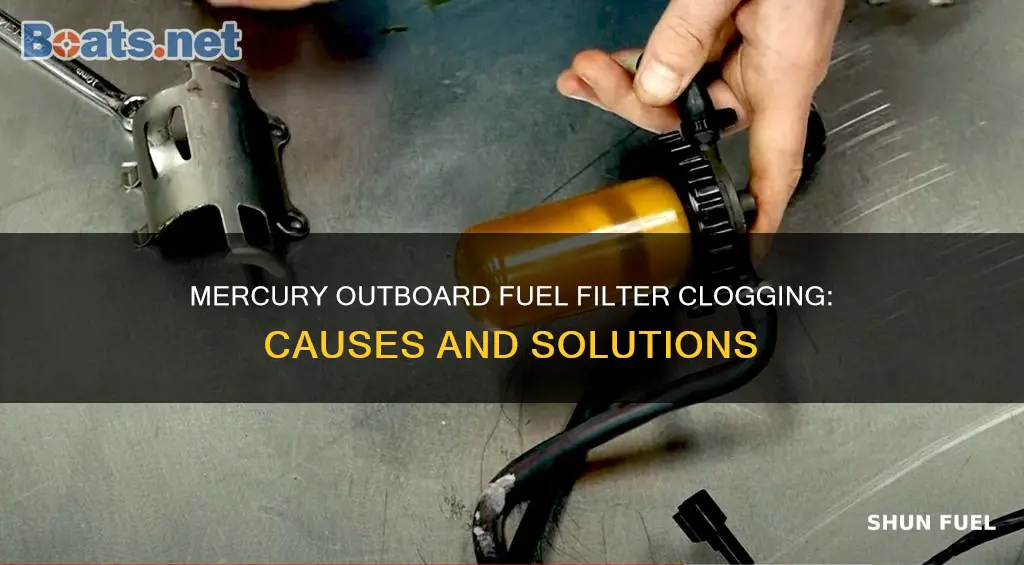

Mercury outboard boat engines rely on in-line fuel filters to keep contaminants from entering the fuel system, ensuring optimal performance. However, these filters can become clogged over time due to various factors, including the type of fuel used, engine age, and maintenance practices. Clogging can lead to reduced engine performance, fuel system damage, and even engine failure. Understanding the causes and signs of a clogged fuel filter is crucial for maintaining the engine's longevity and preventing costly repairs. This article will explore the reasons behind fuel filter clogging and provide practical tips for preventing and addressing this common issue in Mercury outboard engines.

| Characteristics | Values |

|---|---|

| Cause | Clogging can occur due to contaminants in the fuel, such as water, sediment, or varnish. |

| Symptoms | Engine performance issues, stalling, difficulty starting, reduced power, or erratic behavior. |

| Common Clogging Points | The filter itself, fuel lines, and the intake passages. |

| Solutions | Cleaning or replacing the filter, using fuel system cleaner, flushing the system, and ensuring proper fuel storage and handling. |

| Preventive Measures | Regular maintenance, using high-quality fuel, and storing the boat in a dry environment. |

| Frequency | Clogging can happen over time, especially in older engines or those with poor maintenance. |

| Impact | Clogging can lead to engine damage if not addressed promptly. |

| DIY vs. Professional | DIY cleaning is possible, but replacing the filter might require professional help. |

What You'll Learn

- Clogging Causes: Debris, algae, or fuel contamination can block the filter

- Maintenance: Regular cleaning and replacement prevent clogs and ensure engine health

- Filter Material: Choose a high-quality filter to avoid blockages and extend engine life

- Fuel System: Clogs can impact fuel flow, leading to engine performance issues

- Cleaning Methods: Use fuel system cleaner to dissolve clogs and restore filter function

Clogging Causes: Debris, algae, or fuel contamination can block the filter

When it comes to in-line fuel filters on Mercury outboard motors, understanding the potential causes of clogging is essential for maintaining optimal performance. One of the primary reasons these filters can become blocked is the presence of debris. Over time, small particles such as dirt, sand, or even metal shavings from engine wear can accumulate in the fuel system. These particles may originate from the fuel itself or be introduced during the fueling process, especially if the fuel tank is not properly sealed. As the fuel circulates through the system, these tiny particles can gradually build up within the filter, leading to a restriction in flow.

Algae growth is another common issue that can cause filter clogging. Mercury outboard motors, particularly those used in warmer climates, are susceptible to algae intrusion. Algae can thrive in the warm, moist environment of the fuel tank and gradually spread throughout the fuel system. As the algae multiply, they can form a slimy mass that adheres to the walls of the filter, narrowing the passage and impeding fuel flow. This issue is often more prevalent during periods of inactivity when the motor is not in use.

Fuel contamination is a critical factor that should not be overlooked. Contaminants such as water, dirt, or other foreign substances can enter the fuel system, especially if the fuel tank is not properly maintained. Water, for instance, can condense in the tank and find its way into the fuel, leading to phase separation and potential clogging. Similarly, dirt or other solid particles can be drawn into the fuel system, causing blockages. Contaminated fuel can also lead to engine performance issues, such as misfires or reduced power, making it crucial to address any contamination promptly.

To prevent these clogging causes, regular maintenance is key. Keeping the fuel tank clean and dry, ensuring proper fuel storage, and using fuel stabilizers can help mitigate the risk of algae growth and contamination. Additionally, routine inspection and replacement of the in-line fuel filter are recommended to catch any early signs of clogging and maintain the engine's overall health. By being proactive and addressing these potential issues, Mercury outboard motor owners can ensure their engines run smoothly and efficiently.

Kohler XT6 Engine: Fuel Line Size Guide

You may want to see also

Maintenance: Regular cleaning and replacement prevent clogs and ensure engine health

The inline fuel filter on a Mercury outboard engine is a critical component that can often be overlooked during maintenance. Over time, this filter can become clogged with contaminants, leading to a range of performance issues. Regular cleaning and replacement of this filter are essential to prevent clogs and ensure the overall health and longevity of your engine.

One of the primary causes of filter clogging is the accumulation of dirt, debris, and water. Mercury outboard engines are often used in various water conditions, and the filter acts as a barrier to trap these contaminants. However, if not regularly maintained, the filter can become saturated, allowing dirt and water to pass through and potentially damage the engine. This is especially important to consider in areas with poor water quality or for those who frequently use their boats in shallow waters.

To maintain the filter, it is recommended to follow a simple yet effective routine. First, locate the filter and inspect it for any signs of clogging. You may notice a buildup of dirt or a change in water flow. If the filter appears dirty, use a clean cloth or a soft brush to gently remove any visible debris. For a thorough cleaning, you can use a filter cleaning solution or a mild detergent mixed with water. Ensure you rinse the filter thoroughly to remove any cleaning agents.

Regular replacement of the inline fuel filter is another crucial aspect of maintenance. Over time, even with cleaning, the filter's ability to trap contaminants diminishes. Mercury recommends replacing the filter at specific intervals, typically every 50-100 hours of operation or annually, depending on usage. By adhering to this schedule, you can ensure that the filter consistently performs its function, providing clean fuel to the engine and reducing the risk of clogs.

In addition to cleaning and replacement, it is beneficial to practice good boat maintenance habits. This includes using fuel stabilizers to prevent water separation and keeping the engine properly lubricated. Regularly checking the engine's performance and addressing any issues promptly can also help prevent filter clogs. By combining these maintenance practices, you can ensure that your Mercury outboard engine remains reliable and efficient, even in the face of challenging environmental conditions.

Understanding Threaded 8N Fuel Lines: A Comprehensive Guide

You may want to see also

Filter Material: Choose a high-quality filter to avoid blockages and extend engine life

When it comes to maintaining your Mercury outboard engine, one crucial aspect is the inline fuel filter. This filter plays a vital role in ensuring that your engine receives clean fuel, preventing potential issues and extending its lifespan. One common concern among boat owners is the possibility of this filter becoming clogged, which can lead to reduced engine performance and potential breakdowns.

The material of the filter is a critical factor in its performance and longevity. High-quality filters are designed with specific materials that offer superior filtration capabilities. These materials are often engineered to trap contaminants without restricting fuel flow, ensuring a smooth and efficient operation. For instance, some filters use a combination of woven metal mesh and fine paper or synthetic fibers to capture small particles and debris. This multi-layered approach provides excellent filtration while maintaining a low-pressure drop, allowing for optimal fuel delivery to the engine.

Choosing a filter with the right material composition is essential to avoid blockages. Over time, fuel can contain various contaminants, including water, sediment, and engine wear particles. A high-quality filter will effectively trap these impurities, preventing them from reaching the engine's injectors or carburetor. This is particularly important for Mercury outboard engines, as they are known for their sensitivity to fuel quality. By using a well-crafted filter, you can ensure that your engine operates at its best, delivering the performance and fuel efficiency you expect.

In addition to avoiding blockages, selecting a high-quality filter can significantly extend the life of your engine. Poor-quality filters may not effectively separate contaminants, leading to increased wear and tear on engine components. Over time, this can result in more frequent maintenance and potential repairs. Investing in a reputable filter brand that uses advanced materials can provide peace of mind, knowing that your engine is well-protected and less prone to issues related to poor fuel quality.

In summary, when dealing with the inline fuel filter on your Mercury outboard, the choice of filter material is critical. Opting for a high-quality filter with the right composition ensures that your engine receives clean fuel, preventing blockages and potential damage. This simple maintenance step can contribute to the overall reliability and longevity of your boat's engine, allowing you to enjoy hassle-free boating experiences. Remember, regular filter checks and replacements are essential to keep your Mercury outboard running smoothly.

Choosing the Right Fuel Line for Your Outboard Motor: A Guide

You may want to see also

Fuel System: Clogs can impact fuel flow, leading to engine performance issues

Clogs in the fuel system of an outboard Mercury engine can significantly impact performance and potentially lead to more serious issues if left unaddressed. The in-line fuel filter is a critical component designed to trap contaminants and debris from the fuel, ensuring a clean supply to the engine. However, over time, this filter can become clogged, restricting fuel flow and causing a range of problems.

When the filter clogs, it creates a bottleneck in the fuel system, reducing the volume of fuel that can pass through. This restriction can lead to a condition known as 'fuel starvation,' where the engine receives an insufficient amount of fuel to operate efficiently. As a result, the engine may stall, lose power, or even fail to start. In some cases, the engine might run roughly, with frequent stalling, especially during acceleration or when the load increases.

The impact of a clogged fuel filter can be further exacerbated by the presence of contaminants in the fuel. As the filter becomes more blocked, it may allow larger particles to pass through, which can then circulate throughout the fuel system. These contaminants can cause damage to internal engine components, such as the carburetor or fuel injectors, leading to costly repairs. Additionally, the presence of debris in the fuel can result in increased engine wear, reduced performance, and even premature engine failure.

To prevent these issues, it is essential to regularly maintain the fuel system, including the in-line filter. Mercury recommends replacing the fuel filter at specified intervals, typically every 50-100 hours of operation, depending on the model and usage. Regularly checking and replacing the filter can help ensure optimal fuel flow, maintain engine performance, and extend the engine's lifespan.

In summary, clogs in the in-line fuel filter of a Mercury outboard engine can have a detrimental effect on performance. From fuel starvation to increased engine wear, these issues can be costly and inconvenient. Regular maintenance, including filter replacement, is crucial to prevent clogs and ensure the engine operates at its best.

Mini Cooper's Torque Stage: Unlocking Power with Fuel Lines

You may want to see also

Cleaning Methods: Use fuel system cleaner to dissolve clogs and restore filter function

If you've noticed that your Mercury outboard engine's in-line fuel filter is clogged, it's important to address this issue promptly to ensure optimal performance and prevent further damage. One effective method to tackle this problem is by using a fuel system cleaner. This approach can help dissolve the clogs and restore the filter's functionality. Here's a step-by-step guide on how to proceed:

Step 1: Prepare the Necessary Materials

Before you begin, gather the required materials. You will need a fuel system cleaner, which is specifically designed to dissolve deposits and clogs in fuel systems. Choose a cleaner that is compatible with your Mercury outboard engine's fuel type. Additionally, have a container for mixing the cleaner and a funnel to facilitate the cleaning process.

Step 2: Drain the Fuel System

Safety should always be a priority. Start by draining the fuel system to prevent any potential spills or accidents. Locate the fuel drain valve, which is typically found near the fuel tank or the engine. Open the valve and allow the fuel to drain into an appropriate container. Ensure you drain the system completely to avoid any residual fuel that might interfere with the cleaning process.

Step 3: Mix and Apply the Fuel System Cleaner

Once the fuel system is drained, it's time to mix the cleaner. Follow the instructions provided with the fuel system cleaner. Typically, you will need to mix a specific ratio of the cleaner with fuel or water. Carefully measure and combine the required amounts in a clean container. After mixing, use the funnel to carefully pour the cleaner into the fuel tank, ensuring it reaches all parts of the fuel system, including the in-line filter.

Step 4: Run the Engine

With the cleaner in the fuel system, start the engine and let it run. Allow the cleaner to circulate through the entire fuel system, including the filter. Run the engine for a recommended duration, usually around 15-20 minutes, to ensure thorough cleaning. Keep an eye on the engine's performance during this process.

Step 5: Check and Replace the Filter (if necessary)

After running the engine, shut it off and drain the fuel system again to remove any remaining cleaner. Inspect the in-line fuel filter. If you notice significant improvement in flow or no visible clogs, the filter may be clean and functional. However, if the filter still appears clogged or restricted, it might need replacement. Consider consulting the Mercury outboard engine manual for specific filter replacement instructions.

Using fuel system cleaner is a practical and effective way to address clogged in-line fuel filters on Mercury outboard engines. By following these steps, you can restore the filter's function and ensure your engine operates efficiently. Remember to always prioritize safety and consult the manufacturer's guidelines for any specific requirements or recommendations.

Optimizing Fuel Delivery: Choosing the Right Fuel Line Size for 5/16 Nipple Applications

You may want to see also

Frequently asked questions

Yes, it is possible for the in-line fuel filter on a Mercury outboard to become clogged, especially if it is not regularly maintained. Clogging can occur due to the accumulation of dirt, debris, water, or contaminants in the fuel, which can lead to reduced engine performance or even damage.

Some common signs of a clogged filter include engine misfires, reduced power, rough idling, or a noticeable decrease in fuel efficiency. If you notice any of these symptoms, it is advisable to inspect the fuel filter and consider replacing it if necessary.

The frequency of replacing the fuel filter depends on various factors, such as the engine's usage, operating conditions, and the quality of the fuel. As a general guideline, it is recommended to replace the filter every 50-100 hours of operation or at least once a year. Regular maintenance and cleaning can help prevent clogs and ensure optimal engine performance.

Cleaning and reusing the fuel filter is not typically recommended. In-line filters are designed for single-use and may not effectively trap contaminants after cleaning. It is best to replace the filter with a new one to ensure proper filtration and engine protection. Regular replacement will help maintain the engine's performance and longevity.