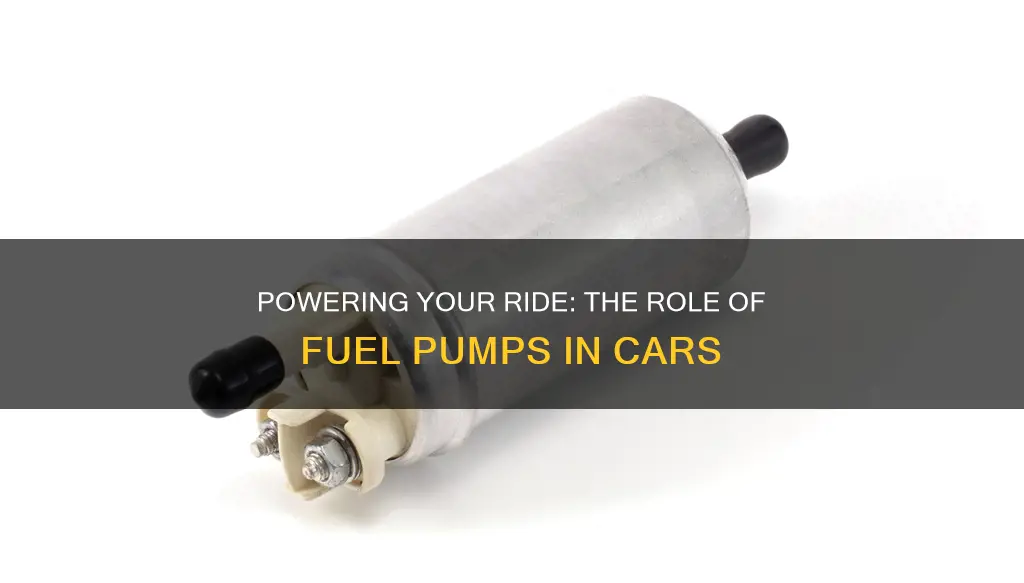

A fuel pump is a crucial component in a car's engine system, responsible for delivering fuel from the tank to the engine. It ensures a steady and controlled supply of fuel, which is essential for the engine to run efficiently. The pump's primary function is to maintain the correct fuel pressure, allowing the engine to ignite the fuel-air mixture and power the vehicle. Without a properly functioning fuel pump, a car may experience poor performance, reduced fuel efficiency, and even engine failure. Understanding the role of the fuel pump is key to maintaining a vehicle's optimal performance and longevity.

What You'll Learn

- Fuel Pumps Deliver Gasoline to Engine: Pumps move fuel from the tank to the engine, enabling combustion

- Pressure Regulation: Maintains optimal fuel pressure for efficient engine operation and performance

- Fuel Injection Control: Regulates fuel injection timing and quantity for precise engine management

- Prevent Engine Stalling: Ensures a steady fuel supply, preventing engine stalls and misfires

- Fuel Pump Location: Often located near the fuel tank for efficient fuel delivery

Fuel Pumps Deliver Gasoline to Engine: Pumps move fuel from the tank to the engine, enabling combustion

A fuel pump is a critical component in a car's fuel system, responsible for delivering gasoline from the fuel tank to the engine. This process is essential for the engine to operate efficiently and produce power. Without a functioning fuel pump, the engine would not receive the necessary fuel, leading to a lack of power and potential stalling.

The primary role of the fuel pump is to ensure a continuous and controlled supply of gasoline to the engine. When the engine is running, the fuel pump is activated, and it begins the process of moving fuel from the tank. This is achieved through a series of precise steps. Firstly, the pump creates a vacuum or low-pressure environment in the fuel line, which draws gasoline from the tank. This is a crucial step as it ensures that the fuel is not under high pressure, which could lead to potential safety hazards.

As the fuel enters the pump, it is then pressurized to a specific level required for the engine's operation. This pressure is carefully regulated to maintain a steady flow of fuel. The pump's design and operation are optimized to deliver the right amount of fuel at the right time, ensuring efficient combustion in the engine's cylinders. This precise control is vital as it prevents fuel wastage and reduces the risk of engine misfires or performance issues.

Once the fuel is pressurized, it is directed through a series of fuel lines and filters, which further ensure the cleanliness and quality of the fuel. These filters remove any contaminants, ensuring that only clean gasoline reaches the engine. The fuel then enters the engine's carburetor or fuel injectors, where it is mixed with air and ignited, producing the power that drives the vehicle.

In summary, the fuel pump's primary function is to facilitate the movement of gasoline from the tank to the engine, enabling the combustion process that powers the vehicle. Its precise control over fuel delivery and pressure ensures optimal engine performance and efficiency. Regular maintenance and inspection of the fuel pump are essential to guarantee its longevity and the overall reliability of the car's fuel system.

A Step-by-Step Guide to Cleaning Your Car's Fuel Tank

You may want to see also

Pressure Regulation: Maintains optimal fuel pressure for efficient engine operation and performance

The fuel pump is a critical component in a car's fuel system, responsible for ensuring a steady and precise supply of fuel to the engine. One of its primary functions is pressure regulation, which plays a vital role in maintaining optimal engine performance and efficiency. When the engine is running, the fuel pump operates to regulate the pressure of the fuel, ensuring it is at the correct level required for efficient combustion. This process is essential as it directly impacts the engine's power output and overall performance.

In the context of pressure regulation, the fuel pump acts as a regulator, adjusting the fuel pressure to match the engine's demands. The engine requires a specific amount of fuel pressure to ignite the air-fuel mixture correctly. If the pressure is too low, the engine may not receive enough fuel, leading to poor performance, reduced power, and potential misfires. Conversely, excessive fuel pressure can result in fuel spray being too strong, causing engine knock and potential damage. Therefore, the fuel pump's role in pressure regulation is to maintain a delicate balance.

This regulation is achieved through a precise mechanism within the fuel pump. It monitors the fuel pressure and makes adjustments accordingly. When the engine is idling or operating at lower speeds, the pump may reduce the pressure to conserve fuel and maintain efficiency. During high-speed or high-load conditions, the pump increases the pressure to ensure the engine receives the required amount of fuel for optimal performance. This dynamic adjustment ensures that the engine always operates within the ideal fuel pressure range.

The fuel pump's pressure regulation capability is particularly important in modern vehicles with electronic fuel injection systems. These systems rely on precise fuel pressure control to deliver the correct fuel-air mixture to the engine cylinders. By maintaining optimal pressure, the fuel pump contributes to improved engine response, better fuel economy, and reduced emissions. Additionally, this regulation helps prevent fuel starvation, ensuring the engine receives a consistent supply of fuel, even during sudden acceleration or high-demand situations.

In summary, the fuel pump's pressure regulation function is a critical aspect of its role in a car's fuel system. By maintaining optimal fuel pressure, it enables efficient engine operation, enhances performance, and ensures the engine receives the right amount of fuel for combustion. This process is a delicate balance, and the fuel pump's precision in adjusting pressure is essential for the overall reliability and efficiency of the vehicle's power delivery.

Car Fuel Type: Quick Guide to Knowing What Your Vehicle Needs

You may want to see also

Fuel Injection Control: Regulates fuel injection timing and quantity for precise engine management

The fuel injection system is a critical component in modern vehicle engines, and its primary function is to ensure optimal fuel delivery for efficient combustion. At the heart of this system is the fuel injection control module, which plays a pivotal role in regulating the timing and quantity of fuel injected into the engine. This control module is an electronic device that acts as the brain of the fuel injection system, making precise decisions to maintain the engine's performance and efficiency.

The fuel injection control module receives input from various sensors within the engine, such as the crankshaft position sensor, camshaft sensor, and mass airflow sensor. These sensors provide real-time data about the engine's operating conditions, including speed, load, and air-fuel mixture. By analyzing this data, the control module calculates the exact amount of fuel required for each cylinder at a specific time. This process is crucial for achieving the ideal air-fuel ratio, which is essential for complete combustion and optimal power output.

One of the key responsibilities of the fuel injection control module is to adjust the fuel injection timing. This timing refers to the precise moment when fuel is injected into the engine's cylinders. By controlling the timing, the module ensures that the fuel is injected at the most efficient point during the engine's combustion cycle. This results in improved power delivery, better fuel economy, and reduced emissions. For instance, during high-speed driving, the module might advance the injection timing to provide more power, while during low-speed cruising, it may retard the timing to conserve fuel.

Additionally, the fuel injection control module regulates the quantity of fuel injected. This involves calculating the exact amount of fuel required based on the engine's load and speed. When the engine demands more power, the module increases the fuel injection rate to meet the demand. Conversely, during lighter loads, it reduces the fuel quantity to prevent excessive emissions and improve fuel efficiency. This dynamic adjustment ensures that the engine always receives the right amount of fuel, optimizing its performance across various driving conditions.

In summary, the fuel injection control module is a sophisticated piece of technology that ensures the engine operates at its peak efficiency. By precisely regulating fuel injection timing and quantity, it enables the engine to deliver optimal power, achieve excellent fuel economy, and minimize harmful emissions. This level of control is essential for modern vehicles, contributing to their overall performance and environmental friendliness.

Fuel Injector Cleaner: Friend or Foe for Your Car?

You may want to see also

Prevent Engine Stalling: Ensures a steady fuel supply, preventing engine stalls and misfires

The fuel pump is a critical component in a car's engine system, playing a vital role in preventing engine stalls and misfires. Its primary function is to ensure a steady and consistent fuel supply to the engine, which is essential for smooth operation and optimal performance. Without a properly functioning fuel pump, the engine may experience a lack of fuel, leading to stalls and misfires, especially during acceleration or when the engine is under load.

When the engine is running, the fuel pump is responsible for drawing fuel from the tank and delivering it to the engine's fuel injectors or carburetor. This process is crucial as it ensures that the engine receives the required amount of fuel at the right pressure and temperature. A steady fuel supply is particularly important during acceleration, as the engine demands more power and fuel to meet the increased load.

One of the key benefits of a fuel pump is its ability to maintain a consistent fuel flow, even under varying driving conditions. This is achieved through the pump's design, which often includes a precision-engineered impeller and a carefully calibrated pressure regulator. These components work together to ensure that the fuel is delivered at the optimal pressure, allowing for efficient combustion and preventing engine stalls. The fuel pump's role is especially critical in modern fuel-injected engines, where precise fuel management is essential for optimal performance and emissions control.

In addition to preventing engine stalls, a well-functioning fuel pump contributes to overall engine health and longevity. By ensuring a steady fuel supply, it helps maintain proper engine lubrication and reduces the risk of fuel-related issues such as varnish and sediment buildup in the fuel system. Regular maintenance and timely replacement of the fuel pump can significantly extend the life of the engine and improve its overall reliability.

In summary, the fuel pump is a vital component that ensures a steady fuel supply to the engine, preventing stalls and misfires. Its precise control over fuel pressure and flow rate is essential for maintaining engine performance and reliability. Regular maintenance and attention to the fuel pump's health can contribute to a smoother driving experience and longer-lasting engine.

Mastering Fuel Injector Testing: A Comprehensive Guide for Car Owners

You may want to see also

Fuel Pump Location: Often located near the fuel tank for efficient fuel delivery

The fuel pump is a critical component in a car's fuel system, responsible for delivering gasoline from the fuel tank to the engine. Its primary function is to ensure a continuous and efficient supply of fuel, allowing the engine to run smoothly and reliably. The location of the fuel pump is strategically chosen to optimize its performance and contribute to the overall efficiency of the vehicle.

As the name suggests, the fuel pump is typically situated near the fuel tank, often within the tank itself or in close proximity to it. This placement is deliberate and offers several advantages. Firstly, it allows for a shorter and more direct path for the fuel to travel from the tank to the engine, reducing the risk of fuel degradation and ensuring a fresh supply. By minimizing the distance, the pump can deliver fuel more efficiently, meeting the engine's demands without unnecessary delays.

The proximity to the fuel tank also enables a more compact and streamlined design for the fuel system. This compactness can contribute to better overall vehicle performance and fuel efficiency. Additionally, having the pump near the tank simplifies the routing of fuel lines, making the system less prone to leaks and potential issues caused by long, twisting lines.

In some vehicles, the fuel pump is integrated into the fuel tank itself, which further enhances its efficiency. This design allows for a more seamless transfer of fuel, as the pump is in direct contact with the fuel, ensuring a consistent and uninterrupted supply. The integrated approach also helps in maintaining the fuel's quality by minimizing exposure to air and potential contaminants.

Proper placement of the fuel pump is essential for the vehicle's performance and longevity. It ensures that the engine receives the required fuel volume and pressure, enabling optimal combustion and power output. Regular maintenance and inspection of the fuel pump and its connections are recommended to prevent issues related to fuel delivery, ensuring the vehicle operates at its best.

Flex Fuel: Universal Compatibility or Limited Use?

You may want to see also

Frequently asked questions

A fuel pump is a vital component in a vehicle's fuel system, responsible for delivering gasoline or fuel from the tank to the engine. It ensures a continuous and controlled supply of fuel, allowing the engine to run efficiently.

The fuel pump is typically driven by the engine's timing belt or chain. As the engine runs, the pump creates suction, drawing fuel from the tank and sending it through a series of filters and lines to the engine's carburetor or fuel injectors. This process ensures the engine receives the required amount of fuel for optimal performance.

A failing or failed fuel pump can lead to serious issues. If the pump stops working, the engine may not receive enough fuel, causing it to stall or not start at all. This is because the pump's primary role is to maintain a consistent fuel supply, and without it, the engine's operation is compromised.

Yes, a malfunctioning fuel pump can exhibit several symptoms. These may include difficulty starting the car, erratic engine performance, reduced power, and in some cases, the engine may stall completely. If left unattended, the pump's failure can result in expensive engine repairs.