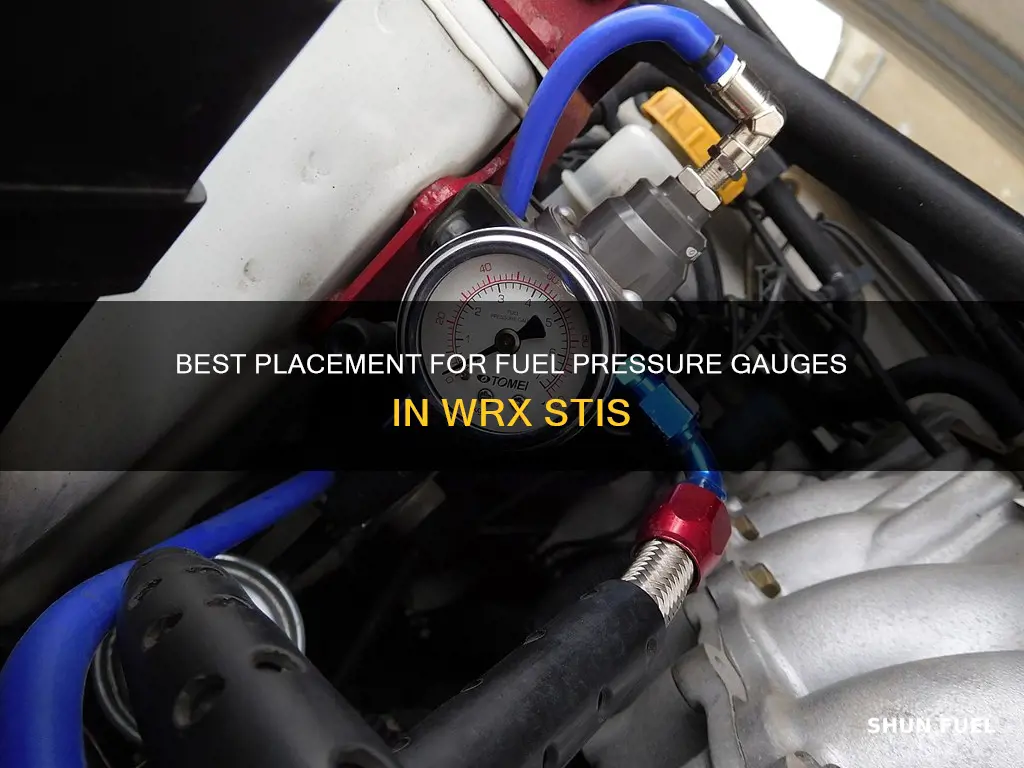

If you're looking to install a fuel pressure gauge in your WRX STI, there are a few things to consider. Firstly, it's important to relieve the pressure in the fuel line before attempting any installation. This can be done by pulling the fuel pump fuse and cranking the engine for a bit. Cutting the fuel hose is usually necessary, but be sure to use proper fittings and clamps to avoid leaks. You can also consider getting an aftermarket FPR and installing a pressure gauge on that. Alternatively, you can buy an inline fitting and put a pressure gauge on that. It's also important to consider the location of the gauge. Options include the A-pillar gauge pod, dual gauge dash bezel, or a custom location of your choosing.

What You'll Learn

The best location to tap into the fuel line

When installing a fuel pressure gauge in a WRX STI, it is important to consider the best location to tap into the fuel line safely and effectively. Here are some detailed instructions and considerations for choosing the best location:

Firstly, ensure you have the necessary tools and parts for the job, including a flat-head and Phillips-head screwdriver, a fuse puller, zip ties, a blow dryer, fuel hose clamps, and fuel-compatible hose. The process will involve depressurising the fuel system, so it is crucial to take safety precautions to avoid any fuel leakage or spray.

The fuel pressure regulator (FPR) is located under the manifold, and accessing it may require removing the intake manifold. Be cautious when working around the FPR, as the vacuum line connected to it is crucial for engine performance. It is recommended to zip-tie this line securely and consider flaring the metal line ends to reduce the risk of it popping off.

When preparing to tap into the fuel line, the first step is to relieve the fuel pressure. This can be done by pulling the fuel pump fuse and cranking the engine to use up the remaining fuel in the lines. Once the pressure is relieved, use the appropriate screwdriver to unscrew the clamp by the FPR and carefully remove the hose, being prepared for any residual fuel to spew out.

When installing the new fuel hose, ensure it is free of any debris. Use a blow dryer to heat up the hose and carefully push it over the bump in the hard line, being cautious not to damage the line. Secure the hose with clamps, both over and before the hump, and route it as desired, using zip ties for support. Finally, re-install the fuel pump fuse, reset the ECU, and check for any leaks before starting the engine.

It is worth noting that some WRX STI models may have different fuel system configurations, so it is essential to consult a mechanic or a forum specific to your vehicle's make and model before beginning any installation or modification work.

Ford F150 Fuel Pressure Regulator: Location and Maintenance Guide

You may want to see also

How to relieve pressure from the fuel line

Installing a fuel pressure gauge in your WRX STI requires relieving the pressure from the fuel line. Here is a step-by-step guide on how to do this safely and effectively:

Step 1: Disconnect the Negative Battery Terminal

Before starting any work on your fuel system, it is crucial to disconnect the negative battery terminal. This will prevent sparks, which could accidentally ignite fuel or fuel vapors.

Step 2: Locate the Schrader Valve

The Schrader valve is usually located on the fuel line in the engine compartment. It resembles the air valve on a bicycle tire. Place a shop towel under and around the Schrader valve to catch any dripping fuel.

Step 3: Depress the Schrader Valve

Using a small screwdriver, press down on the Schrader valve until fuel stops dripping from the line. Be cautious, as fuel may still spray out with some force.

Step 4: Optional - Use a Hand-Operated Vacuum Pump

If you want to push the remaining fuel in the lines back into the fuel tank, you can connect a hand-operated vacuum pump to the fuel pressure regulator. This regulator is located on the fuel rail, which is mounted along the top area of the engine. Ensure that the regulator is vacuum-operated before proceeding.

Step 5: Re-attach the Negative Battery Terminal

Once you have confirmed that the fuel pressure in the line has been relieved, you can re-attach the negative battery terminal.

Now that the pressure has been relieved from the fuel line, you can proceed with installing your fuel pressure gauge. Remember to exercise caution and refer to your WRX STI's service manual for specific instructions and safety precautions.

Additionally, here are some general guidelines for relieving fuel pressure in different vehicle systems:

Relieving Pressure with the Fuel Pressure Regulator:

- Disconnect the negative battery cable.

- Locate the fuel pressure regulator on the fuel rail.

- Remove the vacuum hose from the top of the regulator.

- Connect a hand-operated vacuum pump to push fuel back into the tank.

Relieving Pressure with the Fuel Pump Connector:

- Access the sending unit/fuel pump assembly, which may be located under the rear seat, in the trunk, or underneath the vehicle.

- If necessary, raise the rear of the vehicle using a floor jack and support it on jack stands.

- Remove the mounting screws on the fuel tank access door.

- Unplug the fuel pump electrical connector.

- Start the engine and let it idle until it stalls.

- Disconnect the negative battery cable.

Relieving Pressure with the Fuel Pump Fuse and Relay:

- Locate the fuel pump fuse, usually under the dashboard or in the engine compartment.

- Remove the fuse or the fuel pump relay.

- Start the engine and let it idle until it stalls.

- Disconnect the negative battery cable.

Relieving Pressure with the Ford Inertia Switch:

- Locate the inertia switch, typically found around the trunk, rear compartment, or under the dashboard.

- Unplug the electrical connector.

- Start the engine and let it run until it stalls.

- Disconnect the negative battery cable.

Relieving Pressure with the Test-Port Valve:

- Disconnect the negative battery cable.

- Locate the Schrader valve on the fuel rail around the top of the engine.

- Unscrew the valve cap if there is one.

- Depress the valve using a small screwdriver until fuel stops flowing.

- Replace the test-port valve cap.

Volvo Fuel Pressure Sensor: Location and Installation Guide

You may want to see also

The importance of proper fittings and clamps

When installing a fuel pressure gauge on a WRX STI, it is important to consider the proper fittings and clamps to ensure a safe and secure installation.

The fuel pressure gauge must be installed correctly, with the right fittings and clamps, to avoid fuel leaks and potential safety hazards. As one source states, "if installed incorrectly, the car may turn into a very expensive piece of firewood." It is crucial to use the correct fittings and clamps designed for fuel pressure gauge installation, ensuring they are compatible with the specific WRX STI model and its fuel line specifications.

The fittings and clamps play a critical role in maintaining a secure connection between the fuel line and the gauge. They ensure that the gauge is firmly attached and prevent fuel leaks during vehicle operation. Proper fittings, such as T-fittings or right-angle adapters, facilitate the connection of the gauge to the fuel rail, ensuring an accurate reading. Inaccurate readings can lead to incorrect adjustments, affecting engine performance and fuel efficiency.

Additionally, clamps like hose clamps or aero seal clamps are essential to secure the gauge and prevent it from moving or vibrating loose. Vibrations in the engine can cause connections to loosen over time, leading to potential leaks. Thus, it is crucial to select the appropriate clamps and ensure they are properly tightened to avoid such issues.

Furthermore, the use of proper fittings and clamps can also enhance the aesthetic appeal of the installation. Well-chosen fittings that are appropriately sized and scaled can contribute to a neat and professional appearance under the hood.

In conclusion, proper fittings and clamps are vital to the safe and effective installation of a fuel pressure gauge on a WRX STI. They ensure accurate readings, prevent leaks, enhance aesthetics, and ultimately contribute to the overall reliability and performance of the vehicle.

Understanding the Equinox: Fuel Tank Pressure in 2007 Models

You may want to see also

The use of a T-connector

The T-connector is a vital component when installing a fuel pressure gauge on a WRX STI. This adapter allows you to tap into the pressurised fuel line and get accurate pressure readings.

The T-connector, or T-fitting, is designed to be installed on the 8mm (5/16") fuel line of the WRX STI. It has two barbed fittings that thread into its side ports, and a 1/8-27 NPT female thread port for the fuel pressure gauge sensor. This setup ensures a secure and leak-free connection.

To install the T-connector, you will need to cut approximately one inch from your fuel line. Secure both ends of the cut line with the included hose clamps to prevent any fuel leakage. Then, firmly press the T-fitting into the cut ends until it is fully sealed. At this point, you can tighten the connection using the hose clamps.

It is crucial to ensure that the T-connector is installed correctly and securely. Improper installation may result in fuel leakage, which can be dangerous. Therefore, it is recommended to follow the manufacturer's instructions and take the necessary precautions during the installation process.

The T-connector provides a convenient and effective way to install a fuel pressure gauge on your WRX STI, allowing you to monitor fuel pressure and ensure the optimal performance of your vehicle.

Finding Fuel Pressure: 3406B Cat Inspection Guide

You may want to see also

The grounding of the tee fitting

Step 1: Purchase the Correct T-Fitting Adapter

Ensure you have the correct T-fitting adapter for your WRX STI. The adapter should match the size of your fuel line, which is typically 3/8" for most WRX STI models. You can find these adapters at automotive stores or online.

Step 2: Remove the Fuel Pump Fuse

Before beginning any work on the fuel system, it's crucial to relieve the pressure in the fuel line. To do this, locate the fuel pump fuse in your fuse box and remove it. Then, crank the engine for a short time to release any remaining pressure.

Step 3: Cut the Fuel Line

Using a tube cutter, carefully cut approximately one inch from your fuel line. This will create two open ends where you'll install the T-fitting. Make sure to measure twice and cut once to ensure accuracy.

Step 4: Install the T-Fitting

Take the T-fitting adapter and firmly press it into the two cut ends of the fuel line. Ensure it's seated fully and securely in place. You may need to use some muscle to get it in place.

Step 5: Secure with Hose Clamps

To ensure a leak-free connection, secure the T-fitting to the fuel line using the provided hose clamps. Tighten them down with a screwdriver or a clamp tool to ensure a firm connection.

Step 6: Ground the T-Fitting

Now, you need to ground the T-fitting to complete the circuit for the fuel pressure gauge. You can do this by fabricating an L-bracket and bolting it to a grounded part of the car's body or engine. Ensure a secure connection to the T-fitting, either by clamping or bolting.

Step 7: Connect the Fuel Pressure Sensor

With the T-fitting securely grounded, you can now connect your fuel pressure sensor. Thread the sensor into the port on the T-fitting adapter and tighten it down. Ensure it's seated correctly and won't come loose.

Step 8: Test the Setup

Once everything is connected, turn on the ignition and check for any leaks. Ensure that the fuel pressure gauge is functioning correctly and providing accurate readings. If there are no issues, your fuel pressure gauge installation is complete!

Remember, working on fuel systems can be dangerous, so always take the necessary precautions. If you're unsure about any steps, consult a professional mechanic.

Fuel Pressure Maintenance for the 1992 Acura Vigor

You may want to see also

Frequently asked questions

The best location to tap into a fuel pressure gauge is the supply hose between the fuel filter and the first rail.

RallySport Direct carries a large selection of pressure gauges, including those from Defi, STRI, ProSport, PERRIN, and AEM.

A fuel pressure gauge can help diagnose potential problems and prevent the driver from introducing issues for the engine. For example, if you are leaning out under a load, a fuel pressure gauge can indicate a potentially weak fuel pump before you melt your motor.