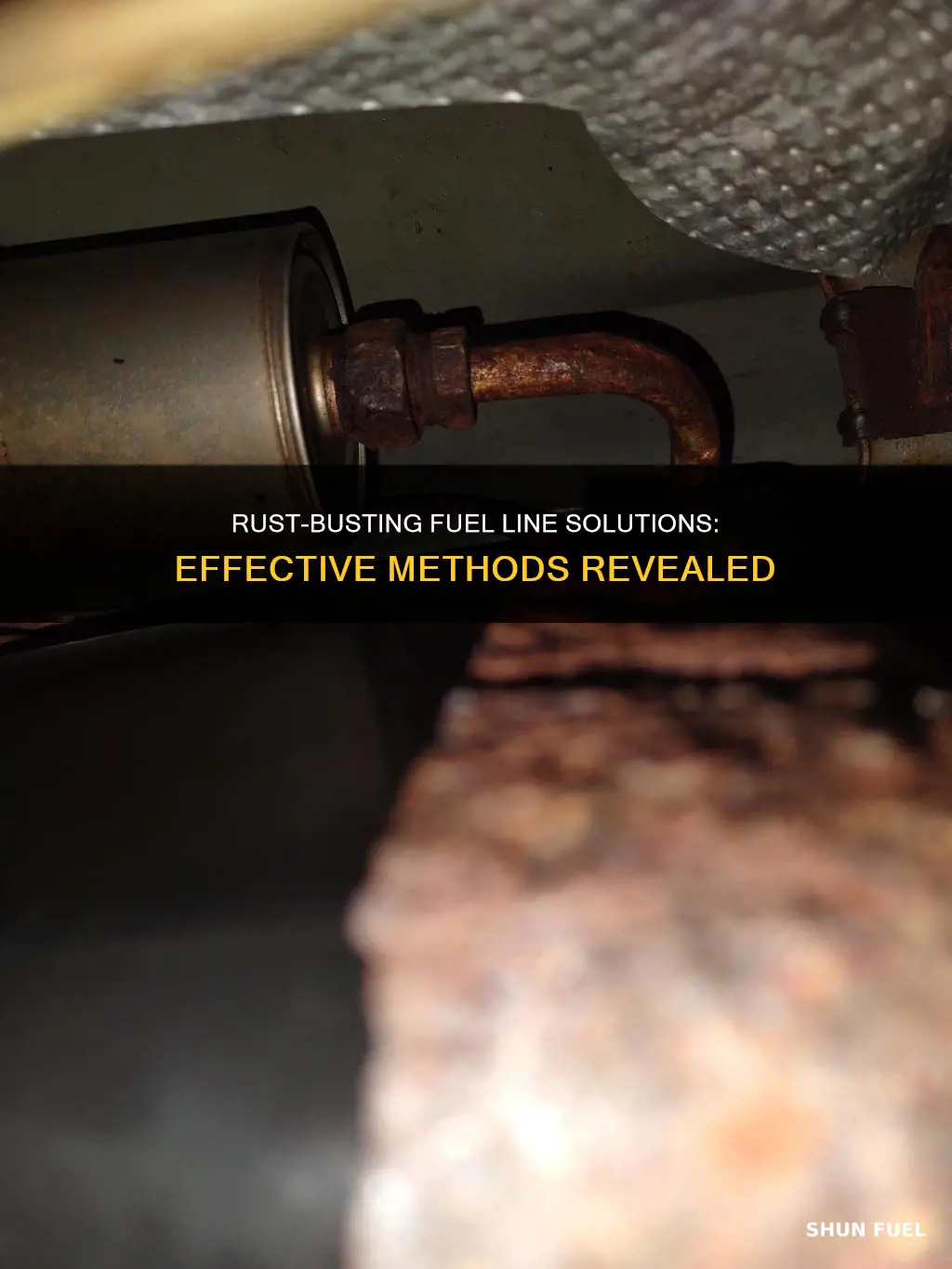

Rust in fuel lines can be a common issue for vehicle owners, especially those with older cars. It can lead to reduced fuel efficiency, engine performance issues, and even potential damage to the engine over time. To address this problem, various methods and products are available to remove rust from fuel lines. These methods range from simple household remedies to specialized cleaning solutions designed for automotive use. Understanding the different options and their effectiveness is crucial for vehicle owners to ensure their cars run smoothly and efficiently.

What You'll Learn

- Chemical Solvents: Use strong acids or bases to dissolve rust and scale

- Mechanical Cleaning: Scrub fuel lines with wire brushes to physically remove rust

- Ultrasonic Cleaning: Employ high-frequency sound waves to dislodge rust particles

- High-Pressure Water Jets: Blast rust with powerful water streams to remove deposits

- Rust Inhibitors: Add specialized coatings to prevent future rust formation in fuel lines

Chemical Solvents: Use strong acids or bases to dissolve rust and scale

When dealing with rust and scale buildup in fuel lines, chemical solvents can be an effective solution. These powerful agents can dissolve and remove the stubborn deposits, ensuring optimal fuel flow and performance. Here's an overview of the process and the chemicals involved:

Strong Acids: Acids, such as sulfuric acid (H₂SO₄) or hydrochloric acid (HCl), are potent tools for rust removal. These acids work by reacting with the iron oxide (rust) and dissolving it. When using acids, it's crucial to follow safety protocols. Wear protective gear, including gloves and goggles, to safeguard your skin and eyes. Start by flushing the fuel lines with water to remove any loose debris. Then, carefully introduce the acid into the system, ensuring it reaches the affected areas. Allow the acid to sit for a specified period, which can vary depending on the severity of the rust. After the recommended time, flush the lines again with water to neutralize the acid and remove any remaining rust particles.

Bases: Strong bases, like sodium hydroxide (NaOH) or potassium hydroxide (KOH), are another class of effective rust removers. These bases react with the rust and scale, breaking them down into soluble compounds. Similar to acid treatments, base solutions should be handled with care. Always wear protective gear and ensure proper ventilation. Begin by cleaning the fuel lines to remove any surface contaminants. Then, introduce the base solution, allowing it to circulate through the system. The duration of contact will depend on the extent of the rust. After the treatment, flush the lines to eliminate any residual chemicals.

It's important to note that while chemical solvents can be powerful, they should be used with caution. Always test these solutions on a small section of the fuel line first to ensure compatibility and avoid any potential damage. Additionally, consider the specific requirements of your fuel system and consult experts or manufacturers' guidelines for the best approach.

Remember, when dealing with chemicals, safety should always be the top priority. Proper ventilation, protective gear, and a well-defined procedure are essential to ensure a successful and safe rust removal process.

Unveiling the Mystery: Small Lines Behind Fuel Filter in Cadillac SRX

You may want to see also

Mechanical Cleaning: Scrub fuel lines with wire brushes to physically remove rust

Mechanical cleaning is a hands-on approach to tackling rust in fuel lines, and it involves a process that can be both effective and straightforward. This method is particularly useful for those who prefer a more traditional, physical approach to maintenance. Here's a step-by-step guide to mechanical cleaning using wire brushes:

Preparation: Before you begin, ensure you have the necessary tools and materials. You'll need a set of wire brushes with various sizes and shapes to accommodate different fuel line diameters. Common options include steel wool brushes and brass wire brushes, as brass is less likely to damage the fuel lines. Additionally, gather some cleaning solvent or fuel line cleaner, which will aid in the removal process.

Safety First: It's crucial to prioritize safety during this process. Wear protective gear, including gloves and safety goggles, to shield your hands and eyes from any potential debris or chemicals. Ensure the fuel lines are disconnected and the fuel supply is turned off to prevent any accidents or spills.

Scrubbing Process: Start by inserting the largest wire brush into the fuel line, ensuring it reaches the affected area. Apply firm, circular motions to scrub away the rust. Work your way along the length of the line, taking care not to force the brush if it encounters resistance. Rust is often stubborn, so patience is key. For more intricate areas, use smaller brushes to navigate around bends and tight spaces. The goal is to physically remove as much rust as possible.

Solvent Application: After mechanical scrubbing, apply the cleaning solvent or fuel line cleaner. This step helps to dissolve any remaining rust and prevents it from re-forming. Allow the solvent to sit for a few minutes, then rinse the fuel lines thoroughly with clean water to remove any residue.

Post-Cleaning Inspection: Once the cleaning is complete, inspect the fuel lines carefully. Check for any remaining rust or debris and repeat the scrubbing process if necessary. Ensure that all traces of rust are eliminated before reassembling the fuel lines and restoring normal operation.

Mechanical cleaning is a reliable method to restore fuel lines, especially for those who prefer a hands-on approach. It may require more time and effort compared to chemical alternatives, but it provides a thorough clean, ensuring the longevity and efficiency of the fuel system.

Ford Focus 2001 Fuel Line Breakdown: Essential Components Explained

You may want to see also

Ultrasonic Cleaning: Employ high-frequency sound waves to dislodge rust particles

Ultrasonic cleaning is a highly effective method for removing rust from fuel lines, offering a non-invasive and environmentally friendly approach. This technique utilizes the power of high-frequency sound waves to dislodge and remove rust particles from the interior walls of the fuel lines. The process is particularly useful for fuel lines that are difficult to access or where traditional cleaning methods may not be feasible.

The equipment required for ultrasonic cleaning includes an ultrasonic transducer, which generates the high-frequency sound waves, and a cleaning solution, typically a specialized detergent or a mixture of water and a rust-removing agent. The transducer is placed in contact with the fuel line, and the high-frequency sound waves are transmitted through the cleaning solution into the fuel line. These sound waves vibrate at a frequency that is beyond human hearing, typically ranging from 18,000 to 40,000 Hz.

As the sound waves travel through the fuel line, they create tiny bubbles and cavitations, which are essentially micro-explosions that occur when the sound waves cause the air in the solution to rapidly expand and contract. These cavitations dislodge rust particles from the fuel line walls, lifting them off the surface and allowing them to be washed away by the cleaning solution. The high-frequency sound waves also help to break down any rust-causing compounds, further enhancing the cleaning process.

One of the key advantages of ultrasonic cleaning is its ability to reach into tight spaces and crevices that are difficult to access with traditional cleaning methods. This makes it particularly useful for fuel lines, which often have complex shapes and narrow passages. The cleaning process is also highly efficient, as the sound waves can cover a large area in a short amount of time, making it a time-saving and cost-effective solution.

Additionally, ultrasonic cleaning is a gentle process that does not cause damage to the fuel line itself or the surrounding components. This is in contrast to some other cleaning methods that may use harsh chemicals or high-pressure water, which can potentially damage the fuel line or cause corrosion. The non-invasive nature of ultrasonic cleaning makes it a preferred choice for maintaining the integrity of the fuel system while effectively removing rust.

In summary, ultrasonic cleaning is a powerful and versatile technique for removing rust from fuel lines. Its ability to dislodge rust particles using high-frequency sound waves, coupled with its non-invasive nature and efficiency, makes it an ideal solution for maintaining the health and longevity of fuel systems in various applications.

Unleash Your OMC Cobra's Power: Discover Plastic Fuel Line's Role

You may want to see also

High-Pressure Water Jets: Blast rust with powerful water streams to remove deposits

High-pressure water jets are an incredibly effective method for removing rust and deposits from fuel lines, offering a powerful and non-invasive solution. This technique utilizes specialized equipment that generates extremely high-pressure water streams, capable of dislodging and flushing out even the most stubborn rust particles. The process is both efficient and environmentally friendly, making it a preferred choice for many professionals in the automotive and industrial sectors.

When dealing with rust in fuel lines, the primary concern is often the potential for damage to the fuel system and the engine. Rust can lead to blockages, reduced fuel flow, and even engine misfires. High-pressure water jets provide a comprehensive cleaning solution by directing a powerful stream of water at the affected areas. This high-pressure water can dislodge rust particles, loose debris, and other contaminants, ensuring a thorough cleaning. The water's force helps to break down and remove the rust, preventing it from spreading further and causing more damage.

The process typically involves the use of a specialized high-pressure water jetting machine, which is connected to a water supply and a high-pressure hose. The operator can control the pressure and direction of the water stream, allowing for precise application. This precision is crucial when dealing with fuel lines, as it ensures that the cleaning process is targeted and controlled, minimizing the risk of damage to the fuel lines themselves. The high-pressure water can be adjusted to suit the specific requirements of the job, making it adaptable for various fuel line sizes and conditions.

One of the key advantages of using high-pressure water jets is the ability to reach confined spaces and hard-to-access areas. Fuel lines often have intricate routes through an engine bay, and traditional cleaning methods may struggle to penetrate these narrow passages. High-pressure water jets can easily navigate these spaces, ensuring a thorough clean. This capability is particularly useful for older vehicles or those with complex fuel systems, where rust and deposits may have accumulated over time.

Additionally, this method is a cost-effective and time-efficient solution. Compared to other cleaning methods, high-pressure water jetting can quickly and effectively remove rust and deposits, reducing downtime for vehicles or machinery. The process is also versatile, making it suitable for a wide range of applications, from automotive maintenance to industrial cleaning. With its ability to provide a deep clean without causing damage, high-pressure water jetting is an invaluable tool for anyone looking to tackle rust and deposits in fuel lines.

Understanding Honda's Fuel Line Pulsation Dampener: A Comprehensive Guide

You may want to see also

Rust Inhibitors: Add specialized coatings to prevent future rust formation in fuel lines

Rust inhibitors are a crucial step in maintaining the health of fuel lines and preventing future corrosion. These specialized coatings are designed to create a protective barrier on the inner surface of the fuel lines, which helps to mitigate the effects of moisture and oxygen, the primary causes of rust formation. By applying these inhibitors, you can ensure that your fuel system remains in optimal condition, reducing the risk of performance issues and potential damage.

The process of using rust inhibitors is relatively straightforward and can be done as a preventive measure during routine maintenance. It involves the application of a specific coating or treatment directly onto the inner walls of the fuel lines. This coating acts as a barrier, preventing the metal surfaces from coming into direct contact with the corrosive elements in the fuel. There are various types of inhibitors available, including liquid solutions, gels, and even dry powders, each offering a unique approach to rust prevention.

When choosing a rust inhibitor, it's essential to consider the specific requirements of your fuel system. Different inhibitors are formulated to cater to various fuel types, such as gasoline or diesel, and different environmental conditions. Some inhibitors are designed to provide long-lasting protection, especially in harsher climates or for vehicles with higher mileage. It's recommended to consult the manufacturer's guidelines or seek professional advice to select the most suitable inhibitor for your needs.

Application methods can vary, but typically involve flushing the fuel lines with the inhibitor solution to ensure an even distribution. Some inhibitors might require multiple applications, especially for extensive corrosion, while others provide immediate and long-term protection with a single treatment. Regular use of rust inhibitors as part of a maintenance routine can significantly extend the lifespan of your fuel lines and overall vehicle performance.

In summary, rust inhibitors are a powerful tool in the fight against corrosion in fuel lines. By applying these specialized coatings, you create a protective shield that safeguards the metal surfaces from rust formation. This simple yet effective method ensures that your fuel system remains reliable and efficient, making it an essential practice for vehicle owners and fleet managers alike. Remember, regular maintenance and the use of appropriate inhibitors can save you from potential costly repairs and ensure a smooth driving experience.

Saab 01 Fuel Line: Return Line Mystery Solved

You may want to see also

Frequently asked questions

To effectively remove rust from fuel lines, a combination of mechanical cleaning and chemical treatment is recommended. Start by using a wire brush or a specialized fuel line brush to physically remove loose rust and debris. Then, apply a rust remover or a fuel line cleaner specifically designed for this purpose. These products often contain acids that dissolve rust and corrosion. Ensure you follow the manufacturer's instructions for application and safety precautions.

While vinegar is a natural acid and can help dissolve some rust, it may not be the most effective or safe option for fuel lines. Vinegar is mild and might not penetrate deep rust deposits. Additionally, it can be corrosive to certain materials in the fuel system. For better results and safety, consider using a dedicated fuel line cleaner or a rust removal product designed for automotive use.

Preventing rust buildup involves regular maintenance and the use of clean fuel. Ensure you use a fuel stabilizer in your fuel tank to prevent corrosion in the fuel system. Regularly check and replace fuel filters to keep contaminants and moisture out of the lines. Keeping the fuel tank full can also minimize the exposure of metal surfaces to air, which can reduce rust formation.

Yes, there are several DIY methods you can try. One popular method is the use of a baking soda and vinegar mixture. Mix baking soda and vinegar to form a paste, then apply it to the rusted areas and let it sit for a while before scrubbing and rinsing. This natural approach can be effective for light rust, but for more severe cases, consider professional-grade cleaning products.

Driving a vehicle with rusted fuel lines is not recommended. Rust can lead to blockages, reduced fuel flow, and potential engine damage. It's essential to address the issue promptly. If you suspect rust in your fuel lines, consult a professional mechanic who can safely clean and repair the lines, ensuring optimal engine performance and longevity.