Fuel pump pressure is an important aspect of your car's performance. While basic OBD2 scanners can help with error codes, they often lack the capability to read fuel pump pressure. To read fuel pressure with a code reader, you can follow these steps: warm up the engine, connect a suitable OBD-II scanner, check for stored error codes, and then check the live fuel pressure data. It's important to note that not all OBD-II scanners can measure real-time engine data, so you may need to refer to the handbook for specific instructions. Additionally, fuel pressure can vary depending on the engine type and size, so it's recommended to refer to a repair manual for the correct specifications.

| Characteristics | Values |

|---|---|

| How to read fuel pressure | Warm up the engine, connect a diagnostic OBD-II scanner, check for stored error codes, and then check the live fuel pressure data. Alternatively, use a manual fuel pressure gauge. |

| Fuel pressure requirements | Depends on the engine. Older throttle-body injected systems need as little as 10 psi, while multi-port injection can see as high as 60 psi. |

| Signs of low fuel pressure | Slow start-up, low performance, misfires, and stalling. |

| Signs of high fuel pressure | Excessive fuel consumption, black smoke from unburned gas, an overheating catalytic converter, and rough idle. |

| Fuel pump diagnostics | Use a scan tool to verify if the modules controlling the fuel pump are receiving the correct data, such as oil pressure, crank position, and security information. |

| Fuel pressure readings | Should be within a few psi of the recommended pressure. |

| Fuel pressure at cold start | Will be less than the hot start. |

| Fuel pressure control | The pressure is software-controlled. |

What You'll Learn

Warm up the engine

Warming up the engine is the first step in checking your fuel pressure with a code reader. This is because cold engines use more fuel, which can affect fuel pressure readings if there is an issue.

To warm up your engine, start your car and take it for a short 10-minute drive. This will ensure the engine is warmed up to a nice 180-190°F, so you get true numbers from the sensors rather than generic numbers from the computer.

Once your engine is warmed up, you can park up and proceed to the next step of connecting your diagnostic OBD-II scanner to your vehicle. If your car engine won't start, you can skip the drive and proceed directly to connecting the scanner.

Pressurizing Diesel Fuel Systems: A Comprehensive Guide

You may want to see also

Connect your OBD-II scanner

To connect your OBD-II scanner, you'll first want to ensure your car engine is warmed up to around 180-190*F. This is known as "Closed Loop" mode and will ensure you get true numbers from the sensors rather than generic numbers from the computer. If possible, take your vehicle for a short 10-minute drive to warm up the engine.

Now, locate the OBD-II socket in your vehicle and plug in your scanner. The socket is usually located under the dashboard and may be covered by some plastic trim. If you have a wireless scanner, you'll need to connect to the wireless OBD-II device using an app on your smartphone or tablet.

With your scanner connected, you can now check for stored OBD-II error codes. This will save you time as you can identify any obvious problems before diving into specific fuel parameter readings. Common OBD-II error codes that relate to fuel system issues include:

- Fuel pump primary circuit malfunction

- Fuel trim malfunction (bank 1)

- System too lean (bank 1)

- Fuel rail pressure sensor circuit/range performance

- System too rich (bank 1)

If there are no obvious issues, the next step is to carry out an analysis of the fuel delivery system by measuring fuel pressure and fuel delivery rate. For this, you'll need an OBD-II code reader that can measure real-time engine data. Not all diagnostic readers can do this, so refer to the handbook for your specific device.

If your diagnostic reader supports real-time data, connect it to the vehicle and enter engine DME diagnostic mode. From here, you can take a reading of current engine parameters. Once the reading is complete, choose the fuel delivery system option, which will allow you to monitor various fuel system parameters such as fuel rail pressure, fuel injection timing, and short and long-term fuel trim.

To measure the actual fuel pressure, select the option that most closely matches 'actual (real-time) fuel pressure parameter' from the menu. You should now see the current fuel pressure on your scanner. To test if this stays constant under load, rev the engine to 1500 rpm and hold it for a few seconds, then try 2500-3000 rpm.

By following these steps and connecting your OBD-II scanner, you can effectively monitor your vehicle's fuel system and identify any potential issues.

Oil Pressure Gauge for Fuel: Will It Work?

You may want to see also

Check for stored OBD-II error codes

Before you dive into specific fuel parameter readings, checking for stored error codes can save you a lot of time. If there is a problem with the fuel delivery, there may be an error code stored in the ECU memory.

- Fuel pump primary circuit malfunction: This indicates an electrical problem with the fuel pump.

- Fuel trim malfunction (bank 1): The fuel trim is outside the acceptable range.

- System Too Lean (Bank 1): This code means there is too much air or not enough fuel.

- Fuel Rail Pressure Sensor circuit/range performance: Inconsistent fuel rail pressure readings.

- System Too Rich (Bank 1): This error code means too much fuel is reaching the injectors.

If you have identified any of these error codes, you can then proceed to clear the fault codes and take the vehicle for a test drive. If the code persists, visually check the fuel tank, fuel lines, and fuel filter for any damage or issues restricting flow.

It is also important to note that not all basic OBD-II scanners are capable of reading fuel pump pressure. They are great at reading error codes and helping to figure out why your check engine light has illuminated, but they often lack the capabilities required for more specific data like fuel pump pressure readings.

However, more advanced OBD-II scanners, such as the Foxwell NT650 Elite or GT60, offer access to more vehicle data, including fuel pressure. These advanced scanners provide much deeper insight into your car's performance by accessing live ECU information directly, making them invaluable investments for anyone serious about maintaining their vehicle.

Fuel Pressure Specifications for 1995 GMC G2500 Models

You may want to see also

Check live fuel pressure data

If you want to check the live fuel pressure data, you will need an OBD-II code reader that can measure real-time engine data. Not all diagnostic readers can do this, so you may need to refer to the handbook for further details.

Once you have confirmed that your diagnostic reader supports real-time data, connect it to the vehicle and enter engine DME diagnostic mode. Then, take a reading of the current engine parameters. When the reading is complete, choose the fuel delivery system (or similar) option.

This will allow you to monitor a number of different fuel system parameters such as fuel rail pressure, fuel injection timing readings for each cylinder, STFT (short-term fuel trim) and LTFT (long-term fuel trim).

The OBD scanner should also show you the fuel rail pressure set point. This is the optimum fuel pressure on the fuel rail when the engine is running, and you can use it to compare to the real-time fuel pressure value.

To measure the actual fuel pressure when the engine is running, select the option that most closely matches 'actual (real-time) fuel pressure parameter' from the menu.

The reader should now display the current fuel pressure. To see if this stays constant under load, try revving the engine to 1500 rpm and hold it there for a few seconds, then try 2500-3000 rpm.

If the actual fuel pressure is the same as the fuel pressure set point, this means that there is no issue with the overall pressure in the system, but there could still be a problem with the timing and amount of fuel being delivered to the injectors.

It is important to note that not all vehicles will have the same fuel pressure set point. For example, older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60. Even the same vehicle can vary; for instance, the LT1 V8 in the 1996 Corvette wants 40-42 psi, while the next year's LS1 V8 should see 58 psi. Therefore, it is essential to consult a repair manual or check the specifications section to determine the correct fuel pressure for your specific engine.

Finding the Fuel Pressure Relief Valve in 2004 Mustangs

You may want to see also

Compare to the fuel pressure set point

The OBD scanner should display the fuel rail pressure set point, which is the optimum fuel pressure on the fuel rail when the engine is running. This set point can be compared to the real-time fuel pressure value.

To do this, rev the engine to 1500 rpm and hold it there for a few seconds, then try 2500-3000 rpm. If the actual fuel pressure is the same as the fuel pressure set point, this means that there is no issue with the overall pressure in the system, but there could still be a problem with the timing and amount of fuel being delivered to the injectors.

If the fuel pressure set point is modified, it is not done so abruptly but with a time delay. The rail pressure set point value is modified to a maximum degree using a maximum gradient for changing the set point value, and the maximum gradient is read from a characteristics map as a function of operating parameters of the internal combustion engine.

The operating parameters of the internal combustion engine are measured or modelled physical variables such as setpoint rotational speed, actual rotational speed, setpoint injected quantity, actual injected quantity, actual rail pressure, engine system quantity, or different temperature or pressure variables of an internal combustion engine.

The characteristics map links input values to output values and may be stored in the form of a one-dimensional or multidimensional table, for example, in a memory control unit.

Best Placement for Fuel Pressure Gauges in WRX STIs

You may want to see also

Frequently asked questions

No, most basic OBD2 scanners cannot read fuel pressure. They are great at reading error codes and helping to figure out why your check engine light has illuminated, but they often need more capabilities to provide specific insights like fuel pump pressure.

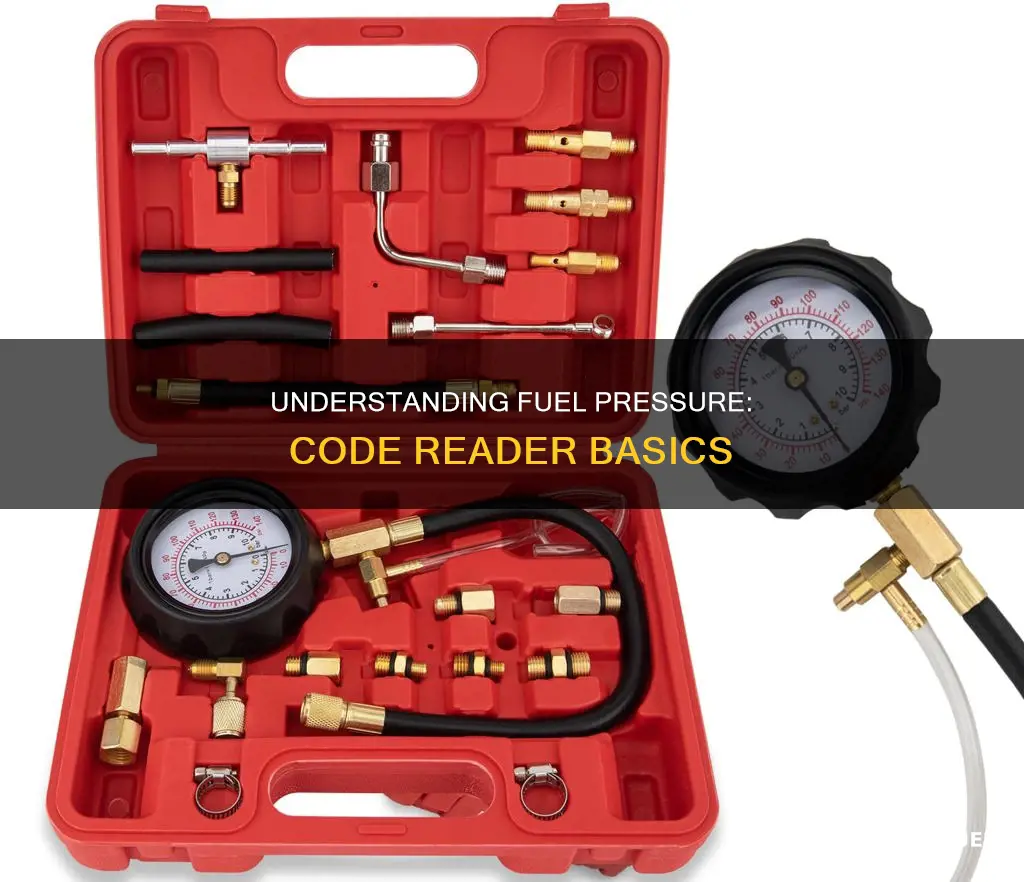

You can test fuel pump pressure using a manual fuel pressure gauge that connects to your fuel system or by using an advanced diagnostic tool that can read this data from your vehicle's ECU.

Modern fuel injection gasoline engines run with a fuel pressure of between 40 PSI and 70 PSI, depending on the engine type and size.

The first step is to perform a visual inspection of the vehicle and verify the customer's complaint. Many diagnostic processes go wrong because the technician fails to verify the customer's concern.