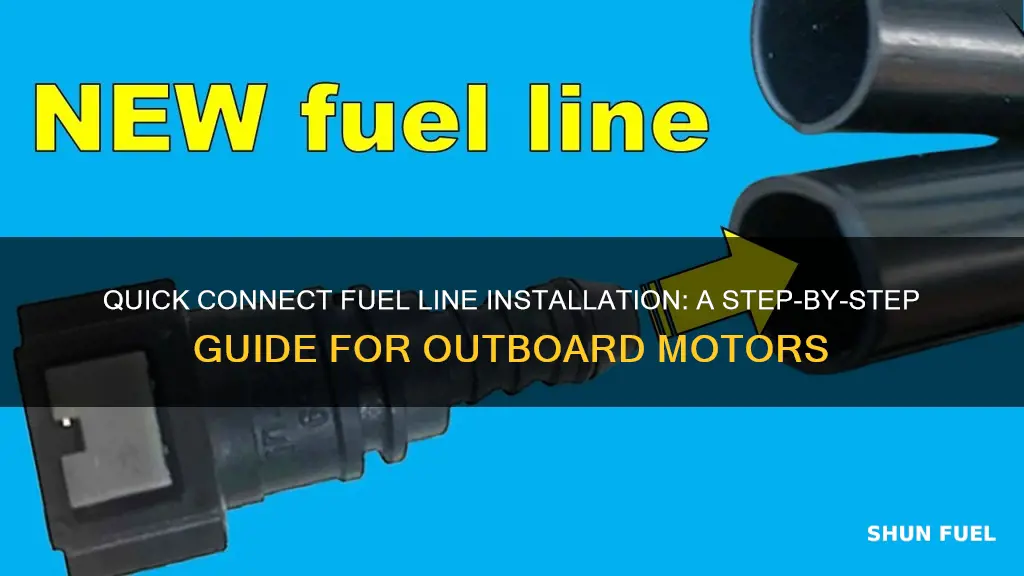

Installing a Quick Connect to an Outboard Motor Fuel Line is a straightforward process that can save time and ensure a secure fuel connection. This guide will provide step-by-step instructions on how to properly attach the Quick Connect fitting to your outboard motor's fuel line, ensuring a reliable and leak-free fuel supply for your boat's engine.

| Characteristics | Values |

|---|---|

| Preparation | Ensure you have the necessary tools: a quick-connect fitting, fuel line, fuel filter, and a fuel pump. Also, make sure the boat is in a secure location and the engine is off. |

| Fuel Line Inspection | Check the fuel line for any damage or leaks. Replace if necessary. Ensure the line is clean and free of debris. |

| Fitting Installation | Locate the fuel inlet on the engine. Slide the quick-connect fitting over the fuel line, ensuring it is aligned with the inlet. Secure it in place using the locking mechanism. |

| Fuel Filter Connection | If applicable, connect the fuel filter to the quick-connect fitting. Ensure a tight seal and secure it. |

| Fuel Pump Check | Verify that the fuel pump is functioning correctly. It should be delivering fuel to the engine at the right pressure. |

| Engine Start | Start the engine and check for any fuel leaks. The engine should run smoothly with the new quick-connect fitting. |

| Safety Precautions | Always wear protective gear when working with fuel. Keep the area well-ventilated and away from open flames. |

| Maintenance | Regularly inspect and maintain the quick-connect fitting to ensure optimal performance and longevity. |

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel filter

- Locate Fuel Tank: Identify the outboard motor's fuel tank and access point

- Connect Fuel Line: Attach the fuel line to the tank and motor, ensuring a secure fit

- Test for Leaks: Inspect connections and run a test to ensure no fuel leaks

- Secure Connections: Tighten connectors and use clamps to secure the fuel line

Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel filter

To begin the process of installing a quick-connect fuel line to your outboard motor, it's crucial to gather the right tools and materials. Start by ensuring you have the following:

- Fuel Line: Obtain a length of fuel line that is compatible with your outboard motor's specifications. Measure the distance between the fuel tank and the engine to determine the required length. It's essential to choose a fuel line with the appropriate diameter to ensure a secure connection.

- Connectors: Quick-connect fittings are a convenient way to join fuel lines. Gather the necessary connectors, typically made of durable materials like brass or stainless steel, to match the fuel line's diameter. These connectors should have a secure locking mechanism to prevent fuel leaks.

- Fuel Filter: A fuel filter is an essential component to ensure clean fuel delivery to the engine. Select a filter that is compatible with your outboard motor's fuel system. It should be capable of handling the expected fuel flow rate and have a suitable mounting position.

- Wrenches and Pliers: Basic hand tools like wrenches and pliers are essential for tightening connections and adjusting fittings. Ensure you have the appropriate sizes to work with the connectors and fuel line fittings.

- Cleaning Supplies: Prepare some cleaning materials such as fuel line cleaner or a mild solvent to ensure a thorough cleaning of the fuel line and connectors before assembly. This step is crucial to prevent contamination and ensure a reliable connection.

By having these tools and materials ready, you'll be well-prepared to proceed with the installation process, ensuring a quick and efficient connection of the fuel line to your outboard motor.

Rusty Fuel Lines: Vinegar Treatment: Effective or Not?

You may want to see also

Locate Fuel Tank: Identify the outboard motor's fuel tank and access point

To begin the process of installing a quick-connect fuel line to your outboard motor, you must first locate the fuel tank. This is a crucial step as it provides access to the fuel system, allowing you to connect the quick-connect fitting securely. Outboard motors typically have a fuel tank mounted either on the side or at the rear of the engine, often in a plastic or metal housing.

Start by consulting your boat's manual or the manufacturer's guidelines, as the specific location can vary depending on the make and model of your motor. Look for any markings or indicators on the motor that might point to the fuel tank's position. Often, a small arrow or a label will be visible when the motor is in its resting position, indicating the direction of the fuel flow.

Once you've identified the general area, inspect the motor's exterior for any visible fuel lines. These lines will lead you to the fuel tank. The fuel tank is usually a small, cylindrical or oval-shaped component, often with a cap or a small door to access the fuel. It may be located beneath a cover or panel, so you might need to remove some protective parts to gain access.

When you've located the fuel tank, ensure you understand the fuel line's current routing. This knowledge will help you plan the new connection's path to avoid any obstructions or interference with other motor components. Take note of any bends, turns, or existing fittings to ensure a smooth and efficient installation.

Remember, the key to a successful installation is proper identification of the fuel tank and its access point. This initial step sets the foundation for the rest of the process, ensuring you have the right components and a clear understanding of the motor's fuel system.

Sonoma Fuel Lines: Uncovering Hidden Intake Secrets

You may want to see also

Connect Fuel Line: Attach the fuel line to the tank and motor, ensuring a secure fit

When attaching the fuel line to the tank and motor, it's crucial to ensure a secure and tight fit to prevent any fuel leaks or spills. Here's a step-by-step guide to help you achieve this:

- Prepare the Components: Start by laying out all the necessary parts: the fuel line, the quick-connect coupling, and any necessary fittings or adapters. Ensure you have the correct size and type of coupling that matches your motor and tank specifications.

- Locate the Connections: Identify the fuel line's inlet and outlet ports on the tank and motor. These ports are typically marked or labeled for easy identification. The inlet port is where fuel will enter the system, and the outlet port is where it exits to the motor.

- Attach the Coupling: Take the quick-connect coupling and align it with the outlet port on the tank. Push the coupling onto the port until it is fully seated. Ensure that the coupling is locked into place and cannot be easily removed by accident. This step creates a secure connection between the tank and the fuel line.

- Connect to the Motor: Now, attach the fuel line to the motor. Locate the inlet port on the motor, which is usually positioned to accept the fuel line. Slide the fuel line into the port until it is fully inserted. You should feel a secure click or hear a slight snap, indicating that the line is properly connected.

- Secure the Connections: To ensure the connections are tight and won't come loose during operation, use fuel line clips or ties to secure the lines to the tank and motor. These clips are typically provided with the fuel line and can be attached at various points to keep the lines in place. Tighten the clips gently to avoid damaging the fuel lines.

- Test the System: After completing the connections, it's essential to test the fuel system. Start the motor and observe for any leaks at the connections. Check for any unusual noises or vibrations that might indicate a loose connection. If everything is secure, the motor should start smoothly, and you can proceed with the installation.

Remember, a proper and secure connection is vital for the safe and efficient operation of your outboard motor. Always refer to the manufacturer's instructions for specific details related to your motor and fuel line setup.

Depressurizing the Fuel Line: A Guide for 2008 Pontiac Torrent Owners

You may want to see also

Test for Leaks: Inspect connections and run a test to ensure no fuel leaks

Before you finalize the installation of the quick-connect fuel line to your outboard motor, it's crucial to conduct a thorough leak test to ensure the system is secure and won't result in any fuel loss. This step is essential to prevent potential engine issues and maintain a safe operation. Here's a detailed guide on how to perform this test:

Inspect Connections: Start by carefully examining all the connections you've made during the installation process. Check the quick-connect fitting, the fuel line, and the engine's fuel intake. Look for any signs of damage, such as cracks or bends in the fuel line, and ensure that the fitting is properly aligned and seated. Pay close attention to the O-rings or seals, as they play a critical role in preventing leaks. Make sure they are intact and not damaged or dislodged.

Prepare for the Test: Gather the necessary tools and materials, including a fuel-safe cleaner or a soapy water solution, a rag or cloth, and a container to catch any potential fuel leaks. It's recommended to wear protective gear, such as gloves and safety goggles, to ensure your safety during the process.

Run the Test: Start the engine and allow it to idle. This step helps to ensure that the fuel system is under slight pressure. Now, spray the fuel-safe cleaner or soapy water solution onto the connections you made. Pay close attention to the areas where the fuel line connects to the engine and the quick-connect fitting. If you notice any bubbles forming or a sudden stream of fuel, it indicates a potential leak. If no bubbles appear, it suggests that the connections are secure and there are no leaks.

Check for Fuel Accumulation: After the test, inspect the rag or cloth for any fuel stains or residue. If you see any, it confirms the presence of a leak, and you should recheck the connections and tighten or replace any faulty parts.

Address Leaks: If you identify any leaks, it's essential to resolve them immediately. Tighten loose connections, replace damaged O-rings or seals, and ensure all fittings are properly torqued to the manufacturer's specifications. Once the leaks are fixed, repeat the test to ensure the problem is resolved.

By following these steps, you can ensure that your quick-connect fuel line installation is leak-free, providing a reliable and safe operation for your outboard motor. Remember, proper maintenance and regular inspections are key to preventing potential engine issues and ensuring optimal performance.

Unraveling the Mystery: Marine-Grade Fuel Lines Explained

You may want to see also

Secure Connections: Tighten connectors and use clamps to secure the fuel line

When it comes to securing the fuel line for your outboard motor, ensuring tight and secure connections is crucial to prevent fuel leaks and maintain optimal performance. Here's a step-by-step guide on how to tighten connectors and use clamps effectively:

Tighten Connectors: Begin by ensuring that the quick-connect coupling is properly aligned with the fuel line. Line up the male and female ends, making sure they are straight and not bent. Use a wrench or a pair of pliers to tighten the coupling nut securely. Apply firm pressure to fasten the connection, but be careful not to over-tighten, as this can damage the fuel line or the connector. The goal is to achieve a snug fit without excessive force.

Secure with Clamps: After tightening the connectors, it's essential to provide additional support and security to the fuel line. Use fuel line clamps to hold the line in place. These clamps are typically made of durable materials like metal or high-quality plastic. Slide the clamp over the fuel line, ensuring it covers the entire length of the connection. Tighten the clamp securely, but be mindful of the fuel line's flexibility. You want to hold it firmly in place without restricting its movement.

When using clamps, consider the following: Ensure the clamp is the correct size for the fuel line diameter. A snug fit is essential to prevent fuel leakage. Avoid using clamps that are too tight, as they can cause damage over time. Additionally, check for any existing damage to the fuel line before clamping to prevent further issues.

Final Checks: Once the connectors are tightened and the clamps are in place, perform a few crucial checks. Inspect the connections for any signs of leakage. Even a small amount of fuel can be a potential fire hazard, so ensure there are no drips or spills. Also, verify that the fuel line is not pinched or caught in any moving parts of the motor. Properly secured fuel lines should allow for smooth operation without any obstructions.

Remember, taking the time to tighten connectors and secure the fuel line with clamps is an essential step in the installation process. It ensures the safety and efficiency of your outboard motor's fuel system. Always refer to the manufacturer's guidelines for specific instructions and recommendations regarding fuel line installation.

Blue Uerathyane Fuel Line: Safe for Ethanol Gasoline?

You may want to see also

Frequently asked questions

Quick Connect is a quick-release coupling system used to connect fuel lines to outboard motors. It provides a secure and efficient way to join fuel lines without the need for threading or welding. To use Quick Connect, ensure the fuel line is clean and free of debris. Attach the Quick Connect coupling to the fuel line, then align the male and female ends of the coupling and firmly push them together until they click into place.

Yes, Quick Connect can be installed on existing fuel lines. Start by disconnecting the fuel line from the motor and the source. Clean the ends of the fuel line and the Quick Connect coupling. Slide the coupling onto the fuel line, ensuring it is the correct size and orientation. Once in place, push the coupling onto the fuel line until it is secure and locked into position.

One common issue is ensuring a proper seal. If the coupling doesn't stay connected, check for any debris or damage on the fuel line ends. Ensure the coupling is the right size and securely attached. If the issue persists, consider using a fuel line cleaner or a small amount of thread seal tape to ensure a tight seal. Always ensure the fuel line is free of any kinks or bends that could cause issues during installation.