Reducing the fuel pump pressure in a generator is important to prevent flooding in the carburetor. This can be achieved by installing a pressure regulator in the fuel line. However, it is important to note that the proper maintenance and use of a generator can also help to reduce fuel consumption and improve fuel efficiency. This includes servicing the generator regularly, using the correct type of fuel, and ensuring proper ventilation and cooling. Additionally, it is recommended to only run necessary equipment and to avoid overloading the generator.

| Characteristics | Values |

|---|---|

| Problem | Too much fuel pump pressure |

| Cause | Fuel is pushed past the needle and seat assembly in the carburetor |

| Solution | Install a pressure regulator |

| Add a TEE and adjustable valve to send unused fuel back to the tank |

What You'll Learn

Install a pressure regulator

Installing a pressure regulator is a great way to reduce fuel pump pressure in a generator. Here is a comprehensive guide on how to do it:

First, it is important to choose the right pressure regulator for your generator. Consider the type of fuel delivery system and fuel pump you are using. Research the specifications of your fuel pump, such as flow, maximum working pressure, and amperage draw. This information will help you select a compatible pressure regulator. Some fuel pumps, particularly low-pressure units designed for carburetors, may not require an external regulator, so it is essential to verify this before purchasing.

Once you have selected the appropriate pressure regulator, carefully review the instructions provided by the manufacturer. Pressure regulator installation can vary depending on the specific product and your generator setup. Refer to your generator's manual to identify the correct fuel pressure feed line and determine the mounting location for the regulator. It is crucial to ensure that the regulator is mounted at least 100mm away from any significant heat source to prevent engine fires.

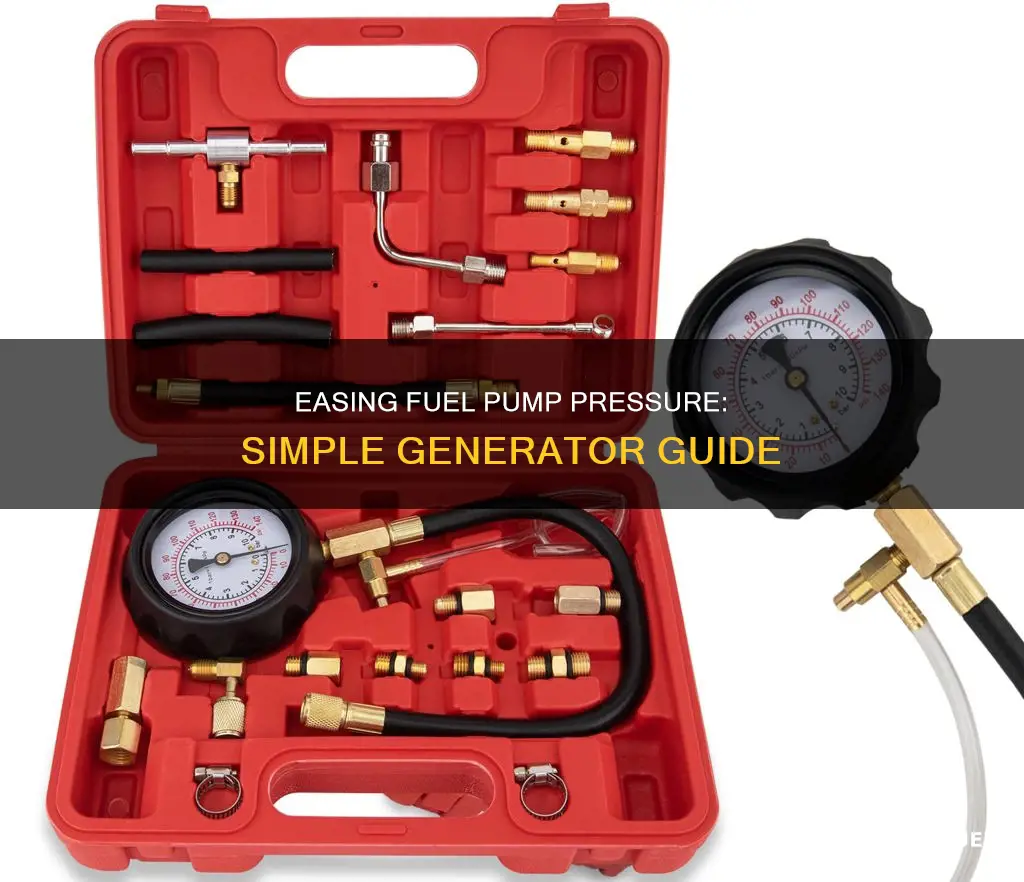

Before beginning the installation, relieve the fuel pressure in the system and ensure there are no leaks in the fuel lines. Then, follow the manufacturer's instructions to prepare the pressure regulator for installation. This may involve installing fittings and ensuring the presence of O-rings. If you are installing a gauge or sensor, now is the time to do so by screwing it into the designated port and tightening it with a suitable tool.

The next step is to mount the pressure regulator in the specified location. Secure the regulator with the provided mounting bracket and screws. Ensure that all connections are tight and secure. Now, you can proceed to connect the fuel lines to the regulator. Pay close attention to the fuel inlet and outlet ports to avoid incorrect connections. Once the fuel lines are connected, start the engine and check for any fuel leaks. If leaks are present, shut off the engine immediately and rectify the issue.

Finally, you will need to adjust the base fuel pressure. Consult the manufacturer's instructions to learn how to adjust the pressure using the provided tools. It is important to note that an incorrect setting of fuel pressure can cause the engine to run lean, leading to potential engine damage. Therefore, always refer to the recommended fuel pressure settings provided by the manufacturer.

By following these steps and adhering to safety precautions, you can successfully install a pressure regulator to reduce the fuel pump pressure in your generator.

Finding the Fuel Pressure Regulator in Your Supercharged 3800

You may want to see also

Adjust the regulator to two pounds of pressure

To adjust the regulator to two pounds of pressure, you will need to make adjustments to the regulator itself. The regulator is a critical component of your fuel delivery system and should be matched to your fuel pump.

First, it is important to note that not all fuel pumps require an external regulator. Some lever-style mechanical fuel pumps don't require a regulator, and some electric fuel pumps have one built-in. If your fuel pump falls into either of these categories, you will not need to make any adjustments.

If your fuel pump does require an external regulator, you will need to determine what type of regulator you have. The two most common types are deadhead-style regulators and bypass regulators. Deadhead-style regulators are the simplest and most popular type. They use a restriction to lower fuel pressure by decreasing fuel flow with a diaphragm and seat, and they typically regulate fuel pressure in the 1-9 psi range. Bypass regulators, on the other hand, bleed off excess fuel pressure and return it to the fuel tank, helping to eliminate pressure creep and lower fuel temperatures.

Once you have identified the type of regulator you have, you can begin the adjustment process. If you have a deadhead-style regulator, you will need to locate the hex screw on top of the regulator. Turning this screw will allow you to adjust the fuel pressure. To achieve two pounds of pressure, you will need to turn the screw to decrease the pressure until your engine nearly starves of fuel, and then turn it back up just a hair. This may require some trial and error, as there is no exact measurement for how many turns will result in a specific amount of pressure drop.

If you have a bypass regulator, you will need to refer to the manufacturer's instructions for adjusting the fuel pressure. Bypass regulators are typically more complex than deadhead-style regulators and may require additional components or adjustments to achieve the desired fuel pressure.

It is important to note that adjusting your fuel pressure can have significant effects on your engine's performance. Too low of fuel pressure can cause your engine to starve for fuel, while too high of fuel pressure can lead to flooding. It is recommended to use a fuel pressure gauge to ensure you are achieving the desired pressure and avoid any potential issues.

Locating Fuel Pressure Checkpoints in a 2003 Ford Focus

You may want to see also

Test drive the vehicle

Once you've performed the electrical and fuel pressure tests, it's time to take your vehicle for a test drive to check the fuel pump pressure. Here's a step-by-step guide:

Start the Engine:

Before you begin your test drive, start the vehicle's engine and let it warm up slightly. This will ensure that the engine is at the optimal temperature for the test.

Initial Observations:

As you start the engine, pay attention to any unusual noises or vibrations. A healthy fuel pump should operate quietly and smoothly. Listen for any strange sounds, such as whining, buzzing, or rattling noises, which could indicate a problem with the fuel pump.

Drive at Different Speeds:

During the test drive, vary your driving speed. Drive at a constant speed on a straight road, then accelerate and decelerate to observe the engine's response. A properly functioning fuel pump will deliver a consistent flow of fuel, resulting in smooth acceleration and deceleration.

Observe Engine Performance:

Pay close attention to the engine's performance during the test drive. A faulty fuel pump may cause the engine to sputter, hesitate, or stall. If the engine struggles to maintain a steady speed or exhibits a lack of power, it could be due to insufficient fuel pressure.

Uphill and Downhill Driving:

Test the vehicle's performance on both uphill and downhill slopes. Driving uphill places more demand on the fuel pump, as the engine requires more fuel to maintain power. If the engine struggles or loses power while climbing a hill, it may be an indication of a weak fuel pump. Downhill driving, on the other hand, reduces the load on the fuel pump, and you should notice a smooth and consistent performance.

Highway and City Driving:

Drive the vehicle on both highways and city roads. Highway driving typically involves maintaining a constant speed, while city driving includes frequent stops, starts, and speed changes. Observe how the engine performs in these different conditions. A properly functioning fuel pump should allow for seamless transitions and consistent power delivery.

Check for Surging or Jerking:

One common symptom of a faulty fuel pump is surging or jerking while driving. Pay attention to any sudden surges in speed or unexpected jerking motions. This could indicate that the fuel pump is struggling to maintain a consistent fuel flow, resulting in erratic engine behaviour.

Monitor Fuel Efficiency:

Keep an eye on the vehicle's fuel efficiency during the test drive. A weak fuel pump may cause the vehicle to consume more fuel than usual. If you notice a significant decrease in fuel efficiency, it could be an indication that the fuel pump is not delivering fuel efficiently to the engine.

Listen for Unusual Noises:

Throughout the test drive, continue to listen for any unusual noises coming from the engine bay. A failing fuel pump may produce whining or grinding sounds, indicating that it is struggling to function properly. These noises may become more pronounced as the engine speed changes or when accelerating.

Extended Idling:

During your test drive, find a safe place to idle the vehicle for a few minutes. Observe the engine's behaviour during idle. A properly functioning fuel pump should maintain a steady idle speed without any stuttering or stumbling. If the engine stalls or struggles to stay running, it could be due to a faulty fuel pump.

Accelerate Rapidly:

Test the vehicle's acceleration by pressing the accelerator pedal firmly and rapidly. A healthy fuel pump should respond quickly, providing a smooth and immediate increase in power. If the vehicle hesitates or struggles to accelerate, it may be an indication of low fuel pressure.

Stop and Restart the Engine:

During your test drive, find a safe location to stop the vehicle and turn off the engine. Wait a few minutes, then restart the engine. Observe how the engine starts. If it cranks slowly or struggles to start, it could be due to insufficient fuel pressure.

Drive with Different Loads:

If possible, drive the vehicle with different loads to simulate real-world conditions. For example, you can drive with passengers or cargo to increase the load on the engine. A properly functioning fuel pump should be able to handle varying loads without affecting engine performance.

Note Any Warning Lights:

Pay attention to the vehicle's dashboard and instrument cluster during the test drive. If the "Check Engine" light illuminates or any other warning lights appear, take note of them. These warning lights could be indicative of a problem with the fuel pump or another issue that requires further investigation.

Compare with Similar Vehicles:

If possible, compare the performance of the test vehicle with that of a similar vehicle. Drive both vehicles back-to-back and note any differences in acceleration, engine response, and overall performance. This comparative analysis can help you identify if the fuel pump is performing as expected.

Post-Test Drive Checks:

After completing the test drive, there are a few additional checks you can perform to further assess the fuel pump's condition:

- Check the fuel pressure again using the fuel pressure gauge. Compare the pressure readings before and after the test drive. A significant drop in pressure could indicate a weak fuel pump.

- Inspect the fuel filter for any signs of clogging or debris buildup. A clogged fuel filter can restrict fuel flow and affect the performance of the fuel pump.

- Listen to the engine at idle again. If the fuel pump is faulty, you may notice unusual noises or vibrations that were not present before the test drive.

- Observe the vehicle's exhaust. Excessive smoke or unusual colours in the exhaust fumes could indicate incomplete combustion due to improper fuel delivery.

By following these comprehensive test drive procedures, you will be able to gather valuable insights into the performance of the fuel pump and make an informed decision about any necessary repairs or replacements. Remember to always refer to the vehicle's owner's manual and seek professional assistance if you are unsure about any aspects of the testing process.

Fuel Pressure: Low Levels, Big Problems

You may want to see also

Increase pressure if the vehicle hesitates or stalls

If your vehicle is hesitating or stalling, it could be a sign of low fuel pressure. This can cause a lack of horsepower, slow starting, an inability to start the engine, or stalling. If you've adjusted the pressure regulator and the vehicle still hesitates or stalls, you'll need to increase the pressure.

To do this, locate the regulator and adjust the knob in the centre of it. Turn the pointer to increase the pressure by 1/2-pound increments until the vehicle runs smoothly without hesitation. This will ensure the engine gets enough fuel and prevent stalling.

It's important to note that fuel pressure is a delicate aspect of your vehicle. Too much pressure can cause flooding, while too little can lead to stalling and a lack of power. Finding the right balance is crucial for optimal vehicle performance and fuel efficiency.

If you're experiencing issues with your vehicle's fuel pressure, it's always best to consult a qualified mechanic or auto repair specialist. They can diagnose the problem and make the necessary adjustments to ensure your vehicle runs efficiently and safely.

Cold Fuel Pressure: Why Engines Start Roughly

You may want to see also

Add another fuel filter

One way to reduce fuel pump pressure is to add another fuel filter. This can be done by adding a filter with a third nipple for a return line back to the fuel tank, which some claim reduces pressure enough to prevent flooding.

However, it is important to note that adding another fuel filter can reduce the volume of fuel and the pressure, which may cause the engine to starve for fuel under load. It is also important to ensure that the filter is installed correctly, as installing it before the pump can lead to fuel starvation problems and reduce pressure in the suction line.

The "Pre-Pump" filter, often called the "Straining Filter", is responsible for preventing debris in the fuel from damaging the fuel pump. This filter is typically very coarse to reduce pressure drop and ensure that fine debris does not block flow over time. While it may be tempting to use a finer filter upstream from the fuel pump, it can lead to pump failure as finer filters are more restrictive and can increase pressure drop.

The "Post-Pump" filter is typically the one that is replaced during normal vehicle maintenance. Considerations for this filter include fuel type, filtration, and capacity. The micron rating of the filter relates to the size of the particle that is blocked, with finer filters having smaller micron ratings.

Nylon Fuel Line: Understanding Safe Pressure Limits

You may want to see also

Frequently asked questions

You can install a pressure regulator. First, locate the rubber fuel hose that runs from the fuel pump to the carburettor. Cut the hose at a safe spot to install the regulator. Place a hose clamp over each end of the fuel hose and push the hose ends onto the regulator's fittings. Be sure to note the flow direction indicated by an arrow on the regulator. Tighten the hose clamps and set the regulator for two pounds of pressure.

Too much fuel pump pressure can cause fuel to be pushed past the needle and seat assembly in the carburettor, leading to flooding.

Some other ways to reduce fuel pump pressure include bleeding fuel back to the tank, adding another fuel filter, or using a brass needle valve to reduce pressure and volume.