Fuel pressure is an essential part of a Mack truck's fuel injection system. It is important to regularly check the fuel pressure to prevent engine issues. Too high or too low fuel pressure can cause significant damage to the engine and other components of the truck. There are a few ways to check the fuel pressure, such as using a fuel pressure tester kit or a fuel pressure gauge. It is important to take necessary safety precautions when checking fuel pressure, such as wearing safety gear and working in a well-ventilated area.

What You'll Learn

Safety precautions

Checking the fuel pressure on a Mack Truck engine is an essential part of troubleshooting fuel injection issues. However, it is important to prioritize safety before attempting any diagnostic tests. Here are the safety precautions to follow:

Personal Protective Equipment:

- Wear safety glasses to protect your eyes from any fuel or debris.

- Put on gloves to minimize direct skin contact with fuel and to provide a secure grip when handling tools.

- Ensure you are wearing appropriate clothing that covers your body. Avoid wearing loose-fitting clothing that could get caught in moving parts.

Work Environment:

- Always work in a well-ventilated area to prevent the buildup of fuel vapors, which can be highly flammable.

- Keep the work area free from sparks or open flames. Do not smoke or bring any flammable materials near the truck when checking the fuel pressure.

- Make sure there is a fire extinguisher nearby in case of emergencies.

Fuel Handling:

- Fuel under pressure can cause injury if released accidentally. Be cautious when handling fuel lines and connections.

- Before starting any work, familiarize yourself with the fuel system components, including the location of the fuel pressure regulator, fuel pump, and fuel injectors.

- Always use a fuel pressure gauge specifically designed for automotive use. Do not use makeshift gauges or tools that are not designed for this purpose.

- Ensure that the fuel pressure gauge is securely attached to the Schrader valve before taking any readings.

Vehicle Preparation:

- Park the truck on a level surface and set the parking brake to prevent accidental movement.

- Before starting any engine work, make sure the engine is cool to the touch. This will reduce the risk of burns and prevent any potential issues with high-temperature components.

- Disconnect the battery negative terminal to prevent any accidental electrical shorts during the diagnosis.

Remember, working on a fuel system can be dangerous if the proper safety precautions are not followed. Always take your time, stay alert, and follow the recommended procedures to ensure your safety and the protection of those around you.

Fuel Pressure Regulator Fittings: Aeromotive Size Guide

You may want to see also

Checking fuel pressure

Checking the fuel pressure of your Mack truck is an essential part of troubleshooting any issues with the fuel injection system. Fuel pressure that is too high or too low can cause a range of problems, from engine weakness and dirty burning to engine deflagration and damage to the piston, piston rod, and connecting rod.

To check the fuel pressure, you will need to follow these steps:

Step 1: Safety First

Before performing any diagnostic tests, it is important to prioritize safety. Releasing fuel under pressure can cause fires and injuries. Wear safety glasses and gloves, ensure you are working in a well-ventilated area, and avoid smoking or having any objects nearby that could create a spark.

Step 2: Check Fuel Pressure

Start by starting the car and letting it idle. Install a fuel pressure gauge and run the pump, noting the pressure reading. Compare this reading to the manufacturer's specifications. If the pressure is low, this could indicate an issue that needs to be addressed.

Step 3: Perform a Fuel Volume Test

If the fuel pump is supplying sufficient pressure, the next step is to perform a fuel volume test to determine if the correct amount of fuel is being delivered to the fuel injectors. This can be done using a flowmeter or a glass measuring container.

Step 4: Collect a Fuel Sample

Start the car and let it idle. Collect a fuel sample for a specified period, typically around five seconds, with the pump running. Refer to the manufacturer's specifications to determine the expected fuel delivery rate and compare it to your collected sample to ensure your system is working correctly. You may need to convert units to make an accurate comparison.

By following these steps, you can effectively check the fuel pressure and volume in your Mack truck, helping to identify and troubleshoot any issues with the fuel system.

Locating the Fuel Pressure Regulator in a 99 Ford F150

You may want to see also

Comparing pressure to manufacturer specifications

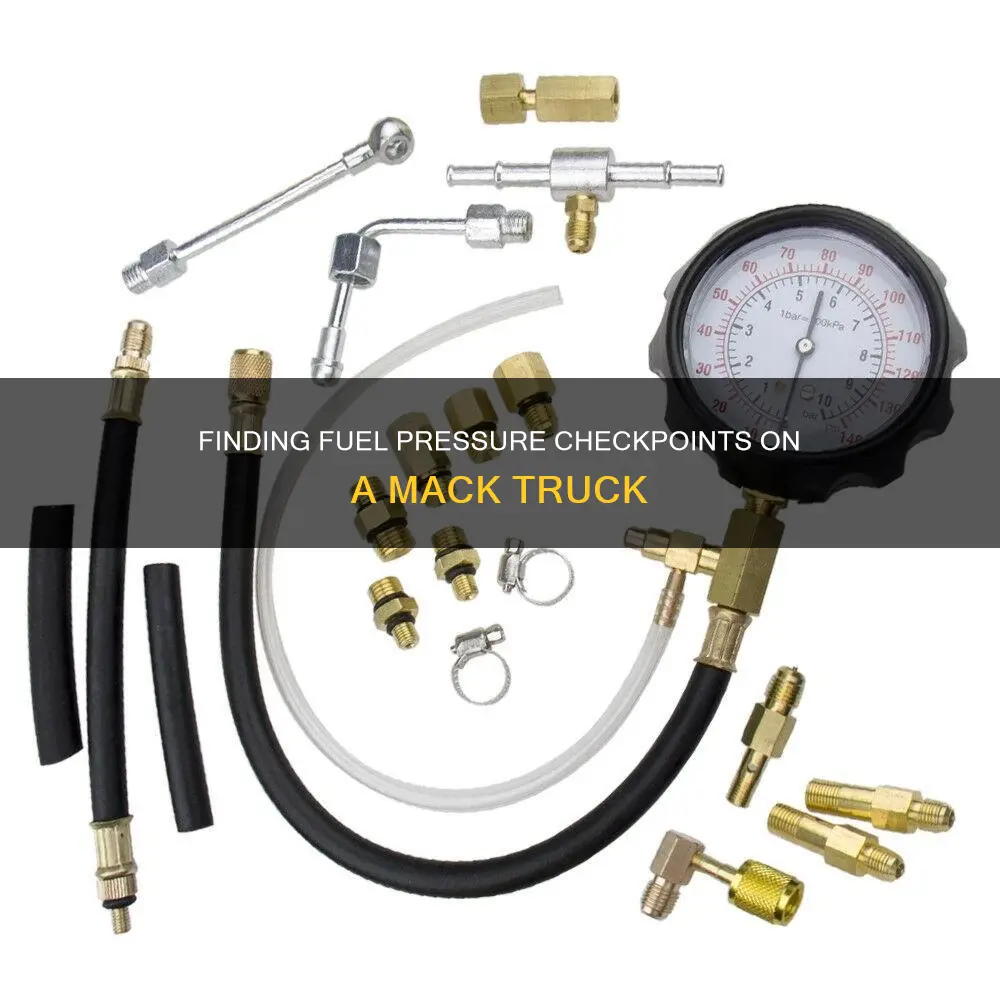

To compare fuel pressure to manufacturer specifications, you will need to obtain a fuel pressure tester kit. This kit will allow you to measure the fuel pressure in your Mack truck's engine, which is essential for troubleshooting any issues. Here is a step-by-step guide on how to compare fuel pressure to manufacturer specifications:

Step 1: Understand the Importance of Fuel Pressure

Firstly, it is important to understand that the correct fuel pressure is critical for the optimal performance of your Mack truck's engine. If the fuel pressure is too high, it can lead to engine weakness, increased carbon deposition, and tail gas exceeding standards. On the other hand, if the fuel pressure is too low, it can cause injector ablation, engine deflagration, and damage to the piston, piston rod, and connecting rod.

Step 2: Obtain a Fuel Pressure Tester Kit

Purchase a fuel pressure tester kit that is compatible with your Mack truck's engine. Make sure the kit has all the necessary fittings, a dual scale gauge (kPa & psi), and an easy-to-read display.

Step 3: Prepare for the Test

Before performing the fuel pressure test, refer to your Mack truck's repair manual for specific instructions and safety precautions. Ensure that you are wearing appropriate protective gear, such as safety goggles and gloves, to safeguard against any potential fuel leaks or spray. It is also advisable to have a fire extinguisher nearby when working with the fuel system.

Step 4: Locate the Fuel Pump Fuse and Relay

Find the fuel pump fuse and relay in your Mack truck's engine. This is usually located near the battery or in the engine compartment fuse box. Check the fuse for continuity and replace it if necessary. Test the relay for proper operation.

Step 5: Inspect Wiring Connections

Inspect the wiring connections for any signs of corrosion, damage, or loose connections. Ensure that all connections are secure and free of debris.

Step 6: Relieve Residual Fuel Pressure

Follow the safety precautions outlined in your repair manual to safely relieve residual fuel pressure. This step is crucial to reduce the risk of fire when opening the fuel line.

Step 7: Install the Fuel Pressure Gauge

Install the fuel pressure gauge at the appropriate location, as specified in your repair manual. Common locations include the fuel rail, fuel filter, or the cold start valve. Ensure that the gauge is securely connected.

Step 8: Start the Engine and Observe the Gauge Reading

With the fuel pressure gauge installed, start the engine and observe the reading on the gauge. Let the engine run for a few minutes to stabilize the fuel pressure.

Step 9: Compare the Reading to Manufacturer Specifications

Now, compare the fuel pressure reading from the gauge to the manufacturer's specifications for your specific Mack truck model and year. This information can usually be found in the owner's manual or repair manual.

Step 10: Interpret the Results

If the fuel pressure reading is within the manufacturer's specified range, your Mack truck's fuel system is functioning correctly. However, if the reading is higher or lower than the specified range, it indicates an issue with the fuel system. Common causes of fuel pressure issues include a faulty fuel pressure regulator, a clogged fuel filter, or a failing fuel pump.

By following these steps and comparing the fuel pressure reading to the manufacturer's specifications, you can effectively troubleshoot and diagnose any issues with your Mack truck's fuel system, ensuring optimal performance and preventing potential damage to the engine.

Troubleshooting Kubota ZD 331 Fuel Pressure Drop Issues

You may want to see also

Fuel volume test

The fuel pressure in a Mack truck's engine is an essential part of the fuel injection system and can cause a range of issues if it is too high or too low. A fuel pressure test can be carried out using a Mack Fuel Pressure Tester Kit, which includes all the fittings needed to tackle any problems. The kit is compatible with different models by selecting the year and version.

The fuel pressure tester kit has a dual-scale gauge that measures in kPa and psi, with a 3.5-inch display for easy reading. The case is durable and can be stored and moved easily.

To test fuel volume, you will need to locate the fuel filter and fuel lines. The fuel filter on a Mack truck is typically located on the frame rail on the driver's side, near the fuel tank. The fuel lines are the hoses that connect the fuel tank to the engine.

Once you have located the fuel filter and fuel lines, follow these steps:

- Disconnect the fuel lines from the fuel filter.

- Attach the fuel pressure tester kit to the fuel lines.

- Open the valve on the tester kit to allow fuel to flow into the gauge.

- Read the fuel pressure on the gauge.

- Compare the reading to the specified fuel pressure for your Mack truck model.

If the fuel pressure is too high or too low, you may need to adjust the fuel pump or replace the fuel filter. It is important to refer to the specific instructions and guidelines provided by Mack for your truck model.

It is also worth noting that fuel economy testing for trucks can be conducted in various ways, including on public roadways and closed test tracks. These tests are designed to simulate long-haul routes and measure fuel consumption using weigh tanks.

Fuel Pressure Requirements for the MK3 Supra Explained

You may want to see also

Using a flowmeter or glass measuring container

To check the fuel pressure on a Mack truck, you can use a flowmeter or a glass measuring container. Here's a step-by-step guide:

- Safety First: Releasing fuel under pressure can be dangerous, so always put safety first. Wear safety glasses and gloves, ensure you work in a well-ventilated area, and avoid any smoking or sparking objects nearby.

- Check Fuel Pressure: Start by starting the car and letting it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Compare this reading to the manufacturer's specifications. If the pressure is low, address this issue first.

- Use a Flowmeter or Glass Measuring Container: The most accurate way to test fuel delivery is by using a flowmeter. However, if you don't have access to a flowmeter, you can use a glass measuring container as fuel can corrode or fog up plastic.

- Collect a Fuel Sample: Start the car and let it idle. Collect a fuel sample for five seconds with the pump running. Refer to your manufacturer's specifications to determine the expected fuel delivery amount within this timeframe. You may need to convert units (e.g., milliliters per second to gallons per hour) for accurate comparison.

- Analyze Results: Compare the amount of fuel delivered by the pump with the manufacturer's specifications. If the pump is not delivering the right amount, there may be an issue with your fuel system.

By following these steps, you can safely and effectively check the fuel pressure on your Mack truck using a flowmeter or glass measuring container. Remember to prioritize safety and always refer to manufacturer guidelines for the most accurate information.

Finding the Fuel Pressure Sensor in a '99 Corvette

You may want to see also

Frequently asked questions

You can check the fuel pressure on your Mack truck by installing a fuel pressure gauge and running the pump to get a pressure reading.

If the pressure reading is low, you should address this issue.

If your Mack truck is not building up fuel pressure, it could be due to a failing fuel pump or a faulty fuel regulator. Check for leaks around the regulator and the vacuum line connected to it. Listen for any unusual noises from the fuel pump, such as excessive whining or an uneven whine.

Incorrect fuel pressure can lead to various issues. Too high fuel pressure can cause engine weakness, increased carbon deposition, and tail gas exceeding standards. Insufficient fuel pressure can lead to injector ablation, engine deflagration, and damage to the piston, piston rod, and connecting rod.