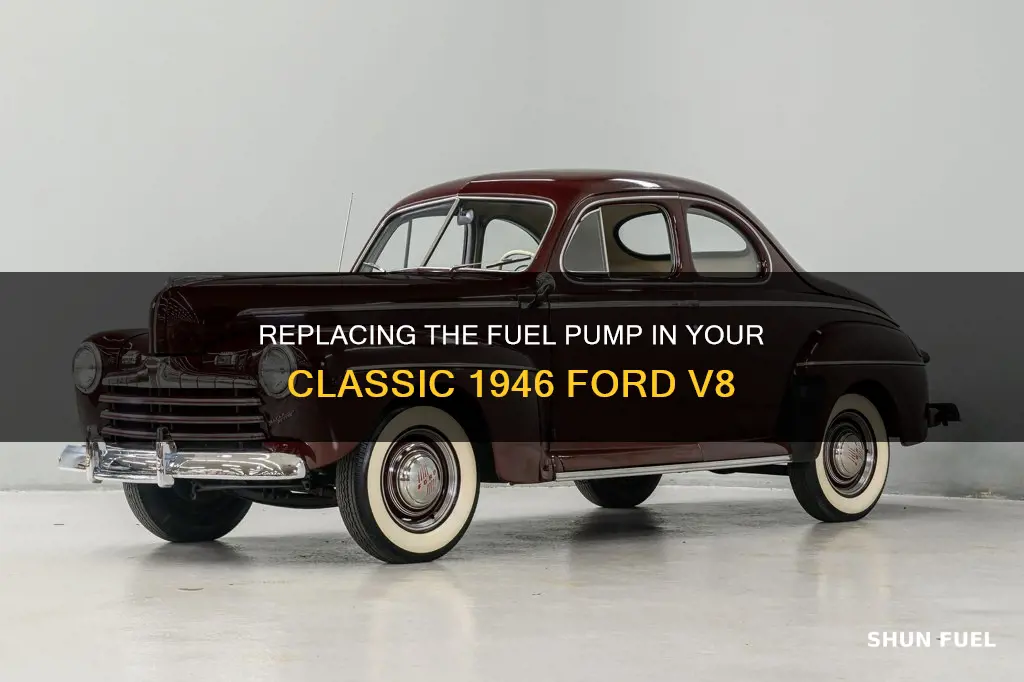

Replacing the fuel pump on a 1946 Ford V8 engine is a complex task that requires careful attention to safety and a range of tools. The fuel pump is located inside the fuel tank, so access is challenging and will require either removing the truck bed or the fuel tank itself. The process involves multiple steps, including siphoning fuel, jacking up the truck, removing the heat shield and fuel tank or truck bed, cleaning the engine block, and carefully aligning and installing the new fuel pump. Safety precautions, such as working on a flat surface and draining the gas tank, are crucial to ensure a successful and secure replacement.

What You'll Learn

Siphon gas and use a car jack to elevate the truck

To siphon gas from your 1946 Ford V8, you will need a gas can, some clear plastic tubing, and a rag. Park your truck on level ground, preferably on a paved surface. If you have to park on an incline, make sure to park close to the curb and turn the wheels inward. Block the downside wheels with wheel wedges, wood blocks, or bricks to prevent the wheels from accidentally rolling. Put the car in park and engage the emergency brake. If your truck has a manual transmission, put it in first gear and engage the parking brake.

Now, find a gas can or another closed container to siphon the gas into. Take a clear plastic tube that is 1 inch (2.5 cm) in diameter and feed it into the gas tank. You will need two lengths of tubing for this: one long enough to reach deep into the gas tank and another shorter length that will just reach the inside of the tank. Push the longer tube well into the gas tank, making sure that it is fully submerged in the gasoline. You can check this by carefully blowing into the tube and listening for bubbles, being careful not to inhale any fumes. Push the shorter tube just a few inches into the tank so that both tubes sit side by side.

Use a rag to create a seal around the tubes. This will help increase the air pressure in the tank and displace the gas through the longer tube into your gas can. Pack the rag tightly around the tubes, ensuring that it conforms to the shape without compressing the tubes and restricting the flow of air and gas. If you are having trouble creating a tight seal, try soaking the rag in water, ringing it out, and then packing it around the tubes.

When you are ready, blow air into the shorter tube to increase the air pressure inside the tank. You can do this with your lungs, but be extremely careful not to inhale any fumes. Alternatively, you can use a mechanical air pump. As you blow into the short tube, you should see the gas move through the longer tube into your gas can. Once the gas is flowing freely, you can stop blowing, and gravity will do the rest. When you want to stop siphoning, cover the long tube with your thumb, raise it above the level of the gas in the tank, and remove your thumb. Any remaining gas in the tube should flow back into the tank.

Now that you have siphoned the gas, it is time to use a car jack to elevate your 1946 Ford V8. Car jacks can be intimidating and dangerous to use, so it is important to follow the proper safety precautions and procedures. Make sure you have the correct type of car jack for your vehicle. The two basic types of car jacks are scissor jacks and hydraulic jacks, which include hydraulic floor jacks, bottle jacks, and ram jacks. Place the jack under the car frame, following the instructions in your owner's manual for the proper placement. If you are only lifting one wheel, lift that corner of the vehicle. If you need to lift the front or rear of the car, choose a jack point at the center of the suspension or frame.

Once the jack is in place, you can start raising the truck. If you are using a scissor jack, insert the rod and crank it to raise the jack until it connects with the car's lift point. If you are using a hydraulic jack, place the handle into the body of the jack and pump the handle smoothly to raise the jack until it contacts the car frame. Lift the truck to the desired height, making sure to do so slowly and with caution.

Once your 1946 Ford V8 is elevated, be sure to secure it with jack stands. Place the jack stands under the car frame near the jack, and then slowly lower the vehicle until it is securely resting on the stands. Give the truck a gentle push to ensure that it is stable and balanced on the jack stands. Remember never to climb under the truck while it is only supported by the car jack. Always use jack stands that are properly rated for the weight of your vehicle.

Replacing Fuel Pump in 2009 Nissan Rogue: Step-by-Step Guide

You may want to see also

Remove the heat shield

To remove the heat shield, first, grab an impact wrench and crawl under the truck. You will notice that the heat shield is protecting the fuel pump, and there will be two sets of bolts. One set holds the heat shield in place, and the other set holds the fuel tank in place. Make sure to locate the bolts that hold the heat shield. They will be aligned with the heat shield strap.

Be careful not to remove the bolts for the tank straps before removing the heat shield. After removing the bolts, the heat shield will start to drop as you take it out. Place your knee against it so that it doesn't fall on you as you wiggle it free. Once it is free, put it aside.

Replacing Vectra C Fuel Filter: Step-by-Step Guide for DIYers

You may want to see also

Disconnect the fuel tank

Disconnecting the fuel tank on a 1946 Ford V8 is a complex and time-consuming process. It is important to work on a flat and safe surface with the engine off, and to drain the gas tank before starting.

First, siphon the gas out of the tank using a clear hose and air pump. Next, jack up your truck so that it is at least 18 inches off the ground. Place the jack in the groves along the frame of the truck. Once the truck is secure, crawl underneath and locate the heat shield. Use an impact wrench to remove the bolts holding the heat shield in place. As you remove the bolts, support the heat shield with your knee to prevent it from falling. Once the heat shield is removed, set it aside.

Now, grab two floor jacks and place them under the fuel tank to support it while you remove its bolts. Remember to insert soft padding between the jack stand and the tank to avoid damage. Use the impact wrench again to remove the four long bolts from the fuel tank. Once the straps are loosened, lower and twist them off gently. Set the straps and bolts aside.

At this point, the fuel tank should only be supported by the jack stands. Slowly lower the jack stands while holding the fuel tank. The front end will need to be disconnected from the fuel fill line using a 1/4 inch hex socket. Once the fuel fill line is disconnected, you can fully remove the fuel tank from under the truck.

Replacing Mantis Tiller Fuel Line: A Step-by-Step Guide

You may want to see also

Clean the engine block surface

To clean the engine block surface of your 1946 Ford V8, you'll want to follow these steps carefully to ensure you don't damage the mating surfaces.

Firstly, you'll want to remove any large pieces of gasket material that may be stuck to the engine block. This can be done with a razor edge scraper and a vacuum. Next, you'll want to use a chemical cleaner or a wire wheel to remove any remaining residue. Be careful when choosing your cleaner, as some chemicals can be too strong and cause oxidation or discolouration. Castrol engine cleaner, for example, may not be the best choice as it can oxidize the intake manifold and carburettor. Instead, try using a mild detergent, like Simple Green, and a stainless steel brush to gently scrub the engine block surface. If you want to be extra cautious, you can use a plastic brush to avoid any potential scratches.

Another option is to use a pressure washer with hot soapy water to clean the engine block. This method can be very effective at removing built-up grime. If your engine is already apart, you could consider sandblasting the engine block to get it looking like new again. Just be sure to protect the carburettor pad and intake flanges if you go this route.

Alternatively, you could take the intake manifold to a transmission shop to have it cleaned. They use solutions and temperatures that are better suited for aluminium than what you'd find at a typical engine shop. You could also consider powder coating the intake manifold, which will seal up the porosity and make it easier to clean in the future. A silver powder coating will give you that new aluminium finish without the risk of staining.

Once you're finished cleaning, be sure to inspect the engine block surface for any scratches or warping. You can use a flashlight and a straight edge to check for flatness. Hold the straight edge against the surface and move it along, looking for any light coming through that would indicate low or raised spots.

By following these steps, you'll have a clean engine block surface that's ready for gasket installation or any other necessary repairs.

Best Replacement Fuel Tanks for Ford Mustangs: Top Brands

You may want to see also

Reattach the fuel tank and reconnect the fuel lines

Now that you've replaced the fuel pump, it's time to reattach the fuel tank and reconnect the fuel lines.

First, you'll need to reconnect the fuel tank. Ask your assistant to slowly raise the jack stands while you slide the fuel tank back under the truck. Once the tank is in position, reconnect the fuel fill line using a 1/4 inch hex socket. Be sure to tighten the connection securely.

Next, you'll reconnect the fuel lines. If you haven't already, be sure to clean the area around the fuel pump module and the tank to ensure no dirt or debris falls into the tank. Then, reconnect the fuel outlay and relay lines, as well as the evaporative hoses, to the fuel pump module. If you had to remove any hoses or lines, be sure to reattach them securely.

Now, you'll want to lower the fuel tank back into place. Slowly lower the jack stands while you guide the fuel tank into position. Once the tank is in place, reattach the straps and bolts that secure it. Be careful not to over-tighten the bolts, as this can damage the mounting points.

Finally, you'll want to reconnect the fuel lines to the fuel pump. If you had to cut any fuel lines or remove any clips, be sure to replace them with new parts. Securely attach the fuel lines to the input and output of the fuel pump, using the appropriate clips or fittings. Be sure to check for any leaks once you've finished.

And that's it! You've successfully replaced the fuel pump on your 1946 Ford V8 and can now safely refill your fuel tank and continue your restoration project or enjoy your classic car on the open road.

Craftsman Lawn Tractor: Replacing the Fuel Line

You may want to see also