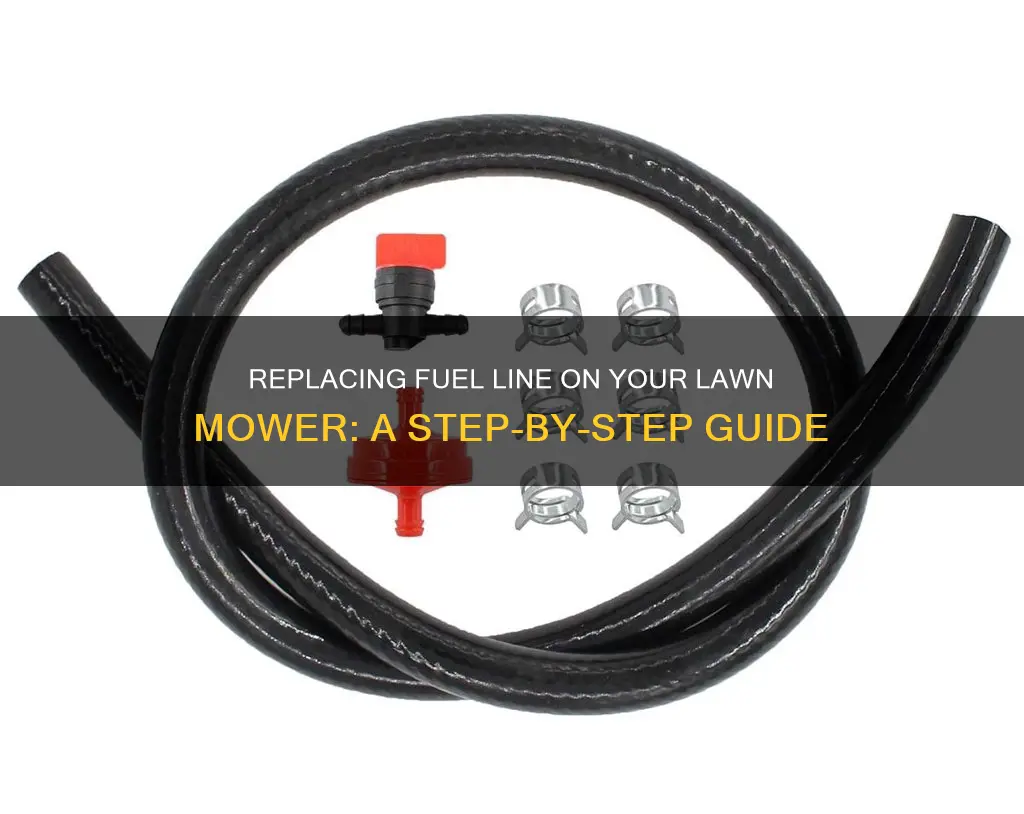

Replacing the fuel line on a lawnmower requires several steps and safety precautions. Before starting, run the engine until it stops due to lack of fuel and wait for it to cool down. Then, use standard pliers to squeeze the tabs on the hose clamps and slide them away from the hose ends. Remove the hose from the fittings, being cautious of any residual fuel. Keep the old hose to measure the proper length for the new one. Trimming the replacement hose may create small burrs or particles that could fall into the hose, so ensure it's clear before installing. Install new clamps on each end of the new hose, slide it over the fittings, and secure it with the clamps. Finally, check for leaks during the first use and stop the engine immediately if any fuel leakage is detected.

Characteristics and Values for Fuel Hose Replacement

| Characteristics | Values |

|---|---|

| Engine | Run until it stops due to lack of fuel |

| Maintenance | Wait for the engine to cool |

| Tools | Standard pliers |

| Hose Clamps | Squeeze tabs and slide away from hose ends |

| Hose Fittings | Remove the hose |

| Residual Fuel | Keep old hose for length reference, beware of flammability and wipe up spills |

| New Hose | Trim to match the length of the old hose, check for dirt/particles |

| Installation | Install new clamps, secure with hose over fittings |

| Leaks | Check for leaks, stop the engine and re-secure if leaking |

What You'll Learn

Run the engine until it stops due to lack of fuel

To replace the fuel line on your lawnmower, the first step is to run the engine until the fuel tank is empty. This is an important safety measure to prevent any spillage of gasoline when you remove the hose. Gasoline is highly flammable and explosive, so it's crucial to ensure there is no fuel remaining in the tank before performing any maintenance on the fuel system. Keep running the engine until it stops of its own accord due to a lack of fuel.

Once the engine has run out of fuel and stopped, it's important to let it cool down completely before proceeding. The engine can become very hot during operation, and attempting to work on it before it has cooled may result in injury. Wait patiently for the engine to cool, which could take some time, and do not attempt to rush the process.

During this cooling period, you can take the opportunity to gather the tools and materials you'll need for the job. Standard pliers will be required to squeeze the tabs on the hose clamps, and you may also want to have some rags or absorbent materials on hand in case of any residual fuel in the hose. It's also a good idea to have a container or tray nearby to catch any drips or spills that may occur during the hose removal process.

As you wait for the engine to cool, you can also measure the length of the old hose and purchase or cut a replacement hose to the same length. This will ensure that the new hose fits perfectly and doesn't cause any issues with fuel flow or connectivity to the fittings. Remember to check the new hose for any debris or particles that may have been introduced during the cutting process, as these can clog the fuel line or damage the engine.

When to Replace Your Fuel Filter: Signs to Watch For

You may want to see also

Allow the engine to cool

Before you begin any maintenance on your lawnmower, it is imperative that you allow the engine to cool. This is a crucial safety measure that must not be overlooked. Working on an engine that has not had time to cool down can put you at serious risk of injury.

The first step is to run the engine until it stops due to a lack of fuel. This ensures that you are working with as little fuel as possible when you begin the maintenance process. Once the engine has run out of fuel and stopped, you must exercise patience and give it ample time to cool. Do not be tempted to rush this step. The cooling process can take some time, depending on the ambient temperature and the engine's design. It is better to err on the side of caution and wait a little longer to ensure the engine is sufficiently cooled.

While you are waiting, you can take the opportunity to gather all the tools and materials you will need for the fuel line replacement. Standard pliers, for example, will be required to squeeze the tabs on the hose clamps. It is also important to have a plan for dealing with any residual fuel in the hose. Gasoline is highly flammable and explosive, so have some rags or absorbent materials on hand to wipe up any spills immediately.

By following these steps and allowing the engine to cool, you are prioritising safety and reducing the risks associated with lawnmower maintenance. This cautious approach will help ensure that you can complete the fuel line replacement without incident or injury.

Replacing the Fuel Regulator in Your 2004 Nissan Frontier

You may want to see also

Remove hose clamps with pliers

To remove hose clamps with pliers, first make sure you have the right type of pliers for the job. Hose clamps come in a variety of styles, so you'll need to select the correct tool. For example, you can use flexible hose clamp pliers for a variety of different-sized hose clamps.

Once you have the right tool, follow these steps:

- Using standard pliers, squeeze the tabs on the hose clamps to loosen them.

- Slide the clamps away from the hose ends.

- Remove the hose from the fittings, being careful of any residual fuel in the hose.

- Keep the old hose so you can use it to measure the proper length for the new hose.

It's important to note that gasoline and its vapors are extremely flammable and explosive, so be sure to wipe up any spilled fuel immediately and do not attempt to start the engine until the fuel has evaporated.

Additionally, when selecting your pliers, consider the following:

- Opt for pliers with an ergonomic design and non-slip rubber handles to prevent hand fatigue during prolonged use.

- For hard-to-reach clamps, consider using flexible wire-style hose clamp pliers or slip joint pliers.

- Needle-nose vise grips can also be useful for removing hose clamps.

- If you're having trouble reaching the clamp, you may need to remove any obstructions, such as the T-stat housing, to access the hose and clamp more easily.

By following these steps and selecting the appropriate tools, you can effectively remove hose clamps with pliers during fuel line replacement or other maintenance tasks.

Outboard Fuel Filter: Replacing Yamaha's with Precision

You may want to see also

Remove the hose, being mindful of residual fuel

Before removing the hose, ensure that the engine has cooled down after running out of fuel. Safety is paramount when dealing with flammable and explosive substances like gasoline and its vapors. Once the engine has cooled, use standard pliers to gently squeeze the tabs on the hose clamps. This action will allow you to slide the clamps away from the hose ends. Be cautious, as the hose still contains residual fuel, which could be dangerous if spilled. Carefully remove the hose from the fittings, being mindful of any fuel that might be left inside. It is important to have a container or cloth nearby to catch any fuel that might drip out during this process. Remember to keep the old hose as it will be useful for measuring the proper length when installing the new hose.

The process of removing the hose can be delicate due to the presence of residual fuel. Take slow and deliberate actions to avoid any accidental spills or leaks. Always prioritise your safety and work in a well-ventilated area to minimise the risk of inhaling gasoline vapors. It is also crucial to wipe up any spilled fuel immediately with a cloth or absorbent material. Do not attempt to start the engine until the fuel has evaporated completely. This precaution will help prevent the risk of fire or explosion, which could cause severe damage or injury.

When removing the hose, be mindful of the potential for fuel to spill or leak from the hose ends or fittings. Have a suitable container or absorbent material ready to catch any drips. If fuel spills occur, ensure that you wipe them up immediately. Additionally, keep the work area well-ventilated to prevent the buildup of gasoline vapors, which are highly flammable. By taking these precautions, you can help ensure a safer work environment and reduce the risk of accidents or fires.

After removing the hose, you will notice that it contains residual fuel. This fuel can be dangerous if spilled or leaked, so it is important to handle the hose with care. Carefully transport the hose to a safe area where you can properly dispose of the residual fuel. Remember to follow local guidelines for disposing of flammable liquids. Once the fuel has been safely removed, you can measure the length of the new hose against the old one to ensure an accurate fit. This step will ensure that your new fuel line installation goes smoothly without any issues related to hose length.

Cadillac DeVille: Replacing the Fuel Level Sensor

You may want to see also

Measure the new hose against the old one

To replace the fuel line on your lawnmower, you'll need to measure the new hose against the old one to ensure a proper fit. Here's a step-by-step guide to help you through this process:

- Begin by removing the old fuel hose from your lawnmower engine. It's important to let the engine cool down completely before performing any maintenance work.

- Once the old hose is removed, keep it aside as you'll be using it as a reference for the new hose.

- Take the new fuel hose and place it next to the old one. Carefully measure and compare the lengths of the two hoses to ensure they match.

- If the new hose is too long, you'll need to trim it to the same length as the old one. Use sharp scissors or a utility knife to cut the hose, ensuring a straight and clean cut.

- After trimming, inspect the hose for any small burrs or particles that may have been created during the cutting process. These debris can fall into the hose and cause issues, so it's important to remove them before installation.

- Now that you have the new hose measured and trimmed to the correct length, you can prepare it for installation. Install the new clamps onto each end of the hose, and you'll be ready to proceed with the next steps of the fuel line replacement.

Remember, accurate measurement and trimming of the new fuel hose are crucial to ensure a proper fit and prevent any leaks once it's installed. Take your time and follow the necessary precautions when working with fuel lines to ensure a safe and successful lawnmower maintenance experience.

Replacing Opel Corsa Fuel Pump Relay: Step-by-Step Guide

You may want to see also

Frequently asked questions

If your lawn mower is not starting or is running erratically, it may be time to replace the fuel line.

You will need standard pliers and a new fuel hose that is compatible with your lawn mower's engine.

It is important to run the engine until it stops due to a lack of fuel and to wait until the engine cools before performing any maintenance. Gasoline and its vapors are highly flammable and explosive, so be cautious of any residual fuel in the hose.

First, use standard pliers to squeeze the tabs on the hose clamps and slide them away from the hose ends. Then, remove the hose from the fittings, being careful of any residual fuel.

Trim the replacement hose to the same length as the old hose. Install new clamps onto each end of the hose, then install the new hose over the fittings and secure it with the clamps. Upon first use, check for leaks and ensure that the hose is not clogged with dirt or particles.