Understanding the number of fuel pumps in a car is essential for vehicle maintenance and troubleshooting. Most cars are equipped with one or two fuel pumps, which are critical components in the fuel system. The primary function of these pumps is to deliver fuel from the fuel tank to the engine, ensuring a steady supply of gasoline or diesel for optimal performance. This introduction aims to explore the typical configurations and their significance in vehicle operation.

| Characteristics | Values |

|---|---|

| Typical Number of Fuel Pumps | 1-2 |

| Fuel Pump Location | Engine compartment or fuel tank |

| Function | Delivering fuel from the tank to the engine |

| Types of Fuel Pumps | Mechanical, electric, or combination (e.g., electric with a mechanical backup) |

| Dependence on Engine Type | Can vary; some engines require more pumps for high-performance or fuel injection systems |

| Multiple Pumps for Redundancy | Common in modern vehicles for reliability and safety |

| Fuel Pump Control | Managed by the engine control unit (ECU) |

| Failure Symptoms | Engine misfires, reduced power, or difficulty starting |

What You'll Learn

- Single Pump Systems: Most cars use a single fuel pump to deliver gas to the engine

- Dual Pump Setup: Some vehicles have two pumps for increased fuel flow and reliability

- Electric vs. Mechanical: The type of pump (electric or mechanical) varies by car model

- Fuel Pump Location: Pumps are often located inside the fuel tank or in the engine compartment

- Pump Capacity: Pump capacity varies based on engine size and fuel requirements

Single Pump Systems: Most cars use a single fuel pump to deliver gas to the engine

Most vehicles are equipped with a single fuel pump, a crucial component in the fuel delivery system. This pump is responsible for drawing fuel from the tank and sending it to the engine, ensuring a steady supply of gasoline for combustion. The design of a single pump system is both efficient and cost-effective, making it a common choice for automotive manufacturers. By utilizing a single pump, the system simplifies the fuel delivery process, reducing the complexity and potential failure points of the overall mechanism.

In a single pump system, the pump is typically located near the fuel tank, often integrated into the tank itself or mounted close by. This proximity allows for a shorter fuel line, which minimizes the risk of fuel vaporization and ensures a more efficient transfer of gasoline. The pump's role is to create a sufficient pressure to overcome the resistance in the fuel lines and deliver the fuel to the engine's carburetor or fuel injection system.

The operation of a single pump system is straightforward. When the engine is running or during acceleration, the pump activates, drawing fuel from the tank and pressurizing it. This pressurized fuel is then directed through the fuel lines to the engine, where it is injected or mixed with air for combustion. The pump's performance is critical, as it needs to provide a consistent and adequate flow rate to meet the engine's demands.

One advantage of a single pump system is its reliability. With fewer components, there are fewer opportunities for failure, making it a dependable choice for fuel delivery. However, it's important to note that the pump's capacity and performance can vary depending on the vehicle's make and model, as well as its intended use. Some high-performance vehicles may require more fuel, necessitating a pump with a higher flow rate or additional pumps to ensure optimal engine operation.

In summary, a single fuel pump system is prevalent in most cars, providing an efficient and reliable method of delivering fuel to the engine. This design simplifies the fuel delivery process, reduces potential failure points, and ensures a steady supply of gasoline for combustion. Understanding the role and functionality of this system is essential for vehicle owners and mechanics alike, as it highlights the importance of proper maintenance and the potential need for upgrades in high-performance applications.

Fuel Injector Cleaner: Friend or Foe for Your Car?

You may want to see also

Dual Pump Setup: Some vehicles have two pumps for increased fuel flow and reliability

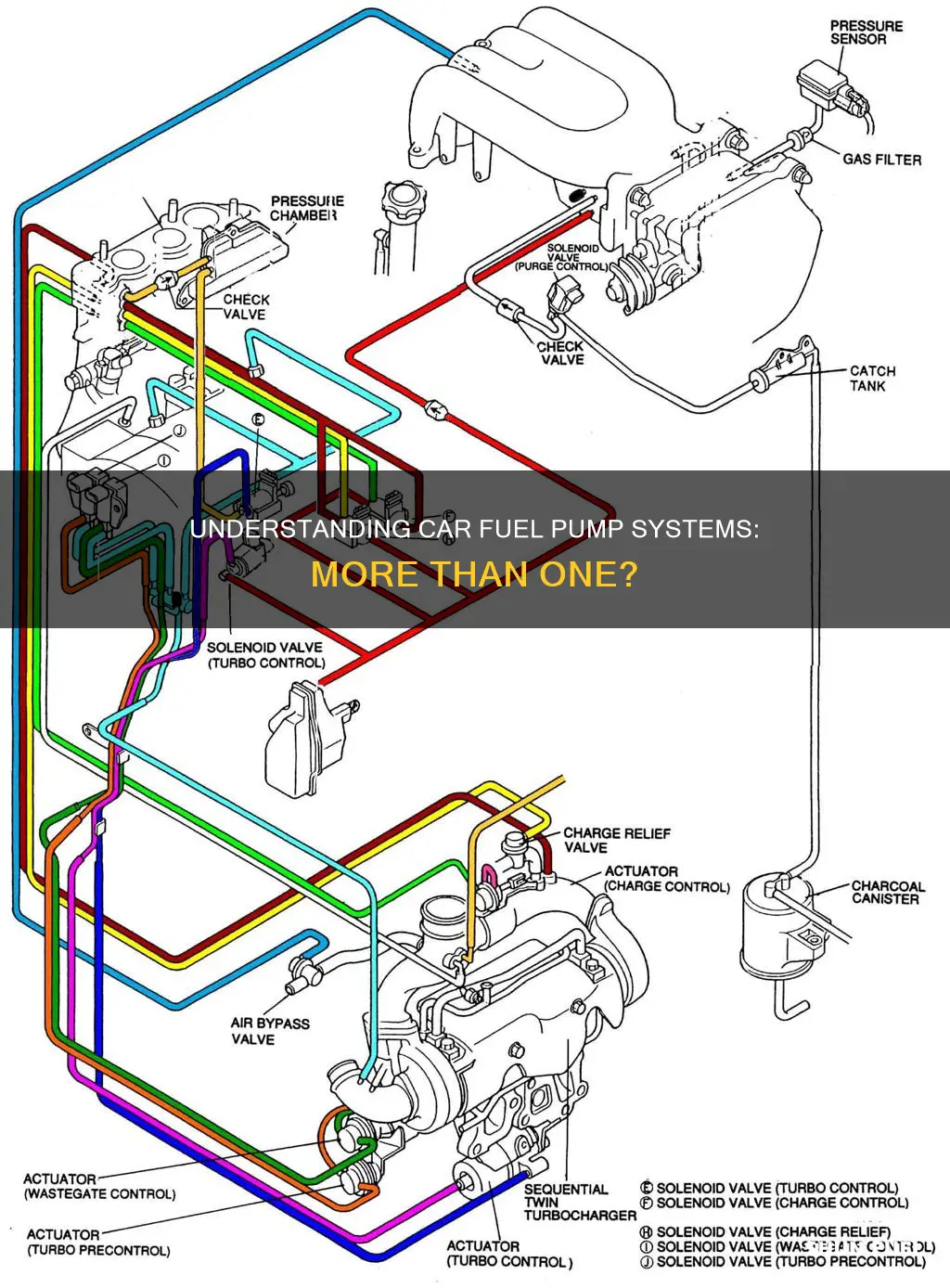

In modern automobiles, the fuel pump is a critical component responsible for delivering fuel from the tank to the engine. The efficiency and reliability of this process are essential for optimal engine performance. One common configuration to ensure a consistent and robust fuel supply is the use of a dual pump setup. This design incorporates two fuel pumps, strategically placed within the vehicle's fuel system.

The primary advantage of a dual pump system is the increased fuel flow it provides. Each pump is designed to deliver a specific volume of fuel, and when combined, they can meet the demands of even high-performance engines. This setup ensures that the engine receives a steady and ample supply of fuel, promoting efficient combustion and power output. For instance, in racing cars or high-performance vehicles, where engine output is maximized, a dual pump arrangement is often employed to handle the increased fuel requirements.

Reliability is another key benefit of this configuration. Having two pumps means that if one fails or experiences an issue, the other pump can compensate, ensuring the engine continues to operate without a significant drop in performance. This redundancy is crucial for maintaining the vehicle's functionality, especially during critical moments like acceleration or high-speed driving. Additionally, the dual pump setup can help prevent issues such as fuel starvation, which can occur if a single pump fails.

The installation of a dual pump system requires careful consideration of the vehicle's architecture and fuel system design. Engineers must ensure that the pumps are positioned to maximize fuel flow while minimizing pressure drops. This often involves intricate plumbing and careful routing of fuel lines to optimize the delivery process. Furthermore, the pumps themselves are typically designed to operate in parallel, allowing them to work together seamlessly.

In summary, the dual pump setup is a sophisticated solution to enhance fuel flow and reliability in automobiles. By employing two pumps, vehicles can achieve higher performance and maintain functionality even in the event of a pump failure. This configuration showcases the intricate engineering that goes into ensuring a car's engine operates at its best under various conditions.

Can You Mix Rec Fuel with Regular Gasoline?

You may want to see also

Electric vs. Mechanical: The type of pump (electric or mechanical) varies by car model

The fuel pump system in a car is a critical component responsible for delivering fuel from the tank to the engine. The type of fuel pump used can vary significantly between different car models, and understanding these differences is essential for maintenance and troubleshooting. The primary distinction lies in the power source of the pump: electric or mechanical.

Mechanical fuel pumps, as the name suggests, are driven by the engine's mechanical components. This type of pump is commonly found in older vehicle models and some classic cars. In this setup, the pump is typically mounted on the engine block and is directly connected to the camshaft or timing gear. When the engine is running, the mechanical motion of the engine drives the pump, which then pushes fuel through the lines to the injectors or carburetor. This design has been widely used due to its simplicity and reliability, especially in high-performance vehicles where fuel delivery needs to be precise and responsive.

On the other hand, electric fuel pumps have become more prevalent in modern automobiles. These pumps are powered by a dedicated electric motor, which is usually controlled by the car's engine control unit (ECU). The electric pump is often located closer to the fuel tank, and its operation is independent of the engine's mechanical components. This design offers several advantages, including improved fuel pressure control, quieter operation, and the ability to adjust the pump's speed based on engine load. Electric pumps are particularly useful in fuel injection systems, where precise fuel delivery is crucial for optimal engine performance and fuel efficiency.

The choice between electric and mechanical pumps often depends on the car manufacturer's design philosophy and the specific requirements of the vehicle. For instance, high-performance sports cars might favor mechanical pumps for their direct response and ability to handle high fuel pressures. In contrast, everyday vehicles and those with fuel injection systems often utilize electric pumps for their convenience and ability to provide consistent fuel delivery.

Understanding the type of fuel pump in your car is essential for maintenance and troubleshooting. If you encounter issues with fuel delivery, such as poor engine performance or strange noises, identifying whether the pump is electric or mechanical can guide you in the right direction for repairs or replacements. Additionally, knowing the pump type can help in selecting the appropriate fuel filter and ensuring that the fuel system is maintained correctly.

Understanding Fuel Injector Systems: A Comprehensive Guide

You may want to see also

Fuel Pump Location: Pumps are often located inside the fuel tank or in the engine compartment

The location of the fuel pump in a car is an important aspect of its design and functionality. As you might have discovered through your initial research, the fuel pump's placement can vary depending on the vehicle's make and model. However, there are two primary locations where fuel pumps are commonly found: inside the fuel tank and in the engine compartment.

When the fuel pump is integrated into the fuel tank, it is designed to be a self-contained unit. This placement offers several advantages. Firstly, it ensures that the pump is always submerged in fuel, which helps to prevent air bubbles from forming, thus maintaining a consistent fuel supply to the engine. This is especially crucial for vehicles with larger fuel tanks, as it reduces the risk of fuel starvation during long journeys or when the tank is nearly empty. Additionally, having the pump inside the tank can provide better protection from physical damage, as the tank is typically a well-guarded area of the vehicle.

On the other hand, fuel pumps can also be located in the engine compartment. This placement is more common in older vehicle designs or in certain engine configurations. By placing the pump in the engine bay, it is easier to access for maintenance and repairs. However, this location may not always provide the same level of protection from contaminants in the fuel, as the pump is exposed to the elements and potential engine heat. This can be a concern, especially for vehicles that frequently operate in harsh conditions.

The decision on where to place the fuel pump is often a trade-off between functionality, protection, and ease of maintenance. Modern vehicles tend to favor the fuel tank location due to its ability to maintain a consistent fuel supply and provide better protection. Nonetheless, understanding the different fuel pump locations can be beneficial for car owners, as it can help with troubleshooting issues related to fuel delivery and ensuring the vehicle's overall performance.

The Ultimate Guide to Using Racing Fuel in Any Car

You may want to see also

Pump Capacity: Pump capacity varies based on engine size and fuel requirements

The fuel pump's capacity is a critical aspect of a vehicle's fuel system, and it directly impacts the engine's performance and efficiency. The primary function of a fuel pump is to deliver the required amount of fuel to the engine at the precise moment it needs it. This process is essential for optimal combustion and power generation. The capacity of a fuel pump is determined by several factors, with the engine size and fuel requirements being the most significant.

Engine size plays a pivotal role in determining the pump's capacity. Larger engines typically require more fuel to operate, and thus, the fuel pump must be capable of delivering a higher volume of fuel to meet the engine's demands. For instance, a high-performance V8 engine will need a more robust fuel pump compared to a smaller, more compact engine. The pump's capacity is measured in terms of its flow rate, which is the volume of fuel it can deliver per minute. A higher flow rate is essential to ensure that the engine receives the required fuel, especially during high-load conditions or when accelerating rapidly.

Fuel requirements also significantly influence pump capacity. Modern vehicles are designed with advanced fuel injection systems that precisely control the amount of fuel entering the engine. These systems demand a consistent and accurate fuel supply, which is where the pump's capacity comes into play. If the pump cannot deliver the required fuel volume, the engine may not perform optimally, and fuel efficiency could be compromised. For example, a sports car with a high-performance engine requires a fuel pump with a higher capacity to handle the increased fuel demand during aggressive driving conditions.

The relationship between engine size, fuel requirements, and pump capacity is intricate. Engineers and designers must carefully consider these factors when selecting or designing fuel pumps for vehicles. A pump with insufficient capacity might struggle to meet the engine's needs, leading to reduced performance and potential fuel starvation. Conversely, an over-capacity pump could lead to unnecessary fuel consumption and increased operating costs. Therefore, matching the pump's capacity to the specific engine and fuel requirements is crucial for achieving the best possible performance and efficiency.

In summary, the capacity of a fuel pump is a critical consideration in vehicle engineering, directly impacting engine performance and efficiency. It is influenced by engine size and fuel requirements, with larger engines and more demanding fuel systems requiring higher-capacity pumps. Understanding this relationship is essential for optimizing vehicle performance and ensuring that the fuel pump meets the engine's needs effectively.

Fuel Filter Issues: Why Your Car Won't Start

You may want to see also

Frequently asked questions

The number of fuel pumps can vary depending on the vehicle's make and model, as well as its engine size and configuration. Most modern cars have one or two fuel pumps. A single pump is common in smaller engines, while larger engines, especially those in high-performance vehicles, may have two pumps to ensure adequate fuel supply and pressure.

Having two fuel pumps allows for better fuel delivery and performance, especially in high-demand situations. The primary pump provides the regular fuel supply for the engine, while the secondary pump is often used for additional power or during high-load conditions, ensuring a consistent fuel flow to meet the engine's needs.

Yes, a car can operate efficiently with just one fuel pump. The single pump is usually sufficient for everyday driving and provides the necessary fuel pressure and volume for the engine to run optimally. However, in some cases, especially for high-performance applications, having a second pump can be beneficial for enhanced performance and reliability.

A failed fuel pump can lead to engine starting issues, reduced power, and potential stalling. If the primary pump fails, the car may still run, but it will likely experience reduced performance and fuel efficiency. In some cases, the secondary pump can compensate, but if both pumps are compromised, the vehicle will require immediate attention and potential fuel pump replacement to restore normal operation.