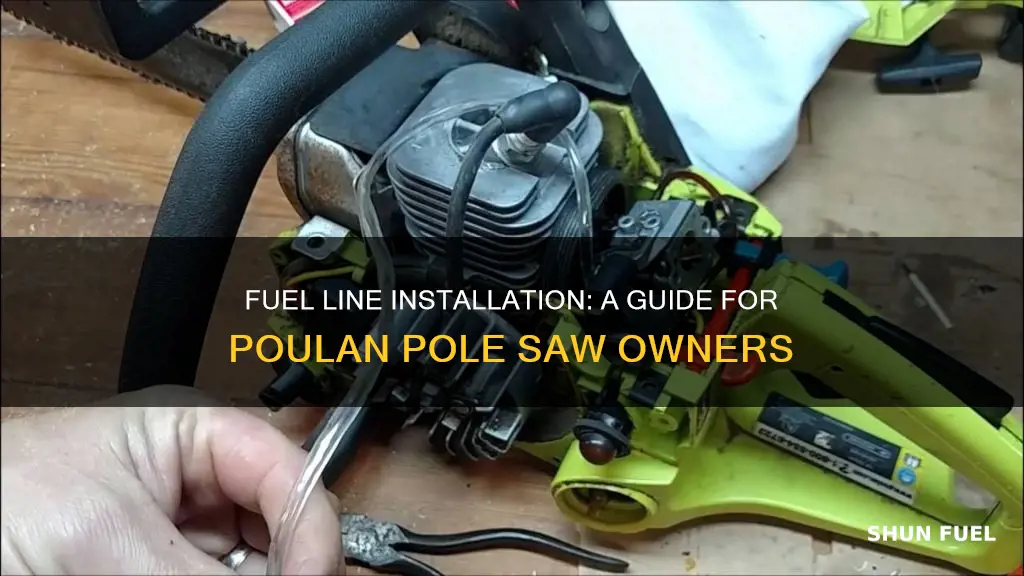

Installing fuel lines on a Poulan pole saw is a crucial step for those looking to enhance their cutting power and efficiency. This process involves connecting the fuel lines to the engine, ensuring a steady supply of gasoline to the carburetor. By following a step-by-step guide, you can safely and effectively attach the lines, allowing for a more powerful and controlled cut. The process typically includes removing the old lines, cleaning the engine, and carefully routing and securing the new fuel lines to the appropriate ports. With the right tools and a methodical approach, you can achieve a professional-looking installation, ensuring your Poulan pole saw operates at its best.

| Characteristics | Values |

|---|---|

| Fuel Line Material | Typically made of rubber or vinyl, designed to withstand fuel and weather conditions. |

| Fuel Line Diameter | Common sizes include 5/16", 3/8", and 1/4" ID (Inner Diameter). |

| Fuel Line Length | Varies based on the model and intended use, often ranging from 2 to 10 feet. |

| Fuel Pump | Required to push fuel from the tank to the engine. |

| Fuel Filter | Installed in the fuel line to prevent contaminants from reaching the engine. |

| Fuel Gauge | Helps monitor fuel levels in the tank. |

| Fuel Shut-Off Valve | Allows for easy fuel cutoff when not in use. |

| Engine Type | Two-stroke or four-stroke engines, each with specific fuel delivery requirements. |

| Fuel System Maintenance | Regular cleaning and inspection of the fuel system to ensure optimal performance. |

| Safety Precautions | Wear protective gear, work in a well-ventilated area, and follow manufacturer guidelines. |

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel gauge

- Remove Old Line: Carefully disconnect and remove the old fuel line from the saw

- Route New Line: Route the new fuel line through the saw's frame, following the manufacturer's guide

- Connect Components: Securely attach the new line to the fuel tank and engine

- Test and Adjust: Ensure proper fuel flow, make adjustments, and test the saw's performance

Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel gauge

Before you begin the installation process, it's crucial to gather all the necessary tools and materials to ensure a smooth and efficient job. Here's a detailed guide on preparing the tools required for installing fuel lines on your Poulan pole saw:

Fuel Line and Connectors: The primary component you need to install is the fuel line, which is typically a flexible hose made of rubber or a similar durable material. Measure the length of fuel line required, considering the distance between the fuel tank and the engine of your pole saw. Ensure you purchase a fuel line that is compatible with the specific model of your Poulan saw. Along with the fuel line, you'll need various connectors to join the line to the fuel tank, the engine, and any other components. Common connectors include quick-connect fittings, barbed fittings, and fuel filters. Obtain the appropriate connectors that match the fuel line's diameter and the engine's requirements.

Fuel Gauge (Optional but Recommended): A fuel gauge is an essential accessory to monitor the fuel level in your saw's tank. It provides real-time feedback on the remaining fuel, ensuring you never run out unexpectedly. When installing the fuel line, consider routing it near the gauge to make it easily accessible. This tool is particularly useful for larger equipment or for those who prefer a more comprehensive view of their fuel levels.

Additional Tools: Along with the primary components, you'll require standard automotive tools for the installation. This includes a fuel pump primer bulb, which is used to prime the fuel system, and various wrenches or pliers for tightening connections. It's also a good idea to have a fuel filter if your saw doesn't already have one, as this can improve fuel flow and engine performance.

By gathering these tools and materials in advance, you'll be well-prepared to tackle the fuel line installation process, ensuring a successful and efficient outcome. Remember to double-check the compatibility of the fuel line and connectors with your specific Poulan pole saw model to avoid any potential issues.

LSX Swap: Choosing the Right 6-Fuel Line for Optimal Performance

You may want to see also

Remove Old Line: Carefully disconnect and remove the old fuel line from the saw

To begin the process of replacing the fuel line on your Poulan pole saw, you must first carefully remove the old line. Start by ensuring the saw is turned off and the engine is cool to avoid any accidents. Locate the fuel line, which is typically a rubber or plastic hose that runs from the fuel tank to the carburetor. It is important to identify the correct connections to avoid any confusion.

Using a pair of pliers or a fuel line cutter, carefully disconnect the fuel line from the tank. You may need to twist or turn the line to release the connection. Be gentle to avoid damaging the line or the tank. Once disconnected, set the old fuel line aside, ensuring it is not kinked or damaged during removal.

Next, locate the carburetor and identify the fuel line connection there. This connection is usually a small fitting or a quick-release clip. Carefully disconnect the line from the carburetor, again being mindful of any twists or turns to avoid damage. You might need to use a small tool to release the connection if it is tight.

With the old fuel line now removed, inspect the area where it was connected to ensure there is no damage or debris. Clean the ports and fittings if necessary to ensure a proper seal when reinstalling the new line. Take this opportunity to check for any signs of fuel leakage, and if found, address the issue before proceeding.

Remember, when removing the old fuel line, take your time and be cautious to avoid any spills or damage. Properly disposing of the old line is also essential to prevent environmental hazards. Once you have completed this step, you are ready to install the new fuel line, ensuring a smooth and efficient fuel supply to your Poulan pole saw.

Mastering Harbor Freight Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Route New Line: Route the new fuel line through the saw's frame, following the manufacturer's guide

When replacing or installing a new fuel line on your Poulan pole saw, proper routing is crucial to ensure optimal performance and prevent any potential issues. Here's a step-by-step guide on how to route the new fuel line through the saw's frame, adhering to the manufacturer's instructions:

Step 1: Locate the Fuel Line Path: Begin by carefully examining the Poulan pole saw's frame and identifying the path the original fuel line took. This information is typically provided in the manufacturer's manual. Locate the fuel tank, the carburetor, and the various connections along the line. Understanding this layout will help you plan the new route efficiently.

Step 2: Prepare the New Route: Based on the manufacturer's guidelines, decide on the optimal path for the new fuel line. Consider factors such as ease of access, minimal obstruction, and proximity to other components. Ensure that the route allows for sufficient length to accommodate any necessary bends and turns without causing strain or damage to the line. Mark the starting and ending points of the new route on the frame for reference.

Step 3: Remove Obstructions: Carefully follow the marked path and remove any obstacles or existing lines that might interfere with the new installation. Use appropriate tools to carefully cut or pry away any obstructions, ensuring you don't damage the surrounding components. Take your time to avoid causing any harm to the saw's internal parts.

Step 4: Route the Fuel Line: Start at the fuel tank and carefully feed the new fuel line through the frame, following the predetermined route. Use a suitable tool, such as a fuel line cutter or a small wire, to guide the line through any tight spaces or bends. Ensure that the line is securely attached to the frame using the appropriate clips or ties provided by the manufacturer.

Step 5: Secure and Connect: As you progress along the route, secure the fuel line at regular intervals using the recommended clips or ties. This will prevent the line from moving or becoming damaged. Once you reach the carburetor, carefully connect the new fuel line to the appropriate port, ensuring a tight and secure fit. Double-check all connections to guarantee a proper seal.

Remember, the key to a successful installation is careful planning and adherence to the manufacturer's instructions. Take your time during each step, and don't hesitate to refer to the guide if you encounter any specific requirements or variations for your Poulan pole saw model.

Fuel Line Issues: A Possible Cause of P0011 Code

You may want to see also

Connect Components: Securely attach the new line to the fuel tank and engine

When connecting the new fuel line to the Poulan pole saw's fuel tank and engine, it's crucial to ensure a secure and tight attachment to prevent any leaks or fuel loss. Here's a step-by-step guide to help you with this process:

Step 1: Prepare the Components

Before you begin, make sure you have the necessary tools and components ready. You'll need the new fuel line, which should match the original in terms of length and diameter, and a fuel line connector kit. Ensure you have the appropriate connectors for your specific model of Poulan pole saw.

Step 2: Locate the Fuel Tank and Engine

Locate the fuel tank, which is typically a small container attached to the pole saw's handle. Identify the fuel inlet, which is the opening where the fuel line connects to the engine. This inlet is usually located near the engine's carburetor or fuel injection system.

Step 3: Attach the Fuel Line to the Tank

Using the connector kit, carefully attach the new fuel line to the fuel tank. Tighten the connector securely, ensuring there is no play or movement in the connection. Make sure the line is positioned in a way that allows for easy access and does not interfere with the saw's operation.

Step 4: Connect to the Engine

Now, connect the other end of the fuel line to the engine's fuel inlet. Again, use the appropriate connector from the kit. Tighten it firmly, but be careful not to overtighten, as this can damage the fuel line or engine components. Double-check that the connection is secure and leak-free.

Step 5: Test and Inspect

After connecting the fuel line to both the tank and the engine, it's essential to test the system. Start the pole saw and let it run for a few minutes. Check for any signs of fuel leakage and ensure that the engine operates smoothly. Inspect the connections for any signs of strain or damage. If everything is secure and there are no leaks, you've successfully installed the new fuel line.

Effective Fuel Line Cleaning: Methods and Solutions

You may want to see also

Test and Adjust: Ensure proper fuel flow, make adjustments, and test the saw's performance

Once the fuel lines are installed, it's crucial to test and adjust the system to ensure optimal performance. Start by verifying that the fuel is flowing correctly through the lines. Check for any blockages or restrictions that might hinder the flow. Ensure that the fuel filter is clean and free of debris, as a clogged filter can restrict fuel delivery. If you notice any kinks or bends in the fuel lines, straighten them out to maintain a smooth path for the fuel.

The next step is to make adjustments to the fuel mixture. This is typically done by modifying the carburetor settings. Locate the carburetor and access the adjustment screws. You might need to consult the owner's manual or online resources specific to your Poulan pole saw model to understand the correct screw adjustments. Fine-tune the fuel-to-air ratio by turning the screws clockwise or counterclockwise to achieve the optimal performance. A properly adjusted carburetor ensures that the engine receives the correct amount of fuel, resulting in efficient combustion and improved performance.

After making the necessary adjustments, it's time to test the saw's performance. Start the engine and let it run for a few minutes to reach operating temperature. Pay close attention to the engine's behavior, listening for any unusual noises and monitoring the exhaust for excessive smoke or unusual colors. Check the oil level and top it up if needed. Ensure that the engine is running smoothly and that there are no sudden surges or stalls. If you notice any issues, such as rough idling or difficulty starting, you may need to make further adjustments or consult a professional for assistance.

Additionally, test the saw's cutting capabilities. Perform a few test cuts on a piece of wood or a test stand to assess the saw's performance. Observe the smoothness of the cut, the depth of the cut, and the overall precision. If the saw is not performing as expected, double-check your fuel line installation and carburetor adjustments. Sometimes, a simple re-tightening of connections or a slight adjustment can make a significant difference. Remember, proper testing and adjustment are essential to ensure your Poulan pole saw operates efficiently and reliably.

Air Filter Clog: A Hidden Fuel Line Filter Problem

You may want to see also

Frequently asked questions

Before you begin, ensure you have the correct fuel line size and type for your model. Clean the fuel lines with a suitable solvent to remove any debris or old fuel. Inspect the lines for any damage or kinks, and replace if necessary.

Start by locating the fuel inlet on your engine, which is usually a small opening near the carburetor. Slide the fuel line over the inlet and secure it with a clamp or a fuel line fitting. Ensure a tight connection to prevent fuel leaks.

It's recommended to use the fuel type specified by the manufacturer. Poulan pole saws typically require a mixture of gasoline and oil. Always refer to the user manual for the correct fuel ratio and any additional instructions related to fuel preparation and storage.