Fuel injectors are an essential component of modern engines, and a fuel injection pressure tester is a valuable tool for identifying and diagnosing issues with your vehicle's fuel system. If your car is running rough or using gas inefficiently, it may be time to test your fuel pressure. A fuel pressure tester can help you check the fuel pump and fuel system, and troubleshoot any issues with your fuel injector.

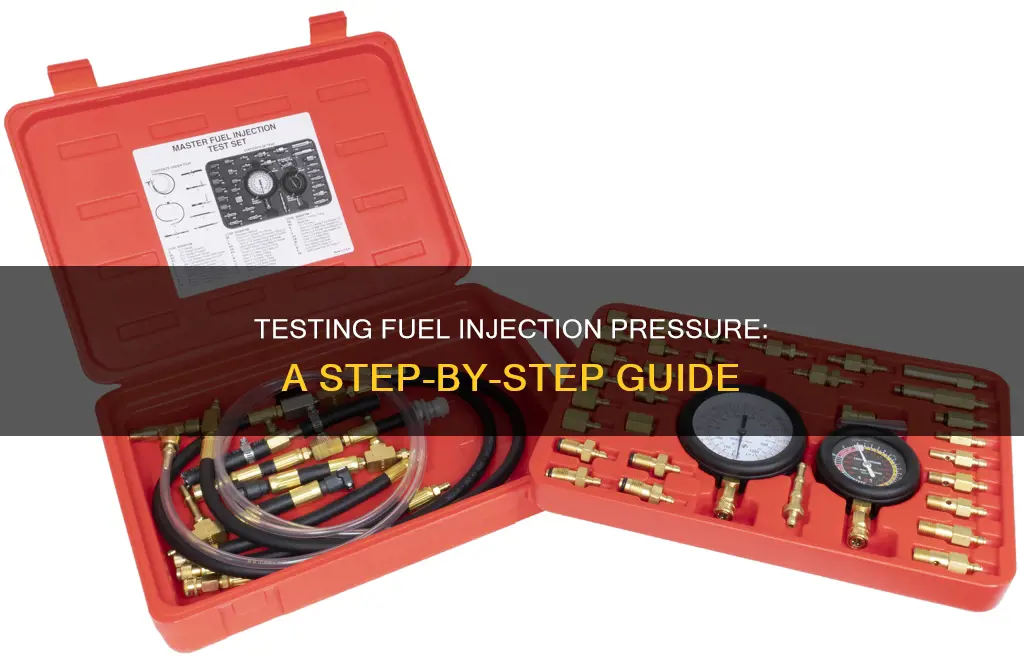

There are a variety of fuel injection pressure testers available on the market, offering different features and compatibility with different vehicles. When choosing a tester, it's important to ensure it has the right adapters for your vehicle and that it is designed for repeated use with high-quality materials.

By using a fuel injection pressure tester, you can easily identify and address issues with low fuel pressure, faulty fuel pressure regulators, leaking injectors, fuel leaks, or clogged fuel filters. This can help improve your vehicle's performance and fuel efficiency, ensuring a smoother and more reliable driving experience.

| Characteristics | Values |

|---|---|

| Purpose | Identify and diagnose low fuel pressure, faulty fuel pressure regulator, leaking injectors, fuel leaks, and/or clogged fuel filters |

| Vehicle compatibility | Most domestic fuel-injected vehicles and many imported cars |

| Usage | Attach the tester to the vehicle's fuel injection system, and read the pressure gauge |

| Adapter compatibility | Various vehicles, including cars, motorcycles, trucks, SUVs, ATVs, UTVs, and RVs |

| Features | Quick-release valve button for single-handed operation, dual-color-coded scale gauge, storage case |

What You'll Learn

Identify and diagnose low fuel pressure

To identify and diagnose low fuel pressure, you can look out for several signs and symptoms. Here are some detailed instructions to help you identify and diagnose low fuel pressure:

Signs of Low Fuel Pressure:

- Unresponsive Throttle or Engine Stalling: The most common symptom of low fuel pressure is an unresponsive throttle or a stalling engine. You may experience little to no response from the engine, and the car may struggle to start or stall while running.

- Difficulty Starting the Car: Low fuel pressure can make it difficult to ignite the engine. You may notice that it takes longer to start the car or that it requires multiple attempts.

- Check Engine Light: Modern vehicles are equipped with a fuel pressure sensor that can detect low fuel pressure. If there is an issue, the "check engine" light will illuminate on the dashboard, and you may receive error codes such as P0087 (low fuel pressure) or P0190 (low fuel pressure in the fuel rail).

- Low Performance: Low fuel pressure can cause a drop in the car's performance, including reduced acceleration and overall power.

Diagnosing Low Fuel Pressure:

- Check Battery Voltage: Use a multimeter to test the battery's voltage. It should measure at 12.4 volts or slightly above.

- Check Engine Codes: If the "check engine" light is on, use a scanner to pull the error codes, which can help identify the specific issue.

- Test Fuel Pressure:

- Locate the fuel rail and connect the fuel pressure gauge to the valve on the fuel rail or as specified in your vehicle's repair manual.

- Turn the key to the "ON" position without starting the engine to build up pressure.

- Observe the initial measurement and watch for any drops in pressure over a span of 10-30 minutes. A significant drop in pressure indicates low fuel pressure.

- Compare the measured fuel pressure to the specifications for your car model. Normal fuel pressure is typically between 55-65 pounds per square inch (psi) for most vehicles, but it can vary depending on the type of fuel injection system.

Check the Fuel Pressure with the Vehicle Running:

Observe the fuel pressure gauge needle for excessive movement or fluctuations. If the needle bounces or fluctuates, it indicates an issue with the fuel system, possibly due to a faulty fuel pressure regulator or a leaking fuel injector.

Common Causes of Low Fuel Pressure:

- Clogged Fuel Filter: The fuel filter may be clogged, restricting fuel flow. It is recommended to replace the fuel filter at regular intervals.

- Faulty Fuel Pump: A bad fuel pump is a common cause of low fuel pressure. Running the vehicle on low fuel can damage the fuel pump over time.

- Defective Fuel Pressure Regulator: The fuel pressure regulator controls the fuel pressure in the fuel rail. If it is faulty, it can cause too low or too high fuel pressure.

- Stuck Fuel Injector: A stuck-open fuel injector can cause low fuel pressure in the rail, often accompanied by misfire codes on a specific cylinder.

- Leaking Fuel Line: Driving on bumpy roads can damage the fuel lines, leading to leaks and low fuel pressure.

By following these steps and identifying the specific symptoms and causes of low fuel pressure, you can effectively diagnose and address the issue to ensure the proper functioning of your vehicle's fuel system.

Troubleshooting Car Fuel Pressure Loss Overnight

You may want to see also

Check for a faulty fuel pressure regulator

A faulty fuel pressure regulator can cause a lot of problems with your car's engine. The regulator ensures a consistent stream of pressurised fuel is delivered to the fuel rail for the fuel injectors. It works with the fuel rail sensor to ensure precise delivery of the correct amount of fuel to support the ideal fuel/air mixture for the given conditions.

- Your engine feels down on power.

- Black smoke is coming from the exhaust.

- Your car is hard to start.

- Your car feels rough at idle.

- Your car frequently stalls.

- You can smell fuel inside the car.

- Your check engine light comes on.

If you notice any of these issues, you should test your fuel pressure regulator. Here is a step-by-step guide to testing the regulator:

- Turn off the car and allow the engine to cool down completely.

- Locate the fuel rail's pressure test port and remove the cap.

- Connect the fuel pressure test gauge and tighten it.

- Start the engine and take a reading on the gauge. For a fuel-injected engine, the reading should be between 45 to 55 PSI. If it reads below 40 or above 60 PSI, then you likely have a faulty regulator.

- Turn off the engine and disconnect the vacuum line running to the fuel pressure regulator. Check inside the line for any signs of fuel. If there is fuel inside, it means the regulator's diaphragm has failed and is causing fuel leaks.

- Reattach the vacuum line and start the engine again.

- Check the reading on the fuel pressure gauge, then disconnect the vacuum line. The pressure reading should drop by around 5 to 10 PSI. If it remains the same, the regulator is faulty and needs to be replaced.

How Fuel Pressure Regulators Optimize Engine Performance

You may want to see also

Test for leaking injectors

To test for leaking injectors, you will need a fuel pressure gauge. Follow these steps:

- Install the fuel pressure gauge on the fuel rail Schrader valve.

- Pressurize the system by turning the key on for a few seconds.

- Turn the key off and time the pressure reduction on the gauge. Initial pressure should be approximately 40 pounds per square inch (PSI). Note the time it takes for a pressure drop of 20 PSI to occur. If the time exceeds 20 minutes, the check valve, regulator, and fuel injectors are likely not leaking, and you should refer to the Service Manual for other potential causes.

- If the system pressure drops by 20 PSI or more in 20 minutes or less, one or more of the components mentioned (check valve, regulator, or injectors) may be faulty.

- To isolate the issue further, turn the key on for a few seconds to re-pressurize the system, then clamp the rubber portion of the supply line closed using a pair of vise grips and a shop towel to protect the fuel line.

- Turn the key off and again note the time it takes for a reduction of 20 PSI. If this time is significantly longer than the previous time noted, replacement of the fuel pump is indicated.

- If the times are similar, repeat steps 5 and 6, but this time clamp the return line instead of the supply line. If the time is much longer, a faulty pressure regulator is indicated. If the time remains short, leaking injectors are suspected.

- To confirm leaking injectors, slightly raise the fuel rail out of the inlet manifold without disconnecting any fuel lines and place a small napkin or piece of paper under each injector.

- Pressurize the system by turning the key on for a few seconds, then turn the key off and allow it to sit for about 10 minutes.

- If a leaking injector is indicated by one or more drops of fuel on any of the napkins, all injectors should be replaced.

Alternatively, you can try the following method:

- Turn the key to "ON" to prime the fuel rail, then turn the key "OFF".

- Pinch the return line and observe the fuel pressure gauge. If the pressure drops rapidly (e.g., 5 PSI in a minute), your injector(s) are likely leaking.

- For a more comprehensive test, pinch off both the supply and return lines after building up pressure. If the pressure drops, you have a leaky injector. If the pressure holds, release the supply line. If the pressure then drops, you have a bad check valve in the pump. If the pressure still holds, release the return line. If the pressure drops, you have a faulty pressure regulator.

- To confirm leaking injectors, you can also try lifting the injector rail out of the inlet without depressurizing the system and powering the pump to pressurize the system. This will allow you to see which injectors leak.

Fuel Pressure Maintenance for Jaguar XJ8 Owners

You may want to see also

Check for fuel leaks

Checking for Fuel Leaks

Preparation

Before you begin, ensure you are wearing protective clothing, including work gloves, eye protection, and long sleeves or coveralls. It is also important to work in a well-ventilated area, ideally outside, as fuel vapors are highly flammable. If you must work in a garage, ensure the doors are open and consider using fans to increase airflow. Do not smoke, and avoid any open flames during testing.

Locating Fuel Injectors

Fuel injectors spray fuel into the cylinders in the engine, and are located on the engine manifold positioned on top of the engine. Consult your owner's manual for specific instructions relating to your vehicle.

Listening Test

Start the engine and let it idle. Using a long metal screwdriver, place the tip against one of the fuel injectors, and put your ear to the handle of the screwdriver. A clicking sound indicates a functioning injector. If you hear nothing, the injector may need to be cleaned or replaced. Repeat this process for each injector, making a note of any that are quiet.

Leak Test

Turn on the engine and let it idle for a few minutes. Shine a flashlight or work light under the hood, and look for any signs of leaking gas. If you smell gasoline or spot any leaks, one or more fuel injectors may need to be replaced.

Diagnostic Scanner

A diagnostic scanner, or on-board diagnostics (OBD) reader, can help identify bad fuel injectors by reading the data stored in your vehicle's computer system. Refer to the manufacturer's instructions for guidance on how to connect the scanner to your vehicle and interpret the results.

Fuel Pressure Tester

With the engine off, locate the Schrader valve fitting on the fuel rail, and remove the Schrader valve cap. Attach the appropriate fuel pressure tester fitting, ensuring it is leakproof. Turn the ignition to "on," and check the psi reading. If the pressure drops over 10 minutes, this indicates a leak in the fuel system. Start the engine and let it idle, checking for steady fuel pressure within a few psi of the recommended pressure. Once warmed up, slowly rev the engine, ensuring pressure rises with RPMs. If the pressure holds steady and rises with engine speed, your engine problem is likely not fuel-related.

Troubleshooting

- Zero fuel pressure – Check the fuel pump fuse, and verify power to the pump with a multimeter. If power is present, replace the fuel pump.

- Low fuel pressure – The fuel filter may be clogged, or the pump could be failing. If it is a serviceable type filter, replace it. This could also be caused by improper tank venting or a loose gas cap. Check the cap gasket for damage, and tighten it until it clicks.

- High fuel pressure – Suspect a clogged or kinked fuel return line, a bad fuel pump driver module, or a faulty fuel pressure regulator. These issues may also trigger a "check engine" light.

Additional Notes

- Fuel injectors can wear out over time, typically lasting through 50,000 to 100,000 miles of driving.

- Fuel injectors can become clogged, and sensors can fail, leading to poor performance.

- Always refer to your owner's manual for specific fuel injector testing and engine care instructions.

- Before conducting any tests, ensure your vehicle is in park with the emergency brake applied. Check the temperature of the hood; if it is warm, allow the car to cool completely before proceeding.

- When using a fuel pressure tester, ensure the engine is entirely cold before popping the hood.

- If you suspect a leaky injector, pinch the return line and watch the fuel pressure gauge. If the pressure drops rapidly (e.g., 5 psi in a minute), your injector(s) may be leaking.

Fuel Tank Pressure: What's the Cause?

You may want to see also

Check for clogged fuel filters

Checking for Clogged Fuel Filters

A clogged fuel filter can cause a host of problems for your vehicle, from poor performance to engine failure. It is important to check for a clogged fuel filter if you are experiencing any of the following symptoms:

- Difficulty starting the engine

- Sluggish acceleration, especially uphill or with heavy loads

- Rough idling or intense vibrations when accelerating

- Frequent stalling, especially at idle

- Poor fuel economy

- Strong smell of gasoline in the cabin

- Unusual noises from the fuel pump

- Check engine light is on

To check for a clogged fuel filter, you will need to remove the filter and perform a blow test. Here are the steps to follow:

- Drain the gas from the fuel filter as much as possible.

- Locate the inlet to the fuel filter, which should be labelled as "in" or have an arrow pointing to the direction of the fuel flow. Clean this inlet with a shop towel.

- Place a disposable rag or shop towel on your workbench.

- Gently blow into the inlet of the fuel filter, aiming towards the shop rag on the bench. If the filter is clogged, you will feel resistance when blowing into it.

- Exercise extreme caution when handling gasoline, as it is flammable and has a strong odour. Allow any rags or towels to dry completely before disposing of them, and never throw gasoline or gasoline-soaked rags into the trash.

It is important to note that fuel filters are maintenance items and need to be replaced routinely. The interval between replacements varies depending on the vehicle, with some filters lasting 20,000 to 30,000 miles and others lasting up to 150,000 miles. Always refer to your vehicle's owner's manual or maintenance guide for specific recommendations.

Rebuilding Holley Fuel Pressure Regulators: Step-by-Step Guide

You may want to see also