If you're looking to enhance the performance of your 1969 Mustang, one of the key areas to focus on is the fuel system. Running a return fuel line is a great way to improve fuel efficiency and power output. This guide will walk you through the process of installing a return fuel line on your classic Mustang, ensuring you have the necessary tools and knowledge to complete the job successfully. By following these steps, you'll be able to enjoy a smoother, more responsive drive while keeping your engine running at its best.

| Characteristics | Values |

|---|---|

| Fuel Line Material | Typically made of rubber or vinyl, but can also be steel or aluminum. |

| Line Diameter | Common sizes include 3/8" and 1/2" ID. |

| Length | Varies depending on the vehicle's configuration and fuel tank location. |

| Clamps | Used to secure the fuel line to the tank and other components. |

| Fittings | Includes fuel line connectors, bends, and adapters for various connections. |

| Installation | Requires careful routing to avoid damage and ensure proper function. |

| Maintenance | Regularly inspect for cracks, leaks, and signs of deterioration. |

| Compatibility | Ensure the fuel line is compatible with the fuel type (gasoline, ethanol, etc.) and vehicle's fuel system. |

| Safety | Properly secured fuel lines prevent fuel leaks and potential fire hazards. |

What You'll Learn

- Preparation: Gather tools, safety gear, and the necessary fuel line components

- Fuel Tank Access: Locate and open the fuel tank for line installation

- Line Routing: Plan and route the line, considering engine bay space

- Clamps and Fittings: Use appropriate clamps and fittings for a secure connection

- Testing: Check for leaks and ensure proper fuel flow after installation

Preparation: Gather tools, safety gear, and the necessary fuel line components

Before you begin the process of installing a return fuel line on your 1969 Mustang, it's crucial to prepare the necessary tools, safety equipment, and components to ensure a smooth and safe installation. Here's a detailed guide on what you need to gather:

Tools and Equipment:

- Wrenches and Pliers: You'll need a variety of wrenches and pliers to tighten connections and adjust fittings. Ensure you have adjustable wrenches, pipe wrenches, and channel locks for gripping and turning.

- Fuel Line Cutter: A specialized fuel line cutter will allow you to precisely cut the fuel line to the required length. This tool is essential for creating clean and accurate cuts.

- Fuel Line Crimper: A crimper is used to install fuel line fittings securely. Get a crimper that can handle the size of the fuel lines you'll be working with.

- Sandpaper or Embelishing Tool: These tools are used to smooth and prepare the fuel line ends for insertion into fittings.

- Rags or Cloths: Keep a supply of rags or old clothes to protect your hands and work area from fuel spills.

- Safety Goggles and Gloves: Eye protection is essential to shield your eyes from any potential fuel splashes. Gloves will also protect your hands during the installation process.

Safety Gear:

- Safety Mask: If you're working in a well-ventilated area, a safety mask can help prevent inhaling fuel vapor.

- Gloves: Leather or heavy-duty gloves will provide grip and protect your hands from sharp edges and potential cuts.

- Old Clothing: Wear old clothes that you don't mind getting dirty or stained with fuel.

- Fire Extinguisher: Keep a fire extinguisher nearby as a safety precaution, especially when working with fuel.

Fuel Line Components:

- Fuel Line: Purchase a new fuel line that is compatible with your 69 Mustang's fuel system. Ensure it is the correct size and length for your specific application.

- Fittings: Gather the necessary fittings, such as fuel line connectors, bends, and adapters. Common fittings include 90-degree bends, straight connectors, and fuel filter adapters.

- Fuel Line Clamps: You'll need rubber or metal clamps to secure the fuel line to the vehicle's body and other components.

- Fuel Line Primer (Optional): Consider using fuel line primer to ensure a clean and secure connection between the fuel line and fittings.

By gathering these tools, safety gear, and components, you'll be well-prepared to tackle the installation of the return fuel line on your classic 69 Mustang. Remember to work in a well-ventilated area and take the necessary safety precautions to ensure a successful and safe project.

1985 Mariner Fuel Line Connections: A Style Guide

You may want to see also

Fuel Tank Access: Locate and open the fuel tank for line installation

To access the fuel tank and prepare for the return fuel line installation on your 69 Mustang, follow these detailed steps:

Locate the Fuel Tank: The fuel tank on a 69 Mustang is typically located behind the rear seat, accessible by removing the seat or the rear panel. If your car has a center console, you might need to remove it as well. Carefully inspect the area and identify the fuel tank, which is usually a large, cylindrical component.

Prepare for Access: Before opening the fuel tank, ensure you have the necessary tools, such as a fuel pump shut-off tool or key, and a fuel line disconnect tool. It is crucial to shut off the fuel supply to prevent any spills or accidents. Locate the fuel shut-off valve, often found near the fuel tank or under the hood, and turn it to the 'off' position. Then, disconnect the fuel lines leading to the tank.

Open the Fuel Tank: Carefully lift the rear seat or remove the rear panel to access the fuel tank. You might need to unbolt or release any retaining clips or fasteners. Once the access panel is open, locate the fuel tank's release mechanism, which could be a lever or a button. Press or pull this mechanism to release the tank's locking mechanism. Gently pull the fuel tank away from the vehicle, ensuring you have a stable base to work on.

Install the Return Line: With the fuel tank accessible, you can now install the return fuel line. Ensure the line is routed correctly and securely attached to the appropriate fittings on the tank. Use fuel line connectors or clamps to ensure a tight and leak-free connection. Double-check the routing to avoid any sharp bends or stress on the line.

Remember, when working with fuel, safety is paramount. Always wear protective gear, and ensure proper ventilation in the workspace. If you are unsure about any step, consult a professional mechanic or refer to detailed guides specific to your 69 Mustang model.

Fuel Line Sources for 2000 Mercury Mountaineer: Quick and Easy Access

You may want to see also

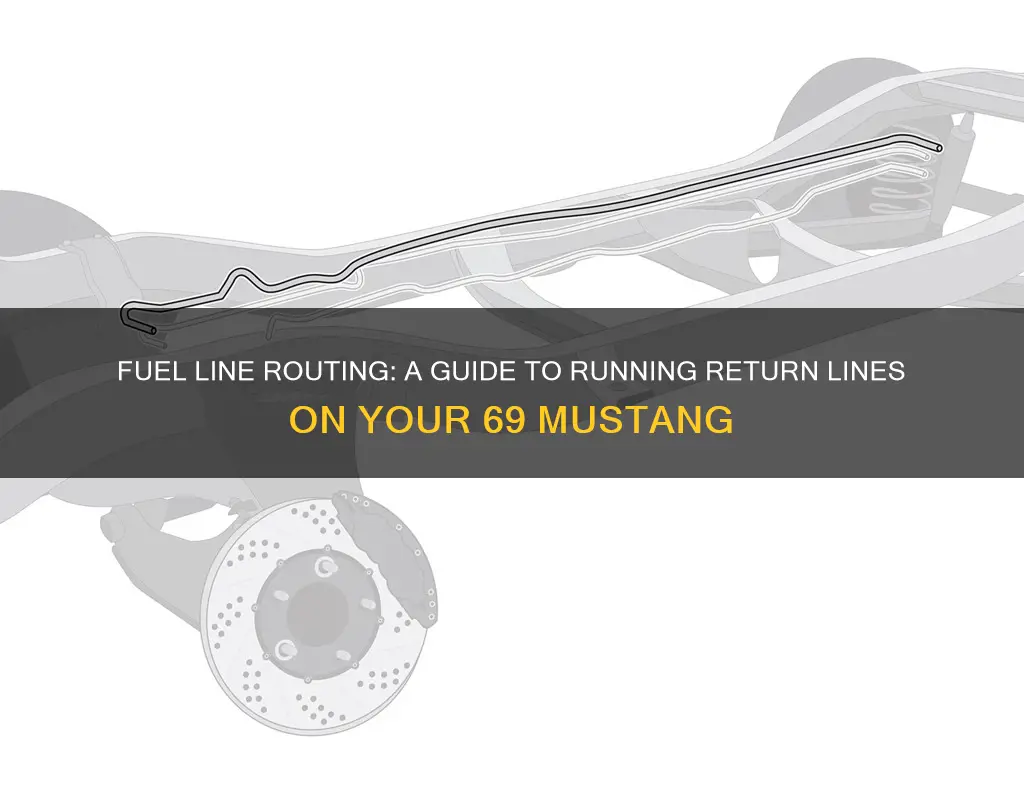

Line Routing: Plan and route the line, considering engine bay space

When working on a classic car like a 69 Mustang, proper fuel line routing is crucial for both performance and aesthetics. The return fuel line, which carries unused fuel back to the tank, needs to be carefully planned to ensure it doesn't interfere with other components and maintains optimal flow. Here's a step-by-step guide to routing the return fuel line, keeping in mind the engine bay space:

- Assessment and Planning: Begin by assessing the engine bay layout of your 69 Mustang. Identify the available space and consider the positions of the engine, transmission, radiator, and other critical components. The goal is to find a path that minimizes interference and allows for easy access during maintenance. Typically, the return fuel line will need to pass through the engine bay, possibly crossing various components like the firewall, air intake, or even the alternator.

- Route Selection: Choose a route that provides a clear path from the fuel pump to the tank. One common approach is to run the line along the firewall, utilizing the existing mounting holes or creating new ones if necessary. This route often provides a clean and unobstructed path. Alternatively, you might consider routing the line behind the alternator or along the top of the engine bay, ensuring it doesn't interfere with the air intake or other moving parts.

- Material and Protection: Opt for a fuel-resistant material for the line to prevent leaks and ensure longevity. You can use a flexible fuel line or even a braided option for added durability. Consider covering the line with a heat shield or protective tape to safeguard it from engine heat and potential damage.

- Secure Mounting: Properly secure the fuel line to prevent movement and potential damage. Use appropriate clamps or ties to attach the line to the firewall, fender, or other suitable mounting points. Ensure the line is taut and doesn't rub against any sharp edges or components.

- Testing and Adjustments: After installation, start the engine and check for any leaks or unusual noises. Ensure the line is securely fastened and doesn't interfere with other components during engine operation. Make any necessary adjustments to optimize the route and clearances.

Remember, the key to successful fuel line routing is careful planning and consideration of the engine bay's layout. By following these steps, you can ensure a clean, functional, and aesthetically pleasing fuel system for your 69 Mustang.

Unveiling Destiny 2's Fuel Line: Location Guide

You may want to see also

Clamps and Fittings: Use appropriate clamps and fittings for a secure connection

When working on the fuel system of a classic 69 Mustang, ensuring a secure and reliable connection for the return fuel line is crucial. The process involves several key steps, and using the right clamps and fittings is an essential part of this. Here's a detailed guide on how to achieve this:

Selecting the Right Clamps and Fittings:

The first step is to choose the appropriate clamps and fittings that are compatible with your Mustang's fuel system. For the return fuel line, you'll typically need a fuel line clamp and a fitting that matches the line's diameter. Common sizes for fuel lines in older Mustangs range from 3/8" to 1/2" in diameter. Ensure you measure the fuel line to get the correct size. Look for high-quality clamps and fittings made from durable materials like stainless steel or brass to withstand fuel pressure and potential heat.

Preparing the Line and Fitting:

Before installation, inspect the fuel line for any damage or bends that might cause issues. Straighten the line if necessary. Then, cut the fitting to the appropriate length, ensuring it provides enough space for the clamp to secure the line firmly. Clean the fitting and the fuel line to remove any dirt or debris that could interfere with the connection.

Installation Process:

- Start by positioning the fitting onto the fuel line, ensuring it is centered and aligned correctly.

- Tighten the clamp securely over the fitting and fuel line. Use a wrench to apply firm pressure, but be careful not to overtighten, as this can damage the line.

- Check for any leaks by applying fuel to the line and inspecting for any drips. If there are any leaks, tighten the clamp further or adjust the fitting position.

- Repeat this process for any additional fuel lines or fittings required in your setup.

Security and Aesthetics:

Properly secured clamps and fittings not only ensure the fuel system's reliability but also contribute to the overall appearance of your Mustang. Well-organized and neatly installed fuel lines can enhance the visual appeal of your engine bay. Consider using different colors or types of clamps to create a custom look while maintaining functionality.

Remember, when working with fuel lines, it's crucial to follow safety guidelines and ensure all connections are secure to prevent fuel leaks and potential hazards. This detailed approach to installing clamps and fittings will help you achieve a professional-looking and functional fuel system for your 69 Mustang.

The Ultimate Guide to Choosing the Right Hose Clamp for Your 3/8" Outboard Fuel Line

You may want to see also

Testing: Check for leaks and ensure proper fuel flow after installation

After completing the installation of the return fuel line on your 69 Mustang, it's crucial to thoroughly test the system to ensure it functions correctly and safely. This step is often overlooked, but it's essential to verify that the fuel lines are leak-free and that the fuel is flowing properly to the engine. Here's a detailed guide on how to test and ensure the integrity of your fuel system:

Step 1: Visual Inspection

Start by visually inspecting the fuel lines and connections. Look for any signs of damage, cracks, or bulging. Ensure that all fittings and clamps are secure and tightly in place. Check for any visible leaks around the connections, especially where the fuel lines attach to the fuel tank, pump, and engine. Even a small leak can lead to fuel wastage, contamination, or potential fire hazards.

Step 2: Pressure Test

Perform a pressure test to check for leaks and ensure the fuel system's integrity. You can use a fuel pressure gauge for this test. Start the engine and allow it to idle. Connect the gauge to the fuel rail or the point where the fuel lines connect to the engine. Read the pressure and ensure it falls within the recommended range specified for your Mustang model. If the pressure is too low, it may indicate a restriction or leak in the system. If the pressure is too high, it could suggest an issue with the fuel pump or injectors.

Step 3: Leak Down Test

A leak-down test is another effective method to identify any fuel leaks. With the engine off, disconnect the fuel lines one by one and apply a small amount of diesel fuel or soapy water to the connections and lines. Inspect the area for any bubbles or soap suds, indicating a leak. Reattach the lines and repeat the process until all connections are checked. This test is crucial as it helps identify hidden leaks that might not be visible during the visual inspection.

Step 4: Ensure Proper Fuel Flow

With the engine running, monitor the fuel flow to ensure it's adequate. Check for any unusual noises, such as hissing or roaring, which could indicate a restricted fuel line or a potential leak. Feel the fuel lines for warmth, as this can suggest proper fuel flow and pressure. If the fuel lines are cold, it might indicate a restriction or a need for more fuel pressure.

Step 5: Professional Assistance

If you encounter any issues during the testing process, it's advisable to consult a professional mechanic. They can provide specialized tools and expertise to diagnose and resolve any problems. They might also offer valuable advice on maintaining and optimizing your fuel system's performance.

Remember, proper testing ensures the longevity and reliability of your 69 Mustang's fuel system. It's an essential step that should not be overlooked to avoid potential issues on the road.

Ford Fuel Line Clip Removal: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Running the return fuel line on a classic Mustang involves a few steps. First, you'll need to locate the fuel pump and identify the return line, which is typically a smaller diameter hose. Then, you can start by disconnecting the fuel pump from the existing return line. Next, measure and cut the new return line to the appropriate length, ensuring it's compatible with the fuel pump and the vehicle's frame. Secure the new line with clamps or brackets to maintain a tight fit. Finally, reconnect the fuel pump and test the system to ensure proper fuel flow.

You'll need some basic automotive tools and supplies for this task. A fuel pump disconnect tool or a suitable socket is essential to release the fuel pressure safely. Additionally, have a new return fuel line ready, preferably made of durable materials like stainless steel or high-quality rubber. Clamps, hose clips, or brackets to secure the line are also necessary. It's recommended to have a fuel pressure gauge to monitor the system during the installation process.

Yes, there are a few potential challenges. Ensure that the fuel pump is functioning correctly before starting the installation. Check for any signs of damage or wear that might affect the pump's performance. Also, be cautious when handling fuel lines to avoid kinks or damage. Properly secure the lines to prevent leaks and ensure a tight fit. Finally, double-check all connections and test the fuel system thoroughly to identify and address any potential issues before taking the car for a test drive.