Installing a fuel line for a kicker boat motor is a crucial step in ensuring your boat's engine runs smoothly and efficiently. This process involves connecting the fuel source to the motor, which requires careful planning and execution to avoid potential issues. The following guide will provide a step-by-step approach to installing the fuel line, covering essential considerations such as choosing the right materials, ensuring proper connections, and testing the system for leaks. By following these instructions, you can effectively set up your kicker boat motor for optimal performance and peace of mind on the water.

| Characteristics | Values |

|---|---|

| Preparation | Ensure you have the necessary tools: fuel line, fuel filter, fuel gauge adapter, fuel gauge, fuel pump, and a wrench. Also, locate the fuel tank and the engine's fuel inlet. |

| Fuel Line Material | Choose a fuel line made of durable materials like nylon or vinyl, compatible with gasoline. Ensure it's the correct size and length for your application. |

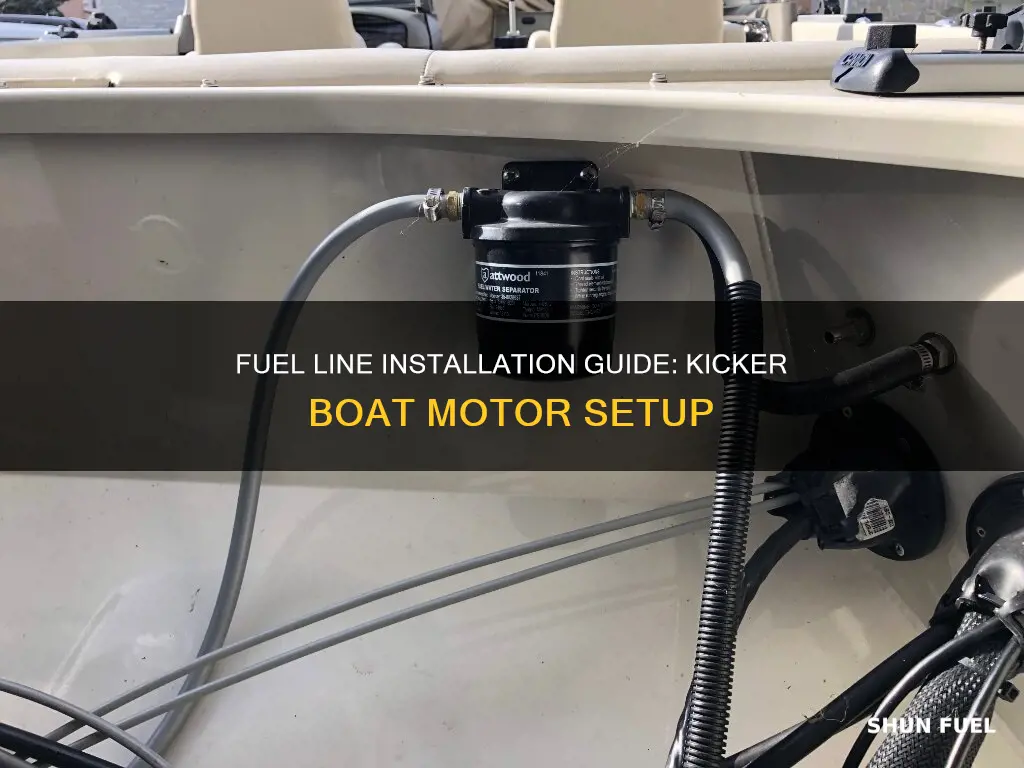

| Fuel Filter | Install a fuel filter to prevent contaminants from entering the engine. This is crucial for maintaining engine performance and longevity. |

| Fuel Gauge Adapter | If your boat doesn't have a built-in fuel gauge, you'll need an adapter to connect the fuel gauge to the fuel line. |

| Fuel Pump | Ensure the fuel pump is functioning correctly and capable of supplying fuel to the engine at the required pressure. |

| Fuel Line Routing | Route the fuel line away from heat sources and sharp bends to prevent damage and ensure a steady fuel supply. |

| Fuel Tank Connection | Securely attach the fuel line to the fuel tank using appropriate fittings and ensure a tight seal. |

| Engine Fuel Inlet | Connect the fuel line to the engine's fuel inlet, ensuring a proper fit and orientation. |

| Testing | Start the engine and check for any leaks. Verify that the fuel gauge reads accurately and that the engine runs smoothly. |

| Safety Precautions | Always work on a level surface, wear protective gear, and ensure proper ventilation when handling gasoline. |

What You'll Learn

- Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel filter

- Locate Mounting Points: Identify suitable spots on the boat for the motor's fuel line

- Route the Line: Carefully guide the fuel line through the boat's structure, avoiding sharp bends

- Connect to Motor: Securely attach the fuel line to the motor's fuel inlet using the appropriate fittings

- Test and Adjust: Ensure the fuel line is properly sealed and test the motor to check for leaks

Prepare Tools: Gather necessary tools like fuel line, connectors, and a fuel filter

Before you begin the installation process, it's crucial to gather all the necessary tools and materials to ensure a smooth and efficient setup. Here's a step-by-step guide on preparing the tools required for the job:

Fuel Line and Connectors: Start by acquiring the appropriate fuel line, which is specifically designed for marine applications. Measure the length of fuel line needed to connect the kicker motor to the main fuel source on your boat. Typically, this involves running the line from the fuel tank or the engine's fuel supply to the motor. Ensure you purchase fuel line with the correct diameter and compatibility for your motor. Along with the fuel line, you'll need various connectors to join the line to the motor, the fuel source, and any intermediate components. These connectors should be made of durable materials like brass or stainless steel to withstand the marine environment.

Fuel Filter: A fuel filter is an essential component to ensure clean fuel delivery to the motor. It helps remove contaminants and debris from the fuel, preventing potential damage to the engine. Choose a fuel filter that is compatible with your boat's fuel system and the type of fuel you are using. Consider the filter's capacity and replace it regularly to maintain optimal performance.

Additional Tools: Gather some basic tools that will aid in the installation process. This includes a wrench or socket set for tightening connections, a fuel gauge (if applicable), and a fuel pressure gauge to check the system's integrity. Additionally, have a supply of rags or cloth to wipe away any fuel spills and keep the work area clean.

By preparing these tools and materials in advance, you'll be well-equipped to tackle the fuel line installation for your kicker boat motor. This organized approach ensures that you have everything readily available, making the installation process more efficient and less stressful.

Mastering Fuel Line Pitch: The Vise Grip Technique

You may want to see also

Locate Mounting Points: Identify suitable spots on the boat for the motor's fuel line

When installing a fuel line for a kicker boat motor, the first crucial step is to locate the appropriate mounting points on your vessel. This process ensures the fuel line is securely attached and positioned to withstand the rigors of the water. Begin by consulting the boat's manual or manufacturer's guidelines, as these resources will provide specific instructions tailored to your boat model. Look for diagrams or illustrations that show the recommended mounting locations for the fuel line. Typically, these points are strategically chosen to offer optimal protection and accessibility.

The ideal spots for mounting the fuel line are usually near the engine compartment, ensuring easy access for maintenance and repairs. These areas are often protected by the boat's structure, shielding the fuel line from potential impacts or damage. Additionally, consider the boat's layout and any existing wiring or plumbing to avoid interference. Mounting the fuel line too close to other components might lead to friction or damage over time.

Another critical aspect is the height and angle of the mounting points. The fuel line should be positioned at a slight angle to allow for proper drainage and prevent the accumulation of debris or water. Aim for a height that is comfortable for access during fueling and maintenance. It's essential to ensure that the mounting points are secure and can withstand the boat's movement in the water.

When identifying these locations, take into account the boat's trim and the motor's position. The fuel line should be routed in a way that avoids any potential hazards, such as sharp corners or protruding objects that could cause damage. Proper planning at this stage will make the installation process smoother and more efficient.

Remember, the goal is to create a secure and discreet mounting system that allows for easy access to the fuel line when needed. By carefully selecting the mounting points, you'll ensure a successful and long-lasting installation for your kicker boat motor's fuel line.

Can Car Fuel Lines Still Freeze in Cold Weather?

You may want to see also

Route the Line: Carefully guide the fuel line through the boat's structure, avoiding sharp bends

When routing the fuel line for your kicker boat motor, it's crucial to prioritize safety and functionality. The goal is to ensure a smooth and secure path for the fuel line, avoiding any sharp bends that could lead to damage or reduced performance. Here's a step-by-step guide to help you navigate this process:

Start by identifying the optimal route for the fuel line. This involves considering the boat's structure, including any bulkheads, frames, or other obstacles. The line should be guided in a way that minimizes the risk of damage to the boat's interior. Aim for a path that is as straight and level as possible, avoiding any sharp angles or kinks. Use the manufacturer's diagrams or illustrations if available to ensure you're following the correct route.

As you begin routing the line, take the time to secure it properly. Use appropriate fuel line clips or ties to fasten the line to the boat's structure at regular intervals. This will help maintain tension and prevent the line from becoming tangled or caught on other components. Ensure that the clips or ties are tight enough to hold the line in place but not so tight that they cause any strain or damage to the line itself.

Pay close attention to any sharp corners or turns in the boat's structure. These areas can be particularly challenging when routing the fuel line. Instead of forcing the line through a sharp bend, consider using a flexible elbow or a short length of fuel line with a bend to create a smoother transition. This approach will help reduce the risk of fuel line damage and ensure a more reliable connection.

Additionally, take the time to inspect the fuel line for any potential issues. Look for any signs of wear, cracks, or damage that could compromise the line's integrity. If you notice any problems, it's best to replace the line to ensure a safe and efficient fuel supply. Regular maintenance and inspections will help extend the life of your fuel line and maintain the overall performance of your kicker boat motor.

Remember, the key to successful fuel line installation is patience and attention to detail. Take your time to carefully guide the line, secure it properly, and address any potential challenges along the way. By following these steps, you'll ensure a reliable and safe fuel supply for your kicker boat motor, allowing you to enjoy your boating adventures with peace of mind.

1985 Mariner Fuel Line Connections: A Style Guide

You may want to see also

Connect to Motor: Securely attach the fuel line to the motor's fuel inlet using the appropriate fittings

When connecting the fuel line to the motor, it's crucial to ensure a secure and tight attachment to prevent any fuel leaks or spills. Start by identifying the fuel inlet on your kicker boat motor. This is typically a small opening or port, often located near the motor's base or side. The inlet is designed to accept the fuel line, so you'll need to match the correct size and type of fitting to the motor's specifications.

Obtain the appropriate fittings for your fuel line. Common types include compression fittings, quick-connect fittings, or screw-on fittings, depending on the motor's design. Ensure you have the right size and thread type to match the fuel line and the motor's inlet. For example, if your fuel line has a 3/8-inch inner diameter, you'll need a 3/8-inch compression fitting or a compatible quick-connect fitting.

Now, carefully attach the fuel line to the motor's fuel inlet. Start by inserting the male end of the fitting into the fuel line, ensuring it is aligned correctly. Then, tighten the fitting securely using the appropriate tool, such as a wrench or pliers. Make sure it is tight enough to prevent any movement but be careful not to overtighten, as this can damage the fuel line or inlet.

For added security, consider using a fuel line clamp or a ferrule to further secure the connection. These provide an extra layer of protection against leaks and can be especially useful if you're working in a wet or marine environment. Wrap the clamp or ferrule around the fuel line and tighten it according to the manufacturer's instructions.

Finally, double-check your connections to ensure they are secure and leak-free. Test the fuel line by starting the motor and observing for any signs of fuel escaping. If everything is connected correctly, the motor should start smoothly, and you'll have successfully installed the fuel line for your kicker boat motor. Remember, proper installation and regular maintenance of the fuel line are essential for safe and efficient operation.

Catalyst Fuel Line Removal: A Step-by-Step Guide for 2006 Jeep Liberty Owners

You may want to see also

Test and Adjust: Ensure the fuel line is properly sealed and test the motor to check for leaks

After installing the fuel line for your kicker boat motor, it's crucial to conduct a thorough test and adjustment phase to ensure everything is functioning correctly and safely. This step is often overlooked, but it's essential to verify the integrity of your setup to avoid potential issues on the water.

Start by checking for any visible signs of damage or leaks along the fuel line. Inspect the connections and fittings to ensure they are tight and secure. Look for any cracks, punctures, or signs of corrosion that could compromise the line's integrity. It's important to note that even a small leak can lead to significant problems, so no detail should be overlooked.

Once you've inspected the fuel line, it's time to test the motor. Start the engine and listen for any unusual noises, especially hissing or whistling sounds, which could indicate a fuel leak. Pay close attention to the exhaust and any areas where the fuel line connects to the motor. If you hear any leaks, immediately shut off the engine and address the issue. You can use a soapy water solution to further identify leaks by applying it to the fuel line and watching for bubbles, which will indicate the presence of a leak.

If no leaks are found, it's time to adjust the fuel line's position if necessary. Ensure the line is routed away from moving parts and potential hazards to prevent damage or entanglement. Proper routing will also improve the motor's performance and reduce the risk of fuel contamination.

Finally, always remember to refer to the manufacturer's guidelines and recommendations for your specific boat and motor model. These guidelines will provide specific instructions and best practices for testing and adjusting your fuel line installation. By following these steps, you can ensure a safe and reliable fuel system for your kicker boat motor.

Marine Fuel Line: Top Sources for Your Boat

You may want to see also

Frequently asked questions

It is recommended to use a fuel line specifically designed for marine applications. Look for a line made from durable materials like nylon or braided polyester, which can withstand the harsh marine environment. Ensure it has a suitable inner diameter to handle the expected fuel flow rate for your kicker motor.

Before installing, inspect the fuel line for any damage or kinks. Ensure it is free from bends that could cause stress on the line. If necessary, cut the line to the desired length and use fuel line connectors or fittings to join the ends securely.

The fuel line should be mounted close to the kicker motor to minimize pressure drop. Typically, it is routed from the fuel tank to the engine's fuel inlet. Consider using a fuel line bracket or clamp to secure the line in place, ensuring it is taut and away from moving parts to prevent damage.

Start by identifying the correct fuel tank fitting for your kicker motor. Clean the fuel tank opening and the fuel line connector to ensure a tight seal. Push the fuel line connector onto the tank fitting until it is fully seated. Tighten the connector securely, but be careful not to overtighten, as it may damage the fuel line.

In cold regions, it's essential to prevent fuel line freezing. Ensure the fuel line is insulated, especially if it is exposed to the elements. Consider using a flexible fuel line with built-in insulation or adding an external insulation sleeve. Additionally, keep the fuel tank slightly full to minimize the risk of fuel line damage due to freezing temperatures.