Cars are equipped with two fuel pumps to ensure a consistent and reliable fuel supply to the engine. The primary function of the fuel pump is to deliver fuel from the tank to the engine's carburetor or fuel injection system. Having two fuel pumps, one primary and one secondary, provides redundancy and enhances the vehicle's performance and reliability. The primary pump is responsible for delivering the majority of the fuel needed for regular driving, while the secondary pump kicks in during high-load conditions or when the primary pump is under stress, ensuring a steady fuel flow even under demanding circumstances. This dual-pump system is a common feature in modern vehicles to optimize fuel delivery and maintain optimal engine performance.

What You'll Learn

- Engine Performance: Two pumps ensure consistent fuel delivery for optimal engine operation

- Safety: Redundancy prevents fuel starvation during high-load conditions or failures

- Efficiency: Multiple pumps can improve fuel economy and reduce emissions

- Reliability: Backup pumps enhance vehicle reliability and reduce the risk of breakdowns

- Design: Engineers design systems with two pumps for specific performance and safety needs

Engine Performance: Two pumps ensure consistent fuel delivery for optimal engine operation

The presence of two fuel pumps in a car's engine is a design choice that significantly contributes to optimal engine performance and reliability. While it might seem redundant, having two pumps serves a crucial purpose in ensuring consistent and efficient fuel delivery to the engine. This setup is particularly important for engines that require precise and timely fuel injection to operate at their best.

One of the primary functions of the two fuel pumps is to provide a continuous and steady supply of fuel to the engine. The primary pump, often located near the fuel tank, is responsible for delivering the majority of the fuel required for the engine's operation. This pump operates continuously as long as the engine is running, ensuring that the fuel system is always pressurized and ready to supply fuel to the engine's injectors. The secondary pump, typically a smaller one, is designed to kick in when the engine is at rest or during sudden acceleration demands. This secondary pump provides an additional boost of fuel pressure, ensuring that the engine receives the necessary amount of fuel even under high-load conditions.

The dual-pump system offers several advantages. Firstly, it ensures that the engine always has access to the required fuel volume, regardless of the engine's speed or load. This is crucial for maintaining optimal engine performance, especially during rapid acceleration or when the engine is under stress. By having two pumps, the car can quickly respond to these demands without compromising fuel delivery, resulting in improved throttle response and overall engine efficiency.

Secondly, the two-pump system provides a level of redundancy, which is essential for reliability. If one pump fails or becomes inoperable, the other pump can take over, ensuring that the engine still receives fuel. This redundancy is vital for preventing engine stalls or performance degradation due to fuel-related issues. Modern vehicles often incorporate sophisticated control units that monitor the pumps' performance and can activate the secondary pump if the primary one fails, demonstrating the advanced engineering behind this design choice.

In summary, the use of two fuel pumps in a car's engine is a strategic design feature that enhances engine performance and reliability. It ensures consistent fuel delivery, supports rapid acceleration, and provides a safety net in case of pump failure. Understanding this system's role highlights the intricate engineering that goes into modern vehicle design, aiming to provide a seamless and efficient driving experience.

Troubleshooting Fuel Issues in a 1988 Reliant Car: A Comprehensive Guide

You may want to see also

Safety: Redundancy prevents fuel starvation during high-load conditions or failures

The presence of two fuel pumps in a vehicle's fuel system is a safety feature designed to prevent fuel starvation, especially during high-load conditions or in the event of a failure. This redundancy is crucial for maintaining optimal engine performance and overall vehicle safety. Here's a detailed explanation of how this system works and why it's essential:

In automotive engineering, the primary function of fuel pumps is to deliver fuel from the tank to the engine's fuel injectors or carburetor. During high-load conditions, such as when accelerating rapidly or driving uphill, the engine requires a significant amount of fuel to meet its power demands. A single fuel pump might struggle to meet this increased demand, leading to a condition known as fuel starvation. This occurs when the engine doesn't receive enough fuel to operate efficiently, resulting in reduced power, poor performance, and even potential engine damage.

To address this issue, modern vehicles are equipped with two fuel pumps, often located within the fuel tank or close to it. These pumps are designed to work in tandem, ensuring a consistent and adequate fuel supply to the engine. When one pump operates, the other remains in a standby mode, ready to activate if needed. This redundancy is a critical safety measure, especially in high-performance vehicles or those with larger engines that require substantial fuel volumes.

In the event of a failure in one fuel pump, the second pump automatically takes over, ensuring that the engine continues to receive the necessary fuel. This prevents sudden power loss and maintains the vehicle's drivability. For instance, if a pump fails due to wear and tear or a mechanical issue, the second pump can compensate, providing fuel to the engine without disrupting the driver's experience. This level of redundancy is particularly important during critical driving situations, such as highway driving or when overtaking, where rapid acceleration is required.

Furthermore, the use of two fuel pumps also contributes to the overall reliability of the vehicle. By having a backup system, manufacturers can ensure that their vehicles meet strict safety standards and provide a seamless driving experience. This design consideration is a testament to the importance of safety in automotive engineering, where every component, including the fuel system, plays a vital role in ensuring the vehicle's performance and the driver's peace of mind.

Alcohol's Green Revolution: Powering Cars Sustainably

You may want to see also

Efficiency: Multiple pumps can improve fuel economy and reduce emissions

The use of multiple fuel pumps in modern vehicles is a design choice that significantly contributes to improved fuel efficiency and reduced emissions. This is particularly important in the context of an engine's performance and environmental impact. The primary reason for having two fuel pumps is to ensure a consistent and efficient fuel supply to the engine, which directly translates to better fuel economy and lower emissions.

In a typical engine, the primary fuel pump is responsible for delivering fuel from the fuel tank to the engine's high-pressure fuel rail. This pump operates continuously, ensuring a steady flow of fuel to meet the engine's demands. However, during periods of high engine load, such as when accelerating rapidly or driving uphill, the engine requires a higher volume of fuel. This is where the secondary fuel pump comes into play.

The secondary fuel pump is designed to provide an additional boost of fuel when the engine needs it most. This pump is typically activated when the engine's speed and load exceed a certain threshold, indicating a need for extra power. By having a secondary pump, the engine can maintain a higher fuel pressure, ensuring that the engine receives the required amount of fuel even under demanding conditions. This results in improved performance and a more responsive driving experience.

The efficiency gains from using multiple fuel pumps are twofold. Firstly, the secondary pump ensures that the engine always has the necessary fuel volume, preventing the primary pump from becoming overwhelmed and maintaining a consistent fuel supply. This consistency leads to better fuel economy, as the engine can operate at its most efficient levels more often. Secondly, by reducing the strain on the primary pump, the system minimizes the risk of fuel pressure drops, which can cause engine misfires and reduced performance.

In addition to improved fuel economy, the use of multiple fuel pumps also contributes to reduced emissions. Efficient fuel delivery means that the engine can burn fuel more effectively, resulting in lower unburned hydrocarbons and carbon monoxide emissions. This is particularly beneficial for vehicles with advanced engine management systems, as it allows for better control and optimization of the combustion process, further enhancing the vehicle's environmental performance.

Modern Cars: Fuel Efficiency vs. Horses: A Comparative Analysis

You may want to see also

Reliability: Backup pumps enhance vehicle reliability and reduce the risk of breakdowns

The presence of two fuel pumps in a vehicle is a crucial design feature that significantly contributes to its reliability and performance. One of the primary reasons for having two fuel pumps is to ensure a consistent and reliable fuel supply to the engine, especially during demanding driving conditions. The primary fuel pump is responsible for delivering fuel from the tank to the engine, while the secondary or backup pump is designed to kick in when the primary pump fails or becomes overloaded. This dual-pump system provides a safety net, preventing potential fuel starvation and subsequent engine misfires or stalls, which could lead to dangerous situations on the road.

In the event of a primary pump failure, the backup pump takes over, ensuring that the engine continues to receive the necessary fuel. This redundancy is vital as it allows for uninterrupted operation, especially in critical moments such as when a vehicle is driving at high speeds or during sudden stops. The backup pump's ability to maintain fuel flow can prevent the engine from losing power, which could result in a loss of control and potential accidents. This feature is particularly important for vehicles used in commercial or emergency services, where reliability is paramount.

Furthermore, the dual-pump system also helps in reducing the risk of fuel-related issues caused by engine overload. When the engine operates at high RPMs or during rapid acceleration, the fuel demand increases significantly. The primary pump may struggle to meet this demand, leading to a potential shortage of fuel. In such scenarios, the backup pump can provide additional fuel, ensuring that the engine receives the required amount to maintain optimal performance. This feature is especially beneficial during high-performance driving or when the vehicle is carrying heavy loads, as it prevents the engine from becoming starved of fuel, thus maintaining its efficiency and longevity.

The reliability offered by the dual-fuel pump system extends beyond the immediate benefits of preventing breakdowns. It also contributes to the overall longevity of the vehicle. By ensuring a consistent fuel supply, the engine operates within its optimal parameters, reducing the risk of premature wear and tear. This, in turn, leads to lower maintenance costs and a longer lifespan for the vehicle. Additionally, the backup pump's ability to handle increased fuel demand without failing can help prevent the development of fuel-related issues, such as engine knocking or pre-ignition, which can cause significant damage over time.

In summary, the presence of two fuel pumps in a vehicle is a strategic design choice that significantly enhances its reliability and performance. The backup pump provides a safety net, ensuring uninterrupted fuel supply during critical situations and reducing the risk of breakdowns. This system also contributes to the vehicle's longevity by maintaining optimal engine operation and preventing fuel-related issues. Understanding the role of these dual pumps can help drivers appreciate the importance of this seemingly simple yet vital component of modern automotive engineering.

Ethanol Fuel: Exploring the Limits: Can I Use 10% Ethanol in My Car?

You may want to see also

Design: Engineers design systems with two pumps for specific performance and safety needs

The concept of dual fuel pumps in automotive engineering is a strategic design choice that significantly impacts vehicle performance and safety. Engineers have developed this system to address specific challenges related to fuel delivery and system efficiency. The primary reason for employing two pumps is to ensure a consistent and reliable fuel supply to the engine, especially during demanding driving conditions.

In a typical car engine, one pump is responsible for delivering fuel from the tank to the fuel pressure regulator, which then regulates the pressure and sends the fuel to the injectors or carburetor. This primary pump is crucial for maintaining the required fuel pressure to ensure optimal engine performance. However, during high-load situations, such as rapid acceleration or towing heavy loads, the engine demands a higher fuel flow rate. This is where the second pump comes into play.

The second pump, often referred to as the auxiliary or secondary pump, is designed to provide an additional fuel supply when the engine requires more power. This auxiliary pump is typically smaller and operates at a lower pressure compared to the primary pump. When the engine's demand exceeds the primary pump's capacity, the secondary pump activates, ensuring a steady fuel flow to meet the increased power requirements. This design feature is particularly beneficial in high-performance vehicles or those with larger engines, where the engine's fuel demand can vary significantly during operation.

Engineers carefully consider the placement and design of these pumps to optimize performance and safety. The primary pump is usually located closer to the fuel tank to ensure a quick response during acceleration. In contrast, the secondary pump might be positioned closer to the engine to provide a rapid fuel supply when needed. This strategic placement allows for efficient fuel management, ensuring that the engine receives the required fuel without compromising performance or safety.

Furthermore, the dual-pump system enhances safety by reducing the risk of fuel starvation. If one pump fails or becomes clogged, the other pump can compensate, preventing the engine from running out of fuel. This redundancy is a critical aspect of vehicle design, especially for long-distance travel or in regions with challenging fuel quality. By incorporating two pumps, engineers create a robust and reliable fuel system, contributing to the overall safety and longevity of the vehicle.

Nitro Fuel for RC Cars: The Ultimate Guide to Finding the Right Amount

You may want to see also

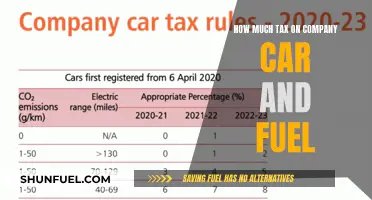

Frequently asked questions

Having two fuel pumps in a car's fuel system is a common design choice to ensure optimal fuel delivery and performance. The primary pump is responsible for supplying fuel from the tank to the engine when the vehicle is idling or moving at lower speeds. This pump is usually smaller and more efficient for everyday driving conditions. The secondary or high-pressure pump, on the other hand, comes into play during acceleration or when the engine demands more fuel. It provides a higher volume of fuel at increased pressure, allowing for quicker response times and better performance, especially during rapid acceleration or when the engine requires an immediate surge of power.

Yes, removing or inactivating one of the fuel pumps can significantly impact a car's performance and drivability. The primary pump ensures a steady and consistent fuel supply for normal operation, and its removal might lead to reduced power, poor fuel efficiency, and even stalling. However, the high-pressure pump is crucial for delivering the extra fuel required during high-load conditions, such as rapid acceleration or climbing steep hills. Disabling this pump could result in a noticeable loss of power and performance, especially during aggressive driving or when the engine needs an immediate boost.

Absolutely! The dual-fuel pump system offers several benefits. Firstly, it provides better fuel management and distribution, ensuring that the engine receives the required amount of fuel at the right pressure, regardless of the driving conditions. This results in improved performance, faster response times, and better overall driving experience. Additionally, having two pumps allows for more efficient fuel usage, as the smaller pump can handle everyday driving, while the high-pressure pump is ready for when the engine demands more power. This setup also contributes to better fuel economy and reduced stress on the fuel system components.