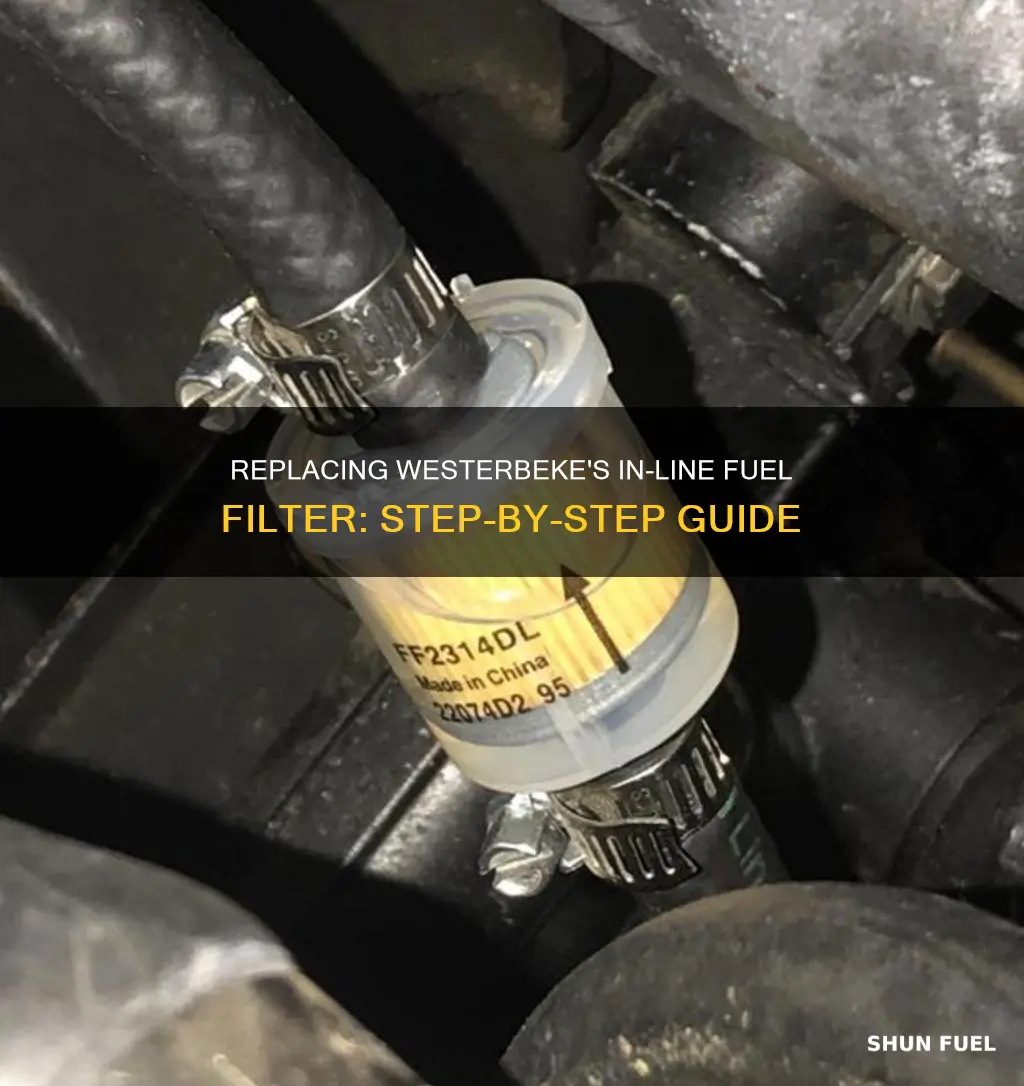

Replacing the Westerbeke in-line fuel filter can be a messy job. Before starting, it is important to pull the fuel shut-off, drain water from the filter/separator, and clamp the fuel lines shut. The process involves changing the filter and rubber gasket within the fuel lift pump canister, as well as removing the spin-on oil filter to access the fuel filter element. One challenge is managing the flow of fuel when the filter canisters are open, which can result in nearly a quart of fuel streaming out. Additionally, there may be difficulties with changing the rubber O-rings. It is recommended to have absorbent pads, containers, and shut-off valves to minimize the mess and make the process easier.

What You'll Learn

Draining water from the Groco filter/separator

To drain water from the Groco filter/separator, you need to release the vent valve at the top of the filter housing. If there isn't a valve, loosen the top fuel pipe from the filter housing.

Before you begin, place a jar under the drain plug or tap. Now, loosen the plug or tap. You will see the filter begin to drain. Once clean diesel fuel starts flowing out, close the plug or tap, and then close the vent valve.

It is recommended that you drain water from the separator every 10,000 miles. This is because water can enter your diesel fuel system through condensation, human error, ingress during refuelling, and water leakage into the tank. Water in your fuel system can cause rust, corrosion, abrasion, pitting, and microbial growth, which can lead to serious engine problems.

Some cars are equipped with a Fuel in Water (FIW) sensor to indicate when there is a substantial amount of water in the fuel filter.

Replacing the Fuel Pump in Your 2009 Ford Escape

You may want to see also

Shutting off the fuel valve

- Locate the fuel shut-off valve: The fuel shut-off valve is typically located in the fuel lines just outside the fuel tank. To access it, you may need to remove the switch/gauge panel aft of the cockpit.

- Shut off the valve: Once you have located the fuel shut-off valve, turn it to the "off" position. This will stop the flow of fuel and allow you to change the fuel filters without getting drenched.

- Clamp the fuel lines: Before beginning any work, it is important to clamp the fuel lines (supply and return) shut using vise grips or similar tools. This will provide an extra layer of protection and help prevent fuel leaks.

- Absorbent pads and containers: Place absorbent pads or rags underneath the engine and filters to soak up any fuel that may leak during the process. You can also use a small plastic container or a fuel catch container to catch the drained fuel and prevent spills.

- Work on the fuel filters: With the fuel valve shut off and the fuel lines clamped, you can now work on changing the fuel filters. Refer to other guides or resources for the specific steps involved in changing the Westerbeke fuel filters.

- Priming the fuel system: After changing the fuel filters, you may need to prime the fuel system to remove any residual air in the lines. This can be done by gradually increasing the engine throttle over a period of time, allowing the system to expel any air and ensuring a smooth fuel flow.

Remember to exercise caution when working with fuel and always ensure a safe and well-ventilated workspace. It is recommended to wear protective gear, such as gloves and eye protection, to safeguard against any fuel spills or splashes.

Replacing Fuel Filter in 2004 Envoy: Step-by-Step Guide

You may want to see also

Clamping the fuel lines

To begin, locate the fuel lines, which are usually found just outside the fuel tank. These lines include the supply line, which brings fuel from the tank to the engine, and the return line, which carries any unused fuel back to the tank. Once you have identified these lines, you can start the clamping process.

The clamping process itself is straightforward but requires careful execution. Use a pair of vise grips or a similar tool to securely clamp each fuel line shut. Ensure that the clamps are tight enough to completely stop the flow of fuel. This step is crucial, as it prevents fuel leakage during the filter replacement process.

It is also recommended to place absorbent pads or rags underneath the engine and filters before proceeding. This will help catch any fuel that may leak or spill during the filter change, making the process less messy and reducing the risk of fuel damage to surrounding components.

After clamping the fuel lines and taking the necessary precautions, you can proceed with confidence to the next steps of replacing the Westerbeke in-line fuel filter. Remember to follow manufacturer guidelines and safety procedures throughout the replacement process.

Replacing Lawnmower Fuel Pumps: A Step-by-Step Guide

You may want to see also

Changing the filter and rubber gasket

To change the filter and rubber gasket, start by pulling the fuel shut-off in the cockpit. Next, drain water from the Groco filter/separator in the sail locker. Then, shut off the fuel valve in the fuel lines, which is just outside the fuel tank. Clamp the fuel lines (supply and return) shut using vise grips.

Now, you can remove the fuel lift pump canister bottom and change the filter and rubber gasket within. Wipe the magnet and replace it in the bottom of the twist portion of the canister. You may also need to remove the spin-on oil filter to access the fuel filter.

The next step is to remove the collar of the canister containing the filter and change the filter and the two rubber O-rings. This can be tricky, so take your time and be prepared for some fuel to leak out. Have some fuel-absorbing sheets, shop towels, or rags on hand to soak up any spills.

Finally, reassemble the fuel filter housing and tighten all connections. Be sure to prime the fuel system and bleed any air from the lines before starting the engine.

Replacing the Fuel Pump in a 2003 Honda Pilot

You may want to see also

Removing the collar of the canister

To remove the collar of the canister, you will need to first access the fuel filter by removing the switch/gauge panel aft of the cockpit. Shut off the fuel supply by closing the fuel shut-off valve, which is located just outside the fuel tank. Clamp the fuel lines (supply and return) using vise grips or similar tools to prevent fuel flow.

Now, focus on the canister: start by removing the bottom of the fuel lift pump canister and changing the filter and rubber gasket inside. Clean the magnet at the bottom of the canister's twist portion and put it back in place. Next, remove the collar of the canister itself. This part can be challenging, so take your time and be prepared for some fuel spillage. Have fuel-absorbing sheets, shop towels, or rags ready to catch any diesel that may escape. Change the filter and the two rubber O-rings inside the canister, then carefully put everything back together, ensuring the O-rings are correctly seated and the canister is securely attached.

To minimise fuel spillage during this process, consider adding additional shut-off valves near the entry port of the lift pump and on the fuel return line to the tank. You can also place an oil absorbent rag or a plastic container under the filter to catch any fuel that may drain out during the removal process. Remember to wear appropriate protective gear, including gloves and eye protection, when handling diesel fuel.

Husqvarna Push Mower Fuel Filter: Step-by-Step Replacement Guide

You may want to see also

Frequently asked questions

The steps to replace a Westerbeke in-line fuel filter include: pulling the fuel shut-off, draining water from the filter/separator, clamping the fuel lines shut, removing and replacing the fuel lift pump canister bottom and filter, and changing the filter canister and O-rings.

To prevent fuel spills when changing the Westerbeke fuel filter, use absorbent pads, and place a plastic container under the filter to catch any drips. Install shut-off valves near the entry port of the lift pump and in the fuel return line to the tank.

Regularly changing the Westerbeke fuel filter helps maintain engine performance and prevents fuel-related issues. Clogged or dirty fuel filters can cause the engine to stall or run erratically.

Signs that the Westerbeke fuel filter may need replacement include engine stalling, difficulty starting, and reduced engine performance. Unusual engine noises, such as sputtering or knocking, may also indicate a clogged fuel filter.