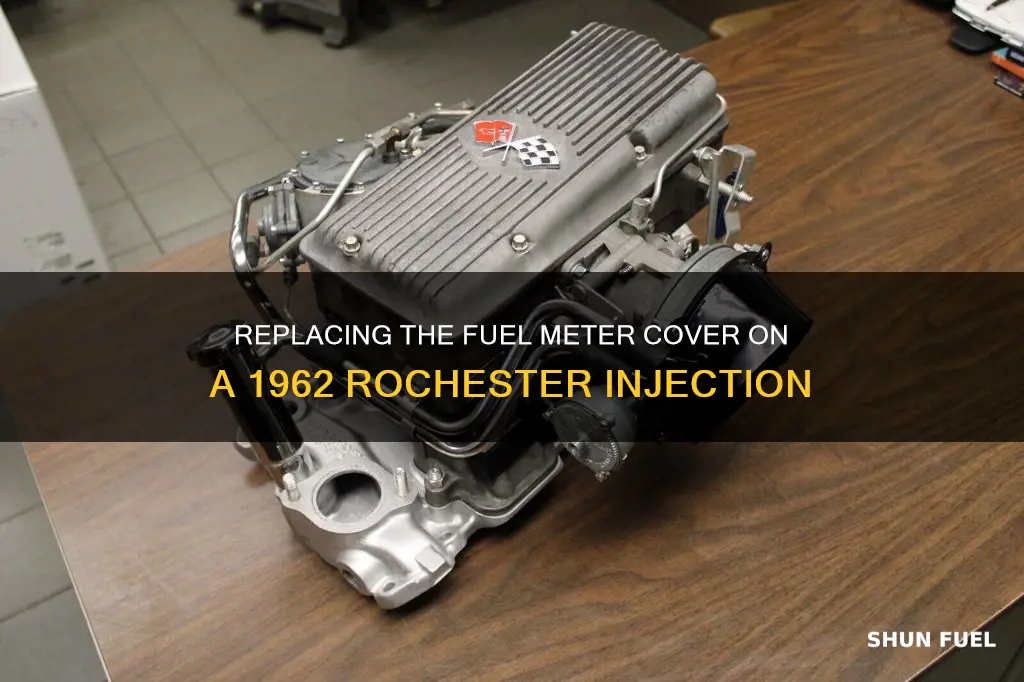

The Rochester Ramjet fuel injection system was first offered as a high-performance option for the Corvette in 1957. The system is complex and prone to vapor locking, causing hot starts to be difficult. This is an entirely mechanical unit that uses a vacuum to operate a spill gate to control fuel flow to eight injection nozzles. The 1962 Rochester fuel injection unit has a flat top plenum. This article will provide a step-by-step guide on how to replace the fuel meter cover of the 1962 Rochester fuel injection system.

What You'll Learn

- The Rochester Ramjet is a continuous-flow port-injection system

- The air meter measures airflow and manages thermostatic warmup enrichment

- The fuel meter contains the high-pressure fuel pump and controls fuel delivery to the injector nozzles

- The cranking signal valve can cause reliability issues

- The Rochester fuel injection unit was redesigned in 1963

The Rochester Ramjet is a continuous-flow port-injection system

The system has three main components: the air meter, the fuel meter, and the intake manifold. The air meter measures airflow into the engine and manages the thermostatic warmup, fuel shutoff, and idle settings. These measurements are sent as pressure and vacuum signals to the fuel meter, which contains the high-pressure fuel pump and controls the delivery of fuel to the injector nozzles. The intake manifold distributes the air-fuel mixture to the cylinders.

The Ramjet's unique design and complexity made it a challenge for mechanics, and it gained a reputation for being difficult to maintain. Its performance and efficiency made it a groundbreaking innovation in the automotive industry, but it was eventually discontinued in 1965 in favour of the Chevrolet Big Block.

The system has undergone several revisions, each spanning three years of its nine-year production life. The first revision (1957-1959) is identified by its "'finned top' sand cast plenum", followed by the "'flat top' plenum" (1960-1962), and the die-cast plenum (1963-1965). Despite its complexities, the Rochester Ramjet remains an important milestone in the history of automotive technology.

Firestone's Fuel Line Innovations: Replacement Revolutionized

You may want to see also

The air meter measures airflow and manages thermostatic warmup enrichment

The Rochester Ramjet is an automotive fuel injection system first offered as an option on the Corvette and GM passenger cars in 1957. The system was discontinued in 1965. The two main sub-assemblies of the system are the air meter and the fuel meter.

The air meter measures airflow into the engine and manages thermostatic warmup enrichment, fuel shutoff on overrun, and idle settings. These measurements are sent via pressure and vacuum signals to the fuel meter, which contains the high-pressure fuel pump and controls the delivery of fuel to the injector nozzles.

The air meter is an essential component of the Rochester Ramjet fuel injection system, which was designed to provide increased engine performance. By measuring the airflow and managing the thermostatic warmup enrichment process, the air meter ensures that the engine receives the optimal air-fuel mixture, resulting in improved engine performance and efficiency.

The air meter's role in thermostatic warmup enrichment is particularly crucial during cold starts. It helps to ensure that the engine receives the necessary fuel enrichment for easy starting and smooth operation until the engine reaches its optimal operating temperature. This process involves a complex interplay of vacuum signals, diaphragms, and the spill plunger, all working in harmony to provide precise fuel metering and injection.

The Rochester Ramjet's air meter is a testament to the engineering ingenuity of its time, contributing to the system's overall complexity and performance enhancement in automotive fuel injection technology.

Fuel Rod Replacement: Nuclear Power's Necessary Maintenance

You may want to see also

The fuel meter contains the high-pressure fuel pump and controls fuel delivery to the injector nozzles

The Rochester Ramjet is an automotive fuel injection system that was first offered as a high-performance option on the Corvette and GM passenger cars in 1957. The system was discontinued in 1965, but it left a lasting impact on the automotive industry.

The Ramjet system is purely mechanical, relying on vacuum and pressure signals to measure airflow and meter fuel. It consists of two main sub-assemblies: the air meter and the fuel meter. While the air meter measures airflow and manages thermostatic warm-up enrichment, the fuel meter contains the high-pressure fuel pump and controls fuel delivery to the injector nozzles. This process ensures that the engine receives the precise amount of fuel required for optimal performance.

The fuel meter's design remained largely unchanged during the production of the Ramjet. However, there were some modifications made to the metering valve, and the spill plunger was replaced with a poppet-type valve. Additionally, the cranking signal valve was relocated to the cover of the power enrichment diaphragm. These changes improved the functionality and reliability of the fuel injection system.

The Rochester Ramjet's fuel meter played a crucial role in the overall performance of the vehicle. Its ability to control fuel delivery to the injector nozzles ensured that the engine received a precise air-fuel mixture, resulting in enhanced engine performance and efficiency. The complex interplay of the fuel meter's components, including the lever, pivot assembly, and diaphragms, contributed to the overall effectiveness of the Rochester Ramjet fuel injection system.

The Rochester Ramjet's fuel meter was an engineering marvel for its time, and its impact can still be felt in modern fuel injection systems. While the technology has evolved, the fundamental principles established by the Ramjet continue to influence the design and development of fuel injection systems today.

Replacing Fuel Line on a Weedeater: A Step-by-Step Guide

You may want to see also

The cranking signal valve can cause reliability issues

The Rochester fuel injection system was discontinued in 1965 due to reliability issues, among other reasons. The cranking signal valve was identified as a source of reliability issues.

The cranking signal valve was designed to pass a maximum vacuum signal to be used for fueling during cranking, or before the engine starts. However, the valve would sometimes fail in a partially open position, causing the fueling to be much richer than stoichiometric. This issue was addressed in the 1962 model, where the cranking signal valve was relocated to the cover of the power enrichment diaphragm. This new location virtually eliminated the possibility of failure due to backfire.

The 1962 Rochester fuel injection system was also designed to address issues with cold-start fuel enrichment. Earlier models would toggle fuel enrichment on or off rather than using a gradual series of steps. The 1962 model incorporated a nearly conventional blade-type choke valve, which eliminated the complex valving of cold enrichment systems found in previous models. This new design also included an electrically heated thermostatic coil mounted on the air meter inlet, which provided the necessary venturi signal "boost" for fuel enrichment.

The 1962 Rochester fuel injection system was a significant improvement over earlier models, offering increased reliability and performance. However, it was still a complex system that required proper maintenance and understanding.

Fuel Pump Replacement: Essential Tools and Components

You may want to see also

The Rochester fuel injection unit was redesigned in 1963

The 1963 Rochester fuel injection unit featured a larger and wider removable top plenum cover, adorned with a crossed flag emblem. This new design replaced the \"flat top\" plenum of the 1960-1962 models. The air meter was also substantially shorter, although the choke setup remained largely unchanged from the previous year.

The 1963 unit utilised a two-line system with a cranking signal valve and a built-in siphon breaker. This was an evolution of the previous design, which had the internal siphon breakers located within the fuel meters. Additionally, the spider component was also redesigned for this model.

The early 1964 design, known as #7017375R, was a recalibration of the 1963 unit, adapted for use with the new 1964 camshaft and larger-valved cylinder heads. This transition marked a shift from the two-line system to a one-line system without a cranking signal valve, identified as #7017380.

The Rochester fuel injection system had been steadily refined since its debut in 1957, but despite its reliability, it was ultimately discontinued in 1965. This decision was largely driven by the introduction of the new Mark IV 396 cubic-inch engine, which offered greater horsepower and torque at a lower cost.

The complexity of the Rochester fuel injection system, particularly the fuel meter, made it a challenge for mechanics to service. As a result, it was often replaced with carburetors, which were simpler and more familiar to Chevrolet service personnel.

Replacing the Fuel Pump in a 2003 Avalanche: Step-by-Step Guide

You may want to see also

Frequently asked questions

The fuel meter cover on a 1962 Rochester fuel injection system is part of the "'flat top' plenum" design. To replace it, you will need to remove the old cover and install a new one, ensuring that all parts are clean and properly assembled.

You will need standard automotive tools, including wrenches and screwdrivers. It is also recommended to have a repair manual specific to the Rochester fuel injection system for reference during the replacement process.

Replacement fuel meter covers for the 1962 Rochester fuel injection system may be available from specialty automotive suppliers or online marketplaces, such as eBay.

It is important to ensure that all parts are clean and free of debris before assembly. It is also crucial to follow the proper assembly and adjustment procedures, as outlined in the repair manual, to ensure the system functions correctly.