If your fuel gauge is inaccurate or not working at all, the problem could be with the gauge or the sending unit. To determine which one is at fault, you can perform a simple test. First, check if the gauge is receiving 12 volts of power by probing with a multimeter. If there is no voltage, the fault lies in the ignition circuit. If there are 12 volts, you need to proceed to the next step, which is disconnecting the sending wire. If the gauge jumps to its highest reading, the gauge is good, and you can move on to testing the wire and sender. If the gauge does not reach its maximum reading, it needs to be replaced.

Once you've identified that the sender is at fault, you can replace it. The process for doing so varies depending on the model of your car. For example, for early C5 Corvette owners, the process is relatively straightforward and does not require removing any major components. On the other hand, replacing the unit on a C6 or late-2003 to 2004 C5s requires removing the entire rear drivetrain cradle to access the tank and fuel pump assembly. It is important to refer to specific instructions for your vehicle model when undertaking this task.

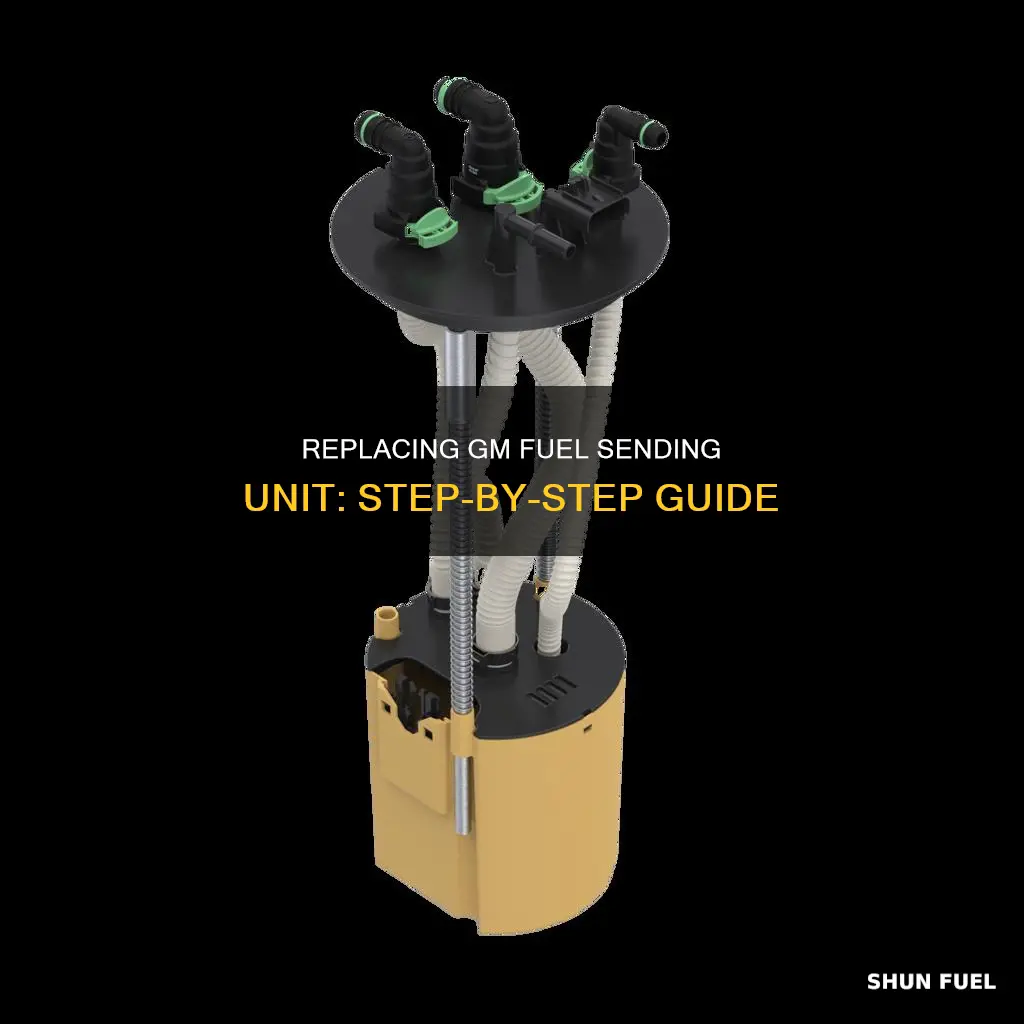

| Characteristics | Values |

|---|---|

| Difficulty of replacement | Varies depending on the model of the car. For older C5s, the process is much easier and doesn't require removing any major components. For C6s and late-2003 to 2004 C5s, the whole rear drivetrain cradle needs to be removed to access the tank and fuel pump assembly. |

| Parts required | A new fuel sending unit, a new O-ring, a new fuel sock, a new gasket, a new fuel pump, a new fuel filter sock, and copper washers. |

| Tools required | A strong pair of wire cutters, a hacksaw, and a multimeter. |

| Steps | 1. Remove the driver-side rear wheel. 2. Remove the shield in front of the sending unit. 3. Loosen the shield/plate that holds the tank in place. 4. Disconnect the fuel lines and electrical connection. 5. Remove the bolts holding the fuel pump assembly in place and pull it out of the tank. 6. Remove the wires from the plug and insert the wires from the new sending unit. 7. Install the new sending unit into the tank and clip it onto the fuel pump assembly. 8. Check that the float arm travels freely and has a full range of motion. 9. Bolt the fuel pump assembly back in place, reattach the fuel lines, and plug the harness back in. 10. Tighten the bolts on the fuel tank retaining plate and reinstall the shield. |

What You'll Learn

Test if the fuel gauge is faulty

To test if the fuel gauge is faulty, you must first check that the gauge is receiving 12 volts of power. Turn on the ignition and use a multimeter to probe the voltage between the ground and the positive terminal on the back of the gauge; it should be marked with a “+” or an “I”. If there is no voltage, the fault is in the ignition circuit, and the gauge is likely to be working correctly.

If there are 12 volts at the gauge, either the sender, the gauge, or its wiring is the issue. With the power running to the gauge, disconnect the sending wire; it will be marked with an “S” at the back of the gauge. Once the wire is disconnected, the gauge should jump to its highest possible reading. If this is the case, the gauge is working, and you can move on to the next step. If the gauge does not reach its maximum reading, it is faulty and must be replaced.

Another test involves jumping a wire or a screwdriver across the sending pin to the ground pin on the back of the gauge. If there is no ground pin, use a longer wire and jump the sending pin to the engine block. The gauge should now go to its lowest reading. If it does, it is working properly.

If the gauge is working, the next step is to check the other system components, as either the wire running to the sender or the sender itself must be faulty. To check the wire, disconnect it from both the sender and the “S” pin on the back of the gauge. Set your multimeter to the Ohms scale and check the resistance within the wire. If there is no resistance, the circuit is good and the sender is faulty. In most cases, the sender and the fuel gauge need to be matched to the resistance in the sender’s rheostat, so to be completely sure you are getting accurate readings, replace both the sender and the gauge.

Replacing the Fuel Pump in Your Lexus IS300: Step-by-Step Guide

You may want to see also

Disconnect the sending wire

Disconnecting the sending wire of a GM fuel sending unit is a crucial step in the replacement process. Here is a detailed guide on how to do it:

Before beginning, it is important to note that the process may vary slightly depending on the specific GM vehicle model and year. For example, the process for a 1998 Tahoe with a 3-wire connector is different from that of a C5 Corvette. It is recommended to consult vehicle-specific repair manuals or seek advice from a qualified mechanic for the most accurate instructions.

Now, let's focus on the steps to disconnect the sending wire:

- Locate the Fuel Sending Unit: The fuel sending unit is typically located inside the fuel tank. In some cases, you may need to remove the fuel tank to access it, while in other cases, you can replace it with the tank in place. Refer to your vehicle's repair manual or seek advice from a mechanic to determine the best approach for your specific vehicle.

- Access the Sending Unit Connector: Once you have located the fuel sending unit, identify the electrical connector that joins the sending unit to the vehicle's wiring harness. This connector is usually plugged into the sending unit and may be secured with a locking mechanism or a slide lock.

- Disconnect the Sending Unit Connector: To disconnect the sending unit connector, you may need to release the locking mechanism or slide lock. For example, in some Dodge vehicles, there is a red slide lock on the connector that needs to be moved first. Then, squeeze the main connector lock and slide it off. In other cases, you may need to use a small flat-blade screwdriver to release the connector by pressing or squeezing specific parts of the connector.

- Clean the Connector (if necessary): In some cases, dirt accumulation in the connector can make it challenging to disconnect. If you are having difficulty, try using compressed air or a can of computer keyboard cleaner spray to blow away any dirt or debris.

- Disconnect the Sending Wire from the Sending Unit: With the connector disconnected, you can now focus on the sending wire itself. Gently pull the sending wire out of the sending unit. Take care not to damage the wire or any nearby components. In some cases, the sending wire may be secured with a clip or retainer, which you will need to release before removing the wire.

- Label and Set Aside the Sending Wire: Once the sending wire is disconnected, label it to avoid confusion during the reassembly process. Set it aside in a safe place, ensuring it does not get damaged or entangled with other components.

By following these steps, you will have successfully disconnected the sending wire from the GM fuel sending unit. Remember to consult vehicle-specific repair manuals or seek advice from a qualified mechanic if you encounter any challenges or uncertainties during the process.

Replacing Fuel Pump in Nissan Frontier: Step-by-Step Guide

You may want to see also

Check the wiring

To check the wiring of your GM fuel sending unit, you will need to use a multimeter to measure the resistance of the fuel sender. This can be done either at the sending unit directly or at the gauge by probing the fuel sender wire at the dash.

Step 1: Set your multimeter to OHMs (O)

Keep it on auto or in the

Step 2: Ground one of the multimeter probes

Ground one of the multimeter probes somewhere on the vehicle chassis/body/tank. Don’t forget your sender needs to be grounded too! You can use some alligator clips to hold the probe in place or as a jumper for hands-free working.

Step 3: Probe the sender wire with the other end of the multimeter

Probe the sender wire with the other end of the multimeter. This will display a number in OHMs (O). If you have another set of alligator clips, these can be useful, especially when you are under the dash. Write down this number.

Step 4: Approximate the amount of fuel in the tank

- If the sender is out of the tank, move the float up and down while measuring the resistance (ohms).

- If the sender is in the tank and installed in the vehicle, check the resistance (ohms) when the tank is full or empty. Use the Fuel Level Sender Resistance Value Chart to see the resistance and check the amount of fuel in the tank.

If the wiring is good, you should see a very similar reading at the tank and at the gauge end of the sender wire. If there is a break in the wire, you may see infinite or 1000s of ohms (O). If the wire is grounded out somewhere, you may see zero ohms (O). In these cases, it may be easier to run a new wire from the tank back to the gauge.

Replacing Fuel Pump Relay in 06 Expeditions: A Step-by-Step Guide

You may want to see also

Remove the driver-side rear wheel

To remove the driver-side rear wheel, you will need to jack up the car and place it on jack stands. This will give you access to the wheel and the necessary space to work. Here are the steps to follow:

- Loosen the lug nuts: Use a lug wrench to turn the lug nuts in the counter-clockwise direction and loosen them. Do not remove the lug nuts yet, just loosen them enough to be able to turn them by hand.

- Jack up the car: Place the jack under the car, following the manufacturer's instructions for the correct jack point. Lift the car slowly until the wheel is off the ground. Ensure the car is secure and stable on the jack.

- Place jack stands: Position the jack stands under the car, again following the manufacturer's recommendations for placement. Carefully lower the car onto the jack stands. Make sure the car is securely supported by the jack stands before proceeding.

- Remove the lug nuts and wheel: Fully remove the lug nuts by turning them counter-clockwise with the lug wrench. Set them aside in a safe place. Gently pull the wheel away from the car.

- Secure the car: Ensure the car is securely supported by the jack stands and will not shift or move during the repair process. You may want to engage the parking brake and place chocks behind the other wheels for added safety.

With the driver-side rear wheel removed, you will now have access to the fuel sending unit and can proceed with the next steps of the replacement process. Remember to keep the work area well-lit and follow all safety precautions when working under a car.

Replacing the Fuel Pump in Your 2008 Buick Lucerne

You may want to see also

Install the new sending unit

Now that you have removed the old sending unit, it is time to install the new one.

First, you will need to measure the depth of your fuel tank from the top of the tank, near the sending unit, to the bottom. This measurement will determine the length of the sending unit's float arm. Next, trim the new sending unit's arm to match the depth of your tank. Most units can be cut with a strong pair of wire cutters, but some may require a hacksaw. Once you have the correct length, fasten the float arm to the flange of the new sending unit with setscrews.

The next step is to lower the new sending unit into the tank, ensuring that the float arm can move freely and will not stick in any corners or against any vertical walls. You can check this ahead of time by holding the sending unit next to the tank before installation, allowing you to duplicate the correct orientation when you put the unit in the tank. To minimize confusion, use a marker to indicate the direction of travel of the float arm.

Now, slide a new gasket into place under the flange and align the gasket with the holes in the sender and the tank. As the flange may turn while you are centering the screw holes, mark the gasket in relation to the flange to ensure it stays aligned. Additionally, mark the screw holes in the tank for easier alignment, as the flange will cover them.

Finally, put in the new screws and tighten them down. With the new sending unit installed, you can now reconnect the wiring and bolt the fuel pump assembly back in place. Don't forget to reattach the fuel lines and plug the harness back in.

Replacing Fuel Tank Pump in '87 Chevy C30: Step-by-Step Guide

You may want to see also

Frequently asked questions

If your fuel gauge is inaccurate or not working at all, there may be a problem with the sending unit. You can test this by checking if the gauge is receiving 12 volts of power. If there is no voltage, the fault is in the ignition circuit. If there are 12 volts, you need to proceed to the next step, which is to disconnect the sending wire. If the gauge jumps to its highest reading, the gauge is good and the sending unit may be faulty.

First, remove the driver-side rear wheel. Then, remove the shield in front of the sending unit. Next, loosen the shield/plate that holds the tank in place, but do not fully remove it. Pull it out of the way when removing the fuel pump/sending unit assembly. Before removing the bolts that hold the fuel pump assembly in place, disconnect the fuel lines and unplug the electrical connection. With the bolts removed, pull the assembly part of the way out of the tank.

No, you can replace the sending unit without dropping the tank. However, be careful not to knock the filter sock off into the tank when pulling the sender out.

It is recommended to use a cork gasket when replacing the fuel sending unit. Do not use the rubber gasket that may come with the sending unit. Make sure not to over-tighten the gasket, just snug it up nicely.

It is a good idea to replace the fuel filter sock at the end of the pump when installing a new fuel sending unit. Over time, crud buildup can occur in the sock, so it is recommended to replace it. Additionally, always install a new O-ring on the end of the pump when replacing the fuel sock.