With fewer moving parts and less reliance on mechanical components, fuel injection systems tend to be more reliable and less prone to issues. This reduced maintenance can lead to lower overall costs for car owners, as they may spend less on regular servicing and repairs.

In summary, while the initial costs of a fuel-injected engine may be higher, the long-term savings and benefits are significant. Improved fuel efficiency, enhanced performance, and reduced maintenance requirements contribute to a more economical and enjoyable driving experience. For those seeking a more efficient and powerful vehicle, the investment in a fuel-injected system can be well worth it, despite the higher upfront expenses.

Unveiling the Fuel Injection Mystery: Do Cars Need Them?

You may want to see also

Frequently asked questions

No, fuel-injected cars do not use a carburetor. Carburetors are an older technology used in naturally aspirated engines to mix air and fuel for combustion. With the advent of fuel injection, engines can now precisely control the air-fuel mixture, delivering more efficient and powerful performance.

A carburetor is a mechanical device that mixes air and fuel in a specific ratio, which is then drawn into the engine. Fuel injection, on the other hand, uses an electronic system to inject fuel directly into the engine's intake manifold or cylinders. This process allows for better control over the air-fuel mixture, resulting in improved performance, fuel efficiency, and reduced emissions.

Fuel injection offers several advantages over carburetors. It provides more accurate fuel delivery, ensuring the engine receives the precise amount of fuel required at any given speed and load. This results in better performance, higher fuel efficiency, and reduced emissions. Additionally, fuel-injected engines can operate at higher compression ratios, allowing for more powerful and responsive performance.

Yes, some vehicles may have a hybrid system where they use a carburetor for low-speed or idling conditions and switch to fuel injection at higher speeds or during more demanding driving conditions. This setup provides the benefits of both technologies, ensuring efficient performance and fuel economy.