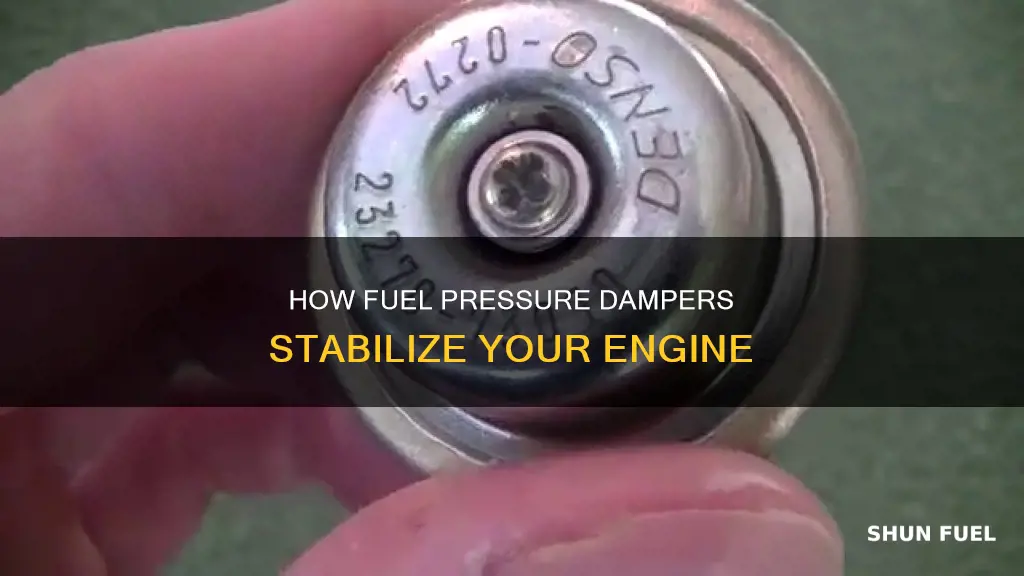

A fuel pressure damper, also known as a fuel pulsation damper, is a device used to regulate the oscillation of fuel caused by the injectors opening and closing. This smooths out the fuel delivery and ensures an even pressure. Without a fuel pressure damper, the injectors opening and closing against the pressure sent by the pump would cause waves in the fuel system. This can lead to unstable fuel pressure and erratic lean air/fuel ratio spikes, commonly experienced as stumbling.

What You'll Learn

Fuel pressure dampers absorb pulses from the fuel pump

Fuel pressure dampers are designed to absorb pulses from the fuel pump, ensuring a consistent pressure and preventing fuel surges. This is achieved through the use of a diaphragm that smooths out the waves created by the injectors' opening and closing. Without a damper, these waves can cause a "water-hammer" effect, leading to pressure spikes and potential damage to the fuel injectors.

While some consider fuel pressure dampers non-essential, they can play a crucial role in maintaining stable fuel delivery and reducing noise, vibration, and harshness (NVH). The damper's ability to absorb pulses is especially important in vehicles with batch injection systems, where multiple injectors open and close simultaneously, creating more significant waves in the fuel system.

Additionally, fuel pressure dampers can help compensate for temporary drops in pressure caused by the injectors. By keeping the pressure up, they ensure that the engine has enough fuel pressure to operate optimally, reducing the number of cranks needed to start the car.

In summary, fuel pressure dampers are designed to absorb and smooth out the pulses from the fuel pump, maintaining consistent fuel pressure and reducing potential issues caused by pressure spikes. While not all vehicles require them, fuel pressure dampers can be beneficial in ensuring stable fuel delivery and reducing NVH.

Understanding the Role of Fuel Injector Pressure Sensors

You may want to see also

They prevent fuel pressure from surging

Fuel pressure dampers prevent fuel pressure from surging by absorbing the pulsing of fuel caused by the fuel pump and the opening and closing of the injectors. This creates an even pressure and smooth fuel delivery, preventing pressure spikes and "water hammer" in the fuel rail.

The fuel pump creates pressure pulsations as it turns, and the injectors opening and closing against this pressure cause waves in the fuel system, similar to the waves created by bouncing a ball in a pool. The damper's diaphragm absorbs these waves, preventing the fuel pressure from surging.

Without a damper, the fuel in the rail wants to rush out when the injectors open and then crashes back and bounces around when they close, creating a pressure spike and potential damage to the fuel lines from vibration and metal fatigue.

Some fuel pressure regulators also have dampening capabilities built-in, and mounting these close to the fuel rail can eliminate the need for additional dampening. However, many cars with fuel injection systems do use a separate fuel pressure damper to prevent fuel pressure from surging.

Understanding the Role of Fuel Injector Pressure Dampers

You may want to see also

They compensate for temporary drops in pressure

A fuel pressure damper is a device that helps to regulate the oscillation of fuel caused by the injectors opening and closing, and smooths out the fuel delivery. It compensates for temporary drops in pressure, which can be caused by the injectors. This is achieved through the use of a spring-loaded device that keeps the pressure up.

The damper's function is to absorb the pulses or waves in the fuel caused by the injectors opening and closing. This is often referred to as the "water-hammer effect", where the fuel in the tube wants to rush out of the valves when they open, but then crashes back and bounces around when they close, creating a pressure spike. The damper's diaphragm absorbs these waves and stabilises fuel delivery.

The fuel pressure damper is particularly useful when there is a lean spot in the engine's performance at a certain RPM range, which can be caused by pressure spikes in the fuel rail. This can be rectified by flattening the frequency through the use of a damper, which will help the fuel pressure regulator perform its job properly.

In some cases, the fuel pressure regulator may have dampening capabilities built into it, so a separate damper may not be necessary. However, this is not always the case, and for some vehicles, a fuel pressure damper can be essential to smooth out fuel delivery and prevent pressure drops.

Fuel Pressure Woes: Bad Pressure, Bad Performance

You may want to see also

They are spring-loaded devices that maintain pressure

Fuel pressure dampers are spring-loaded devices that maintain pressure by absorbing the pulsing of fuel caused by the fuel pump and the opening and closing of the injectors. This helps to prevent surging and creates a consistent pressure.

The fuel pump creates pressure pulsations as it turns, but the real issue that the damper tries to solve is the water-hammer effect inside the fuel rail when the injectors open and close. This effect is similar to water hammer in plumbing systems, where the liquid in the pipes wants to rush out of the valves and starts moving but then crashes back against the closed valve and bounces around, creating a pressure spike.

The damper's spring-loaded design allows it to expand and contract quickly, absorbing these pressure spikes and reducing the noise and vibration caused by the fuel system. This is especially important in luxury vehicles, where a smooth and quiet ride is a key feature.

Additionally, the damper helps to keep the fuel pressure even, which is crucial for the injectors to function properly. If the pressure is inconsistent, the amount of fuel delivered by the injectors can vary, leading to a lean or rich fuel mixture. By maintaining a consistent pressure, the damper ensures that the injectors deliver the correct amount of fuel, improving the engine's performance and fuel efficiency.

In summary, fuel pressure dampers are essential components in fuel systems, ensuring smooth and efficient engine operation by maintaining consistent pressure and reducing the negative effects of pressure spikes.

Diagnosing Faulty Fuel Pressure Regulators by Listening for Symptoms

You may want to see also

They work with fuel pressure regulators to keep pressure even

Fuel pressure dampers work with fuel pressure regulators to keep the pressure even. The damper absorbs the pulses coming into the fuel rail from the fuel pump, preventing a "surge". The fuel pressure regulator, on the other hand, is located on the outlet side of the rail and controls the amount of pressure in the fuel rail. It releases excess fuel back into the tank when the pressure is too high, maintaining a consistent level.

The fuel injectors opening and closing can also cause pressure drops. Each time an injector opens, the fuel pressure drops slightly, and this is where the damper comes into play. It compensates for this temporary drop by maintaining the pressure using a spring-loaded mechanism. This ensures that the fuel pressure remains stable and that the injectors receive a consistent amount of fuel.

Together, the fuel pressure damper and the fuel pressure regulator work in harmony to maintain an even and consistent fuel pressure, allowing the engine to run smoothly. The damper smooths out the pulses, while the regulator controls the overall pressure, ensuring that the fuel system operates efficiently and effectively.

While some people argue that a fuel pressure damper is not necessary, others believe it is essential to prevent fuel hammering, which can lead to injector failure. Additionally, the damper can help reduce noise, vibration, and harshness (NVH) in the fuel system, making the vehicle more comfortable to drive.

Diagnosing Faulty Fuel Pumps: Sounds and Solutions

You may want to see also

Frequently asked questions

A fuel pressure damper is a device that regulates the oscillation of fuel caused by the injectors opening and closing, and smooths out the fuel delivery. It is sometimes referred to as an FPD.

The damper uses a diaphragm to absorb pulses or waves in the fuel. It absorbs the waves and smooths the fuel delivery, preventing a "surge" caused by the pump.

Many people say you do not need a fuel pressure damper. However, some argue that it is necessary to prevent fuel hammering the injector so hard that it fails.

If a fuel pressure damper fails, it could cause an engine fire.

A faulty fuel pressure damper could cause misfires, gas in the oil, and erratic fuel trims.