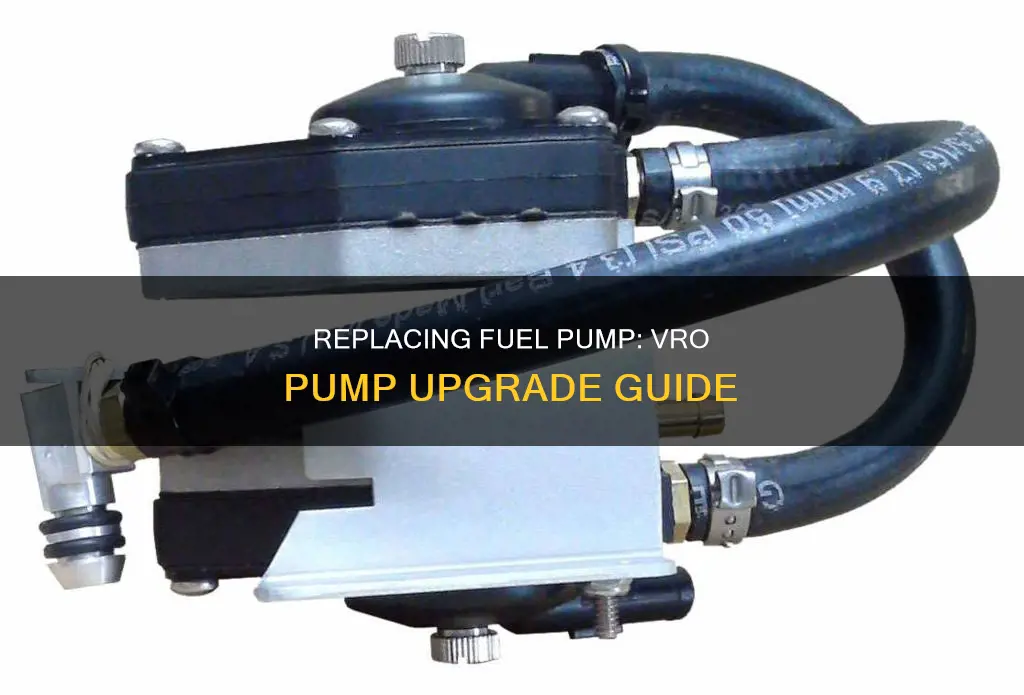

Replacing a VRO pump with a standard fuel pump is a common modification for boat engines, especially Johnson and Evinrude outboard motors. The VRO (Oil Injection) system has a reputation for being unreliable, with many reports of it failing and mixing oil and gas incorrectly, which can cause significant engine damage. The standard fuel pump is a simpler and more reliable system that has been used for many years. The conversion involves removing the VRO pump and related hoses, and installing a new fuel pump and mounting bracket. This can be a fairly easy process, with many people reporting successful conversions and improved engine performance. However, it is important to do thorough research and consult experts or mechanics before attempting any modifications.

What You'll Learn

Identify the correct replacement pump for your engine

When replacing a VRO pump with a standard fuel pump, it is important to identify the correct replacement pump for your engine. Here are some steps and considerations to help you with this process:

- Engine Model and Specifications: Begin by identifying the specific model and specifications of your engine. This includes the make, model, year, horsepower, and any other relevant details. This information is crucial in finding the right replacement pump.

- Research and Compatibility: Do thorough research to find a compatible standard fuel pump for your engine. Consult manufacturer catalogues, online forums, or seek advice from marine mechanics or dealers. Ensure that the replacement pump is designed for your engine's horsepower and fits the existing mounting brackets.

- Aftermarket Options: Consider aftermarket options if you cannot find an exact OEM replacement. Aftermarket pumps can be more affordable and may work just as well, but be sure to verify their compatibility with your specific engine.

- Conversion Kits: If you're converting from a VRO pump to a standard fuel pump, look for conversion kits specifically designed for this purpose. These kits usually include the necessary components and instructions for a successful conversion.

- Part Numbers and Cross-Referencing: Pay close attention to part numbers when identifying the correct replacement pump. Cross-reference the part numbers of your existing VRO pump with those of potential replacement pumps. This will help ensure you find an exact or compatible match.

- Online Resources: Utilise online resources such as maxrules.com, crowleymarine.com, or boats.net to look up specific part numbers and cross-reference different pump models. These websites can provide valuable information and recommendations for replacement pumps.

- Seek Expert Advice: If you're unsure, consult a marine mechanic or a dealer who specialises in your engine brand. They can guide you in selecting the correct replacement pump and provide valuable insights based on their experience.

- Consider Performance and Reliability: When choosing a replacement pump, consider factors such as performance, reliability, and durability. Opt for pumps that have a good reputation and are known for their longevity.

- Compatibility with Other Components: Ensure that the replacement pump is compatible with other engine components, such as fuel lines, hoses, and fittings. You may need to make adjustments or replacements to ensure a proper fit and functioning.

- Safety and Warranty: Prioritise safety and only choose replacement pumps that meet industry standards and safety regulations. Also, consider the warranty offered by the manufacturer to protect your investment.

Remember, proper identification of the correct replacement pump is crucial for a successful and safe conversion from a VRO pump to a standard fuel pump. Taking the time to research and consult experts will help ensure a smooth transition and reliable engine performance.

Replacing Mantis Tiller Fuel Filter: Step-by-Step Guide

You may want to see also

Remove the VRO pump and related hoses

To remove the VRO pump and related hoses, follow these steps:

Locate the VRO pump on your engine. It is usually found near the carburetors and is connected to the fuel system via hoses. Before beginning the removal process, it is recommended to take pictures of the existing setup or make notes of the hose routing for reference during the reinstallation process.

Disconnect the hoses leading to and from the VRO pump. Be sure to have a container ready to catch any fuel that may spill during this process. Use hose clamps or tie wraps to secure the hoses and prevent fuel leakage. Once all the hoses are disconnected, set the VRO pump aside.

Remove any brackets or mounting hardware that secured the VRO pump in place. Some pumps may have additional mounting screws that need to be removed. Be sure to keep track of all the removed parts for reinstallation or future reference.

At this point, you should have successfully removed the VRO pump and related hoses. You can now proceed to install the new fuel pump according to the manufacturer's instructions or seek further guidance from a marine mechanic or a boating forum. Remember to dispose of the old pump and hoses properly, following local regulations for hazardous waste disposal.

It is important to note that removing the VRO pump and converting to a standard fuel pump may require additional modifications to the fuel system. Always refer to a qualified technician or a detailed conversion guide for your specific engine model before proceeding with the replacement.

Replacing the Fuel Tank on a Santa Fe: Step-by-Step Guide

You may want to see also

Install the new pump using the existing VRO bracket

To install the new pump using the existing VRO bracket, you will need to first remove the old VRO pump. Make sure to tape up the electrical wire that was connected to the old pump.

Next, you will need to cut the fuel line that goes into the new pump and connect it to the existing carb line. You will also need to connect the hose from the block to the new pump; this is an important step, as failing to do so will cause the new pump not to work.

The new pump can then be mounted onto the engine using the existing VRO bracket. It is recommended to reuse the old VRO stainless bracket to ensure the new pump doesn't rattle around.

Finally, you will need to connect the fuel lines to the new pump. Take your time with this step and cut the fuel lines about an inch longer than you think you need, as it is better to have a little extra length than to cut them too short.

Replacing Ryobi Trimmer Fuel Lines: A Step-by-Step Guide

You may want to see also

Connect the fuel lines and pulse limiter (if applicable)

When connecting the fuel lines and pulse limiter, it is important to follow the correct procedure to ensure a safe and proper installation. Here is a step-by-step guide on how to connect the fuel lines and pulse limiter when replacing a VRO pump with a fuel pump:

- Identify the Components: Before beginning the installation, it is important to identify all the components involved. This includes the fuel lines, pulse limiter, fuel pump, and any other relevant parts.

- Disconnect the Old Fuel Lines: Start by disconnecting the fuel lines from the old VRO pump. Be sure to label or mark the fuel lines to ensure proper reconnection.

- Remove the Old Pulse Limiter: If your engine has a pulse limiter, it will need to be removed as well. The pulse limiter is typically connected to the VRO pump via a hose. Carefully detach the hose and set the pulse limiter aside.

- Install the New Fuel Pump: Mount the new fuel pump in the same location as the old VRO pump. You may need to reuse some of the original mounting screws or hardware. Ensure that the fuel pump is securely fastened in place.

- Connect the Fuel Lines: Connect the fuel lines to the new fuel pump. Refer to the instructions or diagrams provided with the fuel pump to identify the correct ports for the fuel lines. Take your time and cut the fuel lines to the appropriate length if necessary. Use fuel line clamps or other appropriate fittings to secure the connections and prevent leaks.

- Reconnect the Pulse Limiter (if applicable): If your engine uses a pulse limiter, connect it to the new fuel pump using a suitable hose. Ensure that all connections are secure and that there are no leaks.

- Verify the Connections: Once all the connections have been made, carefully inspect your work to verify that the fuel lines and pulse limiter (if applicable) are properly connected. Double-check that all clamps, fittings, and hoses are secure and tight.

- Test the Installation: Before starting the engine, perform a final inspection and ensure that there are no leaks present. Refer to the engine's manual or a mechanic for specific instructions on testing the fuel system and starting the engine after the installation.

Remember to exercise caution when working with fuel systems. Ensure that the work area is well-ventilated and that there are no sources of ignition nearby. If you are unsure about any aspect of the installation, it is always best to consult a qualified marine mechanic for assistance.

Replacing Fuel Regulator in Your 03 Fatboy: Step-by-Step Guide

You may want to see also

Test the engine and address any issues

Once you've replaced your VRO pump with a standard fuel pump, it's important to test the engine and address any issues that may arise. Here are some detailed steps to help you through the process:

Test the Engine:

- Initial Checks: Before starting the engine, perform a visual inspection of your work. Ensure that all fuel lines are properly connected, secured, and free of leaks. Check that the new fuel pump is securely mounted and that there is no damage to any components.

- Listen for the Fuel Pump: With the ignition turned on but the engine not running, listen closely near the fuel tank. You should hear a humming or buzzing sound, indicating that the fuel pump is operational.

- Check Fuel Pressure: Utilize a fuel pressure gauge to verify that the fuel pump is maintaining the correct pressure. Attach the gauge to the fuel rail or a test port on the fuel line. Turn the ignition key to the "on" position without starting the engine. The pressure should fall within the manufacturer's specified range, typically around 30-50 psi.

- Inspect Electrical Connections: Use a multimeter to check the voltage at the fuel pump's electrical connector. With the ignition on, you should read approximately 12 volts. If the voltage is low or absent, there may be an issue with the wiring, fuse, or relay.

- Start the Engine: If the initial checks are satisfactory, attempt to start the engine. Pay attention to any unusual noises or behaviours. An ideal start-up will have the engine running smoothly without sputtering or stalling.

Address Common Issues:

- Hard Starting or Engine Not Starting: If the engine is hard to start or fails to start, ensure that the fuel pump is receiving fuel and delivering it to the engine properly. Check for blockages or leaks in the fuel lines.

- Engine Stalling: Sudden stalling while driving can indicate an intermittent issue with the fuel pump. Verify fuel pressure and listen for any unusual sounds from the fuel pump, such as a whining or buzzing noise.

- Loss of Power: If you experience difficulty in accelerating, check the fuel pump's ability to deliver the required fuel pressure to the engine. Also, inspect the fuel lines for any restrictions or leaks.

- Strange Noises: A whining or buzzing sound from the fuel tank area could indicate a failing fuel pump. This may be accompanied by a "lean mixture" check engine code.

- Poor Fuel Economy: If you notice a decrease in fuel efficiency, the fuel pump may be malfunctioning, affecting fuel delivery.

Additional Tips:

- Safety First: Always prioritize safety when working on your engine. Ensure proper ventilation to avoid inhaling harmful fumes, keep sparks or open flames away from the fuel system, and wear protective gear, including gloves and safety glasses.

- Refer to Manual: Consult your engine's service manual for specific instructions and guidelines related to your particular model. This can provide valuable information on fuel pump specifications, troubleshooting, and maintenance.

- Seek Professional Help: If you encounter persistent issues or feel uncomfortable performing certain tasks, don't hesitate to seek assistance from a qualified marine mechanic. They can provide expert guidance and ensure that your engine is safe and properly maintained.

Replacing the Fuel Pump Relay in Your 1998 Mustang

You may want to see also

Frequently asked questions

If your engine is smoking badly at idle and has a loss of power, it could be a fuel delivery issue or a leak in the diaphragm in the VRO pump.

You can replace your VRO pump with a standard pulse-driven fuel pump.

The process for replacing a VRO pump with a standard fuel pump involves removing the VRO pump and mounting the new pump in the same spot. You will also need to connect the new pump to the fuel lines and the pulse fitting.

Yes, it is important to ensure that the new fuel pump is getting the correct pressure. Issues with the pulse limiter or vacuum switch can cause the engine to run rich or lean.