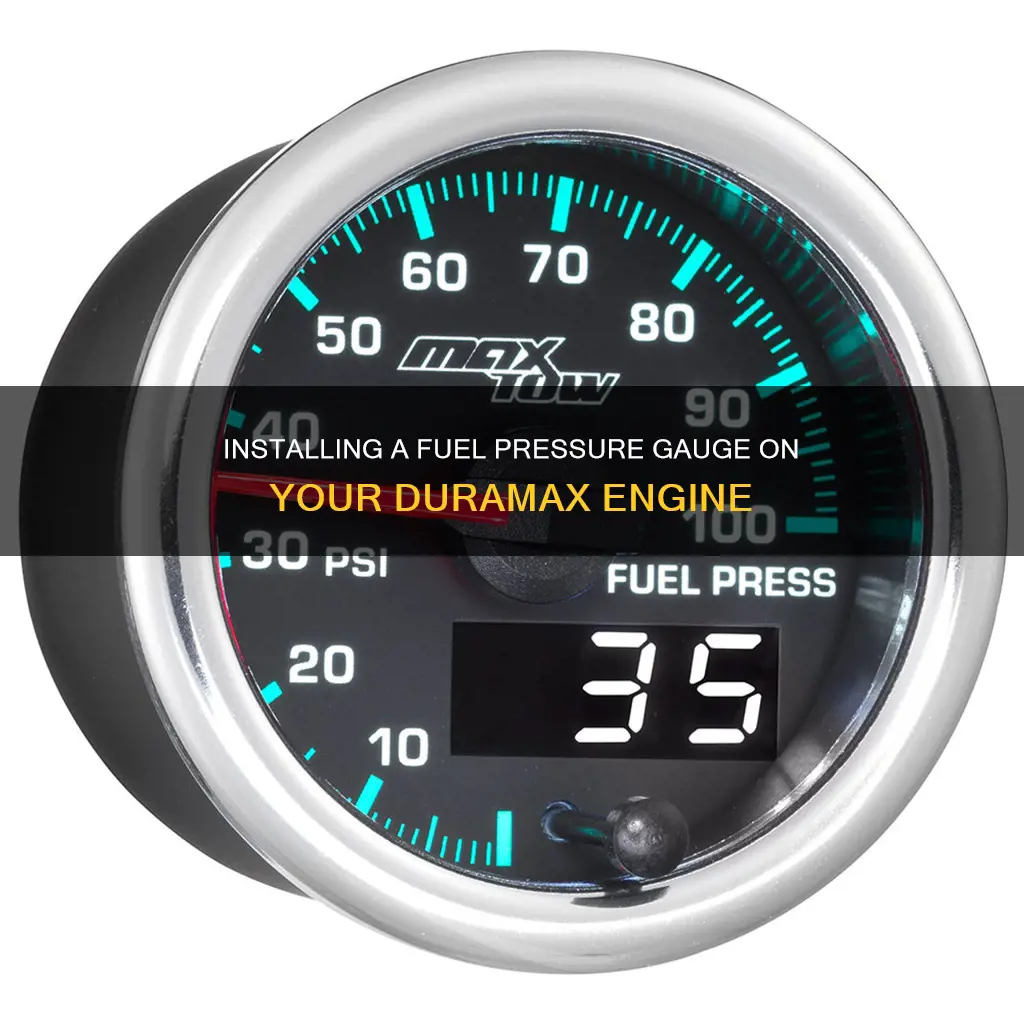

Installing a fuel pressure gauge on a Duramax engine is a common modification, with several methods and tools available. The pressure gauge can be installed in various locations, such as the bleeder screw, fuel filter housing, or a T-adapter with a needle valve. Mechanical and electronic gauges are available, with electronic gauges requiring additional wiring. Aftermarket lift pumps, such as the Airdog or FASS, are often used in conjunction with fuel pressure gauges to ensure optimal fuel pressure and supply. It is important to consider factors such as engine bay heat conditions, filter restrictions, and fuel flow when installing and monitoring fuel pressure gauges.

What You'll Learn

Choosing the right fuel pressure gauge

When choosing the right fuel pressure gauge for your Duramax, there are a few things to consider. Firstly, you need to decide whether you want a mechanical or electronic gauge. Mechanical gauges are generally less expensive, but they may not be as accurate or durable as electronic gauges. Electronic gauges often offer more features and can be easier to read, but they may also be more costly.

Another factor to consider is the range of the gauge. Some gauges may have a higher maximum value, which can make it harder to read the small range that Duramax engines typically operate in (around 5-10 psi). Look for a gauge with a lower maximum value, such as 15 or 20 psi, to get a more precise reading.

Additionally, you'll want to choose a gauge that is compatible with your Duramax's fuel system. Some gauges may require additional adapters or fittings to install, so be sure to check the compatibility before purchasing. You can also opt for a gauge that comes with an adapter specifically designed for Duramax engines, such as the OTC 6754 Diesel Fuel Pressure Gauge, to make installation easier.

Finally, consider the placement of the gauge. Do you want it to be visible from the cab, or are you okay with it being under the hood? If you want to monitor the pressure while driving, you'll need to choose a gauge that can be mounted in the cab and has a long enough hose to reach the fuel system.

Remember to do your research and read reviews before purchasing a fuel pressure gauge to ensure you get a reliable and accurate product that meets your specific needs.

Fuel Pressure Maintenance for 2007 Can-Am 500 Outlander

You may want to see also

Adapters and fittings needed

To install a fuel pressure gauge on a Duramax, you will need a range of adapters and fittings. The specific adapters and fittings you require will depend on the model year of your Duramax, as well as the type of gauge you are installing.

For a 2001-2018 GM 6.6 Duramax, you can use a GlowShift Fuel Rail Pressure Gauge. This will require a 6.6L Pressure adapter, GS-FA_Duramax, which is suitable for model years 2000-2013 6.6L. This adapter replaces the stock bleeder screw next to the filter housing, allowing you to install a ⅛ - 27 NPT pressure sensor. The thread size for this adapter is M10 x 1.5.

Alternatively, for a 2001-2006 6.6 Duramax LB7, LLY, or LBZ, you can also use a GlowShift Fuel Pressure Gauge. This will require a similar adapter, which replaces the bleeder screw, but the specific part number may differ.

If you have an Airdog lift pump, you can purchase a merchant automotive adapter to plug the gauge into the filter head. This will allow you to monitor the fuel pressure directly from the Airdog system.

For a FASS lift pump, you can install a fuel pressure gauge directly on the pump housing, as there is a dedicated fuel pressure port. Simply remove the plug and install a fuel pressure sensor. Additionally, you can purchase an adapter that allows you to thread the gauge into the bleeder screw on the fuel filter housing.

For a mechanical gauge, you will need an M10 to 1/8" NPT adapter, which can be purchased from GlowShift Gauges or Auto Meter. This adapter is installed in place of the bleeder screw, and the gauge is then run off of this adapter.

Finally, for an electronic gauge, you will need to supply power and ground the gauge. You can do this by splicing into an accessory slot in the fuse panel and grounding to a bolt.

Fuel Pressure Requirements for a 1995 Kia Sportage

You may want to see also

Where to splice the gauge into the Airdog 150

To splice the gauge into the Airdog 150, you can use an inline T-fitting. This will allow you to tap into the Airdog line that goes to the CP3 (also referred to as the injection pump). You can also replace the banjo bolt where the low-pressure system feeds the CP3 with a banjo bolt that has a 1/8" port for the pressure sensor.

Another option is to splice into the rubber fuel line at the injection pump using an inline fuel fitting with a 1/8" port. You can also replace the bleeder screw with an M10 to 1/8" NPT adapter and run the gauge from there.

If you are installing an Airdog II, you can remove the small Allen head plug on the pump and run a "grease gun" line with a 1/8" NPT female/female coupler, then attach the snubber valve and the sensor. Alternatively, you can drill and tap the 90-degree fitting that comes with the Airdog II kit for the 1/8" NPT thread used by the pressure sensor.

Tire Pressure: Fuel Economy's Best Friend

You may want to see also

Mounting the gauge inside or outside the cab

When it comes to mounting the gauge, you have a few options: inside the cab, outside the cab, or under the hood. Each location has its own advantages and considerations. Here is a detailed guide to help you decide and instruct you on the installation process:

Mounting Inside the Cab

The advantage of mounting your fuel pressure gauge inside the cab is that it provides a comfortable and easily accessible location for viewing the gauge. You can choose to mount it on the A-pillar, which is the vertical portion of the frame between the windshield and the front side window, or on the dash. Here's what you need to do:

- Selecting the Mounting Location: Choose a spot that is easily visible and accessible, ensuring that it does not obstruct your view while driving or interfere with other components.

- Preparing the Mounting Surface: Clean the selected area to ensure that the adhesive or drilling process will result in a secure mount.

- Mounting the Gauge: Follow the instructions provided with your gauge kit. This may involve using an adhesive backing or drilling and securing the gauge with screws. Ensure that the gauge is securely mounted before proceeding.

- Wiring the Gauge: Connect the wiring harness provided with your gauge to the appropriate power source and ground. Ensure that all connections are secure and insulated to prevent any potential short circuits.

- Testing the Installation: Once the wiring is complete, turn on the ignition and check that the gauge is functioning properly. Ensure that the needle moves smoothly and that the displayed values are accurate.

Mounting Outside the Cab

If you prefer to keep your cab clutter-free or want to monitor the fuel pressure more discreetly, you can choose to mount the gauge outside the cab. Here's how you can do it:

- Selecting the Mounting Location: Choose a spot that is protected from the elements and will not obstruct your driving. A common location is on the firewall, which is the separation between the cab and the engine compartment.

- Preparing the Mounting Surface: Clean and prepare the mounting surface to ensure a secure installation. If you're drilling, make sure you don't interfere with any existing components or wiring.

- Mounting the Gauge: Follow the instructions provided with your gauge kit for external mounting. This may involve using a different mounting bracket or hardware compared to an internal mount.

- Wiring the Gauge: Carefully route the wiring harness from the gauge to the appropriate power source and ground locations inside the cab or engine compartment. Ensure that the wiring is secured and protected from potential damage or abrasion.

- Testing the Installation: As with an internal mount, test the gauge's functionality by turning on the ignition and verifying that the gauge operates correctly. Ensure that the values displayed are accurate and that the needle movement is smooth.

Under the Hood Mounting

Some users opt to mount their fuel pressure gauge under the hood, usually near the engine. This option provides easy access for monitoring and maintenance but may be less convenient for frequent viewing while driving. Here are the general steps:

- Selecting the Mounting Location: Choose a spot that is easily accessible and won't interfere with the engine or other components. Ensure that the location can withstand the heat and vibrations from the engine.

- Preparing the Mounting Surface: Clean and prepare the surface, ensuring that it can accommodate the mounting hardware securely.

- Mounting the Gauge: Follow the instructions provided with your gauge kit for under-hood mounting. This may involve using heat-resistant mounting hardware or additional brackets for stability.

- Wiring the Gauge: Connect the wiring harness to a suitable power source and ground, ensuring that the connections are secure and insulated. Consider using heat-shrink tubing or similar protection for the wiring to withstand the engine bay environment.

- Testing the Installation: As with the other mounting options, test the gauge's functionality by turning on the ignition and verifying that the gauge operates as expected. Ensure the accuracy of the readings.

Remember to consult a professional or a mechanic if you have any doubts or concerns during the installation process.

Fuel Pressure Regulator: Why Your Car Won't Start

You may want to see also

How to power the gauge

There are a few ways to power your fuel pressure gauge. One method is to splice into the rubber line or harness of your Airdog. You can also use a fuse panel by the driver's door, such as a Bussman Mini Add-A-Line with a 10-amp fuse, and plug it into an accessory slot. You can then tie all the hot wires for the gauges together and run them to the Add-A-Line. For the ground wires, you can ground them to a bolt inside the fuse panel.

Another option is to use a mechanical gauge, which doesn't require any wiring. However, keep in mind that most mechanical gauges won't withstand the engine bay heat conditions over the long term.

If you want to avoid splicing wires, you can use an electric gauge. AlligatorPerformance, a user on the DuramaxForum, recommends this option and suggests using a $40 electric pressure gauge to avoid the hassle of fiddling with wires.

If you're looking for a more innovative solution, MMLMM, another user on the same forum, shares their experience of powering their mechanical gauge without any wiring. They mention that their setup cost them around $30, and they only use the gauge to set up their lift pump psi when adjusting it.

For those who prefer to have their gauges inside the cab, you can consider installing a gauge like the ISSPRO 0-20 psi #18066, which has a low-pressure light that can be set to your desired pressure. This gauge can be mounted within your driving view, providing convenient access to monitor your fuel pressure.

Fuel Pressure: Friend or Foe to Your Vehicle?

You may want to see also

Frequently asked questions

You must have an aftermarket lift pump installed. You can use a 6.6L Pressure adapter, GS-FA_Duramax, when installing in a 2000-2013 6.6L.

You can put a M10 to 1/8" NPT adapter where your bleeder screw is and run the gauge off that.

The recommended pressure is 8 psi at idle.

The thread size is M10 x 1.5.