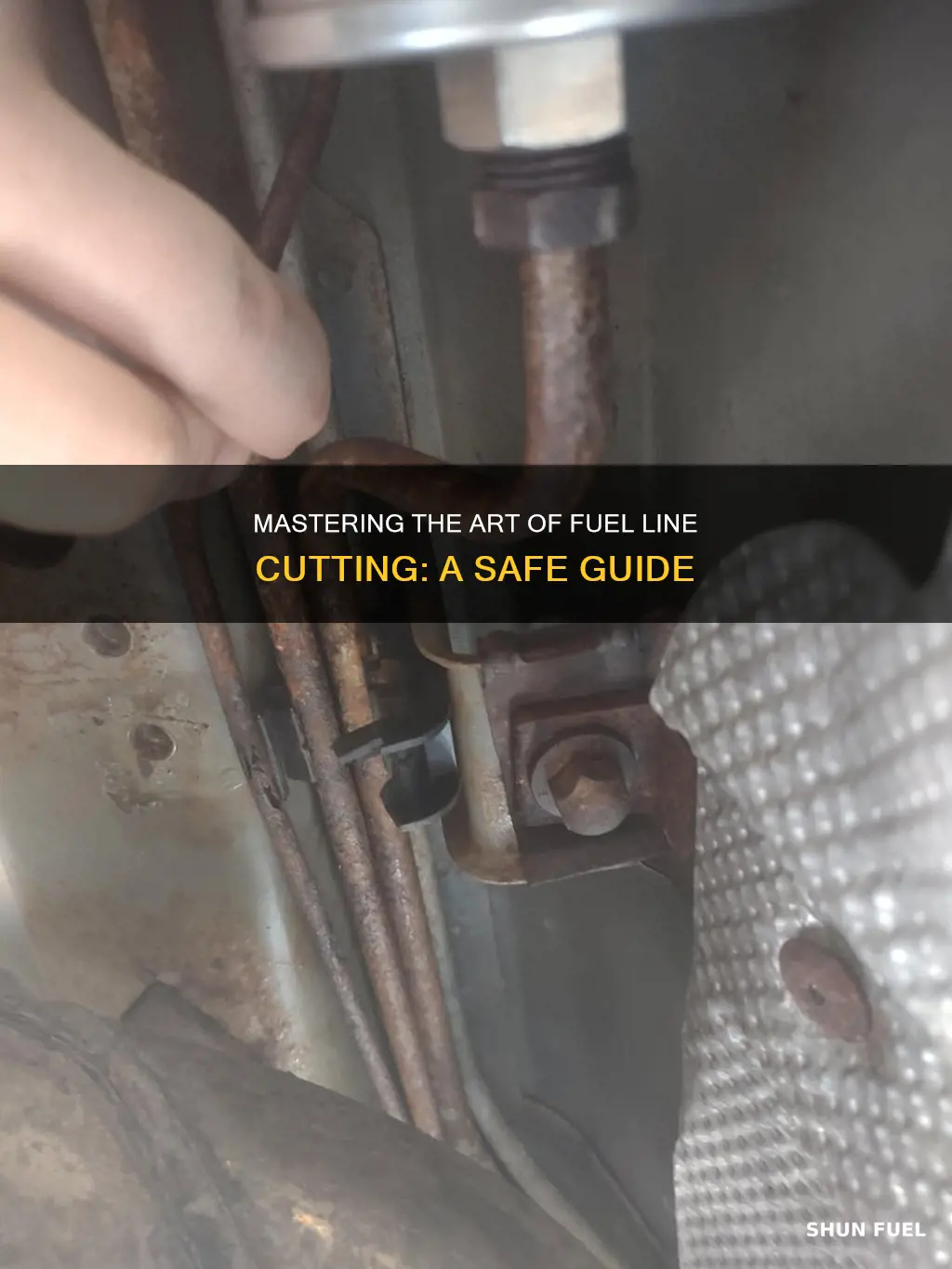

Cutting a fuel line can be a dangerous task if not done properly. It requires careful planning and the right tools to ensure safety. This guide will provide step-by-step instructions on how to safely cut a fuel line, including the necessary safety equipment and precautions to take. By following these guidelines, you can minimize the risk of accidents and ensure a successful and safe cut.

What You'll Learn

- Preparation: Gather tools, wear protective gear, and ensure a well-ventilated workspace

- Location: Identify the fuel line, often near the engine, and mark its position

- Cutting Technique: Use a sharp, clean tool to make a precise cut, avoiding damage to surrounding components

- Bleeding: Release any residual fuel pressure before and after the cut

- Safety Checks: Inspect the cut end for damage, and test for leaks before reassembly

Preparation: Gather tools, wear protective gear, and ensure a well-ventilated workspace

Before attempting to cut a fuel line, it's crucial to prioritize safety and take the necessary precautions. Here's a detailed guide on the preparation phase:

Gather the Right Tools: Ensure you have the appropriate tools for the job. A fuel line cutter or a sharp, clean pair of scissors or a utility knife designed for cutting metal or rubber hoses is essential. Additionally, you'll need a pair of gloves, safety goggles, and a respirator or dust mask to protect your hands, eyes, and lungs from potential hazards. Having a fire extinguisher nearby is also a good idea, especially when dealing with fuel.

Protective Gear: Safety should always be your top priority. Wear thick, heavy-duty gloves made of leather or a similar durable material to protect your hands from cuts and potential burns. Safety goggles are essential to shield your eyes from any debris or sparks that might occur during the cutting process. Consider wearing a full-face respirator or a mask specifically designed for fuel vapor to ensure you're not inhaling any dangerous fumes.

Workspace Preparation: Choose a well-ventilated area for your work. Working in a poorly ventilated space can lead to the inhalation of harmful fuel vapors, which can be dangerous and even life-threatening. If you're working indoors, open windows and doors to allow fresh air to circulate. Alternatively, consider using a portable air purifier or a fan to improve ventilation. Ensure the area is clear of any flammable materials or debris that could create a fire hazard.

Additional Safety Measures: Before starting, double-check that the fuel source is turned off and that the vehicle's ignition is disabled. This is crucial to prevent any accidental fuel release or ignition during the cutting process. It's also a good practice to have someone assist you, especially if it's your first time. Their role can be to monitor the area and ensure your safety. Always be mindful of your surroundings and keep a fire extinguisher close by as a precaution.

By following these preparation steps, you'll be well-equipped to safely cut a fuel line, minimizing potential risks and ensuring a controlled environment for your work. Remember, safety should never be compromised when dealing with fuel or any potentially hazardous materials.

Optimizing Fuel Flow: Choosing the Right Line Size

You may want to see also

Location: Identify the fuel line, often near the engine, and mark its position

When it comes to safely cutting a fuel line, the first and most crucial step is to locate it. The fuel line is a critical component of your vehicle's fuel system, and it's essential to identify it before attempting any modifications or repairs. This process is particularly important if you're working on an older vehicle or one with a non-standard fuel system.

The fuel line is typically located near the engine bay, running from the fuel tank to the engine. It's often a thin, flexible tube with a protective covering. To identify it, start by inspecting the engine bay. Look for any tubes or hoses that appear to be connected to the fuel tank. These are likely to be the fuel lines. You might also notice them because they often have a distinct color or marking, especially if your vehicle has a fuel system diagram or manual available.

Once you've identified the general area of the fuel line, it's a good idea to mark its position. This step is crucial for two reasons. Firstly, it helps you remember the location, especially if you're working on the vehicle in a confined space or low light conditions. Secondly, marking the line ensures that you can easily locate it again if you need to refer back to your work. You can use a piece of tape or a small piece of chalk to mark the spot. Place the marker where the fuel line enters the engine bay, as this is a critical point for cutting the line.

If you're working on a vehicle with a complex fuel system, you might find that there are multiple fuel lines. In this case, it's essential to identify and mark each line separately. This ensures that you don't accidentally cut a line that is still connected to the fuel tank or engine. Take the time to carefully inspect the entire fuel system and mark each line's position accordingly.

Remember, when dealing with fuel lines, it's always better to be cautious and take your time. Proper identification and marking of the fuel line will not only make your task safer but also ensure that your vehicle remains reliable and efficient. Always refer to your vehicle's manual or seek professional advice if you're unsure about any part of the process.

Understanding the Role of AV in Fuel Lines

You may want to see also

Cutting Technique: Use a sharp, clean tool to make a precise cut, avoiding damage to surrounding components

When it comes to safely cutting a fuel line, precision and care are paramount. The process requires a sharp, clean tool to ensure a clean and accurate cut, minimizing the risk of damage to surrounding components. Here's a detailed guide on the cutting technique:

Select the Right Tool: Begin by choosing a high-quality, sharp utility knife or a specialized fuel line cutting tool. Ensure the tool has a fine, sharp blade that can make a clean cut without causing excessive damage. A dull or damaged tool can lead to uneven cuts and potential harm to nearby parts.

Prepare the Work Area: Before you start, clear the area around the fuel line to be cut. Remove any obstacles, tools, or components that might interfere with the cutting process. A clean and organized workspace is essential to prevent accidents and ensure accuracy.

Position the Tool: Hold the fuel line firmly with one hand, providing stability. Position the sharp tool at the desired cut location, ensuring it is aligned with the fuel line's direction. Apply gentle pressure to the tool, allowing it to glide smoothly along the line. This technique ensures a precise cut without putting excessive force on the tool.

Make the Cut: With steady hands, guide the sharp tool along the fuel line, making a clean and straight cut. Keep the blade at a slight angle to the line, ensuring a smooth and accurate cut. Avoid applying too much pressure, as it may cause the tool to wander or damage surrounding components. Take your time and be patient, as rushing can lead to mistakes.

Clean and Inspect: After the cut is made, use a clean cloth or brush to remove any debris or fuel residue from the cut area. Inspect the cut to ensure it is clean and straight. If there are any imperfections, carefully re-cut the line using the same technique. Precision is key to a successful and safe fuel line cut.

Remember, when working with fuel lines, always prioritize safety and precision. This cutting technique ensures a controlled and accurate process, reducing the chances of accidents or damage to the vehicle's internal components.

Optimizing Performance: Choosing the Right Fuel Line for Your Go Devil Engine

You may want to see also

Bleeding: Release any residual fuel pressure before and after the cut

Before you begin the process of cutting a fuel line, it is crucial to ensure that you release any residual fuel pressure to prevent accidents and maintain safety. This step is often overlooked but is essential for a successful and safe procedure. Here's a detailed guide on how to properly bleed the fuel system:

Step 1: Locate the Fuel Tank and Lines: Start by identifying the fuel tank and the fuel lines that connect it to the engine. Typically, there will be a fuel pump, a filter, and multiple lines leading to the engine. Locate the fuel lines that you intend to cut and ensure you have a clear understanding of their connections.

Step 2: Turn Off the Engine and Allow it to Cool: Before proceeding, turn off the engine and allow it to cool down. This is an important safety measure as it prevents any sudden movements or vibrations that could cause fuel to spray or ignite. Working on a hot engine can be extremely dangerous and should be avoided.

Step 3: Relieve Fuel Pressure: The next critical step is to relieve the fuel pressure. This can be done by opening the fuel tank vent or using a fuel pressure release valve, if available. Locate the fuel tank's vent and open it to allow air to enter the system, which will help release the pressure. Alternatively, some engines have a dedicated fuel pressure release button or valve that can be pressed to bleed the system.

Step 4: Cut the Fuel Line: Once the fuel pressure has been relieved, you can safely proceed with cutting the fuel line. Use a sharp, clean tool to make a precise cut, ensuring you cut through the fuel line only. Avoid damaging nearby components or creating a sharp edge that could cause fuel to leak. It is recommended to wear protective gear, such as gloves and safety goggles, to protect yourself from any potential fuel splashes.

Step 5: Verify the Cut: After cutting the fuel line, check for any signs of fuel leakage. If there is no leakage, you can proceed to the next step. However, if any fuel is observed dripping or leaking, immediately stop and address the issue. Ensure that the area around the cut is clean and free of any flammable substances.

Step 6: Re-bleed the System (Optional): Depending on the specific application and your comfort level, you might want to re-bleed the fuel system after cutting the line. This step ensures that any remaining fuel pressure is released, providing an extra layer of safety. Simply repeat the process of opening the fuel tank vent or using the fuel pressure release valve.

Remember, safety should always be the top priority when working with fuel lines. Taking the time to properly bleed the system will significantly reduce the risk of accidents and ensure a smooth and controlled process. Always follow manufacturer guidelines and consult professional resources for specific instructions related to your vehicle or equipment.

Small Engine Fuel Line: Top Stores and Online Sources

You may want to see also

Safety Checks: Inspect the cut end for damage, and test for leaks before reassembly

Before reassembling the fuel line, it's crucial to perform a series of safety checks to ensure that the cut end is intact and secure. Start by carefully inspecting the cut end of the fuel line for any signs of damage. Look for cracks, tears, or any other imperfections that could compromise the line's integrity. If you notice any damage, it's essential to address it immediately. In some cases, minor damage might be repairable with a specialized fuel line repair kit, but severe damage may require replacing the entire line.

Next, you should test the cut end for leaks. This step is critical to ensure that there are no fuel leaks, which can be dangerous and environmentally harmful. Here's how to do it:

- Prepare the Environment: Ensure you are working in a well-ventilated area, preferably outdoors, to minimize the risk of inhaling fuel vapor.

- Use a Soapy Water Solution: Mix a few drops of dish soap with water in a spray bottle. This solution will help you detect leaks more easily.

- Spray the Cut End: Spray the soapy water solution generously onto the cut end of the fuel line. Pay close attention to the area where the fuel line was cut.

- Look for Bubbles: If you see any bubbles forming on the surface of the fuel line or near the cut, it indicates a leak. Bubbles are a clear sign that fuel is escaping.

- Test for Air Leaks: If no bubbles form, it's important to test for air leaks. You can do this by holding a piece of paper or a rag over the cut end and gently blowing air towards it. If you see any movement or air escaping, there is a leak.

If you detect any leaks, you must address them immediately. Leaks can lead to fuel contamination, engine performance issues, and potential safety hazards. Depending on the severity of the leak, you might need to clean the affected area, apply a fuel line repair compound, or replace the fuel line entirely.

Once you've confirmed that the cut end is free of damage and leaks, you can proceed with reassembling the fuel line. Always follow the manufacturer's instructions for reassembly to ensure a secure and safe connection.

Finding the Perfect Fuel Line for Your 1993 Toyota 4Runner

You may want to see also

Frequently asked questions

Prior to cutting any fuel line, it is crucial to ensure your safety and that of those around you. Always wear protective gear, including gloves and safety goggles, to guard against potential splashes or debris. Additionally, make sure the engine is cool to avoid burns from hot lines.

Locating the specific fuel line can be done by consulting your vehicle's manual or by using a fuel line identifier. Often, fuel lines are colored-coded for easy identification. For example, a blue line might indicate the primary fuel supply, while a red line could be for the return line. If you're unsure, it's best to consult a professional or use a fuel line tracer.

When cutting a fuel line, use a sharp, clean pair of fuel line cutters or a utility knife designed for fuel lines. Ensure the cutting tool is appropriate for the diameter of the line. Always cut straight and avoid cutting too close to the fuel source to prevent spills. After cutting, use a fuel line ferrule or tape to create a secure, leak-free seal at the end.