Military-style fuel lines are an essential component of any vehicle's fuel system, especially in military and off-road applications. These fuel lines are designed to withstand harsh conditions and provide a reliable fuel supply to the engine. They are typically made from durable materials such as high-pressure hoses and are often reinforced with layers of protective covering to ensure they can handle extreme temperatures, vibrations, and impacts. The design and construction of these fuel lines prioritize safety, efficiency, and longevity, making them a critical part of any vehicle's performance and reliability, particularly in demanding environments.

What You'll Learn

- Materials: Military-grade fuel lines are made from durable materials like high-strength polymers and braids

- Design: These lines feature a flexible, lightweight design with reinforced layers for strength

- Performance: Military fuel lines maintain performance in extreme conditions, including high temperatures and vibrations

- Compatibility: They are designed to fit various fuel tanks and engines, ensuring a secure connection

- Maintenance: Regular inspection and maintenance are crucial to ensure the lines remain in optimal condition

Materials: Military-grade fuel lines are made from durable materials like high-strength polymers and braids

Military-grade fuel lines are an essential component of any vehicle's fuel system, especially in high-performance and military applications. These fuel lines are designed to withstand extreme conditions and provide a reliable and efficient fuel supply to the engine. The primary focus of these fuel lines is to ensure that the fuel is delivered under pressure to the engine without any leaks or loss of performance.

The materials used in manufacturing military-grade fuel lines are of utmost importance to their durability and performance. High-strength polymers are a key component, offering exceptional resistance to wear and tear. These polymers are engineered to handle the rigorous demands of military operations and racing environments. The use of polymers ensures that the fuel lines can withstand high temperatures, chemical exposure, and mechanical stress without compromising their structural integrity.

Braiding is another critical aspect of these fuel lines' construction. By braiding the polymers, the fuel lines become more flexible and resistant to kinking. This flexibility is crucial for navigating through tight spaces and complex engine layouts, ensuring a secure and reliable connection. The braiding technique also helps distribute the material evenly, providing uniform strength and durability along the entire length of the fuel line.

The combination of high-strength polymers and braiding results in fuel lines that are not only durable but also lightweight. This lightweight design is advantageous in military vehicles, where every gram of weight reduction can significantly improve performance and fuel efficiency. The reduced weight also contributes to better handling and overall vehicle agility.

In summary, military-grade fuel lines are engineered with specific materials to meet the demanding requirements of their intended use. The use of high-strength polymers and braiding techniques ensures that these fuel lines are robust, flexible, and capable of withstanding the harshest environments. This level of durability and performance is essential for maintaining a consistent and reliable fuel supply, especially in critical military and racing applications.

Unveiling the Secrets: Red Line Fuel System Explained

You may want to see also

Design: These lines feature a flexible, lightweight design with reinforced layers for strength

Military-style fuel lines are an essential component in the design and functionality of fuel systems, particularly in high-performance vehicles and aircraft. These fuel lines are engineered with a specific focus on durability, flexibility, and strength, ensuring they can withstand the rigorous demands of military and aviation applications. The design philosophy behind these fuel lines is to create a lightweight yet robust solution that can handle extreme conditions, including high-pressure environments and rapid acceleration.

The key feature that sets military-style fuel lines apart is their flexible and lightweight construction. Traditional fuel lines often use rigid materials that can become brittle over time, especially in harsh operating conditions. In contrast, these lines are crafted from advanced materials that offer superior flexibility, allowing them to navigate through tight spaces and complex engine architectures without compromising performance. This flexibility is crucial for maintaining a secure and reliable fuel supply, especially in high-stress scenarios.

Reinforced layers are an integral part of the design, providing enhanced strength and durability. These layers are strategically placed to reinforce critical areas, such as the connections and bends, where fuel lines are most susceptible to damage. By using high-strength materials and innovative reinforcement techniques, the fuel lines can withstand the forces exerted by high-pressure fuel, vibrations, and potential impacts. This reinforcement ensures that the fuel lines remain intact and functional even in the most demanding situations.

The lightweight aspect of the design is achieved through the use of advanced materials and manufacturing processes. By reducing the weight of the fuel lines, engineers can improve overall system efficiency and performance. Lighter fuel lines contribute to better handling and acceleration, especially in aircraft, where every pound matters. This design consideration is particularly important in military applications, where vehicles and aircraft need to be agile and responsive in dynamic environments.

In summary, military-style fuel lines are designed with a unique blend of flexibility, lightweight construction, and reinforced strength. This combination ensures that the fuel lines can endure the extreme conditions encountered in military and aviation operations while maintaining a reliable fuel supply. The advanced design philosophy behind these fuel lines showcases a commitment to performance, safety, and durability, making them an indispensable component in the power and performance of modern vehicles and aircraft.

Ford Focus 2001 Fuel Line Breakdown: Essential Components Explained

You may want to see also

Performance: Military fuel lines maintain performance in extreme conditions, including high temperatures and vibrations

Military-style fuel lines are an essential component of any vehicle or equipment used in harsh environments, especially those exposed to extreme conditions. These fuel lines are designed to withstand the rigors of military operations, ensuring optimal performance even in the most challenging circumstances. One of the key aspects of their performance is the ability to maintain functionality under severe temperature variations. High temperatures, often encountered in desert warfare or during intense training exercises, can cause traditional fuel lines to degrade and lose their structural integrity. Military-grade fuel lines, however, are constructed with materials that can endure these extreme heat conditions, preventing leaks and maintaining the flow of fuel to the engine. This is crucial for the continuous operation of vehicles and equipment, especially in critical missions where reliability is paramount.

Vibrations and shocks are another set of challenges that military fuel lines are engineered to overcome. In off-road vehicles or aircraft, fuel lines must withstand the constant vibrations and movements during operation. Military-style fuel lines are typically made with flexible yet robust materials that can absorb and distribute these mechanical stresses without compromising the integrity of the fuel system. This level of durability ensures that fuel remains contained and is delivered efficiently to the engine, even when the vehicle is subjected to rough terrain or rapid maneuvers.

The performance of military fuel lines is further enhanced by their resistance to corrosion and chemical degradation. In outdoor environments, exposure to moisture, dirt, and various chemicals can lead to the deterioration of fuel lines over time. Military-grade fuel lines are treated with protective coatings and materials that prevent corrosion, ensuring long-term reliability. This is particularly important in applications where fuel lines are exposed to the elements for extended periods, requiring them to maintain performance consistently.

In addition to their ability to withstand extreme conditions, military fuel lines are also designed with ease of installation and maintenance in mind. This is crucial for operational efficiency, as it allows for quick replacements or repairs in the field. The lines are often equipped with quick-connect fittings and are manufactured to precise specifications, ensuring a secure and reliable connection to the fuel tank and engine. This ease of maintenance contributes to the overall reliability of the fuel system, even in the most demanding operational scenarios.

In summary, military-style fuel lines are engineered to excel in performance under extreme conditions. Their ability to maintain functionality in high temperatures and vibrations, coupled with resistance to corrosion and ease of maintenance, makes them indispensable in military and industrial applications. These fuel lines are a testament to the rigorous testing and development processes that ensure the reliability and safety of critical systems in harsh environments.

Understanding Fuel Lines in Kerbal Space Program (KSP)

You may want to see also

Compatibility: They are designed to fit various fuel tanks and engines, ensuring a secure connection

Military-style fuel lines are an essential component in the automotive and aviation industries, particularly for applications that require robust and reliable fuel delivery systems. These fuel lines are designed with a specific focus on compatibility, ensuring they can seamlessly integrate into a wide range of fuel tanks and engines. This compatibility is a key feature that sets military-style fuel lines apart from standard lines, making them a preferred choice for demanding environments.

The design philosophy behind these fuel lines emphasizes durability and flexibility. They are constructed using high-quality materials that can withstand extreme conditions, including high temperatures, pressure variations, and exposure to harsh chemicals. This robust construction ensures that the fuel lines remain intact and functional even in the most challenging environments, such as military operations or high-performance racing. The flexibility of these lines allows for easy routing and installation, accommodating various fuel tank and engine configurations without compromising on performance.

One of the critical aspects of military-style fuel lines is their ability to provide a secure connection. The lines are engineered with specialized fittings and connectors that ensure a tight and leak-proof seal. This secure connection is vital to prevent fuel leaks, which can be dangerous and detrimental to the performance of the vehicle or aircraft. By using precision-engineered fittings, these fuel lines maintain a reliable and consistent fuel supply, even under intense operational conditions.

In addition to their compatibility and secure connections, military-style fuel lines often feature a protective outer layer or sheath. This protective covering shields the inner fuel line from potential damage caused by abrasion, impact, or exposure to harsh weather conditions. The sheath provides an extra layer of durability, ensuring the fuel lines remain intact and functional over extended periods of use.

The versatility of military-style fuel lines makes them an ideal choice for a variety of applications. They are commonly used in military vehicles, aircraft, and high-performance racing cars, where reliability and performance are critical. These fuel lines can also be adapted for use in marine environments, off-road vehicles, and even in industrial settings where fuel delivery systems require maximum durability and flexibility. By offering a secure and compatible solution, these fuel lines ensure that fuel is delivered efficiently and safely, even in the most demanding circumstances.

Understanding the Choke Fuel Line: A Car's Essential Component

You may want to see also

Maintenance: Regular inspection and maintenance are crucial to ensure the lines remain in optimal condition

Military-style fuel lines are an essential component of any vehicle's fuel system, especially in high-performance or military applications. These lines are designed to withstand rigorous conditions, including extreme temperatures, vibrations, and pressure. Regular maintenance and inspections are critical to ensuring their longevity and optimal performance.

The primary purpose of these fuel lines is to deliver fuel from the tank to the engine while maintaining a secure and reliable connection. Over time, fuel lines can deteriorate due to various factors such as fuel contamination, environmental conditions, and mechanical stress. Therefore, a proactive maintenance approach is vital to prevent potential issues.

Maintenance protocols should include routine visual inspections to identify any signs of damage, corrosion, or deterioration. Inspectors should look for cracks, leaks, or any unusual wear and tear. It is recommended to use specialized tools and equipment to measure the pressure and flexibility of the fuel lines, ensuring they meet the required specifications. Regular cleaning and lubrication of the connections can also prevent rust and ensure a tight seal.

In addition to visual inspections, it is essential to check the fuel lines' condition during routine engine maintenance. This includes inspecting the fuel filter, as a clogged filter can put additional strain on the fuel lines. Regularly replacing worn-out components and keeping the fuel system clean will contribute to the overall health of the fuel lines.

For military or high-performance vehicles, where fuel efficiency and reliability are critical, adhering to a strict maintenance schedule is non-negotiable. By implementing regular inspection and maintenance practices, operators can ensure that the fuel lines remain in top condition, reducing the risk of fuel-related issues and enhancing the overall performance and safety of the vehicle.

E85 Fuel Line Maintenance: What to Flush and Why

You may want to see also

Frequently asked questions

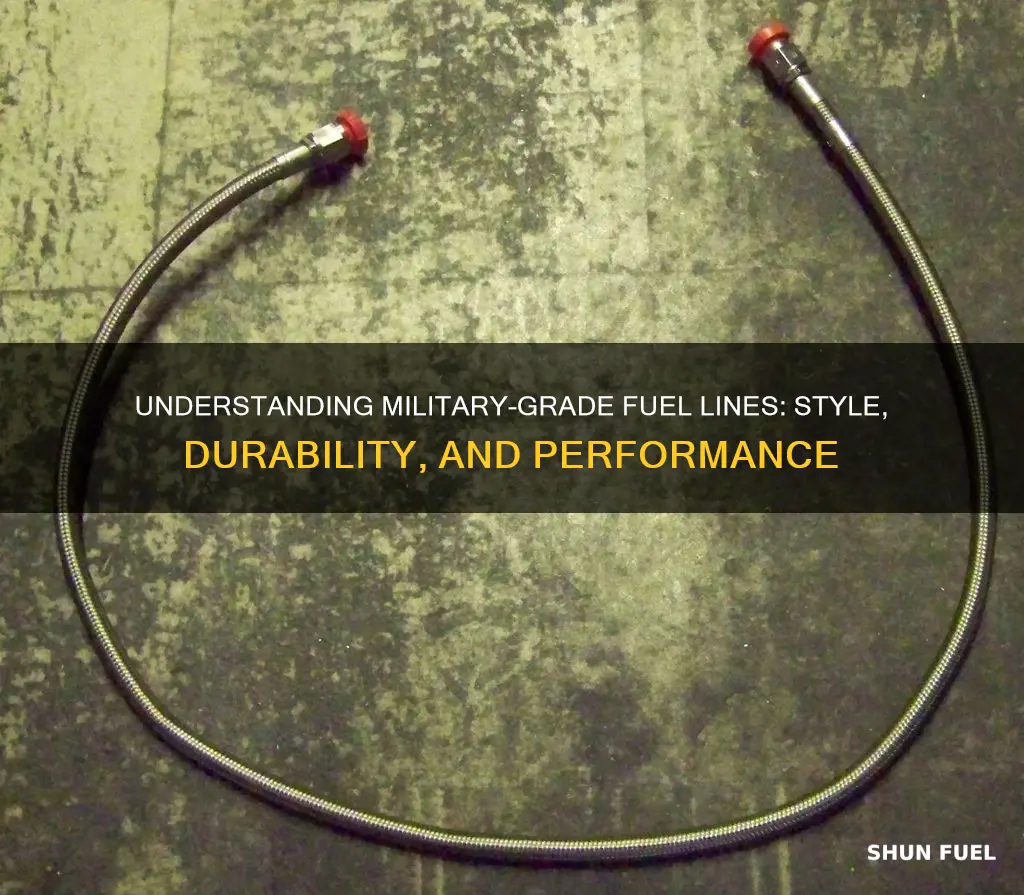

Military-style fuel lines are a type of fuel line system designed to meet the rigorous demands of military applications, such as aircraft, vehicles, and marine engines. These fuel lines are known for their durability, flexibility, and ability to withstand extreme conditions, including high temperatures, vibrations, and exposure to fuel contaminants. They are often constructed with high-quality materials like stainless steel or braided nylon, ensuring long-lasting performance and reliability.

Military-style fuel lines offer several advantages over standard fuel lines. Firstly, they are built to last longer due to their reinforced construction and resistance to corrosion. These fuel lines can handle higher pressure and temperature fluctuations, making them ideal for high-performance engines. Additionally, military-style fuel lines often feature a more flexible design, allowing for easier installation and routing in tight spaces. The materials used are often more resistant to fuel degradation, ensuring a longer lifespan and reduced risk of fuel leaks.

Military-style fuel lines are generally designed to be compatible with various fuel types, including gasoline, diesel, and aviation fuels. However, it's essential to choose the appropriate fuel line material based on the specific fuel being used. For example, aviation fuel lines might require a different material to withstand the unique properties of aviation gasoline. Always refer to the manufacturer's guidelines or consult an expert to ensure the correct fuel line material is selected for your application.