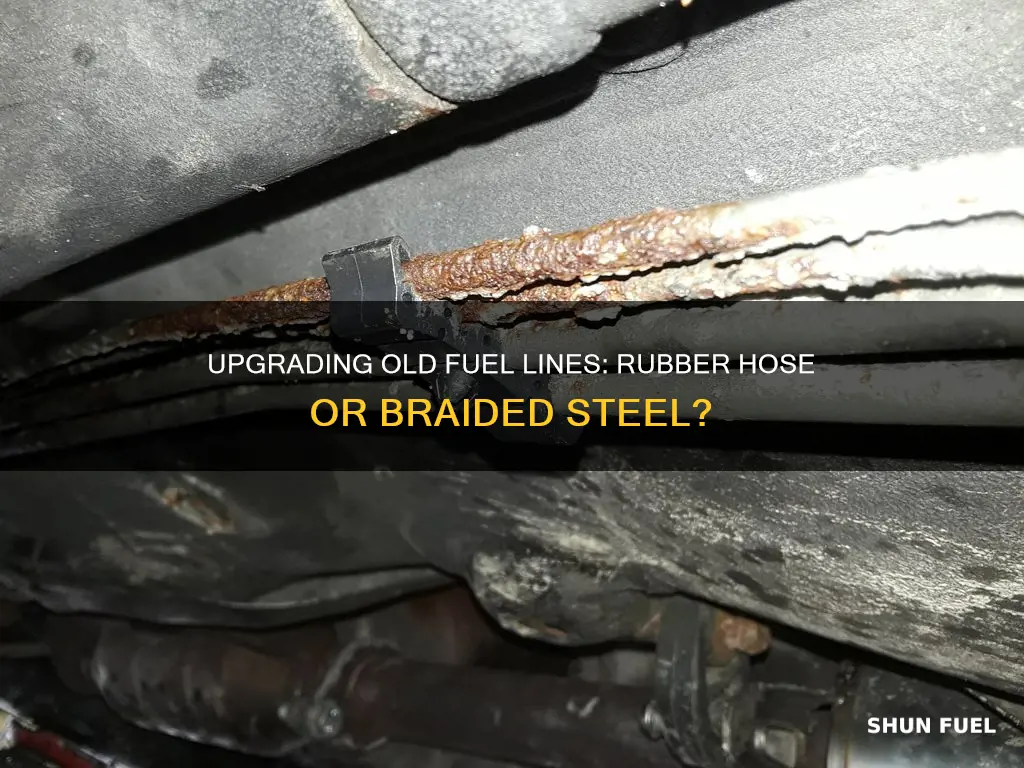

Replacing old, rusty fuel lines with rubber hoses is a common DIY project for car owners. While rubber hoses are more flexible and easier to install than rigid metal lines, they may not be as durable or reliable in the long term. This guide will explore the pros and cons of using rubber hoses as a replacement for rusty fuel lines, including their potential impact on performance, safety, and longevity.

| Characteristics | Values |

|---|---|

| Durability | Rubber hoses are generally less durable than fuel lines made of materials like steel or brass. They can crack or become brittle over time, especially in harsh environments. |

| Flexibility | Rubber hoses offer more flexibility, making them easier to route and install, especially in tight spaces. |

| Corrosion Resistance | Rubber hoses are not as resistant to corrosion as metal fuel lines. They may degrade or become brittle when exposed to fuel, moisture, or extreme temperatures. |

| Cost | Rubber hoses are typically more affordable than high-quality metal fuel lines. |

| Installation | Replacing with rubber hoses is often a simpler process, requiring fewer tools and less expertise. |

| Longevity | Metal fuel lines tend to have a longer lifespan, especially when properly maintained, whereas rubber hoses may need more frequent replacements. |

| Compatibility | Ensure the rubber hose is compatible with the fuel type and pressure requirements of your vehicle. |

| Maintenance | Regular inspection and maintenance are crucial for both rubber hoses and metal fuel lines to ensure optimal performance and safety. |

| Safety | While rubber hoses can be safe, it's important to choose high-quality products and ensure proper installation to avoid fuel leaks. |

What You'll Learn

- Safety: Ensure proper ventilation and avoid inhaling fumes when working with fuel

- Material Compatibility: Choose rubber hose compatible with fuel type and temperature

- Pressure Rating: Select hose with sufficient pressure rating for fuel system

- Flexibility: Opt for flexible hose to accommodate engine movement

- Installation: Follow manufacturer's instructions for secure and leak-free connections

Safety: Ensure proper ventilation and avoid inhaling fumes when working with fuel

When undertaking any fuel system repair or modification, prioritizing safety is paramount. One critical aspect often overlooked is the importance of proper ventilation to prevent the inhalation of harmful fumes. Fuel, especially when it has aged or is contaminated, can release volatile organic compounds (VOCs) and other toxic substances when disturbed. These fumes are not only hazardous but can also be flammable, posing a significant risk to both you and your surroundings.

Inhaling fuel fumes can lead to a range of health issues, including respiratory problems, dizziness, and, in severe cases, loss of consciousness. The risk is heightened in enclosed spaces or areas with poor air circulation, where fumes can quickly accumulate. Therefore, it is essential to work in a well-ventilated area, preferably outdoors, to minimize the exposure to these dangerous gases. If working indoors is necessary, ensure that the room is equipped with a powerful exhaust fan or ventilation system to continuously remove the air inside and replace it with fresh, clean air.

To enhance safety, consider wearing a respirator mask designed for chemical protection. This simple yet effective measure can significantly reduce the risk of inhaling harmful substances. Additionally, always work with the fuel system in a cool, calm state. Avoid tasks that might generate sparks, such as using power tools or smoking, as these can ignite the fuel and lead to dangerous explosions.

Furthermore, it is crucial to handle fuel with care. Always add fuel to your vehicle's tank when it is cool, and never use a hand-primed pump for fuel transfer, as this can create a vacuum that draws air into the fuel, increasing the risk of inhalation. Always use a dedicated fuel transfer pump and ensure that all connections are secure to prevent fuel leaks, which can also release harmful fumes.

In summary, when replacing rusty fuel lines with rubber hoses or performing any fuel-related work, prioritize your safety and that of those around you by ensuring adequate ventilation and taking the necessary precautions to avoid inhaling fuel fumes. This simple yet crucial step can help prevent accidents, health issues, and potential legal consequences associated with fuel-related incidents.

When to Replace Fuel Injectors: All at Once?

You may want to see also

Material Compatibility: Choose rubber hose compatible with fuel type and temperature

When considering replacing rusty old fuel lines with rubber hoses, it is crucial to prioritize material compatibility to ensure the safety and efficiency of your fuel system. Rubber hoses are a popular choice due to their flexibility and ease of installation, but not all rubber hoses are created equal. The compatibility of the hose material with the fuel type and operating temperature is essential to avoid potential issues.

The first step is to identify the type of fuel you are dealing with. Different fuels have varying chemical compositions and properties. For example, gasoline and diesel have distinct characteristics that require specific hose materials. Gasoline is a volatile fuel that can dissolve certain rubber compounds, so it's crucial to choose a hose made from materials resistant to gasoline dissolution. On the other hand, diesel fuel, being less volatile, may not have the same stringent requirements but still needs to be compatible with the chosen hose material.

Temperature is another critical factor. Rubber hoses can be affected by extreme temperatures, which can lead to degradation and potential fuel leaks. High-temperature environments, such as those found in some engines or during prolonged idling, may require hoses with a higher temperature resistance rating. Similarly, low-temperature conditions can cause rubber to become brittle, so it's essential to select a hose material that can withstand the expected temperature range. Look for hoses with appropriate temperature ratings, often indicated by a T-code (for temperature) on the hose's identification tag.

Additionally, consider the operating pressure of your fuel system. Rubber hoses have pressure limits, and exceeding these limits can lead to hose failure. Ensure that the chosen hose material can handle the expected pressure without compromising its integrity.

In summary, when replacing rusty fuel lines with rubber hoses, carefully select the hose material based on its compatibility with the fuel type and temperature conditions. This ensures the longevity and reliability of your fuel system, preventing potential hazards and costly repairs. Always refer to the manufacturer's guidelines and consult experts if needed to make an informed decision.

Cleaning and Replacing Fuel Injectors in a 2000 GMC Yukon XL

You may want to see also

Pressure Rating: Select hose with sufficient pressure rating for fuel system

When considering replacing old, rusty fuel lines with rubber hoses, one of the most critical factors to evaluate is the pressure rating of the hose. The fuel system in your vehicle operates under specific pressure conditions, and using a hose with an inadequate pressure rating can lead to various issues and potential safety hazards.

The pressure rating of a hose refers to the maximum pressure it can withstand without failing or leaking. Fuel systems typically operate at relatively low pressures, often ranging from 50 to 100 psi (pounds per square inch). However, it's essential to check your vehicle's specific requirements as some engines may have higher pressure needs. If you opt for a hose with a lower pressure rating than your fuel system requires, it could result in reduced performance, fuel leaks, or even engine damage over time.

To ensure a safe and reliable replacement, you should select a rubber hose with a pressure rating that exceeds the expected operating pressure of your fuel system. This extra margin of safety is crucial, especially in high-temperature environments where fuel lines can become more susceptible to pressure-related issues. A pressure-rated hose will provide the necessary flexibility and durability while maintaining a tight seal, preventing fuel from leaking out.

When choosing the hose, look for specifications that clearly indicate the pressure rating. This information is typically provided by the manufacturer and can be found on the hose's packaging or data sheet. Ensure that the selected hose meets or exceeds the pressure requirements of your fuel system to guarantee optimal performance and safety.

In summary, selecting a rubber hose with an appropriate pressure rating is vital when replacing old fuel lines. It ensures that the new hose can handle the fuel system's operating conditions, providing a secure and efficient connection without compromising safety. Always refer to the manufacturer's guidelines and consult a professional if needed to make the right choice for your specific vehicle.

Replacing Stihl FS45 Fuel Tank: Step-by-Step Guide

You may want to see also

Flexibility: Opt for flexible hose to accommodate engine movement

When considering replacing old, rusty fuel lines with rubber hoses, one crucial aspect to keep in mind is flexibility. The engine in your vehicle is a complex machine with various moving parts, and the fuel lines play a vital role in delivering fuel to the engine. Over time, these lines can become brittle and cracked due to exposure to heat, cold, and the corrosive effects of fuel. This is where the importance of flexibility comes into play.

Flexible hoses offer a significant advantage in terms of accommodating the natural movement and expansion of the engine. As the engine operates, it experiences thermal expansion and contraction, especially during the combustion process. Rigid fuel lines may not be able to adjust to these changes, leading to potential issues. Rubber hoses, on the other hand, are designed to be pliable, allowing them to bend and move with the engine's components. This flexibility ensures that the fuel supply remains uninterrupted, even when the engine is in motion or when it undergoes temperature fluctuations.

The engine's movement is not the only consideration. Rubber hoses also provide a level of insulation, protecting the fuel lines from excessive heat generated by the engine block. This insulation helps prevent the fuel from overheating and potential evaporation, ensuring that the fuel remains in a liquid state and ready for combustion. Additionally, the flexibility of rubber hoses reduces the risk of damage during routine engine maintenance or when accessing hard-to-reach areas under the hood.

When replacing fuel lines, it is essential to choose the right type of flexible hose for your specific vehicle. Different engines have varying requirements, and the hose should be compatible with the fuel type and pressure. Consulting the vehicle's manual or seeking advice from a professional mechanic can help ensure you select the appropriate hose with the necessary flexibility and durability.

In summary, flexibility is a key factor when opting for rubber hoses as a replacement for old fuel lines. The ability to accommodate engine movement and thermal changes ensures a reliable fuel supply, contributing to the overall performance and longevity of your vehicle's engine. By prioritizing flexibility, you can make an informed decision when replacing rusty fuel lines, ensuring a smooth and efficient operation of your car's fuel system.

Replacing Fuel Filter in 2006 Powerstroke: Step-by-Step Guide

You may want to see also

Installation: Follow manufacturer's instructions for secure and leak-free connections

When replacing old, rusty fuel lines with rubber hoses, it's crucial to follow the manufacturer's instructions to ensure a secure and leak-free connection. This process requires careful attention to detail and the right tools to guarantee optimal performance and safety. Here's a step-by-step guide to help you through the installation process:

Preparation: Before you begin, ensure you have the necessary tools and materials, including the new rubber hoses, fuel line connectors, and any required adapters. Clean the existing fuel lines and remove any rust or debris to create a smooth surface for the new hose. This step is essential to prevent any potential leaks.

Connection Process: Start by cutting the new rubber hose to the appropriate length, ensuring it is slightly longer than the distance between the fuel source and the engine. Slide the hose onto the fuel line connector, making sure it fits snugly. Use the manufacturer's recommended tools to tighten the connector securely. It's important to follow the specific torque specifications provided to avoid over-tightening, which can damage the hose.

Leak-Proof Seal: To create a leak-proof seal, insert the fuel line connector into the hose and ensure it is properly aligned. Use a fuel line tape or a suitable sealant to wrap around the connection, providing an additional layer of protection against leaks. This step is critical, especially if the original fuel lines had corrosion or damage.

Final Checks: After completing the installation, double-check all connections for tightness and security. Look for any signs of leaks by applying a small amount of fuel to the connections and observing for any seepage. If everything is leak-free, you can proceed to test the fuel system.

Testing and Safety: Once the installation is complete, start the engine and monitor for any unusual noises or behavior. Check for any fuel leaks around the connections. If all is well, you've successfully replaced the old fuel lines with a more flexible and potentially longer-lasting solution. Remember, regular maintenance and inspections are essential to ensure the safety and efficiency of your vehicle's fuel system.

Refueling Your Zippo: A Step-by-Step Guide to Replenishing Your Lighter

You may want to see also

Frequently asked questions

While it might seem like a temporary fix, using rubber hoses instead of proper fuel lines is not recommended. Rubber hoses are not designed for the corrosive nature of fuel and can degrade over time, leading to potential leaks and safety hazards. It's best to replace the old fuel lines with new, fuel-rated hoses or consider a more permanent solution like stainless steel lines.

Rubber hoses can become brittle and crack over time, especially when exposed to fuel's volatile compounds. This can result in fuel leaks, which pose a fire and explosion risk. Additionally, rubber hoses may not provide the same level of flexibility and durability as specialized fuel lines, making them more prone to damage from vibrations and temperature changes.

Temporarily, you can use fuel line tape or clamps to seal small leaks. However, this is a short-term fix and does not address the underlying issue. It's crucial to replace the entire length of the fuel line to ensure safety and prevent further corrosion.

Regular maintenance and inspection are key. Keep an eye out for signs of corrosion, cracks, or damage. Use fuel line protectants to slow down corrosion, and ensure that all connections are secure and properly sealed. It's also a good practice to replace fuel lines every few years, especially if they are showing signs of wear and tear.