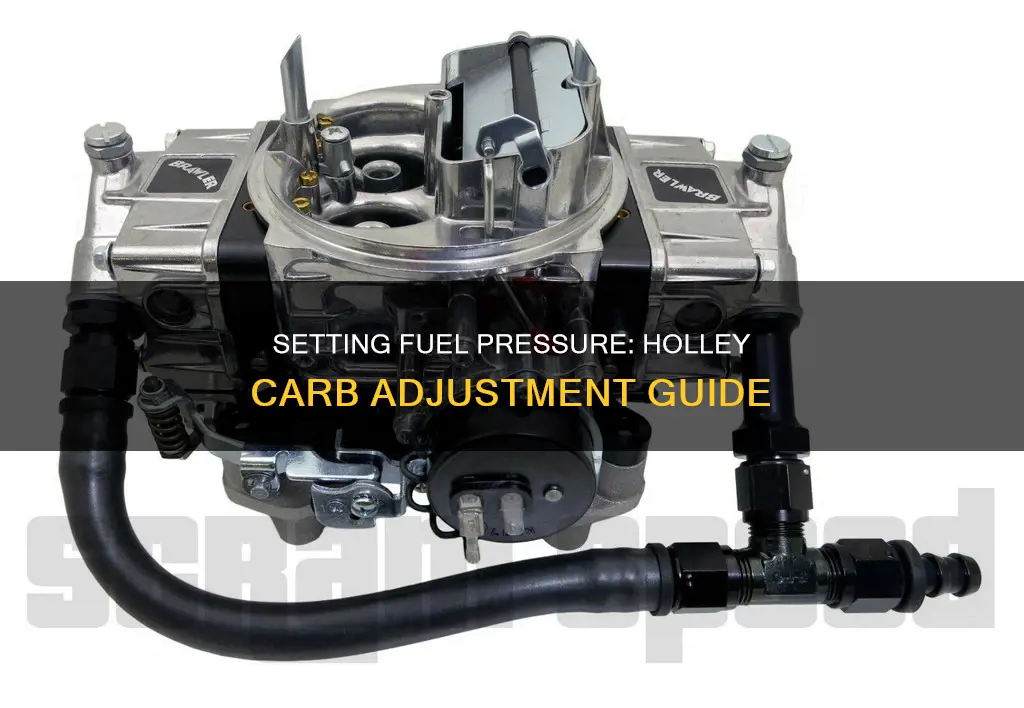

Setting the fuel pressure on a Holley Carburetor is a crucial step in ensuring optimal engine performance. Fuel pressure refers to the force at which fuel is delivered from the fuel tank to the carburetor, and it plays a significant role in how well the carburetor functions. The ideal fuel pressure for a Holley Carburetor is generally considered to be around 6.5 psi, with a maximum pressure of 7 psi.

To check the fuel pressure, it is recommended to use a fuel pressure gauge installed on the outlet side of the regulator, as close to the carburetor as possible. The engine should be running at idle and at full operating temperature for an accurate reading.

Adjusting the fuel pressure can be done through the fuel pressure regulator, which controls the amount of fuel delivered to the carburetor. It is important to note that not all fuel pumps require a pressure regulator. However, for high-performance engines producing 450 hp or more, a regulator is typically necessary to accurately set the desired fuel pressure.

Additionally, there are different types of regulators, such as deadhead (or blocking) regulators and return-style regulators, each operating in distinct ways. Deadhead regulators are normally open, allowing fuel flow until the pre-set pressure limit is reached, while return-style regulators are normally closed until the pressure limit is reached, opening a bypass outlet to return excess fuel to the tank.

When setting the fuel pressure on a Holley Carburetor, it is crucial to consider factors such as engine specifications, fuel pump capabilities, and the type of regulator being used. Making adjustments to the fuel pressure is part of the tuning process and may vary depending on the specific combination of engine components.

| Characteristics | Values |

|---|---|

| Optimum fuel pressure | 6.5psi |

| Maximum fuel pressure | 7psi |

| Ideal fuel pressure | 6psi |

| Minimum fuel pressure | 4psi |

| Maximum fuel pressure for high-pressure regulator | 70psi |

| Minimum fuel pressure for low-pressure regulator | 3psi |

What You'll Learn

- The ideal fuel pressure for a Holley Carb is 6.5 psi

- Fuel pressure gauges should be installed as close to the carburetor as possible

- Fuel foaming and fuel slosh can be combated by using jet extensions

- A return-style regulator is normally closed until the pressure limit is reached

- A deadhead regulator is normally open, meaning fuel will flow through until the pressure reaches its pre-set limit

The ideal fuel pressure for a Holley Carb is 6.5 psi

Setting the ideal fuel pressure for a Holley Carb is important for optimising its performance. The recommended fuel pressure for a Holley Carb is 6.5 psi, with a maximum pressure limit of 7 psi. This can be achieved by using an adjustable pressure regulator, which should be set to the ideal value. It is crucial to perform this check with the engine running at idle and at full operating temperature. Additionally, the fuel pressure gauge should be installed on the outlet side of the regulator, as close to the carburetor as possible.

To elaborate further, the fuel pressure has a significant impact on the performance of a carburetor. By setting the ideal fuel pressure, you can ensure that the carburetor receives the correct amount of fuel at the appropriate pressure. This, in turn, enhances the overall performance of your vehicle.

It is worth noting that not all fuel pumps require a pressure regulator. Low-pressure electric fuel pumps, such as Holley's classic Red vertical pump, are designed to deliver sufficient fuel pressure for mild carbureted applications without the need for a regulator. However, for high-performance engines generating 450 hp or more, and especially for EFI applications, a regulator is essential to accurately set the desired fuel pressure.

In addition to fuel pressure, there are other factors that contribute to the optimal performance of a Holley Carb. These include the float level adjustment, idle mixture screws, power valve, and secondary throttle opening. By fine-tuning these settings, you can further enhance the performance and efficiency of your carburetor.

Fuel Rail Pressure Sensor: Misfiring Culprit or Coincidence?

You may want to see also

Fuel pressure gauges should be installed as close to the carburetor as possible

The fuel pressure gauge should be installed on the outlet side of the regulator, as close to the carburettor as possible. This is because fuel pressure can vary and is part of the tuning process. It will be different for every combination. Most of the motors I've had on the dyno like around 7-7.5 psi. Anywhere in the 7-9 psi range is acceptable as long as the car runs properly.

For a street car, a deadhead system is the simplest and most affordable option. This type of regulator is placed between the fuel pump and the carburettor to limit fuel pressure. It is normally open, meaning fuel will flow through and be restricted once the pressure reaches its pre-set limit. However, this places an additional load on the fuel pump, which can reduce its lifespan and cause vapor lock issues in hot weather.

A return-style regulator, on the other hand, is normally closed until the pressure limit is reached. It then opens the bypass outlet to return excess fuel to the tank, reducing fuel temperature and load on the pump. This type of regulator is more complex and expensive, but it offers many advantages, especially for high-horsepower carbureted drag cars.

Fuel Injectors: Higher Pressure, Higher Horsepower?

You may want to see also

Fuel foaming and fuel slosh can be combated by using jet extensions

To address this issue, you can install jet extensions to raise the fuel pickup point within the fuel bowl. For drag racing applications, longer jet extensions are recommended, while a mid-length setup is better for road or circle track racing. These jet extensions can be of varying lengths, and you may need to cut away a small section of the float to clear the extensions. Additionally, you may need to use a stronger bumper spring to control the float movement during high-G vertical motion.

Another modification to reduce fuel foaming and sloshing is to use a whistle vent or a vent screen in the bowl. This helps to stabilize the fuel level and improve the metering and atomization functions of the carb. It is also important to select an appropriate needle and seat assembly that can provide sufficient fuel flow to meet the engine's demand.

Furthermore, the fuel pressure regulator plays a crucial role in managing fuel foaming and sloshing. It is recommended to use a regulator that can provide the lowest possible fuel pressure while still supplying enough fuel to the engine. This minimizes fuel foaming while ensuring the engine receives the required amount of fuel.

By implementing these modifications and adjustments, you can effectively combat fuel foaming and fuel slosh, improving the performance and reliability of your Holley carb.

Locating the Fuel Pressure Regulator in a 2004 Trailblazer

You may want to see also

A return-style regulator is normally closed until the pressure limit is reached

Setting the fuel pressure on a Holley carb is an important step in ensuring your carburetor and engine are in sync. While there are many adjustments that can be made, fuel pressure has a big effect on how well a carb works.

Now, let's focus on the role of a return-style regulator in this process. A return-style regulator, also known as a bypass regulator, is a common choice for a performance fuel system. It is designed to maintain the set fuel pressure by constantly circulating fuel and keeping the system cool. This type of regulator is normally closed until the pressure limit is reached. Here's how it works:

Fuel enters the regulator through the inlet port and flows towards the bypass valve, which is initially held closed by a spring. As the fuel pressure increases, it pushes against the spring through a diaphragm. When the pressure reaches the set limit, the bypass valve starts to open, redirecting excess fuel back to the fuel tank through the return line. This process reduces the pressure in the system and prevents over-pressurization.

The spring then closes the valve as the pressure drops, allowing the pressure to rise again. This continuous opening and closing of the bypass valve help maintain the desired fuel pressure. The pressure can be fine-tuned using the adjustment mechanism, usually a nut or bolt on top of the regulator.

One of the key advantages of a return-style regulator is its ability to provide consistent and accurate fuel pressure. It also reacts quickly to changes in engine load and reduces Lean Condition spikes. Additionally, by bleeding off excess pressure, the regulator reduces stress on the electric fuel pump, leading to longer pump life, reduced heat, and less noise.

However, it's important to note that a return-style regulator requires additional plumbing and fittings for the return line, adding complexity and cost to the system. It may not be suitable for certain fuel systems, such as those with multiple regulators set at different pressures.

Checking Fuel Pressure: 2001 RXDI Guide

You may want to see also

A deadhead regulator is normally open, meaning fuel will flow through until the pressure reaches its pre-set limit

Setting the fuel pressure on a Holley carb involves adjusting the fuel pressure regulator to the optimum level. The regulator controls the flow of fuel from the pump to the carburettor, and there are two main types: deadhead and bypass.

A deadhead regulator is a normally open valve, meaning fuel will flow through it until the pressure reaches its pre-set limit. When this limit is reached, a spring closes a valve to restrict fuel flow, reducing the pressure after the regulator to the desired amount. Deadhead regulators are simple, involving a one-line installation, and can be used in systems with multiple regulators. However, they are not suitable for most EFI systems, and they can increase fuel temperature and place additional strain on the fuel pump.

In contrast, a bypass regulator maintains a constant pressure by bleeding off excess fuel pressure into a return line, which then recirculates the fuel back into the tank. This type of regulator is more complex to install, as it requires a return line, but it offers several advantages. Bypass regulators keep fuel temperature lower, extend the life of the fuel pump, and reduce noise. They are also better suited to high-output engines, as they can maintain steady fuel pressure even under high fuel flow demands.

When setting the fuel pressure on a Holley carb, it is important to consider the type of fuel pump and regulator you are using, as well as the specific requirements of your engine. For example, a high-pressure mechanical or belt-driven pump typically requires a return-style regulator, while a low-pressure electric pump may not need a regulator at all. Additionally, the regulator should be mounted as close to the carburettor as possible to ensure quick reaction to changes in engine load.

To set the fuel pressure, the first step is to determine the optimal pressure for your specific engine and fuel system. This may vary depending on factors such as engine speed, fuel type, and whether the vehicle is a street car or a race car. Once you know the desired pressure, you can adjust the regulator accordingly. It is important to note that fuel pressure should be checked with the engine running at idle and at full operating temperature.

Installing a Fuel Pressure Gauge in Your LBZ Engine

You may want to see also

Frequently asked questions

The optimum fuel pressure for a Holley Carb is 6.5 psi, with a maximum pressure of 7 psi.

This depends on your setup. If your fuel pump has an output pressure of more than 6 psi, it is worth installing a pressure regulator. If your pump has an output pressure of 9 psi or more, Holley states that a pressure regulator should be used.

There are two types of pressure regulators: deadhead and return style. A deadhead regulator is normally open, meaning fuel will flow through it and be restricted once the pressure reaches its pre-set limit. A return style regulator is normally closed until the pressure limit is reached, then it opens the bypass outlet to return excess volume back to the tank.

This depends on your setup. If you have a single carburetor, a deadhead regulator should be positioned between the fuel pump and the carburetor to limit fuel pressure. If you have a high-performance engine making 450 hp or more, or an EFI application, a regulator is required to accurately set the desired fuel pressure.

Fuel pressure above 9 psi will cause fuel to start pushing past the needle and seat.