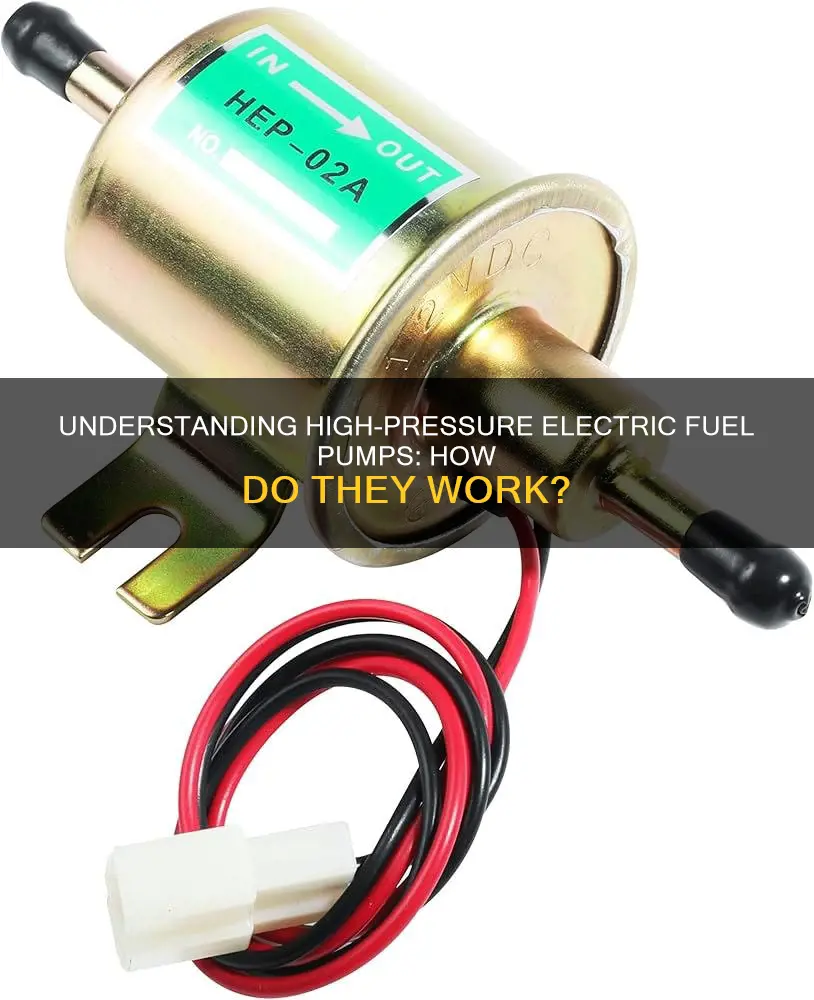

High-pressure electric fuel pumps are used in fuel-injected engines to transfer fuel from the tank to the engine. They are typically located inside the fuel tank and are responsible for supplying and injecting fuel, maintaining appropriate pressure, and protecting the normal operation of the fuel system. They are crucial for engine performance, fuel economy, and emission control.

What You'll Learn

- A high-pressure electric fuel pump can be used in direct petrol injection engines

- It draws fuel from the fuel tank and delivers it to the combustion chamber

- It maintains the pressure in the engine fuel system

- It injects fuel at high pressure into the engine's combustion chamber

- It protects the fuel system by filtering out impurities and particles

A high-pressure electric fuel pump can be used in direct petrol injection engines

A high-pressure electric fuel pump is a crucial component in the engine fuel system of a direct petrol injection engine. It is responsible for supplying and injecting fuel, maintaining appropriate pressure, and protecting the normal operation of the fuel system.

In a direct petrol injection engine, the fuel system is made up of a low-pressure system and a high-pressure circuit. The low-pressure circuit includes an electrical fuel pump that draws fuel from the tank and conveys it to the high-pressure pump. The high-pressure pump then compresses the fuel and makes it available in the fuel distribution pipe (also known as the rail).

The high-pressure electric fuel pump plays a critical role in this system by ensuring the fuel is supplied to the engine at a sufficient pressure for injection and combustion. It also helps maintain stability and accuracy in fuel injection, leading to optimal combustion effects and engine performance. Additionally, the pump protects the fuel system by filtering out impurities and particles, and monitoring the operation status through pressure sensors and control devices.

The use of a high-pressure electric fuel pump in direct petrol injection engines offers several advantages. Firstly, it enables fuel injection at high pressure, which is necessary for the normal operation of the engine. Secondly, it provides pressure regulation, ensuring that the fuel system maintains the appropriate pressure for stable and accurate fuel injection. Thirdly, it protects the fuel system by filtering out impurities and monitoring the operation through sensors and control devices. Finally, by locating the electric pump inside the fuel tank, the pump can be cooled by the surrounding fuel, and the risk of fire is reduced as liquid fuel without oxygen is not flammable.

Overall, the high-pressure electric fuel pump is a vital component for engine performance, fuel economy, and emission control in direct petrol injection engines.

Understanding Fuel Pressure Regulators: Appearance and Functionality

You may want to see also

It draws fuel from the fuel tank and delivers it to the combustion chamber

A high-pressure electric fuel pump is a crucial component of an engine's fuel system. One of its primary functions is to draw fuel from the fuel tank and deliver it to the combustion chamber of the engine. Here is a detailed explanation of this process:

The high-pressure electric fuel pump is responsible for creating sufficient pressure to draw fuel from the tank and push it towards the combustion chamber. This process involves the pump increasing the pressure of the fuel to ensure it can overcome any resistance in the fuel lines and reach the engine. This is especially important in modern fuel-injected engines, where the fuel must be injected at high pressure into the combustion chamber.

The pump's ability to create high pressure ensures that fuel is delivered efficiently to the engine, regardless of the distance between the fuel tank and the engine or any changes in elevation. This is a significant improvement over gravity-feed systems, where the fuel tank must be mounted higher than the engine to utilise gravity for fuel delivery.

Once the fuel is drawn from the tank, it is crucial to maintain appropriate pressure as it travels through the fuel lines. The high-pressure electric fuel pump plays a vital role in this aspect by constantly regulating the pressure. It achieves this by controlling the supply and pressure of the fuel, ensuring it remains within an optimal range. This regulation helps maintain the stability and accuracy of fuel injection, as well as achieving the best combustion effect.

As the fuel travels through the fuel lines towards the combustion chamber, impurities and particles may be present. The high-pressure electric fuel pump addresses this issue by filtering out these contaminants. This function is critical for protecting the engine, as it prevents impurities from entering and causing damage. Additionally, the pump can detect abnormal conditions through pressure sensors and other control devices, further ensuring the fuel's integrity.

Upon reaching the combustion chamber, the fuel must be injected at the right moment and with precise control. The high-pressure electric fuel pump facilitates this process by injecting the fuel at high pressure into the chamber. This injection ensures the fuel can be fully burned, providing the required power and driving force for the engine. The pump's ability to deliver fuel at high pressure enables a more efficient and complete combustion process, enhancing the engine's overall performance.

Understanding Diesel Fuel Pressure Regulators: Their Critical Function Explained

You may want to see also

It maintains the pressure in the engine fuel system

The high-pressure fuel pump is a critical component of the engine fuel system, responsible for maintaining appropriate pressure to ensure the stability and accuracy of fuel injection and the best combustion effect.

The pump achieves this by controlling the supply and pressure of the fuel. The engine control unit monitors the fuel pressure via a pressure sensor and regulates it via a flow control valve installed in the pump. This demand-based control means that only the high pressure that is actually needed for the current operating situation is generated in the pump.

The high-pressure fuel pump is driven mechanically via the camshaft, so its delivery rate is proportional to the engine speed. The pump compresses the fuel provided by the pre-feed pump to the fuel pressure required for the injection valves.

The high-pressure circuit is always tested after the low-pressure circuit, and the target value for the fuel system high pressure is 40-120 bar, depending on the operating status.

Understanding the Role of Fuel Pressure Regulator Valves

You may want to see also

It injects fuel at high pressure into the engine's combustion chamber

The high-pressure electric fuel pump is a crucial component of the engine fuel system. It injects fuel at high pressure into the engine's combustion chamber, which is essential for the normal operation of the engine.

The pump draws fuel from the fuel tank and delivers it to the combustion chamber, creating sufficient pressure to push the fuel into the fuel injector or injection device. This process ensures that the fuel can be fully burned to provide the required power and driving force for the engine.

The high-pressure electric fuel pump also plays a critical role in protecting the fuel system. It filters out impurities and particles, preventing them from entering the engine and causing damage. Additionally, the pump can monitor the operation status of the fuel system through pressure sensors and other control devices, detecting and reporting any abnormal conditions.

The pump's ability to maintain the pressure in the engine fuel system within an appropriate range is another important function. By controlling the supply and pressure of fuel, the pump ensures stability and accuracy in fuel injection, leading to the best combustion effect.

Overall, the high-pressure electric fuel pump is responsible for supplying and injecting fuel, maintaining appropriate pressure, and protecting the normal operation of the fuel system. It plays a vital role in engine performance, fuel economy, and emission control.

Understanding the Audi A4 Fuel Pressure Sensor's Function

You may want to see also

It protects the fuel system by filtering out impurities and particles

A high-pressure electric fuel pump plays a crucial role in an engine's fuel system. One of its main functions is to protect the fuel system by filtering out impurities and particles. This is essential for preventing damage to the engine.

The pump achieves this by drawing fuel from the fuel tank and delivering it to the combustion chamber of the engine. This process involves creating sufficient pressure to push the fuel through the fuel injector or injection device.

By regulating the supply and pressure of the fuel, the high-pressure electric fuel pump maintains the appropriate range of pressure in the engine fuel system. This ensures the stability and accuracy of fuel injection, as well as optimal combustion.

Additionally, the pump can monitor the operation status of the fuel system through pressure sensors and other control devices. It can detect and report any abnormal conditions, such as severe mechanical strain, high fuel pressures, lack of lubricant, or temperature differences that may lead to wear and tear over time.

Overall, the role of the high-pressure electric fuel pump in filtering out impurities and particles is vital for maintaining the performance, fuel economy, and emission control of the engine.

Understanding the Role of Fuel Injector Pressure Dampers

You may want to see also

Frequently asked questions

A high-pressure electric fuel pump is a component used in liquid-fuelled engines to transfer fuel from the tank to the engine. It is used in fuel-injected engines and is located inside the fuel tank.

The pump draws fuel from the fuel tank and delivers it to the combustion chamber of the engine. It creates sufficient pressure to push fuel into the fuel injector and complete the fuel injection and combustion cycles.

A regular fuel pump is often a low-pressure mechanical pump mounted on the engine. A high-pressure fuel pump, on the other hand, is used in fuel-injected engines and is located inside the fuel tank. It operates at a much higher pressure, up to 30,000 psi.

A high-pressure electric fuel pump offers several benefits, including improved fuel supply, pressure regulation, fuel injection, and fuel system protection. It ensures that the fuel is fully burned, providing the required power and driving force for the engine.

There are several signs that may indicate a defective high-pressure fuel pump, including erratic engine running, lack of power in the upper speed range, poor starting behaviour, and the engine stopping unexpectedly with the warning light coming on. If you experience any of these issues, it is recommended to have the pump checked and replaced if necessary.