A fuel sender is a device that transmits data from the fuel tank to the fuel gauge, telling the driver how much fuel is left. A faulty sender unit can cause the fuel gauge to read empty when there is fuel in the tank, or to read full when the car has travelled some distance. Before replacing the fuel sender, there are some simple inspections and tests that can help streamline the repair. If the fuel gauge is faulty, it can be replaced by disconnecting the fuel lines and electrical connections, cleaning the area, and installing a new fuel sender with a new gasket/O-ring.

What You'll Learn

Disconnect the battery and fuel pump

Disconnecting the battery and fuel pump is a crucial step when replacing a fuel sender. Here are some detailed instructions to ensure your safety and effectively disconnect the components:

Preparation:

Before beginning any work on your vehicle, it is essential to take some necessary precautions. Put on safety gear, such as fuel-resistant gloves and protective eyewear, to avoid any accidental spills or splashes. Move your vehicle to a flat, level surface and engage the parking brake to prevent accidental movement. Additionally, if you have a manual transmission, put the car in first gear; for automatics, put it in park.

Disconnecting the Battery:

Open the hood of your vehicle and locate the battery. Identify the ground cable connected to the battery's negative terminal. Using a suitable tool, such as a wrench or socket, carefully loosen and remove the cable from the negative terminal. Ensure that the cable does not touch any metal parts of the vehicle to avoid creating a short circuit. This step is crucial as it disables the power to the fuel pump and sending unit, making it safe to work on the fuel system.

Disconnecting the Fuel Pump:

The fuel pump is typically located inside the fuel tank. To access it, you may need to raise the vehicle and place it on jack stands. Consult your vehicle's repair manual or seek guidance from a certified mechanic if you're unsure about the specific location of your fuel pump. Once you've located the fuel pump, you'll need to disconnect the harness or wiring connected to it. Again, pay close attention to the routing of the wires to avoid damaging them.

At this point, you have successfully disconnected the battery and fuel pump. Remember to exercise caution when working on your vehicle, especially when dealing with the fuel system. If you're uncomfortable performing these tasks, it's best to consult a professional mechanic.

Upgrading the R32 GTR: Replacing Vital Fuel Lines

You may want to see also

Remove the fuel tank

Removing the fuel tank is a complex process that requires careful attention to safety precautions. Here is a step-by-step guide to removing the fuel tank, specifically for the purpose of replacing a fuel sender:

Firstly, ensure that your vehicle is parked on a flat, hard surface. Engage the parking brake and place wheel chocks around the front tires, as the rear of the vehicle will be lifted. It is imperative to take safety precautions to prevent accidents and spills. Disconnect the battery to disable the power to the fuel pump and sending unit.

Next, use a jack to lift the vehicle at its specified jacking points until the wheels are off the ground. Place jack stands under the jacking points and lower the vehicle onto them. Locate the fuel tank and use a transmission jack or similar device to lower it slightly. Loosen and remove the straps securing the fuel tank. Disconnect the harness from the connector by reaching up to the top of the fuel tank.

To provide more clearance, lower the fuel tank further and remove the vent hose attached to it. Twist and pull out the fuel filler neck, guiding it out of the area. Remove the clamp on the rubber hose attached to the fuel filler neck. Be sure to transfer any fuel out of the tank before proceeding to remove it from the vehicle.

Now, you can remove the fuel tank from the vehicle. Wipe out the rubber hose on the fuel tank with a lint-free cloth and place a new clamp onto it. Reinstall the fuel filler neck and twist it into the rubber hose, tightening the clamp to prevent vapor leaks.

Once the fuel tank is removed, it is important to clean any dirt and debris from the fuel pump and sender mounting area. This ensures that no debris falls into the fuel tank during the replacement process.

It is worth noting that some vehicles may have different fuel tank configurations, and the removal process may vary slightly. Always refer to your vehicle's repair manual for specific instructions and safety guidelines.

Replacing Fuel Filter in '98 Mustang: Step-by-Step Guide

You may want to see also

Clean the tank

To clean the tank, it is important to ensure that the area around the fuel sending unit is clean, dry, and free of corrosion. This is to prevent any debris from falling into the fuel tank.

Firstly, use electrical cleaner and a lint-free cloth to clean the harness on the vehicle and the connector to the fuel pump or sending unit on the fuel tank.

Next, remove any dirt and debris around the fuel pump and sender mounting area.

Finally, with the fuel tank out of the vehicle, it is recommended to remove and replace the one-way breather valve on the tank. If the breather valve on the fuel tank is non-serviceable, then you will need to use a pump to check its condition. If the valve has failed, replace the fuel tank.

The breather valve on the fuel tank allows fuel vapors to release into the canister but not allow any water or debris into the tank.

Replacing Fuel Injectors in Your 2009 Lincoln MKZ

You may want to see also

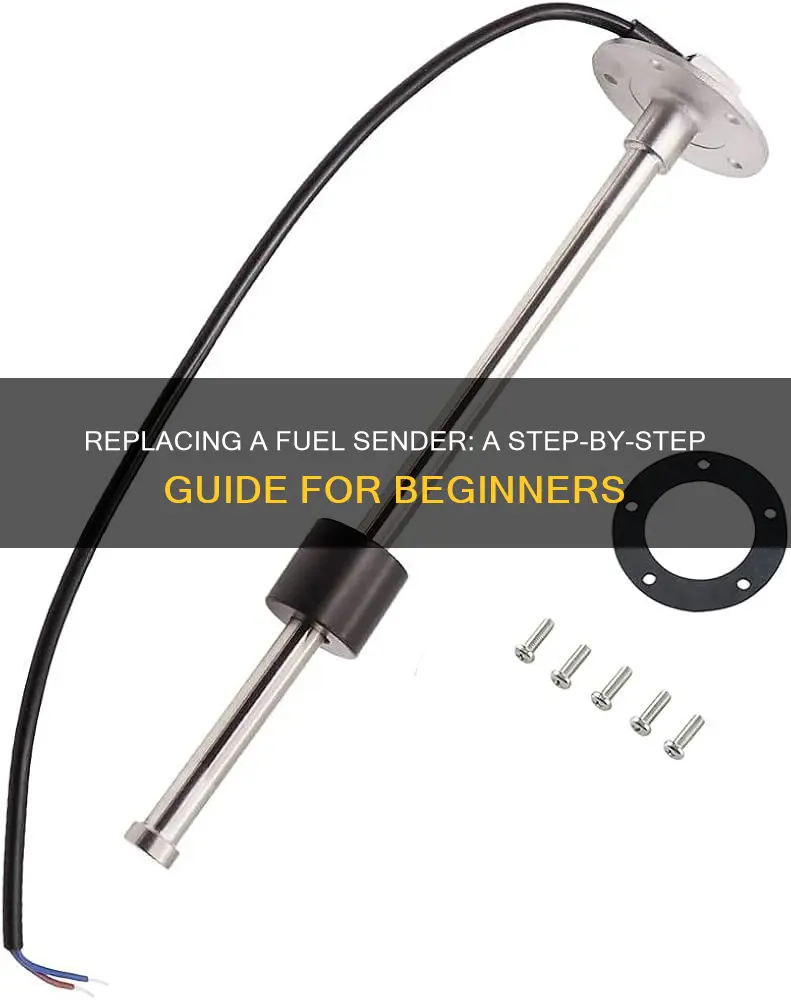

Install the new fuel sender

To install the new fuel sender, follow the steps outlined below:

Firstly, ensure that the new fuel sender unit is compatible with your vehicle's make and model. Refer to the owner's manual or seek advice from a qualified mechanic if you are unsure.

Before beginning the installation, it is crucial to take safety precautions. Make sure the vehicle is parked on a flat, hard surface, and engage the parking brake. Disconnect the negative battery cable to disable the power to the fuel pump and sender unit, and ensure there are no sources of sparks or open flames nearby.

Now, you can begin the installation process:

- Clean the area around the fuel sender plug and ensure it is free of any contaminants.

- Carefully remove the old fuel sender unit, gasket, and/or O-ring from the fuel tank. Take note of the orientation and positioning of the old unit to ensure the new one is installed correctly.

- Inspect the fuel tank for any debris or corrosion. It is important to ensure that the tank is clean and dry before installing the new sender unit.

- Prepare the new fuel sender unit by fitting it with a new gasket or O-ring. Ensure the gasket is properly aligned between the sender unit and the tank.

- Carefully insert the new fuel sender unit into the fuel tank. Be cautious not to bend the float arm, as this can cause inaccurate fuel gauge readings.

- Secure the new fuel sender unit in place using the appropriate screws or bolts. Tighten them by hand, then use a wrench or screwdriver to tighten them further, following the manufacturer's torque specifications.

- Reconnect all electrical connectors and fuel lines to the new fuel sender unit. Ensure that all connections are secure and tight to prevent leaks.

- Refill the fuel tank and check for any leaks around the sender unit and fuel lines.

- Reconnect the negative battery cable and start the vehicle to test the new fuel sender unit.

- Test the vehicle by driving it over bumps and monitoring the fuel gauge for accurate readings.

Note: It is important to follow the specific instructions provided by the manufacturer of the new fuel sender unit, as the installation process may vary slightly depending on the vehicle's make and model.

Replacing Fuel Rail: Disconnecting Chassis Supply Line

You may want to see also

Test the vehicle

Once you have replaced the fuel sender, it is important to test the vehicle to ensure that the new part is functioning correctly. Here is a step-by-step guide on how to do this:

Test Drive the Vehicle

Take the vehicle for a test drive around the block. During the test, drive over different bumps to allow the fuel to slosh around inside the fuel tank. This will help to dislodge any air bubbles that may be trapped in the fuel sender and ensure that the sender is able to accurately read the fuel level.

Monitor the Dashboard

While driving, keep an eye on the dashboard and monitor the fuel level gauge. Watch for any sudden changes or erratic movements of the needle. Also, check for any warning lights, such as the engine light, which may indicate a problem with the fuel sender or another issue with the fuel system.

Observe for Leaks

After the test drive, park the vehicle and inspect it for any signs of fuel leaks. Look under the vehicle for any fuel drips and sniff for any vapors. Use a combustible gas detector if necessary to check for vapor leaks that may be invisible to the naked eye.

Check for Correct Fuel Level

Fill up the fuel tank at a gas station and note the reading on the fuel gauge. Compare this reading to the actual amount of fuel pumped into the vehicle. The readings should be relatively close. If there is a significant discrepancy, it may indicate a problem with the fuel sender or the gauge itself.

Repeat the Process

Repeat the above steps over a few days to ensure consistent results. Drive the vehicle under different conditions, such as on highways and in stop-and-go traffic, to further test the fuel sender's accuracy.

If you notice any issues or inconsistencies during these tests, it is recommended to consult a certified mechanic for further diagnosis and repair.

Troubleshooting Guide: Replacing Fuel Sensors in LS Tractors

You may want to see also