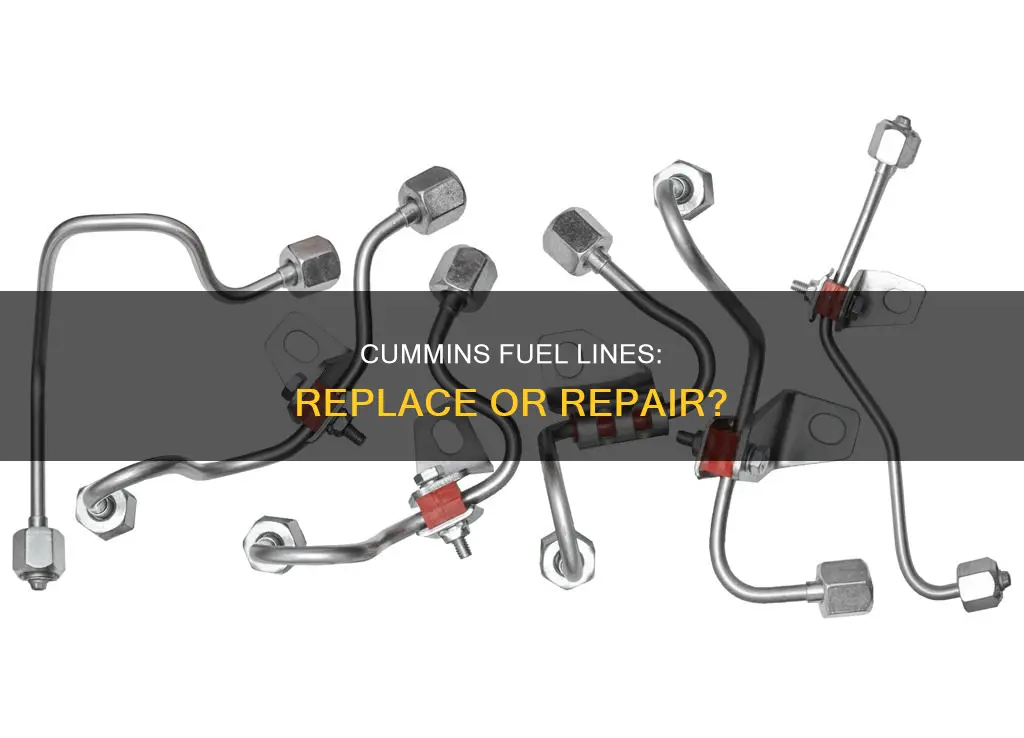

Cummins fuel lines are a common topic of discussion among diesel enthusiasts, with many forum posts dedicated to troubleshooting, replacement, and upgrade options. The fuel lines in Cummins engines play a crucial role in delivering fuel from the tank to the engine, ensuring the proper functioning of the vehicle. While some components of the fuel system may vary depending on the specific Cummins model and year, the fuel lines are a critical aspect that requires regular maintenance and, in some cases, replacement.

| Characteristics | Values |

|---|---|

| Fuel line material | Metal, Rubber |

| Fuel line size | 1/2", 3/8", 5/16", 5/8" |

| Fuel line length | 15 ft, 25 ft, 28 ft |

| Fuel line replacement reasons | Rust, Leak, Hard start, Air leaks |

| Fuel line replacement parts | Banjo bolt, Gasket, Hose clamp, Fuel filter, Fuel hose, Fuel pump |

What You'll Learn

- Metal fuel lines can be replaced with rubber lines

- Fuel line leaks can be identified by spraying with soapy water

- Fuel line leaks can be identified by pressurising the tank

- Fuel line leaks can be identified by coating with baby or talcum powder

- Fuel line leaks can be identified by running a rubber line straight to a jug of diesel

Metal fuel lines can be replaced with rubber lines

When replacing metal fuel lines with rubber, it is important to use a high-pressure, diesel-rated hose and double-clamp it on each end. In addition, the hose must be rated for fuel or be labeled as meeting one of the following SAE grades:

- SAE J30R7: Carburetor-rated fuel hose with a maximum pressure rating of 50 psi.

- SAE J30R9: Fuel injection-rated fuel hose that can handle up to 100 PSI.

Some people have reported success with using high-pressure rubber lines in their vehicles for several years without any issues. However, others have cautioned against using rubber hose, especially with modern ultra-low sulfur diesel fuel, as it can attack the rubber and cause leaks. As an alternative, some people have suggested using nylon tubing or PTFE-lined hose, which is more durable and blocks fuel vapors.

When replacing the metal fuel lines on a Cummins engine, it is recommended to use a kit specifically designed for Cummins engines, such as the Vulcan Big Line Kit. This kit includes all the necessary lines and fittings to replace the metal fuel lines from the tank to the injector pump. In addition, some people have suggested using a pushlock fitting and hose for the connections at the injector pump and filter housing. It is also important to consider the size of the fuel line and the type of fittings required for your specific application.

Replacing John Deere 445 Fuel Hose: A Step-by-Step Guide

You may want to see also

Fuel line leaks can be identified by spraying with soapy water

If you suspect a fuel line leak, it is important to act promptly to prevent any potential safety hazards. A simple and effective method to identify fuel line leaks is by spraying the suspected area with soapy water. Here is a step-by-step guide on how to perform this test:

Prepare the Soapy Water Solution:

Mix one cup of water with a teaspoon of dish soap or liquid laundry detergent in a spray bottle. Dish soap is preferable as it produces more bubbles, making the test easier. Ensure you do not use soap containing ammonia, as it can cause brass fittings to become brittle and crack.

Apply the Soapy Water:

Spray the soapy water solution onto the fuel lines, including pipes, hoses, valves, and connections. Make sure to cover the entire area you suspect a leak may be present.

Pressurise the System:

Turn on the gas bottle or fuel pump to pressurise the system. Do not turn on any burners or ignite any flames during this process.

Observe for Bubbles:

If there is a fuel line leak, you will see bubbles forming in the soapy water. The size of the bubbles can indicate the severity of the leak, with small bubbles indicating a small leak and large bubbles signifying a larger leak. You may also notice a strong odour of sulphur or rotten eggs as ethyl mercaptan, an additive in LPG, has a distinct smell.

Take Action:

If you identify a fuel line leak, immediately turn off the gas supply and disconnect the fuel line. Do not attempt to fix the leak yourself, as working with leaking fuel can be extremely dangerous. Contact a professional or your propane company to address the issue.

It is important to regularly check your fuel lines for any signs of leaks or damage. This simple soapy water test can help you identify issues early on and prevent more significant problems from occurring. Always prioritise safety and ensure you have proper ventilation and a fire extinguisher nearby when working with fuel lines.

Replacing the Fuel Pump in a 95 240SX: Step-by-Step Guide

You may want to see also

Fuel line leaks can be identified by pressurising the tank

To identify a fuel line leak, it is important to look for signs such as a strong fuel odour, visible fuel leaks, a hissing sound, diminished engine performance, or an illuminated check engine light. If any of these symptoms are present, it is crucial to inspect the fuel tank and lines for damage.

One way to identify a fuel line leak is to pressurise the tank. This can be done by using a pressure tester, which can be purchased or rented from most auto parts stores. The tester is connected to the fuel tank, and the system is pressurised to a specified level. If there is a leak in the fuel line, it will be forced out by the pressurised air, making it easier to identify the exact location of the leak.

Another method to identify a fuel line leak is to use a dye tester. This involves adding a fuel-safe dye to the tank and then inspecting the fuel lines for any signs of colour. If the dye is visible outside the fuel lines, it indicates a leak.

Additionally, it is important to inspect the fuel lines for any signs of damage, such as cracks, holes, or deterioration. This can be done by carefully examining the lines, looking for any visible issues. If the lines are metal, check for rust or corrosion, as this can be a common cause of fuel line leaks.

In some cases, it may be necessary to remove the fuel lines for a more thorough inspection. This typically requires dropping the fuel tank and carefully disconnecting the lines. It is important to note that this process can be complex and may require mechanical expertise, especially when reconnecting the lines to ensure proper fittings and clamps are used.

Overall, identifying fuel line leaks through tank pressurisation is an effective method to ensure the issue is addressed promptly. Fuel leaks can pose safety hazards and impact engine performance, so taking the necessary steps to identify and repair leaks is crucial for vehicle maintenance.

Cleaning Fuel Injectors: Worth the Effort or Replace?

You may want to see also

Fuel line leaks can be identified by coating with baby or talcum powder

Fuel line leaks can be identified by coating the suspected area with baby or talcum powder. This method can be used to identify leaks in any vehicle, including Cummins engines.

To identify a fuel line leak, first, inspect the engine for any signs of fresh leakage, which usually appear as wet or shiny spots. If you suspect a fuel line is leaking, liberally apply baby or talcum powder to the area. Be generous with the powder application, as you want to clearly see the contrast between the powder and the fuel leak.

After applying the powder, drive your vehicle for about 20 minutes to allow the leak to continue. Then, re-inspect the area where you applied the powder. Look for any signs of fresh leakage, which will appear as wet stains against the white powder.

If you are unable to identify the leak, you may need to drive the vehicle for a longer period or allow it to sit for a few hours. This method is especially useful for identifying small leaks.

Identifying fuel line leaks is crucial to prevent potential damage to your engine. Cummins engines, in particular, have been known to develop air leaks in the fuel lines, so regular inspection and maintenance are essential.

If you suspect a fuel line leak, it is important to address it promptly to prevent further issues. In some cases, you may need to replace the fuel lines, especially if they are old and worn out. This is a complex process that may require detailed instructions and specialized tools, so it is recommended to seek professional assistance if you are uncomfortable performing the replacement yourself.

By regularly inspecting your fuel lines and promptly addressing any leaks, you can help ensure the optimal performance and longevity of your Cummins engine.

Replacing Honda SH150 Fuel Pump: Step-by-Step Guide

You may want to see also

Fuel line leaks can be identified by running a rubber line straight to a jug of diesel

Step 1: Prepare the Rubber Line and Jug of Diesel

- Obtain a rubber hose that is long enough to run from your fuel tank to a safe location where you can place the jug of diesel. The hose should be diesel-rated to ensure compatibility and safety.

- Prepare a jug or container that can hold diesel fuel. Make sure it is clean and dry before use.

Step 2: Disconnect the Original Fuel Line

- Locate your vehicle's fuel tank and identify the fuel line that needs to be checked for leaks.

- Carefully disconnect the original fuel line from the fuel tank. You may need to refer to your vehicle's repair manual or seek assistance from a mechanic if you are unsure about the procedure.

Step 3: Connect the Rubber Line and Jug of Diesel

- Attach one end of the rubber hose to the fuel tank where you disconnected the original fuel line. Ensure a secure and tight connection to prevent leaks.

- Place the jug or container at a lower level than the fuel tank to allow the diesel to flow down.

- Connect the other end of the rubber hose to the jug or container. Ensure that the connection is secure and tight.

Step 4: Observe for Leaks

- Once the rubber line and jug of diesel are connected, carefully observe the connections and hoses for any signs of diesel leaking out.

- Pay close attention to the connections, junctions, and clamps as these are common areas for leaks.

- If you notice any leaks, tighten the connections or replace any damaged or worn-out parts as necessary.

Step 5: Monitor Fuel Consumption and Engine Performance

- After addressing any visible leaks, fill the fuel tank and jug of diesel to a known level.

- Run your vehicle as you normally would and monitor your fuel consumption. Compare it to your vehicle's usual fuel efficiency.

- Also, pay attention to any changes in engine performance, such as difficulty starting, rough idling, or unexpected power loss. These could be indicators of a fuel line leak.

By performing this test, you can identify fuel line leaks and take appropriate action to repair or replace the necessary components. Remember to use high-quality diesel-rated hoses and always exercise caution when working with diesel fuel.

Replacing Wavian Fuel Can Lid: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Yes, you can replace the old metal fuel lines with rubber lines. However, ensure that you use rubber lines that are rated for diesel fuel.

It is not necessary to replace all the fuel lines. You can replace the sections that are damaged or rusted.

The size of the fuel lines depends on the specific Cummins engine and application. Common sizes include 3/8", 5/16", and 1/2". It is recommended to measure the existing fuel lines or consult a mechanic to determine the correct size for your specific application.

Signs that your Cummins fuel lines may need replacement include rust, leaks, cracks, or damage. It is recommended to inspect the fuel lines regularly and replace them if any issues are identified.

Symptoms of a faulty Cummins fuel line can include hard starting, stalling, loss of power, white smoke, and fuel leaks. If you suspect a fuel line issue, it is important to inspect the lines and replace them if necessary.