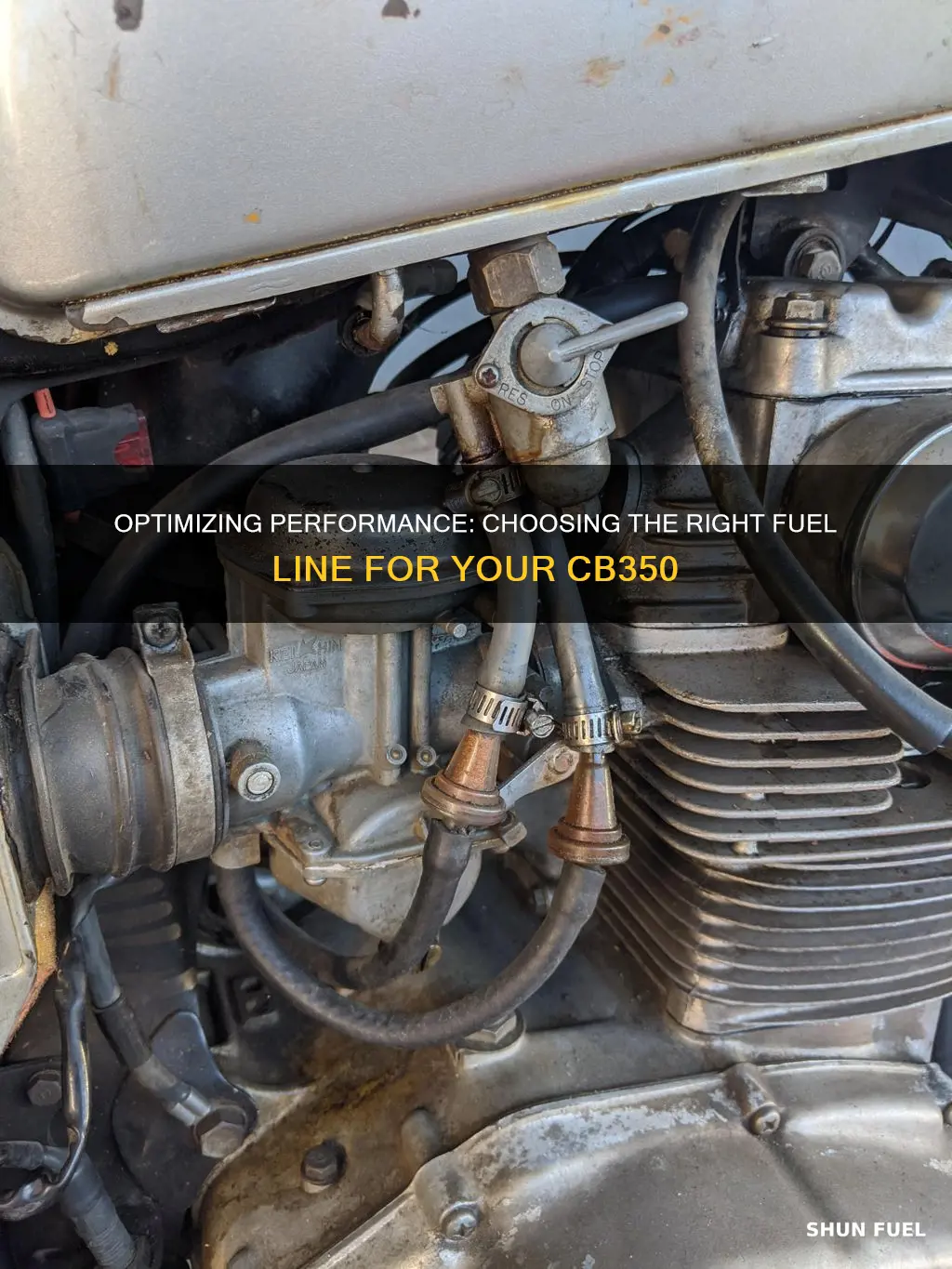

When it comes to your CB350, choosing the right fuel line size is crucial for optimal performance and reliability. The CB350, a classic motorcycle known for its powerful engine, requires a fuel line that can handle the demands of high-performance riding. The size of the fuel line determines how efficiently fuel is delivered to the engine, impacting acceleration, power, and overall engine health. Understanding the specific requirements of your CB350 model and selecting a fuel line that matches these needs is essential to ensure your motorcycle performs at its best. This guide will help you determine the appropriate fuel line size for your CB350, ensuring a smooth and powerful ride.

| Characteristics | Values |

|---|---|

| Engine Type | CB350 |

| Fuel Line Diameter | Typically 3/8" or 1/4" |

| Length | Varies based on the specific model and year of the CB350. Common lengths include 12", 18", 24", and 36" |

| Material | Steel, aluminum, or rubber |

| Pressure Rating | 50-75 psi for steel, 100-150 psi for aluminum |

| Compatibility | Designed for use with Honda CB350 engines |

| Installation | Requires careful routing and secure mounting to prevent damage |

| Maintenance | Regularly inspect for cracks, leaks, and wear |

What You'll Learn

- Fuel Line Diameter: Choose the correct diameter based on engine requirements and flow rate

- Material Compatibility: Ensure the material is compatible with fuel type (gasoline, ethanol, etc.)

- Length Considerations: Measure the distance from the fuel tank to the carburetor for accurate sizing

- Clamping Options: Select appropriate clamps for a secure and leak-free installation

- Pressure Rating: Opt for a line with sufficient pressure rating to handle engine demands

Fuel Line Diameter: Choose the correct diameter based on engine requirements and flow rate

When it comes to selecting the appropriate fuel line for your CB350, the diameter of the fuel line is a critical factor that directly impacts engine performance and reliability. The fuel line's diameter determines the flow rate of fuel, which in turn affects the engine's power output and overall efficiency. Here's a detailed guide on how to choose the correct fuel line diameter based on your engine's requirements and flow rate considerations.

The first step is to understand your CB350's engine specifications. Different engines have varying fuel requirements, and the flow rate of fuel needs to match these demands. For high-performance engines, a larger fuel line diameter is often necessary to ensure a steady and efficient fuel supply. This is especially true for engines with high compression ratios or those designed for racing applications. On the other hand, for standard or slightly modified engines, a smaller diameter might suffice, but it's crucial to consider the engine's power output and the desired performance level.

The flow rate, measured in liters per minute (L/min), is another critical factor. It represents the volume of fuel that needs to pass through the fuel line per minute. A higher flow rate typically requires a larger diameter fuel line to accommodate the increased volume of fuel. For instance, if your CB350's engine requires a fuel flow rate of 100 L/min, you would need a fuel line with a specific diameter to handle this volume efficiently.

To determine the correct diameter, you can refer to engine manuals or consult experts who can provide recommendations based on your specific engine model and modifications. Generally, a larger diameter fuel line (e.g., 6mm or 8mm) is preferred for high-performance applications, while a smaller diameter (e.g., 4mm or 5mm) might be suitable for standard engines. However, it's essential to consider the engine's design and the overall fuel system setup.

In summary, choosing the right fuel line diameter involves a careful balance between engine requirements and flow rate. For high-performance CB350s, a larger diameter fuel line is often recommended to ensure optimal fuel delivery. Conversely, standard engines may require a smaller diameter, but this decision should be made after considering the engine's power output and desired performance. Always consult relevant resources or experts to make an informed choice regarding fuel line diameter for your specific CB350 setup.

Visual Guide: Understanding the Appearance of a Fuel Line Clamp

You may want to see also

Material Compatibility: Ensure the material is compatible with fuel type (gasoline, ethanol, etc.)

When it comes to choosing the right fuel line for your CB350, material compatibility is a critical factor to consider, especially if you're dealing with different fuel types. The primary concern here is ensuring that the material of the fuel line can withstand the specific properties of the fuel it will carry. For instance, gasoline and ethanol are two common fuel types, each with distinct characteristics that can impact the choice of materials.

For gasoline, the primary consideration is the fuel's volatility and the potential for evaporation. Gasoline-compatible materials should be able to resist this volatility without compromising the integrity of the fuel line. Common materials used for gasoline-compatible fuel lines include high-density polyethylene (HDPE) and certain types of rubber, such as natural rubber or EPDM (ethylene propylene diene monomer) rubber. These materials are chosen for their ability to maintain flexibility and resistance to gasoline's corrosive effects over time.

Ethanol, on the other hand, is a more aggressive fuel that can cause issues for certain materials. Ethanol is more corrosive and can lead to degradation of some plastics and rubbers. Materials like HDPE, polypropylene (PP), and specific rubber compounds designed for ethanol resistance are ideal for ethanol-compatible fuel lines. These materials are engineered to withstand the higher alcohol content and provide a longer-lasting solution.

In addition to the fuel type, it's essential to consider the temperature range and operating conditions of your vehicle. Some materials may perform well in certain climates but struggle in extreme temperatures. For instance, in colder climates, you might need materials that remain flexible even when temperatures drop, ensuring the fuel line doesn't become brittle. Similarly, in hot climates, materials that can withstand higher temperatures without degrading are crucial.

To ensure compatibility, it's recommended to consult the manufacturer's guidelines or seek advice from automotive experts who can provide specific recommendations based on your vehicle's make and model, as well as the fuel type you intend to use. This ensures that you select the appropriate size and material for your CB350's fuel line, promoting optimal performance and longevity.

Fuel Injector Line Maintenance: Is Cleaning Necessary?

You may want to see also

Length Considerations: Measure the distance from the fuel tank to the carburetor for accurate sizing

When determining the appropriate fuel line size for your CB350, it's crucial to consider the distance between the fuel tank and the carburetor. This measurement is essential to ensure optimal fuel flow and performance. Here's a detailed guide on how to approach this:

Start by carefully examining the layout of your CB350's engine. Locate the fuel tank and identify its position relative to the carburetor. Understanding the physical layout will help you assess the potential challenges and requirements for fuel line installation. Measure the straight-line distance from the center of the fuel tank's fuel outlet to the carburetor's intake port. This measurement should be taken along the path the fuel line would take, ensuring you account for any bends or angles in the routing. Accurate measurements are key to selecting the right fuel line size.

The length of the fuel line is critical to maintaining the required pressure and flow rate. A fuel line that is too short may restrict fuel flow, leading to performance issues. Conversely, an overly long fuel line can cause pressure drops, affecting the carburetor's ability to atomize the fuel properly. Aim for a fuel line length that provides a balanced approach, ensuring efficient fuel delivery without unnecessary restrictions.

Consider the curvature of the fuel line as well. The line should follow a smooth, gentle curve to minimize stress on the material and reduce the risk of kinking. Avoid sharp bends that could restrict flow or damage the fuel line over time. The curvature should be gradual, allowing the fuel line to maintain its integrity and flexibility.

Additionally, take into account any existing fuel lines or routing constraints. If there are pre-existing fuel lines or other components in the way, you may need to adjust your measurements accordingly. Proper planning and consideration of these factors will ensure a seamless installation.

Remember, the goal is to create a fuel line setup that provides efficient and reliable fuel delivery to the carburetor. By carefully measuring the distance and considering the layout, curvature, and potential constraints, you can select the appropriate fuel line size for your CB350, optimizing its performance and longevity.

Quick Fuel Carb Fuel Line Sizing Guide

You may want to see also

Clamping Options: Select appropriate clamps for a secure and leak-free installation

When it comes to installing a fuel line on a CB350, choosing the right clamping options is crucial for a secure and leak-free setup. The CB350, a classic motorcycle known for its powerful engine, requires a reliable fuel system to ensure optimal performance. Here's a guide to help you select the appropriate clamps for your fuel line installation:

Understanding the Clamps: Clamps are essential components that hold the fuel line in place, providing a tight and secure connection to the fuel tank and the engine. The primary goal is to prevent leaks and ensure the fuel line remains in the desired position during the vehicle's operation. There are various types of clamps available, each with unique features and benefits.

Types of Clamps:

- Spring Clamps: These are commonly used and consist of a metal or plastic body with a spring-loaded jaw. The spring provides the necessary tension to grip the fuel line securely. Spring clamps are adjustable, allowing you to customize the clamping force to fit different fuel line diameters. They are versatile and can be used in various applications.

- V-Clamps: Also known as 'V-band' clamps, these feature a V-shaped jaw that provides a tight grip. V-clamps are often used for larger fuel lines and offer excellent holding power. They are typically made of durable materials like aluminum or stainless steel, ensuring longevity.

- Elbow Clamps: Designed for fuel lines that need to bend or turn, elbow clamps have a curved or angled jaw. These clamps are essential for routing the fuel line around various engine components. They provide a secure hold while allowing flexibility.

Selecting the Right Clamp: When choosing clamps for your CB350, consider the following factors:

- Fuel Line Diameter: Different fuel lines have specific diameters, and clamps should match this size for a proper fit. Measure the fuel line to ensure you select the correct clamp size.

- Material Compatibility: Ensure the clamp material is compatible with the fuel line material to avoid any adverse reactions or degradation over time.

- Clamping Force: Adjustability is key. Spring clamps, for instance, offer the ability to fine-tune the clamping force, ensuring a secure hold without causing damage to the fuel line.

- Environmental Conditions: Consider the operating environment. For high-temperature applications, choose clamps with heat-resistant materials. For outdoor use, opt for clamps that can withstand UV exposure and corrosion.

Installation Process:

- Start by cleaning the fuel line and ensuring it is free of debris.

- Cut the fuel line to the desired length and attach the chosen clamp.

- Slide the clamp onto the fuel line, ensuring it is centered and aligned with the fuel line's path.

- Tighten the clamp securely, but be careful not to overtighten, as it may damage the fuel line.

- Repeat the process for each section of the fuel line, ensuring a consistent and secure installation.

Remember, a well-clamped fuel line is essential for the CB350's performance and longevity. By selecting the appropriate clamps and following a careful installation process, you can ensure a leak-free and reliable fuel system.

Garden Tractor Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Pressure Rating: Opt for a line with sufficient pressure rating to handle engine demands

When it comes to choosing the right fuel line for your CB350, one of the most critical factors to consider is the pressure rating. This is especially important for high-performance engines, as it ensures that the fuel system can handle the demands of your bike's power output. The pressure rating of a fuel line determines its ability to withstand the force exerted by the fuel as it flows through the system.

In the context of the CB350, which is known for its powerful engine, you need a fuel line that can manage the increased pressure generated during acceleration and high-speed cruising. Insufficient pressure rating can lead to fuel pump failure, reduced performance, and even engine damage over time. Therefore, it's essential to select a fuel line that meets or exceeds the engine's requirements.

To determine the appropriate pressure rating, you should consult the manufacturer's specifications for your CB350. Different engines may have varying pressure needs, and it's crucial to match the fuel line's pressure rating to the engine's capabilities. For instance, if your CB350 has a high-performance fuel injection system, you'll likely require a fuel line with a higher pressure rating to ensure optimal fuel delivery.

Opting for a fuel line with a pressure rating that is too low can result in poor fuel atomization, leading to inefficient combustion and reduced power. Conversely, a line with an excessively high pressure rating might be overkill for your engine's needs, potentially causing unnecessary stress on the fuel system components.

In summary, when selecting a fuel line for your CB350, prioritize a pressure rating that aligns with the engine's demands. This ensures that your fuel system operates efficiently and reliably, providing the power and performance you expect from your motorcycle. Always refer to the manufacturer's guidelines to make an informed decision and ensure the longevity of your engine.

Marine Fuel Line: Choosing the Right Option for Your Boat

You may want to see also

Frequently asked questions

The ideal fuel line size for a CB350 is typically 3/8 inch in diameter. This size ensures efficient fuel delivery to the engine while maintaining flexibility and durability.

While using a larger fuel line might seem like an upgrade, it is generally not recommended. The CB350's fuel system is designed for the specific size of the 3/8-inch line, and larger lines can lead to fuel pressure issues and potential engine performance problems.

To check the size of your fuel line, you can use a simple measurement tool. Place the tool across the fuel line and measure the diameter. A 3/8-inch fuel line will have a diameter of approximately 0.875 inches. If your measurement differs, you may need to replace it with the recommended size.

For optimal performance and longevity, it is advised to use fuel lines made from high-quality materials like stainless steel or braided rubber. These materials offer excellent resistance to fuel degradation and can withstand the high temperatures and vibrations encountered in motorcycle engines.