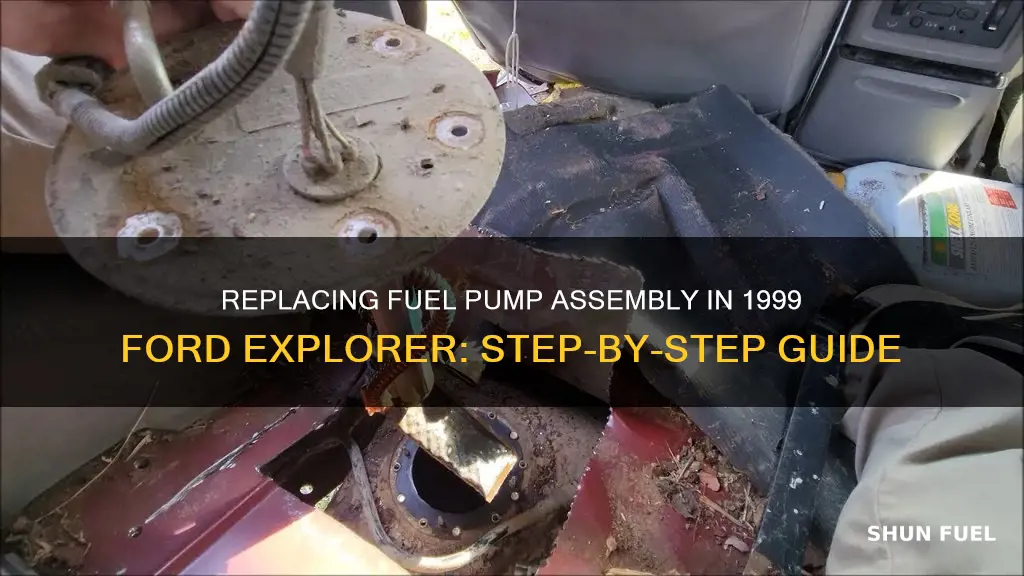

Replacing the fuel pump assembly in a 1999 Ford Explorer is a moderately complicated job that can be done at a dealership's service department or by a mechanic. The fuel pump is located inside the fuel tank and can be accessed by removing the fuel tank from the vehicle or through an access panel in the passenger compartment. The process involves siphoning or draining the fuel from the tank, disconnecting the filler tube hose and electrical connection to the pump, removing the retaining straps or bolts holding the tank in place, and then disconnecting and removing the fuel pump from the tank. A new fuel pump can then be installed, and the fuel tank and connections reassembled. There are also aftermarket electric fuel pump module assemblies available for the 1999 Ford Explorer, which can be purchased online and installed as a replacement.

What You'll Learn

Siphon or drain fuel from the tank

Siphoning or draining the fuel from the tank is an important first step when replacing the fuel pump assembly in a 1999 Ford Explorer. Here is a detailed guide on how to do this safely and effectively:

Firstly, it is important to reduce the fuel in the tank to nearly empty. You can do this by waiting until your fuel gauge is close to empty, or by siphoning the fuel out of the tank. If you decide to siphon, it is recommended to use the vent port instead of the filler port as this will allow you to reach the bottom of the tank.

Once the fuel is reduced, the next step is to relieve the fuel pressure. This can be done in several ways, including:

- Removing the fuel pump relay or fuse in the Battery Junction Box (BJB) and letting the engine run until there is no fuel pressure.

- Activating the Inertial Fuel Shutoff and then running the engine until there is no fuel pressure.

- Disconnecting the fuel pump electrical connector C311 (for 2000 and earlier models).

- Letting the vehicle sit overnight, allowing the pressure to bleed off through the check valve, and then relieving any remaining pressure by depressing the Schrader valve.

After the fuel pressure is relieved, be sure to disconnect the cable from the negative terminal of the battery. You may also choose to disconnect the positive connector as well, to clean the battery posts.

Now you are ready to begin the process of removing the fuel tank and replacing the fuel pump assembly. This will involve a series of steps, including lowering the spare tire, jacking up the rear axle, removing the left rear wheel, and loosening various hoses and clamps. It is important to refer to a repair manual or seek professional guidance for a complete and accurate step-by-step guide.

In summary, siphoning or draining the fuel from the tank is a crucial first step when replacing the fuel pump assembly in a 1999 Ford Explorer. By following the steps outlined above, you can safely and effectively complete this part of the process before moving on to removing the fuel tank and installing the new fuel pump.

Replacing the Fuel Pump in a 2004 Grand Cherokee

You may want to see also

Disconnect filler tube hose and electrical connection

Disconnecting the filler tube hose and electrical connection is a crucial step when replacing the fuel pump assembly in a 1999 Ford Explorer. Here is a detailed guide on how to perform this task:

Firstly, it is important to relieve the fuel pressure before beginning any work. This can be done by removing the fuel pump relay or fuse in the Battery Junction Box (BJB), or by activating the Inertial Fuel Shutoff. Alternatively, you can disconnect the fuel pump electrical connector C311 attached to the inner side of the left frame rail forward of the tank.

Once the fuel pressure is relieved, the next step is to disconnect the cable from the negative terminal of the battery. Both the negative and positive connectors can be disconnected and cleaned if needed.

The next step is to access the fuel tank. This involves blocking the front wheels, lowering the spare tire, and jacking up the rear axle and placing jack stands for support. Remove the left rear wheel and any fuel tank shield or skid plate if present.

Now, you are ready to disconnect the filler tube hose and electrical connection:

- Loosen the vent hose clamp and the fuel filler hose clamp at the tank, and disconnect the hoses. Cover the ports with aluminum foil to reduce fumes and keep out dirt.

- Disconnect the fuel pump electrical connector, which is located inboard of the driver-side frame rail and forward of the fuel tank on 2000 and earlier models. On 2001 and later models, this connector is not present.

- Carefully lower the fuel tank to access the fuel line, electrical connector, and vapor hose connector through the wheel well. Ensure that the hoses do not support the weight of the tank.

- Disconnect the fuel line, vapor hose connector, and electrical connector.

At this point, you have successfully disconnected the filler tube hose and electrical connection. You can now proceed with the next steps of the fuel pump assembly replacement process. Remember to work carefully and refer to a qualified mechanic or repair manual for further guidance if needed.

Replacing Honda SH150 Fuel Pump: Step-by-Step Guide

You may want to see also

Support the tank with a jack and remove it

To support the tank with a jack and remove it, you'll need to follow these steps:

Firstly, make sure to support the fuel tank with a jack or jacks. For better control, you can use scissor jacks and boards. This will ensure that the tank is securely held in place and can be safely lowered.

Next, you'll need to remove the bolts attaching the front of the tank to the support bracket. Depending on your model, you may need to bend or remove the tank strap. If you need to remove it, push the tank sideways towards the driveshaft and swing the strap rearward to align the flat head with the slot in the frame rail. Then, lower the rear of the tank first, followed by the front, while pushing the tank rearward to clear the mounting bracket. Be careful not to stress any of the tank connections during this process.

Once the tank is lowered, you can access the fuel line, electrical connector, and vapor hose connector through the wheel well. Ensure that the tank is not lowered too much, so that the hoses are not bearing the weight of the tank.

Finally, disconnect the fuel line, vapor hose connector, and electrical connector. With these connections disconnected, you can now remove the fuel tank.

Replacing Optavia Fuelings: Healthy Alternatives for Your Diet

You may want to see also

Disconnect fuel lines and remove the pump

Disconnecting the fuel lines and removing the pump is a crucial step in replacing the fuel pump assembly in a 1999 Ford Explorer. Here is a detailed guide on how to approach this task:

Step 1: Disconnect the Fuel Lines

Before disconnecting the fuel lines, it is important to relieve the fuel pressure. This can be done by removing the fuel pump relay or fuse in the Battery Junction Box (BJB), or by activating the Inertial Fuel Shutoff. Alternatively, you can disconnect the fuel pump electrical connector C311, which is located on the inner side of the left frame rail forward of the tank. Once the pressure is relieved, you can proceed to disconnect the fuel lines.

Step 2: Remove the Fuel Pump

To remove the fuel pump, you will need to access it through the fuel tank. Lower the rear of the tank and support it with jacks and blocks of wood. Disconnect the electrical connector from the transducer and carefully remove the bolts attaching the fuel pump assembly to the tank. Slowly raise the fuel pump assembly out of the tank, being cautious not to damage the fuel level float sensor.

Step 3: Inspect and Prepare the New Fuel Pump

Before installing the new fuel pump, inspect the large seal for any cracks or drying. Check the condition of the fuel pressure regulator, hose clamps, and corrugated return hose. If any of these components show signs of deterioration, they should be replaced.

Step 4: Install the New Fuel Pump

Insert the new fuel pump assembly into the tank, ensuring that the float and its arm do not contact the diameter of the tank opening. Position the assembly to align with the marks made prior to removing the old pump. Torque the screws to secure the assembly in place.

Step 5: Reconnect the Fuel Lines

Reconnect the fuel lines, electrical connectors, and vapor hose connector. Ensure that all connections are secure and tight.

By following these steps, you can successfully disconnect the fuel lines, remove the old fuel pump, and install a new fuel pump assembly in your 1999 Ford Explorer.

Replacing Fuel Pump in '03 Vue: Step-by-Step Guide

You may want to see also

Install the new pump and connect the fuel lines

Now that you have siphoned or drained as much fuel as possible from the tank, disconnected the filler tube hose and the electrical connection to the pump, supported the tank with a jack, and removed the old pump, it's time to install the new fuel pump and connect the fuel lines.

First, you'll want to install the new pump into the tank. Be careful not to damage the float arm of the fuel level float sensor, as this can affect the reliability of your fuel gauge reading.

Next, connect the fuel lines to the new pump. Ensure that the hose clamps are tight and in good condition.

Once the new pump is installed and the fuel lines are connected, you can lift the fuel tank back into place and install the retaining strap. Reconnect the filler tube hose and the electrical connector, and then reconnect the negative battery cable.

Finally, fill the tank with gas—usually to about a quarter full—and conduct a road test to confirm that the new pump has been installed successfully.

Oxygen Sensor Replacement: Tahoe Fuel Mileage Fix?

You may want to see also

Frequently asked questions

You will need to remove the fuel tank. Siphon or drain the fuel tank, disconnect the filler tube hose and electrical connection to the pump, and then lower the tank.

First, reduce the fuel in the tank to nearly empty. Disconnect the cable from the negative terminal of the battery, block the front wheels, and then jack up the rear axle and place jack stands underneath. Next, remove the left rear wheel, followed by the fuel tank shield and skid plate (if present). Loosen the vent hose and fuel filler hose clamps, and then disconnect the hoses from the tank. Finally, support the tank with jacks and blocks of wood, and remove the tank mounting bolts.

Disconnect the electrical connector from the transducer, and then clean the top of the tank with a brush. Mark the tank and the fuel pump assembly with alignment arrows, and then remove the bolts attaching the assembly to the tank. Carefully raise the assembly out of the tank, taking care not to apply pressure to the float arm.

First, remove the fuel pump clamp screw and detach the clamp. Pull the pump away from the assembly to access the electrical connector, and then disconnect the pump.

Install the new pump in the reverse of the removal process, taking care to route the wires correctly and to apply vinyl conditioner to the large seal.