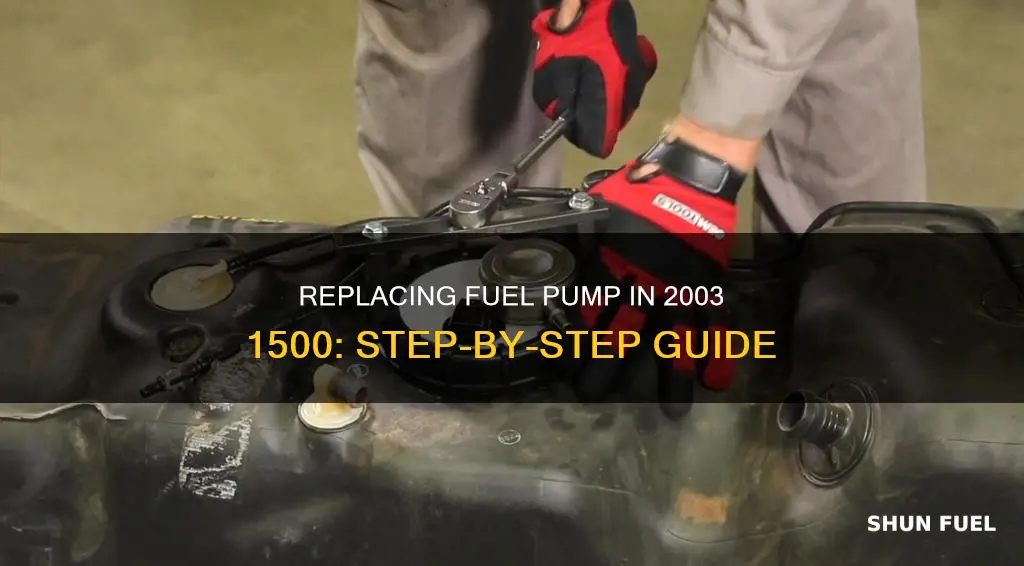

If you're looking to replace the fuel pump in a 2003 Chevy Silverado 1500, there are a few things you should know. Firstly, the fuel pump is located inside the fuel tank, and it has a small electric motor to ensure that pressurised gasoline flows to the engine. While most fuel pumps will last for the life of the vehicle, they can occasionally fail, and you may need to replace the entire pump/sending unit module. Signs of a failing fuel pump include a car that won't start, stalling, or a whirring sound coming from the fuel tank.

Now, onto the replacement process. First, you'll need to remove the fuel pump relay from the engine's fuse box. Then, crank the engine for several seconds until it stalls, and disconnect the negative battery cable. Next, open the gas cap door and unscrew the flange surrounding the filler pipe. Raise the rear end of the truck and support it on jack stands, then unbolt and remove the fuel tank shield. Disconnect the ground strap on the filler pipe and the EVAP canister lines. At this point, you can disconnect the lines and electrical connectors from the fuel pump module's flange on the tank.

To remove the fuel tank, boost it with a transmission jack and unbolt the support straps. Lower the jack and remove the tank. You can now replace the fuel pump module. Make sure you don't damage the pump's float at the bottom, and align the module so its line fittings point in the same direction as the old one. Press down on the module to seat its retaining ring and turn it clockwise to engage the locking tab.

Finally, place the fuel tank back on the jack and raise it into position. Connect the straps, and reconnect the fuel lines and electrical connectors to the fuel pump flange. Reinstall the EVAP canister and connect its lines. Connect the ground strap and shield back to the fuel tank, and you're almost done! Reconnect the battery cable and fuel pump fuse, and you should be good to go.

| Characteristics | Values |

|---|---|

| Vehicle | 2003 Chevy Silverado 1500 |

| Fuel pump location | Inside the fuel tank |

| Fuel pump function | Ensure pressurized gasoline flows to the engine |

| Fuel pump failure signs | Engine stalling, engine not starting, check engine light on, whirring sound from fuel tank |

| Fuel pump replacement | Remove and replace the entire pump/sending unit module mounted within the fuel tank |

| Fuel pump relay location | Driver's side, under the hood, inside the engine's fuse box |

| Fuel level before replacement | Low |

| Fuel removal method | Siphon out with a vacuum pump kit |

| Fuel tank removal | Raise the rear end of the truck, unbolt and remove the fuel tank shield, disconnect the ground strap, EVAP canister lines, and support straps |

| Fuel pump module removal | Disconnect lines and electrical connectors, press and release locking tab, turn the ring counterclockwise, lift the module out of the tank |

| Fuel pump module installation | Lower the new module into the tank, align the line fittings, press down on the module, turn the ring clockwise to engage the locking tab |

What You'll Learn

Removing the fuel pump relay

To remove the fuel pump relay on a 2003 Chevy Avalanche 1500, you will need to locate the fuse box. This is a black box found on the driver's side, under the hood, next to the battery. Remove the cover to expose the fuses and relays. Look inside the cover to find the fuel pump relay. Use the diagram inside the cover to locate the relay. Once found, the relay should just pull out. Sometimes it can be a little tight, so you may need to use pliers and rock it back and forth to remove it.

If you are removing the fuel pump relay on a 2003 Chevy Silverado 1500, the process is slightly different. First, you need to remove the relay from within the engine's fuse box. You can find the location of the relay by looking at the box's diagram. Next, crank the engine for several seconds until it stalls, then disconnect the truck's negative battery cable.

If you are removing the fuel pump relay on other models of car, the process may be different again. For example, on a Chrysler Crossfire, you need to disconnect the negative battery terminal and remove the lid on the fuse box. The relay can then be located and pulled out from the grasp of the two clasps on either side of the module. On a Mazda MX-5, there are two locking tabs on the shorter side of the relay that need to be spread out in order to remove it.

Replacing Fuel Injector in Chevy Cruze: Step-by-Step Guide

You may want to see also

Disconnecting the negative battery cable

To disconnect the negative battery cable on your 2003 1500, follow these steps:

Locate the negative battery terminal: The negative battery terminal is typically marked with a minus sign (-) or a black cover. It is usually located on the driver's side of the vehicle, but can sometimes be found on the passenger side or even in the rear of the vehicle, depending on the make and model. Before beginning, be sure to gather the necessary tools, including a basic socket set or combination wrench set.

Loosen the negative battery cable clamp: Using the appropriate size socket or wrench, loosen the nut that secures the negative battery cable to the negative terminal. Do not remove the nut completely just yet; simply loosen it enough so that the cable can be easily detached from the terminal. Be cautious and aware of any fluids that may be present, as battery acid can be dangerous and corrosive. Always wear gloves and eye protection when working with batteries.

Disconnect the negative battery cable: With the nut loosened, carefully detach the negative battery cable from the terminal. Lift the cable slightly and tilt it away from the terminal to avoid any contact with the metal parts of the battery. Never allow the negative cable to touch any metal parts of the vehicle, as this could result in a short circuit or electrical arcing. Ensure that the cable is secure and will not accidentally fall back into contact with the battery.

Secure the negative battery cable: Once the cable is disconnected, make sure it is properly secured and insulated to prevent accidental contact with the battery terminal. You can use a cable tie or tape to hold the cable in a safe position. It is also a good idea to cover the terminal with a piece of electrical tape or a terminal protector to avoid any unintended connections.

Verify the disconnection: To ensure that the negative battery cable is indeed disconnected, use a voltage tester or a multimeter to check for continuity between the cable and the terminal. A simple voltage tester pen can confirm that there is no electrical current flowing through the circuit. This step is crucial to ensuring safety and preventing short circuits during the fuel pump replacement process.

At this point, you have successfully disconnected the negative battery cable, and you can proceed with the next steps in replacing the fuel pump in your 2003 1500. Remember to exercise caution and adhere to established safety procedures when working with automotive electrical systems.

Replacing Stihl FS45 Fuel Tank: Step-by-Step Guide

You may want to see also

Unscrewing the flange surrounding the filler pipe

To remove the flange that surrounds the filler pipe, you will need a screwdriver with an inverted hex bolt head. This is because the screws that hold the flange in place will have inverted hex bolt heads. Once you have the right screwdriver, you can simply unscrew the flange.

Before you begin this process, you will need to siphon out as much fuel as possible with a proper vacuum pump kit if needed. Do not siphon by mouth. You will also need to remove the fuel pump's relay from within the engine's fuse box. You can find the relay by looking at the box's diagram. Crank the engine for several seconds, then look for it to stall and disconnect the truck's negative battery cable.

After you have unscrewed the flange, you can continue with the following steps:

- Raise the truck's rear end and support it on jack stands.

- Unbolt and remove the fuel tank's shield with a wrench.

- Disconnect the ground strap on the filler pipe.

- Disconnect the EVAP canister lines at its quick-connect fittings.

- Unbolt and remove the canister from its bracket using a wrench.

Replacing Fuel Sender in 2009 Expedition: Step-by-Step Guide

You may want to see also

Disconnecting the EVAP canister lines

Locate the EVAP Canister:

The EVAP canister is usually located in the engine compartment, often near the fuel tank or under the vehicle. It is typically a small, cylindrical or rectangular container with hoses connected to it.

Prepare the Vehicle:

Park the vehicle on a level surface and engage the parking brake. Wear safety gear, including gloves and eye protection, to avoid injury. Ensure you have the necessary tools, such as wrenches and screwdrivers, within easy reach.

Disconnect the Battery:

Disconnecting the battery is an essential safety precaution when working on any electrical or fuel-related system in a vehicle. Locate the negative battery terminal and carefully disconnect the cable.

Access the EVAP Canister:

Depending on the vehicle's configuration, you may need to raise the vehicle or remove certain components to access the EVAP canister and its lines. Refer to your vehicle's repair manual or seek guidance from a qualified mechanic if you're unsure about the specific steps for your vehicle.

Identify the EVAP Canister Lines:

The EVAP canister lines are the hoses or tubes connected to the EVAP canister. They are typically made of rubber or plastic and may have quick-connect fittings or special connectors.

Disconnect the Lines:

To disconnect the EVAP canister lines, follow these steps:

- Inspect the connectors: Before disconnecting the lines, carefully inspect the connectors for any damage or unusual features. In some cases, there may be small tabs or release mechanisms that need to be pressed or manipulated to detach the lines.

- Pinch and wiggle: Gently pinch the flat spots on the connectors and wiggle the lines loose. It may require some force, but be careful not to break the connectors.

- Use tools if needed: If the lines are difficult to detach by hand, you can use needle-nose pliers to press the flat parts of the connectors together while wiggling the lines. Alternatively, there are special tools designed for removing EVAP canister connectors.

- Spray with penetrant: If the connectors seem stuck, you can spray them with a penetrant to help loosen any residue or buildup.

Store the Lines Safely:

Once the lines are disconnected, set them aside in a safe place to avoid accidental damage. Ensure they are properly labelled or marked so you can easily reconnect them later.

Remember, working on fuel systems can be dangerous, and specific procedures may vary depending on your vehicle's make and model. Always refer to the manufacturer's guidelines or seek advice from a qualified mechanic if you're unsure about any steps.

Tractor Maintenance: Replacing Husqvarna Fuel Valve

You may want to see also

Disconnecting the fuel pump module's flange

Prepare Your Work Area

Before you begin, ensure your work area is well-ventilated and well-lit. Park your vehicle in a suitable location and put on the necessary safety gear, including gloves and eye protection. Working on your car's fuel system can be dangerous, so take the time to identify and understand any potential hazards. Consult your vehicle's owner manual to locate the fuel pump and familiarise yourself with the procedure for disconnecting the lines safely.

Locate the Fuel Pump and Lines

The fuel pump is typically located near the gas tank or in the engine compartment. Consult your vehicle's manual or check online resources to pinpoint its exact location in your specific make and model. Once you've found the fuel pump, identify the fuel lines that need to be disconnected. These lines are usually attached using quick-disconnect fittings, which can be easily removed with a special tool. If your vehicle is older and doesn't have quick-disconnect fittings, you may need to use a wrench to carefully loosen the nuts securing the fuel lines to the fuel pump.

Relieve System Pressure

Before disconnecting the fuel lines, it's crucial to relieve the system pressure to prevent fuel from spraying out. To do this, locate the fuel pump fuse or relay and remove it. Then, turn on the car and let it run for a few seconds until it stalls. This will release any built-up pressure in the lines. Make sure to replace the fuel pump fuse or relay before turning on the car again.

Disconnect the Fuel Lines

Now, you can proceed to disconnect the fuel lines from the fuel pump. Ensure you have the correct size wrenches and pliers to safely remove the lines. Locate any clips or connectors holding the lines in place and carefully remove them using pliers or a specialised tool. With the clips removed, use your wrench to loosen the fittings on the fuel pump, then gently pull the lines away. Be cautious, as some fuel may spill out. Have a rag or container ready to catch any spills.

Removing the Fuel Pump Module

After disconnecting the fuel lines, you can focus on removing the fuel pump module itself. This process will vary depending on your vehicle's make and model, so refer to your owner's manual or a repair guide for specific instructions. Typically, you'll need to raise the vehicle's rear end, remove the fuel tank, and then carefully lift out the old fuel pump module. When installing the new module, ensure the pump's float is not damaged and that the module's line fittings align with the previous setup.

Remember, working on your vehicle's fuel system can be dangerous due to the flammable nature of fuel. Always exercise caution, take your time, and refer to reliable sources for guidance if you're unsure about any steps.

Replacing the Fuel Meter Cover on a 1962 Rochester Injection

You may want to see also

Frequently asked questions

Signs of a failing fuel pump include a car that won't start or stalls once it has started. You may also hear a whirring sound coming from your fuel tank, as fuel pumps do not normally make noise.

The fuel pump is located inside your fuel tank. A mechanic will need to get to the failed pump through the top of the fuel tank via an access panel in the passenger compartment or by removing the tank from the vehicle.

This moderately complicated job is best performed at your dealership’s service department.