The fuel line cover is an essential component in the automotive industry, serving as a protective barrier for the fuel lines that transport gasoline or diesel from the tank to the engine. It is a crucial safety feature that helps prevent fuel leaks and potential engine damage. However, the question arises: is there a two-part design to the fuel line cover? This paragraph aims to explore this inquiry, delving into the potential benefits and considerations of a dual-component fuel line cover system. By examining the advantages and potential challenges, we can gain a comprehensive understanding of this innovative design and its implications for vehicle safety and performance.

What You'll Learn

- Fuel Line Material: Different materials like rubber or plastic offer varying durability and flexibility

- Fuel Line Diameter: Size matters; larger diameters handle higher fuel flow rates

- Fuel Line Routing: Proper routing prevents damage and ensures optimal fuel delivery

- Fuel Line Protection: Guards against heat, vibration, and chemical exposure

- Fuel Line Length: Longer lines require additional considerations for flexibility and support

Fuel Line Material: Different materials like rubber or plastic offer varying durability and flexibility

When it comes to fuel lines, the choice of material is crucial for ensuring optimal performance and longevity. Different materials offer varying levels of durability and flexibility, which can significantly impact the overall reliability of your vehicle's fuel system. One of the most common materials used for fuel lines is rubber. Rubber is known for its excellent flexibility, making it ideal for the dynamic nature of fuel lines that are constantly moving and expanding due to engine vibrations and temperature changes. This flexibility helps to prevent cracks and leaks, ensuring a secure and reliable connection between the fuel tank and the engine. Additionally, rubber is resistant to fuel degradation, which means it can withstand the corrosive effects of gasoline and diesel over time.

On the other hand, plastic fuel lines are also widely used and offer their own set of advantages. Plastic is generally lighter than rubber, which can be beneficial for reducing the overall weight of the fuel system, especially in high-performance vehicles. It is also more resistant to heat, making it suitable for engines that operate at higher temperatures. However, plastic may not be as flexible as rubber, which could lead to potential issues with long-term performance. Plastic can become brittle over time, especially in low-temperature conditions, which may result in cracking or breaking.

The choice between rubber and plastic fuel lines often depends on the specific requirements of the vehicle and the operating conditions. For everyday use and standard driving conditions, rubber fuel lines are often preferred due to their superior flexibility and resistance to fuel degradation. They provide a reliable and long-lasting solution for most vehicles. In contrast, plastic fuel lines might be more suitable for high-performance applications where weight reduction is crucial, as long as the operating temperatures and conditions are within the plastic's specified limits.

It's important to consider the environmental factors as well. Rubber fuel lines are generally more resistant to UV radiation and outdoor exposure, making them a better choice for vehicles that are frequently used in sunny or outdoor environments. Plastic, while offering good heat resistance, may not perform as well in direct sunlight, potentially leading to degradation over time.

In summary, the material of the fuel line plays a critical role in its performance and longevity. Rubber provides superior flexibility and resistance to fuel degradation, making it a popular choice for most vehicles. Plastic, while offering advantages in terms of weight and heat resistance, may not be as flexible and could be more susceptible to environmental factors. Understanding the specific needs of your vehicle and the operating conditions will help you make an informed decision when choosing the right fuel line material.

Reusing LB7 Fuel Injector Lines: A Practical Guide

You may want to see also

Fuel Line Diameter: Size matters; larger diameters handle higher fuel flow rates

When it comes to fuel lines, size truly does matter, especially when it comes to the diameter of the fuel line itself. The diameter of a fuel line is a critical factor in determining its ability to handle the flow rate of fuel required for optimal engine performance. Larger diameters are designed to accommodate higher fuel flow rates, ensuring that your engine receives the necessary amount of fuel for efficient operation.

In the world of automotive engineering, the fuel line's diameter is a crucial specification. It is directly related to the engine's power output and overall performance. Engines, especially high-performance ones, require a precise and consistent fuel supply to function optimally. This is where the fuel line's diameter comes into play. A larger diameter fuel line can carry more fuel, which means it can provide the engine with the required amount of fuel at a faster rate. This is particularly important during high-load conditions or when the engine is under stress, such as during acceleration or when climbing steep inclines.

The relationship between fuel line diameter and flow rate is directly proportional. As the diameter increases, the fuel line's cross-sectional area also increases, allowing for a greater volume of fuel to pass through. This is essential for engines that require a rapid and efficient fuel supply to meet their performance demands. For instance, high-performance sports cars or racing bikes often utilize larger diameter fuel lines to ensure that their powerful engines receive the necessary fuel to reach their full potential.

However, it's important to note that there is an optimal range for fuel line diameter. If the diameter is too large, it may lead to unnecessary fuel wastage and increased pressure drop, which can negatively impact engine performance. On the other hand, if the diameter is too small, it may not be able to handle the required fuel flow rate, resulting in engine performance issues. Therefore, selecting the appropriate fuel line diameter is crucial and should be based on the specific requirements of the engine and the vehicle's overall performance goals.

In summary, when considering fuel line covers or replacements, pay close attention to the diameter. Larger diameters are essential for handling higher fuel flow rates, ensuring your engine receives the fuel it needs to perform at its best. Understanding this relationship between size and performance will help you make informed decisions when it comes to optimizing your vehicle's fuel system.

Mastering the Art of Fuel Line Removal: A Step-by-Step Guide for Lawn Mowers

You may want to see also

Fuel Line Routing: Proper routing prevents damage and ensures optimal fuel delivery

Fuel lines are a critical component of any vehicle's fuel system, and their proper routing is essential for optimal performance and longevity. The fuel lines carry gasoline or diesel from the tank to the engine, and any damage or disruption to this route can lead to serious issues. Proper routing ensures that the fuel lines are protected from potential hazards and maintain a consistent flow of fuel, which is vital for the engine's operation.

When installing or replacing fuel lines, it is crucial to follow a systematic approach to routing. The primary goal is to keep the lines away from areas that could cause damage, such as under the vehicle's body, near exhaust systems, or in close proximity to moving parts. A common practice is to route the fuel lines in a loop or a U-shape, ensuring they are not twisted or kinked, as this can restrict fuel flow and potentially cause engine misfires.

One effective method for proper routing is to use a fuel line bracket or a custom-made support system. These brackets are designed to hold the fuel lines in place, providing a secure and organized route. By securing the lines, you prevent them from being pinched or damaged by other components, ensuring a smooth and continuous path from the tank to the engine. This method is especially useful in vehicles with limited space or unique engine configurations.

Additionally, it is important to consider the material of the fuel lines. High-quality rubber or synthetic materials are commonly used, offering flexibility and durability. These materials allow for some movement without compromising the structural integrity of the fuel lines. Proper routing, combined with the right materials, ensures that the fuel lines can withstand the vehicle's operating conditions and potential vibrations.

In summary, proper fuel line routing is a critical aspect of vehicle maintenance. By following a structured approach, using appropriate support systems, and considering the material properties, you can prevent damage, ensure optimal fuel delivery, and extend the life of your vehicle's fuel system. Regular inspections and maintenance can also help identify any potential issues with the fuel lines, allowing for prompt repairs and maintaining the overall health of the engine.

Honda Civic 1998 Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Fuel Line Protection: Guards against heat, vibration, and chemical exposure

Fuel lines are critical components in any vehicle's engine, responsible for transporting fuel from the tank to the engine's combustion chamber. However, they are susceptible to various forms of damage, including heat, vibration, and chemical exposure, which can lead to fuel leaks, engine misfires, and even catastrophic failures. To ensure the longevity and reliability of your vehicle, it's essential to understand the importance of fuel line protection and how guards can safeguard against these potential threats.

Heat is a significant concern for fuel lines, especially in high-performance vehicles or those operating in extreme temperatures. Over time, fuel lines can degrade due to the intense heat generated by the engine, leading to cracks, brittleness, and eventual failure. This can result in fuel leaks, which not only cause environmental damage but also lead to engine performance issues. To combat this, fuel line guards are designed to provide thermal insulation, protecting the lines from the direct heat of the engine and surrounding components. These guards are typically made from heat-resistant materials, such as high-temperature plastics or metal sheathing, ensuring that the fuel lines remain flexible and intact even under extreme conditions.

Vibration is another critical factor in fuel line integrity. The constant movement and shaking of a vehicle's engine can cause fuel lines to become loose, kinked, or damaged over time. This is particularly true for vehicles with high-performance engines or those subjected to rough terrain. Vibration-resistant guards are designed to secure the fuel lines in place, preventing them from moving or becoming dislodged during operation. These guards often feature clamping mechanisms that firmly attach the fuel lines to the vehicle's frame or engine bay, ensuring a stable and secure connection. By minimizing the impact of vibration, these guards contribute to the overall reliability and safety of the vehicle's fuel system.

Chemical exposure is a less obvious but equally important consideration for fuel line protection. Fuel contains various additives and impurities that can corrode or degrade the material of the fuel lines over time. This is especially true for older vehicles or those with less advanced fuel systems. To address this issue, fuel line guards are often made from materials that are resistant to corrosion and chemical attack. These guards create a barrier between the fuel lines and the corrosive elements, ensuring that the lines remain in optimal condition. Additionally, some guards are designed with a protective coating or lining that further enhances their resistance to chemical damage, providing an extra layer of defense against potential degradation.

In summary, fuel line protection is vital for maintaining the health and performance of your vehicle's engine. Guards designed to withstand heat, vibration, and chemical exposure play a crucial role in safeguarding fuel lines from potential damage. By investing in high-quality fuel line guards, vehicle owners can ensure the longevity and reliability of their fuel systems, ultimately contributing to a safer and more efficient driving experience. It is recommended to consult vehicle manufacturers or automotive experts to determine the most suitable fuel line protection solution for your specific make and model.

Locate the Fuel Line: A Guide to Craftsman Chain Saw Maintenance

You may want to see also

Fuel Line Length: Longer lines require additional considerations for flexibility and support

When dealing with fuel lines, especially those that are longer, it's crucial to consider the unique challenges that arise due to their extended length. Longer fuel lines are more susceptible to various issues, and addressing these concerns is essential for maintaining the performance and safety of your vehicle. One of the primary considerations is flexibility. As the fuel line extends, it needs to be able to move and bend without becoming rigid or prone to kinking. This is particularly important during vehicle operation, as the engine and other components may shift or vibrate, causing the fuel line to flex. To ensure flexibility, manufacturers often use specialized materials and designs. For instance, some fuel lines are constructed with a braided or reinforced structure, allowing them to bend and twist without compromising the integrity of the fuel flow. This flexibility is vital to prevent fuel starvation, especially in high-performance vehicles where engine movement can be more pronounced.

Another critical aspect of longer fuel lines is support. These lines need to be securely mounted to prevent excessive movement, which could lead to damage or disconnection. Proper support is essential to maintain the fuel line's position and ensure it doesn't rub against other components, potentially causing wear and tear. One common method of support is the use of brackets or ties. These can be strategically placed along the fuel line's length to keep it in place. For example, in high-performance applications, fuel lines might be secured with custom-made brackets that provide a firm hold while allowing for some movement. This ensures that the fuel line remains intact and continues to deliver fuel efficiently, even under demanding conditions.

In addition to flexibility and support, the material of the fuel line also plays a significant role in its performance. Longer lines may require materials that offer enhanced durability and resistance to wear. For instance, some fuel lines are made with high-temperature-resistant materials to handle the extreme conditions of high-performance engines. The choice of material can also impact the fuel line's flexibility, with some materials being more pliable than others. It's important to select the right material to ensure the fuel line can withstand the rigors of its environment.

Furthermore, when dealing with longer fuel lines, it's crucial to consider the potential for fuel vaporization, especially in high-temperature environments. Longer lines can increase the surface area exposed to heat, leading to faster fuel evaporation. This can result in reduced engine performance and potentially impact fuel efficiency. To mitigate this issue, some fuel lines are equipped with specialized coatings or materials that help retain fuel moisture, ensuring optimal engine operation.

In summary, longer fuel lines present unique challenges that require careful consideration. By addressing flexibility, support, material selection, and potential fuel vaporization issues, you can ensure that your fuel lines perform optimally and contribute to the overall reliability of your vehicle. Proper installation and maintenance of these longer fuel lines are key to avoiding common problems associated with fuel delivery systems.

Fuel Line Liter Valve: Location and Function

You may want to see also

Frequently asked questions

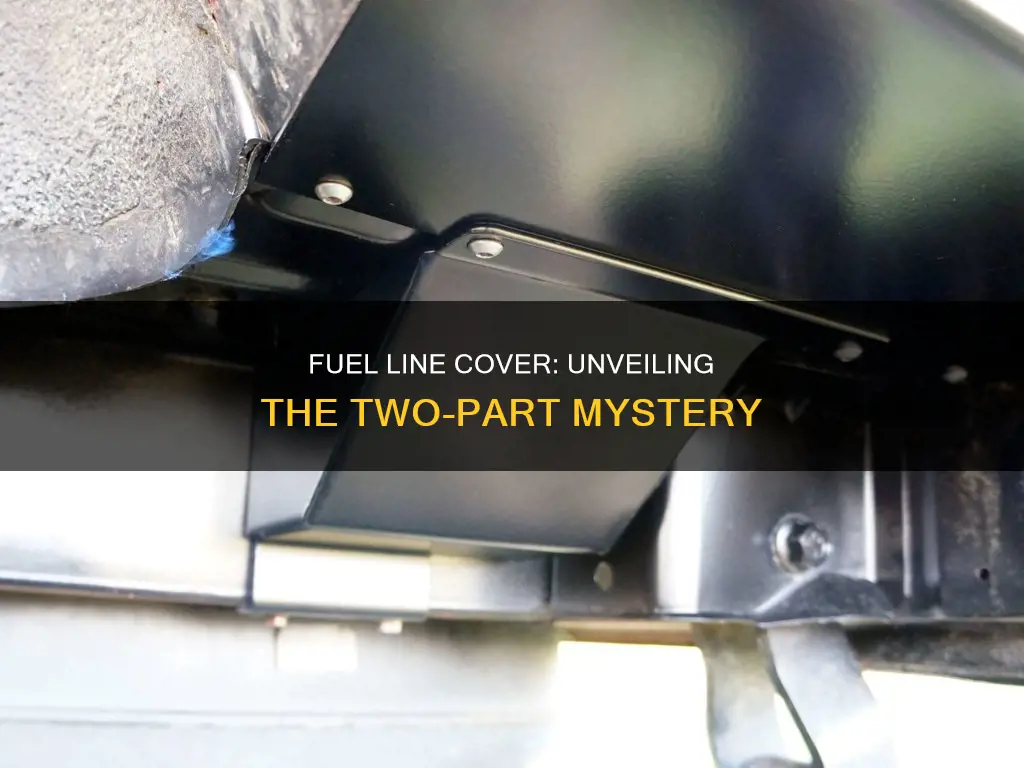

Yes, there are two-part fuel line covers designed to provide comprehensive protection for your vehicle's fuel lines. These covers typically consist of two separate pieces that fit over the fuel lines, offering a secure and customizable fit.

If you notice any signs of fuel line damage, such as leaks, corrosion, or wear, it's essential to consider a two-part cover. Additionally, if you want to enhance the protection of your fuel lines, especially in harsh weather conditions or high-traffic areas, a two-part cover can be a valuable investment.

Many two-part fuel line covers are designed for easy DIY installation. They often come with detailed instructions and require basic tools. However, if you're unsure or prefer professional help, it's recommended to consult a qualified mechanic who can ensure a proper fit and installation.

Absolutely! Two-part covers offer several advantages. They provide a more secure and tailored fit, ensuring optimal protection. This design also allows for easy access to the fuel lines when needed for maintenance or repairs. Additionally, the two-part system can be more durable and long-lasting, offering reliable protection against various environmental factors.