When working on a vehicle's fuel system, it's crucial to understand the proper use of components like hose clamps. One common question arises: Can I use a hose clamp on a fuel line? This query highlights the importance of selecting the right tools for the job to ensure the safety and efficiency of the fuel system. Hose clamps are designed to secure hoses and tubes, but they are not typically used on fuel lines due to the specific requirements and risks associated with fuel systems. This introduction sets the stage for a detailed discussion on the appropriate methods and considerations for working with fuel lines.

| Characteristics | Values |

|---|---|

| Material Compatibility | Hose clamps are typically made from materials like stainless steel, carbon steel, or aluminum. Ensure the material of the clamp is compatible with the fuel line material to prevent corrosion or damage. |

| Clamping Force | The clamping force should be sufficient to secure the fuel line but not so strong that it causes damage. A common rule of thumb is to apply a force of 10-15% of the fuel line's diameter. |

| Temperature Range | Consider the operating temperature range of the fuel system. Hose clamps should be able to withstand the temperatures encountered in the engine compartment without failing or losing their grip. |

| Flexibility | Hose clamps should allow for some flexibility to accommodate slight movements and vibrations without compromising the seal. |

| Corrosion Resistance | For fuel lines, corrosion resistance is crucial. Choose a hose clamp material that is resistant to fuel-related chemicals to ensure long-term reliability. |

| Size and Fit | Select the appropriate size of hose clamp that matches the fuel line diameter. Ensure it fits snugly without being too tight or too loose. |

| Application | Hose clamps are generally not recommended for fuel lines due to the potential risk of fuel leakage. They are more suitable for securing hoses and pipes in non-critical applications. |

| Alternative Solutions | Consider using specialized fuel line clips or fittings designed for fuel systems, as they are specifically engineered to meet the unique requirements of fuel lines. |

What You'll Learn

- Hose Clamp Compatibility: Check fuel line material and diameter for hose clamp suitability

- Fuel Line Reinforcement: Hose clamps can provide additional support and protection for fuel lines

- Secure Connections: Hose clamps ensure tight, leak-free connections for fuel lines

- Material Considerations: Choose hose clamps made from fuel-resistant materials to avoid damage

- Safety and Regulations: Adhere to vehicle and fuel system safety guidelines when using hose clamps

Hose Clamp Compatibility: Check fuel line material and diameter for hose clamp suitability

When considering using a hose clamp on a fuel line, it's crucial to prioritize safety and ensure compatibility. The material and diameter of the fuel line play a significant role in determining the suitability of a hose clamp. Here's a detailed guide to help you make the right choice:

Fuel Line Material: Different fuel lines are made from various materials, such as rubber, vinyl, or synthetic compounds. The choice of material depends on factors like temperature resistance, flexibility, and durability. For instance, rubber fuel lines are commonly used due to their flexibility and ability to withstand high temperatures. When selecting a hose clamp, it's essential to consider the material of your fuel line. Some hose clamps are designed specifically for rubber or vinyl, ensuring a secure and compatible connection. Using a hose clamp designed for a different material may compromise the integrity of the fuel line, leading to potential leaks or damage.

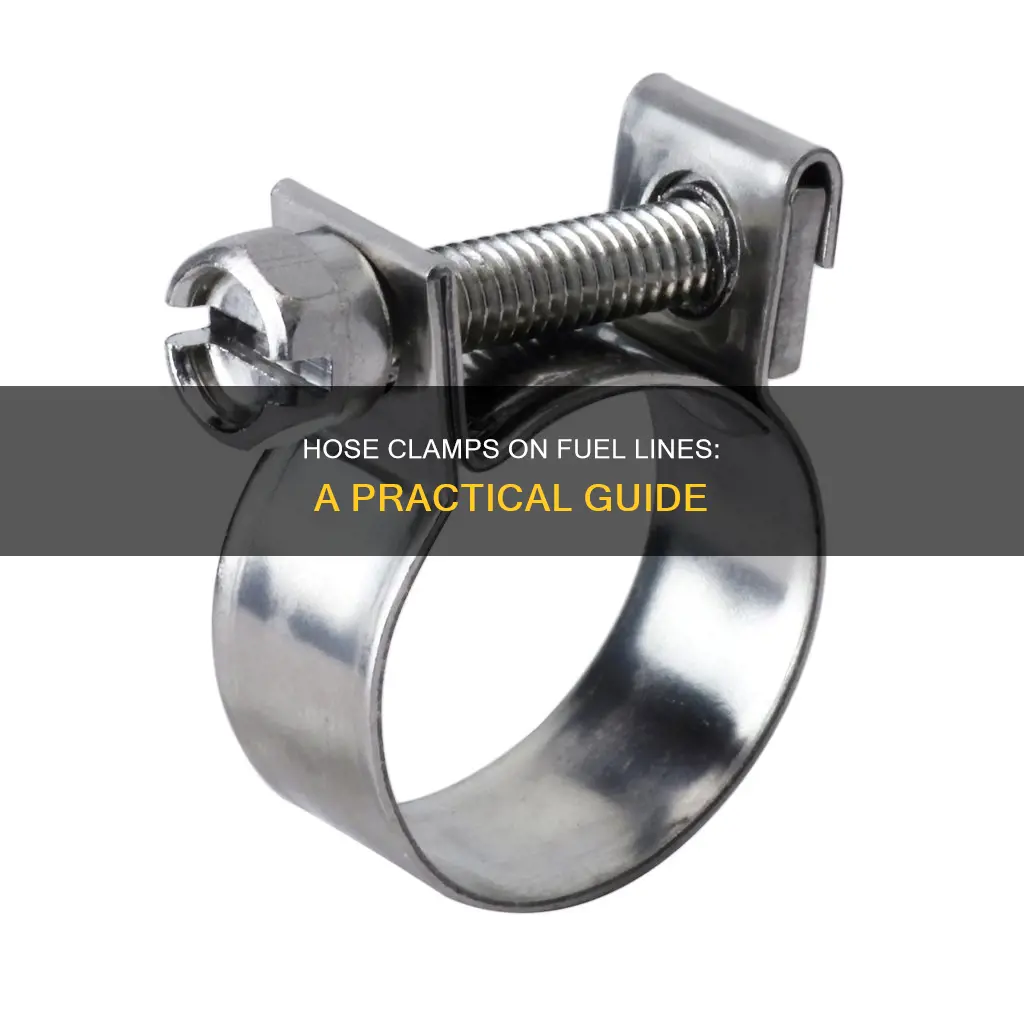

Fuel Line Diameter: The diameter of the fuel line is another critical factor. Hose clamps come in various sizes, and it's imperative to choose one that matches the fuel line's diameter. A hose clamp that is too small may not provide a tight seal, allowing fuel to leak or potentially causing damage to the fuel line. Conversely, a clamp that is too large can be ineffective and may even damage the fuel line over time. Always measure the fuel line's diameter accurately and select a hose clamp with a corresponding inside diameter. This ensures a proper fit and secure attachment.

Compatibility and Safety: To ensure compatibility, refer to the manufacturer's guidelines or specifications for both the fuel line and the hose clamp. Some fuel lines may have specific recommendations or restrictions regarding hose clamp usage. It's crucial to follow these guidelines to maintain the integrity of the fuel system. Using the wrong hose clamp can lead to fuel leaks, which pose a significant safety hazard. Always opt for high-quality, compatible hose clamps to ensure a secure and reliable connection.

In summary, when using a hose clamp on a fuel line, it is imperative to check the material and diameter of the fuel line. Choose a hose clamp that is specifically designed for the fuel line material and has an appropriate inside diameter. This ensures a secure and safe connection, minimizing the risk of fuel leaks and potential damage to the fuel system. Always prioritize safety and compatibility to maintain the reliability of your vehicle's fuel system.

Mastering the Art of Fuel Line Replacement: A Step-by-Step Guide

You may want to see also

Fuel Line Reinforcement: Hose clamps can provide additional support and protection for fuel lines

Hose clamps can indeed be a useful tool for reinforcing and protecting fuel lines, especially in certain applications. While fuel lines are designed to withstand the pressures and temperatures associated with fuel transport, there are scenarios where additional support can be beneficial. Here's how hose clamps can contribute to fuel line reinforcement:

Secure Connections: Fuel lines often connect various components of the fuel system, such as the fuel tank, pump, and injectors. Over time, these connections can loosen due to vibrations, temperature changes, or other factors. Hose clamps can be used to secure these connections, ensuring that the fuel lines remain tightly attached. By applying the right amount of pressure, hose clamps can prevent fuel lines from becoming loose, which could lead to potential fuel leaks or system malfunctions.

Route Management: In some cases, fuel lines may need to be routed around obstacles or through tight spaces. Hose clamps can help manage the fuel line's path, keeping it organized and preventing damage. For example, when routing a fuel line under a vehicle's body or near moving parts, a hose clamp can be used to secure the line, reducing the risk of it being pinched or damaged. Proper routing is crucial to maintaining the integrity of the fuel system and preventing potential hazards.

Vibration Control: Vehicles experience various vibrations during operation, especially when driving over rough terrain or at high speeds. These vibrations can cause fuel lines to shift or become loose over time. Hose clamps can be strategically placed to absorb and distribute these vibrations, ensuring that the fuel lines remain secure. By providing additional support, hose clamps help maintain the stability of the fuel system, reducing the chances of fuel line damage or disconnection.

Environmental Protection: Fuel lines are exposed to various environmental factors, including sunlight, heat, cold, and chemicals. Hose clamps can be used to protect fuel lines by securing them in place, preventing them from being exposed to harsh conditions. For instance, in outdoor applications or areas with extreme temperatures, hose clamps can help shield the fuel lines, ensuring their longevity and reliability. This protection is particularly important in industrial or off-road settings where fuel lines may be exposed to more demanding conditions.

When using hose clamps for fuel line reinforcement, it's essential to choose the right size and type of clamp for the specific application. Proper installation and regular inspection are also crucial to ensure the effectiveness of the reinforcement. By incorporating hose clamps strategically, you can enhance the overall protection and reliability of your fuel system.

Mastering the Metal Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Secure Connections: Hose clamps ensure tight, leak-free connections for fuel lines

Hose clamps are an essential tool for ensuring secure and leak-free connections in various applications, including fuel lines. When it comes to working with fuel lines, the importance of a tight seal cannot be overstated. Fuel lines carry a critical component of your vehicle's operation, and any leaks can lead to significant issues, from reduced performance to potential safety hazards. This is where hose clamps come into play, providing a reliable and effective solution to secure these connections.

The primary function of a hose clamp is to create a tight, friction-fit connection between two surfaces, in this case, the fuel line and the surrounding components. By applying the clamp, you essentially create a barrier that prevents any movement or separation between the fuel line and its attachment points. This is crucial because it ensures that the fuel line remains in place, even under the vibrations and stresses experienced during vehicle operation. A well-secured hose clamp can provide a long-lasting, leak-free seal, which is vital for maintaining the integrity of the fuel system.

When using hose clamps on fuel lines, it's important to choose the right size and type for the specific application. Different hose clamp designs offer varying levels of grip and flexibility, allowing for a customized fit. For instance, a V-band clamp provides a robust and secure hold, ideal for heavy-duty applications, while a wire clamp offers a more flexible solution for delicate fuel lines. The key is to select a clamp that provides a snug fit without causing any damage to the fuel line or surrounding components.

Proper installation is critical to the success of using hose clamps. Start by ensuring the fuel line is clean and free of any debris. Then, carefully position the hose clamp around the fuel line, making sure it is centered and aligned with the attachment point. Apply the clamp by tightening it securely, but be cautious not to overtighten, as this can cause damage. The goal is to achieve a firm hold without applying excessive force. Regularly inspect and maintain the hose clamp to ensure its effectiveness over time.

In summary, hose clamps are a practical and reliable method to secure fuel line connections, providing a tight, leak-free seal. With the right size and type of clamp, along with proper installation techniques, you can ensure the longevity and reliability of your fuel system. This simple yet effective solution is a testament to the power of basic engineering principles in everyday applications.

Mastering the Multistrada's Fuel Lines: A Comprehensive Guide

You may want to see also

Material Considerations: Choose hose clamps made from fuel-resistant materials to avoid damage

When it comes to securing fuel lines, the choice of hose clamp is crucial to ensure the safety and longevity of your vehicle's fuel system. One of the primary considerations is the material of the hose clamp itself. Opting for clamps made from fuel-resistant materials is essential to prevent any potential damage to the fuel lines.

Fuel lines are designed to withstand the corrosive nature of gasoline and diesel, and using the right hose clamp material can help maintain the integrity of these lines. Common materials for fuel-resistant hose clamps include stainless steel and special-grade rubber compounds. Stainless steel is an excellent choice due to its inherent corrosion resistance, ensuring that the clamp remains effective over time, even in the presence of fuel. This material is durable and can withstand the high temperatures and pressure associated with fuel systems.

Rubber compounds, specifically those formulated for fuel-resistant applications, are another viable option. These compounds are engineered to resist the degradation caused by fuel exposure, ensuring the clamp's flexibility and sealing properties remain intact. Look for hose clamps with a clear indication of their fuel-resistant properties, often specified in the product's technical data sheet.

It is imperative to avoid using hose clamps made from materials that are not fuel-resistant, as this can lead to premature failure and potential fuel leaks. Common mistakes include using metal clamps that can corrode and weaken the fuel lines or rubber clamps that may become brittle over time, losing their ability to provide a secure seal.

In summary, when dealing with fuel lines, the material of the hose clamp is a critical factor. By selecting fuel-resistant materials, you ensure that the clamp can effectively secure the fuel line without causing damage or compromising the system's integrity. Always refer to the manufacturer's guidelines and choose the appropriate clamp for your specific fuel line requirements.

Suzuki Eiger Fuel Line: Size and Compatibility Guide

You may want to see also

Safety and Regulations: Adhere to vehicle and fuel system safety guidelines when using hose clamps

When working with fuel lines and hose clamps, it is crucial to prioritize safety and adhere to specific guidelines to ensure the integrity and reliability of your vehicle's fuel system. The fuel system is a critical component of any vehicle, and any modifications or repairs should be approached with caution. Here are some essential safety considerations and regulations to follow:

Vehicle Manufacturer's Guidelines: Always refer to your vehicle's manual or the manufacturer's instructions when dealing with fuel lines. Different vehicles may have unique requirements and specifications for hose clamps. Using the correct type and size of hose clamp recommended by the manufacturer is essential to ensure a proper fit and avoid potential leaks or damage. These guidelines often provide detailed information on the appropriate materials and methods for securing fuel lines.

Fuel System Safety: The fuel system is designed to handle specific pressures and temperatures. Using hose clamps that are not suitable for fuel lines can lead to potential hazards. Clamps that are too tight may restrict fuel flow, causing engine performance issues or even stalling. Conversely, loose clamps might allow fuel to leak, creating a fire hazard. It is crucial to choose hose clamps that provide a secure yet flexible grip, allowing for slight movement to accommodate temperature changes without compromising safety.

Regulations and Standards: Adhering to industry regulations and standards is vital when working on fuel systems. In many regions, there are specific codes and guidelines for fuel line installation and maintenance. These regulations ensure that fuel systems are designed and maintained to the highest safety standards. For example, the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code provides guidelines for pressure-containing systems, which may include fuel lines. Familiarize yourself with these standards to ensure compliance and maintain the safety of your vehicle.

Proper Installation Technique: When using hose clamps, employ the correct installation technique to ensure a secure and reliable connection. Start by cleaning the fuel line and ensuring it is free of any debris or contaminants. Then, apply the hose clamp evenly and tightly, avoiding any sharp bends or kinks in the fuel line. Use a tool, such as a pipe wrench, to tighten the clamp, ensuring it is secure but not overly tight. Regularly inspect the clamped areas for any signs of wear or damage, especially after extended periods of use or exposure to extreme temperatures.

Professional Assistance: If you are unsure about the process or lack the necessary experience, it is advisable to seek professional assistance. Automotive technicians and mechanics are trained to handle fuel systems and can provide expert guidance. They can ensure that the hose clamps are applied correctly and that the overall fuel system is safe and compliant with regulations.

Braided Fuel Line Shopping Guide: Top Sources Revealed

You may want to see also

Frequently asked questions

It is generally not recommended to use a hose clamp directly on a fuel line. Hose clamps are designed for temporary and flexible connections, but fuel lines are rigid and require a more secure and permanent solution. Using a hose clamp can lead to fuel leaks and potential safety hazards.

Fuel lines should be secured using specialized fuel line clamps or fittings. These are designed to withstand the pressure and temperature changes associated with fuel. They provide a tight and reliable seal, ensuring no fuel leakage. It is crucial to choose the correct size and type of clamp for the specific fuel line application.

Yes, there are alternative methods to secure fuel lines. One common method is to use fuel line ties or straps, which are designed to hold the fuel line in place without causing damage. Additionally, fuel line fittings and couplings are available, providing a more permanent and reliable connection.

When installing a fuel line, it is essential to follow the manufacturer's guidelines and best practices. This includes using the correct tools, ensuring proper alignment, and securing the fuel line with the appropriate clamps or fittings. Regular inspections and maintenance can also help identify and prevent potential issues.

While it might be tempting to use a hose clamp in an emergency, it is not a suitable long-term solution. The clamp may not provide a secure enough connection, and fuel leakage can occur over time. In such cases, it is best to seek professional assistance or use temporary measures until a proper repair can be made.