The Workhorse W22 fuel pump is a component of the Workhorse W22 chassis, which is used in recreational vehicles (RVs) such as motorhomes. While some owners have reported issues with the fuel pump, resulting in stalling, sputtering, and loss of power, others have found that the fuel pump generally lasts for a long time without any problems. Replacing the fuel pump can be a complex task, as it involves dropping the fuel tank, and there may be variations in the connector/wiring harness that need to be considered. The cost of a new fuel pump can range from $175 to $700 or more, depending on the source and whether it includes labour for installation. When replacing the fuel pump, it is also recommended to replace other components such as fuel lines, hoses, and filters, to ensure the fuel system is in optimal condition.

What You'll Learn

Fuel pump replacement cost

The cost of replacing a fuel pump varies depending on the vehicle, its age, and the location of the replacement. The average cost of a fuel pump replacement is between $220 and $1,321, with parts costing between $95 and $1,110, and labor costing between $124 and $700.

Factors Affecting Fuel Pump Replacement Cost

Vehicle and Age

The make and model of the vehicle, as well as its age, can impact the cost of replacement. For instance, newer models from automakers like BMW, Honda, Chevrolet, and Toyota have an average cost for fuel pump replacement between $611 and $894.

Labor

The number of labor hours needed and the average cost per hour for labor will affect the overall cost. The average cost per hour for labor is $90, but this can vary between $60 and $140 depending on the location. If the entire fuel assembly needs to be replaced, the average labor time is between 2-3 hours.

Additional Parts

If other parts related to the fuel assembly need to be replaced, this will increase the overall cost. It is generally recommended to replace the fuel filters and the fuel pump relay at the same time as the fuel pump.

Professional vs. DIY

Replacing the fuel pump yourself can save on labor costs, but it is important to note that working with the fuel system is dangerous and it is recommended to leave this job to professionals.

Signs of a Failing Fuel Pump

- Inability to maintain speed

- Engine "choking" or struggling

- Engine overheating

- Sputtering, backfires, and strange noises

- "Check Engine" light is on

- Thick black or white smoke from the exhaust (for gasoline-powered cars)

- Spark plugs dying sooner

Tips for Extending the Life of a Fuel Pump

- Keep the gas tank at least a quarter full

- Replace the fuel filter regularly

- Ensure a secure seal on the gas cap

- Avoid poorly maintained gas stations

- Regularly service your vehicle as recommended

Replacing Fuel Pump in 98 Caravan: Step-by-Step Guide

You may want to see also

Fuel pump failure causes

Fuel pumps are designed to be durable and long-lasting, but they are still susceptible to damage and will eventually need to be replaced. Here are some of the most common causes of fuel pump failure:

Contaminated Fuel

Dirt, debris, or water in the fuel can damage the pump over time. These contaminants can cause increased friction, leading to premature wear of the pump components. This includes fuel that is saturated with rust or other particulates in the gas station's storage tank, as well as moisture that develops in the fuel tank when a vehicle sits for extended periods without using a fuel stabilizer.

Wear and Tear

Like all mechanical parts, fuel pumps have a lifespan. Continuous use over extended periods can lead to decreased efficiency and eventual failure. On average, a fuel pump is built to last between 100,000 and 200,000 miles, but this can be prolonged with good vehicle maintenance.

Electrical Issues

Electrical faults are significant contributors to fuel pump failures. This includes faulty wiring, corroded or loose connections, or blown fuses, which can disrupt the power supply to the pump. In the case of one Workhorse W22 owner, the fuel pump failed due to a newer pump being installed with an incompatible connector/wiring harness.

Overheating

Running a vehicle on low fuel can cause the pump to overheat and fail. Since the fuel acts as a coolant for the pump, consistently low levels can lead to increased temperatures, reducing the pump's lifespan. This is a particular concern for the Workhorse W22, as one owner reported repeated fuel pump failures when the tank level dropped below a quarter full.

Clogged Filters

If the fuel filter gets clogged due to bad fuel or a dirty fuel tank, the pump will work harder to push the necessary fuel to the engine. If left unreplaced, the pump can overheat and corrode.

Replacing the Fuel Pump in a 97 Grand Prix

You may want to see also

Fuel pump maintenance

Weekly Visual Inspections

It is recommended to inspect your fuel pump at least once a week to check for leaks on pumps, filters, hoses, nozzles, joints, and fittings. This can help detect problems early on and prevent them from becoming bigger issues. Keep the pump clean to preserve its functionality and prevent the spread of germs, using a degreaser and gentle cleanser. Avoid harsh solutions, as ammonia-based cleansers can damage the screens and other components.

Underground Tank Checks

If you have underground tanks, regularly inspect the overfill alarms to ensure they are functioning correctly. These alarms identify leaks and help mitigate potential hazards and costly repairs.

Proactive Problem-Solving

Stay ahead of potential issues by scheduling maintenance appropriately. Depending on usage frequency, you may need weekly operational checks and monthly inspections. Address any issues promptly to ensure smooth operations and reduce downtime.

Fuel Pump Replacement

When replacing the fuel pump, choose a high-quality replacement that meets OEM specifications. Properly prime the new pump before installation and ensure secure electrical connections and proper mounting.

General Fuel System Maintenance Tips

- Use high-quality fuel from reputable sources.

- Regularly replace the fuel filter as per the manufacturer’s recommendations.

- Keep the fuel tank at least one-quarter full to prevent pump damage and sediment buildup.

- Promptly address any fuel system issues to prevent further damage.

- Perform regular engine tune-ups to maintain overall vehicle health.

Safety Considerations

When working on a fuel system, always prioritize safety:

- Disconnect the battery before beginning repairs.

- Work in a well-ventilated area to avoid inhaling fuel fumes.

- Wear protective gloves and eyewear to prevent contact with fuel and debris.

- Keep a fire extinguisher nearby.

- Properly dispose of any old fuel or components according to local regulations.

Golf Cart Fuel Vent: Replacing the Essential Part

You may want to see also

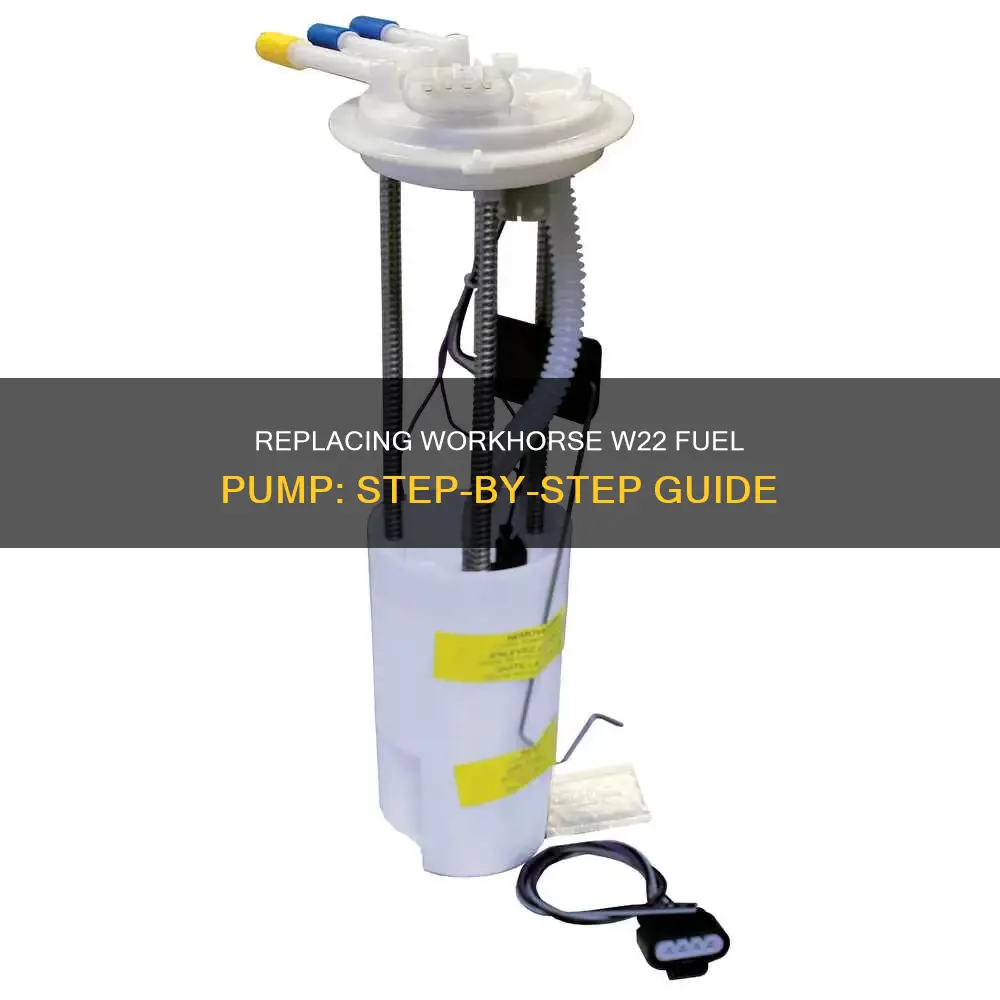

Fuel pump installation

To install a fuel pump for a Workhorse W22, you will first need to drain the fuel tank. This can be done by siphoning the fuel or, if the tank is not too full, lowering it with a floor jack. Once the tank is drained, you can begin the process of removing the old fuel pump and installing the new one.

The next step is to disconnect the fuel lines and vent lines from the tank. This can be a tricky process, so it is important to be careful and take your time. It may be necessary to use a tool to remove the fuel lines, which can be purchased at most auto parts stores. With the lines disconnected, you can now remove the old fuel pump assembly. This typically involves removing some bolts or other fasteners that hold the assembly in place.

With the old fuel pump removed, you can now install the new one. Make sure to follow the manufacturer's instructions for proper installation. It is important to ensure that all connections are secure and that the new fuel pump is properly seated in the tank. Once the new fuel pump is installed, you can reconnect the fuel lines and vent lines.

Finally, you will need to refill the fuel tank and start the engine to test the new fuel pump. It is important to keep an eye on the engine and fuel pump for any signs of leaks or other issues. If everything looks good, then you have successfully installed your new fuel pump!

Note that there are some variations in fuel pump designs, so it is important to consult the specific instructions for your particular model. Additionally, working on fuel systems can be dangerous, so it is always best to consult a professional if you are unsure about any part of the process.

Trimmer Fuel Tubing: Replacing and Revitalizing Your Trimmer

You may want to see also

Fuel pump alternatives

There are several alternative fuel pumps available on the market, each with its own unique features and benefits. Here are some options to consider:

Electric Fuel Pumps

Electric fuel pumps offer a more modern approach to fuel transfer. They are known for their quiet operation and ease of use. Some popular choices include:

- Carter P4600HP: This pump is highly regarded for its whisper-quiet operation and ability to work with a one-way line to the carbs. It has a standard pressure output of 100 GPH at 6-8 PSI and is compatible with braided fuel lines.

- Aeromotive Fuel Pump: Aeromotive offers a range of high-performance fuel pumps known for their reliability. They are a popular choice for those seeking a quiet and efficient fuel delivery system.

- TERA PUMP Electric Multipurpose Gas Pump: With a flow rate of up to 2.5 gallons per minute, this pump is suitable for gasoline, E15, and E85 fuels. It features a long suction tube and is easy to control.

Mechanical Fuel Pumps

Mechanical fuel pumps are a more traditional option and are known for their durability and simplicity. Some well-known mechanical fuel pumps include:

- Edelbrock Victor Fuel Pump: This fuel pump has a reputation for longevity and is designed to resist corrosion from corn-based ethanol fuels.

- Facet Fuel Pump: Facet fuel pumps are commonly used in aviation and are known for their reliability. Pegasus Auto Racing sells these pumps, ensuring a quality product.

- SU Fuel Pump: The SU fuel pump is a popular choice for Austin-Healey vehicles. While they can be expensive, there are more affordable alternatives available that provide similar performance.

Replacing Fuel Lines in a '96 Jeep Cherokee: DIY Guide

You may want to see also

Frequently asked questions

If you're experiencing stalling, sputtering, and loss of power after driving a while, especially when hot, it could be a sign that your fuel pump needs replacing. However, it is recommended to check for fault codes and ensure that your fuel filter and spark plug wires are in good condition before concluding that the fuel pump is defective.

While there is no definitive answer to this question, some Workhorse W22 owners have reported replacing their fuel pumps after approximately 35,000 to 40,000 miles as a preventative measure. However, others have suggested that the fuel pump should last up to 100,000 miles or more with proper maintenance. It is recommended to regularly inspect and replace the fuel filter, spark plugs, and other related components to help extend the life of the fuel pump.

Symptoms of a failing Workhorse W22 fuel pump can include stalling, sputtering, loss of power, and difficulty starting the engine, especially when the fuel tank is less than a quarter full. In some cases, the fuel gauge may also stop working due to a faulty sending unit in the fuel pump assembly.

The cost of replacing the Workhorse W22 fuel pump can vary depending on the year and model of your vehicle. The fuel pump assembly itself can cost around $500 to $700, while the labor to drop the tank and install the new pump can add an additional $400 or more. It is recommended to shop around and compare prices from different suppliers and mechanics to find the best deal.