Cutting and installing a steel fuel line for a Duramax engine can be a precise and potentially dangerous task. It requires careful planning and the right tools to ensure a secure and safe connection. This guide will provide step-by-step instructions on how to cut and install a steel fuel line, covering essential safety precautions, the necessary tools, and the process of making a clean cut to ensure a proper fit for your Duramax engine.

What You'll Learn

- Safety Gear: Wear gloves, goggles, and a respirator to protect against cuts and fumes

- Line Inspection: Check for damage, bends, and kinks before cutting

- Marking: Use a marker to identify the cut length and location

- Cutting Tools: Use a high-speed steel cutter or a band saw for clean cuts

- Safety: Work in a well-ventilated area and avoid sparks or open flames

Safety Gear: Wear gloves, goggles, and a respirator to protect against cuts and fumes

When working with steel fuel lines, especially on a Duramax engine, it's crucial to prioritize safety to avoid injuries and potential health hazards. Here's a detailed guide on the essential safety gear you should wear:

Gloves: Protecting your hands is paramount. Opt for heavy-duty leather or synthetic gloves designed for industrial use. These gloves should provide a secure grip and offer resistance to cuts and punctures. Look for gloves specifically rated for automotive or industrial applications. The gloves will shield your hands from sharp edges, hot surfaces, and potential splashes or leaks of fuel, ensuring you remain safe during the cutting process.

Goggles: Eye protection is non-negotiable. Choose safety goggles or glasses that offer impact resistance and side protection. Look for models with a secure seal to prevent any debris or fumes from entering your eyes. Goggles will safeguard your vision from potential hazards like flying sparks, hot metal, or fuel splatters, which could cause severe eye damage.

Respirator: Working with steel fuel lines may expose you to harmful fumes, especially if the fuel contains lead or other toxic substances. A respirator is essential to filter out these fumes and protect your respiratory system. Select a respirator that meets industry standards and provides adequate coverage for your nose and mouth. Ensure it fits properly to maximize its effectiveness. This simple yet crucial step can prevent inhalation of dangerous substances, reducing the risk of respiratory issues.

Additionally, consider wearing a dust mask or a face shield as a secondary layer of protection. These can further reduce the risk of inhaling fumes and protect your face from any potential splashes. Remember, wearing the right safety gear is a fundamental aspect of engine maintenance and repair, ensuring your well-being throughout the process. Always prioritize safety to avoid accidents and potential health complications.

Quick Connect Fuel Line Security: A Comprehensive Guide

You may want to see also

Line Inspection: Check for damage, bends, and kinks before cutting

Before you begin the process of cutting a steel fuel line for your Duramax engine, a thorough inspection is crucial to ensure a safe and successful installation. This initial step is often overlooked but is essential to avoid potential issues and ensure the longevity of your fuel system. Here's a detailed guide on how to inspect the line:

Start by visually examining the fuel line for any signs of damage. Look for cracks, punctures, or any visible wear and tear. Steel fuel lines can be susceptible to damage from age, heat, or physical impact. Inspect the entire length of the line, paying close attention to areas where it connects to the engine, fuel tank, or other components. Check for any signs of corrosion or rust, especially if the line has been exposed to moisture or harsh environments. These issues can compromise the structural integrity of the line, leading to potential leaks or failures.

Next, check for bends and kinks. Fuel lines should maintain a straight and flexible position to allow for engine movement and vibration. Look for any sharp bends or kinks that might restrict flow or cause stress on the line. Ensure that the line is not pinched or compressed, as this can lead to reduced fuel pressure and potential engine performance issues. Smooth out any sharp bends and ensure the line is free-flowing, especially in areas where it passes through tight spaces or engine compartments.

During the inspection, also verify the line's flexibility. Try to bend the line at various points to ensure it moves freely without any permanent deformation. This is important to maintain the line's ability to adapt to engine vibrations and temperature changes. If you encounter resistance or notice any permanent bends, it may indicate a pre-existing issue that needs to be addressed before cutting.

Additionally, inspect the fittings and connections. Check for any signs of leakage or damage around the fittings, as these are critical points where the line is most vulnerable. Ensure that all connections are secure and tight, as loose fittings can lead to fuel leaks, which are extremely dangerous. If you find any damaged or worn-out fittings, it is recommended to replace them before proceeding with the cut.

By thoroughly inspecting the fuel line for damage, bends, and kinks, you can identify potential issues and ensure a smooth cutting process. This step is a vital part of the preparation process, allowing you to make any necessary adjustments or repairs before cutting the line, ultimately contributing to a safer and more efficient fuel system for your Duramax engine.

Bobcat Engine Issues: Leaking Return Fuel Line Concerns

You may want to see also

Marking: Use a marker to identify the cut length and location

When working with steel fuel lines, especially on a Duramax engine, precise marking is crucial to ensure a successful cut. Here's a detailed guide on how to mark the cut length and location effectively:

Step 1: Measure and Mark: Begin by carefully measuring the length of the fuel line that needs to be cut. Use a flexible measuring tape or a ruler to get an accurate measurement. Mark this length on the fuel line itself using a permanent marker or a piece of chalk. Make sure the mark is clear and visible, indicating the exact spot where the cut should be made.

Step 2: Identify the Cut Location: Locate the desired cut point on the fuel line. This could be where you want to install a new fitting or adjust the line's length. Use a marker to create a visible reference point. You can also use a piece of tape or a small piece of the fuel line material to temporarily mark the location, ensuring it stays in place while you work.

Step 3: Double-Check the Mark: Before making the cut, double-check the marked length and location. Verify that the measurement is correct and that the mark is in the right position. This step is essential to avoid cutting the wrong length or in the wrong place, which could lead to issues with the fuel line's functionality.

Step 4: Use a Marker for Precision: Markers are ideal for this task as they provide a clear and permanent indication of the cut line. You can use a fine-tipped permanent marker to draw a straight line along the fuel line, following the marked length. Alternatively, you can use a chalk line, which is especially useful for longer fuel lines, as it leaves a visible line that can be easily followed.

Step 5: Consider Safety and Accessibility: When marking, ensure that the fuel line is securely held in place to prevent any accidental movement. You might need an assistant to hold the line steady while you mark. Additionally, choose a well-lit area to ensure you can see the markings clearly and make precise adjustments if needed.

By following these steps and using markers effectively, you can accurately mark the cut length and location for your Duramax steel fuel line, ensuring a professional and successful installation or repair process.

Mastering the Art of Fuel Line Bending: Tips for a Tight Fit

You may want to see also

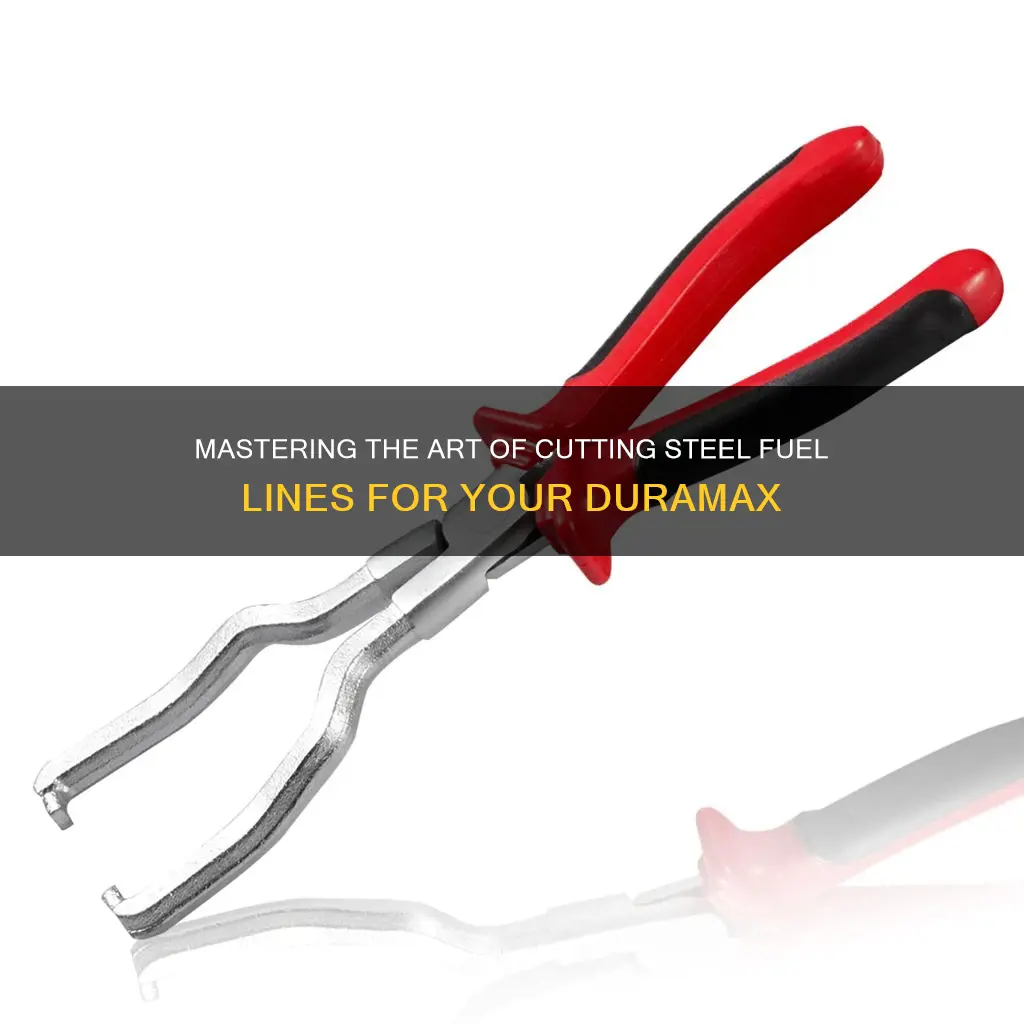

Cutting Tools: Use a high-speed steel cutter or a band saw for clean cuts

When it comes to cutting a steel fuel line for your Duramax, precision and clean cuts are essential to ensure a safe and efficient installation. One of the best tools for this task is a high-speed steel cutter, also known as a high-speed steel (HSS) cutter. These cutters are designed to provide clean and precise cuts, especially on hard materials like steel. The high-speed steel blade remains sharp for a long time, allowing for smooth and accurate cuts without the risk of chipping or breaking.

To use a high-speed steel cutter, ensure you have a steady hand and a firm grip on the line. Position the cutter at the desired cut location, and apply gentle pressure to guide the blade through the material. Start the cut slowly, allowing the blade to bite into the steel, and then increase the speed for a cleaner cut. Remember to keep the cutter at a slight angle to the line to achieve a precise cut.

Alternatively, a band saw is another excellent option for cutting steel fuel lines. Band saws offer a flexible and versatile cutting solution, especially for curved or intricate cuts. The band saw's continuous blade provides a smooth and clean cut, making it ideal for working with steel. When using a band saw, ensure the blade is sharp and properly tensioned. Position the line securely on the saw bed, and use the saw's adjustable speed to control the cutting process. Start the cut slowly, allowing the blade to engage with the steel, and then increase the speed for a faster and more precise cut.

Both high-speed steel cutters and band saws require some practice and technique to master. It's important to take your time and focus on making clean, straight cuts. Always wear appropriate safety gear, including gloves and eye protection, when operating cutting tools. Additionally, ensure you have a well-ventilated workspace and consider using a cutting fluid to reduce heat and provide lubrication, especially when working with thicker steel fuel lines.

By utilizing these cutting tools and techniques, you can ensure a professional-looking installation, maximizing the performance and longevity of your Duramax's fuel system. Remember, taking the time to make precise cuts will pay off in the long run, as it will contribute to a safer and more efficient vehicle.

Catalyst Fuel Line Removal: A Step-by-Step Guide for 2006 Jeep Liberty Owners

You may want to see also

Safety: Work in a well-ventilated area and avoid sparks or open flames

When working with a steel fuel line on a Duramax engine, prioritizing safety is paramount. One crucial aspect is ensuring you are in a well-ventilated area. This is essential because fuel lines, especially those made of steel, can release volatile gases when cut or modified. These gases are highly flammable and can pose a significant fire hazard if exposed to sparks or open flames. Working in a poorly ventilated space increases the risk of these gases accumulating, making a fire more likely. Therefore, it is imperative to choose a work area with proper ventilation to disperse any potentially hazardous fumes.

Additionally, it is imperative to avoid sparks or open flames during the cutting process. Steel fuel lines are designed to carry fuel, which is a highly flammable substance. Any spark, whether from a cutting torch, a static discharge, or even a nearby electrical source, can ignite the fuel and lead to a dangerous fire. To mitigate this risk, it is recommended to use a non-sparking cutting tool specifically designed for fuel lines. These tools are typically made of materials that do not generate sparks, such as brass or aluminum. By eliminating the potential source of ignition, you create a safer working environment.

To further enhance safety, consider wearing protective gear, such as heat-resistant gloves and safety goggles, to shield yourself from any potential splashes or debris during the cutting process. It is also advisable to have a fire extinguisher nearby, specifically rated for fuel or flammable liquid fires, as a backup precaution. By combining these safety measures with a well-ventilated work area and spark-free environment, you significantly reduce the risks associated with cutting a steel fuel line on a Duramax engine.

Remember, taking these safety precautions is not just a recommendation but a necessity to ensure your well-being and prevent potential accidents. Always prioritize safety when working with fuel lines or any other hazardous materials.

E85 Fuel Line: Choosing the Right Option for Your Engine

You may want to see also

Frequently asked questions

To cut a steel fuel line, you will need a good quality steel pipe cutter or a band saw. It's important to have a sturdy cutting tool to ensure a clean and precise cut.

Measuring the fuel line accurately is crucial. Use a tape measure or a flexible measuring tool to determine the exact length required. Consider the length of the line needed for the specific application and add a small margin for any potential adjustments.

Absolutely! When cutting steel, always wear protective gear such as gloves and safety goggles to prevent any injuries. Ensure you are working in a well-ventilated area, especially if you are using a cutting torch. It's also a good practice to have a fire extinguisher nearby as a safety measure.

For steel fuel lines, a precise and slow cutting technique is recommended. Use steady cuts, applying pressure evenly to avoid any uneven cuts. Take your time to ensure a clean and straight cut, especially if you are cutting multiple lines.

After cutting, it's essential to deburr the edges to remove any sharp points. You can use a file or a deburring tool for this purpose. Additionally, consider using a primer or a suitable adhesive to ensure a secure connection and a proper fit when reassembling the fuel line.