Installing a Big Line Fuel Line Kit on a 00 Cummins engine can significantly enhance your vehicle's performance and reliability. This comprehensive guide will walk you through the process step-by-step, ensuring a successful installation. From preparing the necessary tools and materials to carefully routing the fuel lines and securing them in place, each phase is crucial for a professional finish. You'll learn how to connect the new fuel lines to the engine and the fuel tank, ensuring a tight and leak-free fit. By following these instructions, you'll be able to enjoy a smoother ride and improved fuel efficiency with your Cummins engine.

| Characteristics | Values |

|---|---|

| Installation Process | The process involves replacing the original fuel lines with the new, larger diameter lines. It requires careful routing and securing to ensure optimal performance and prevent leaks. |

| Compatibility | Specifically designed for 2000 Cummins engines, ensuring a precise fit and compatibility with the existing fuel system. |

| Material | Typically made from high-quality materials like stainless steel or braided rubber, offering durability and resistance to fuel contamination. |

| Performance Improvement | Increases fuel flow, resulting in improved engine performance, faster response times, and better low-end torque. |

| Ease of Installation | Can be a complex task due to engine layout and space constraints. May require specialized tools and knowledge of engine mechanics. |

| Benefits | Provides a more efficient fuel delivery system, reduces pressure drop, and can enhance overall engine operation. |

| Maintenance | Regular inspection and replacement of fuel lines are recommended to prevent fuel leaks and maintain engine health. |

| Cost | The price can vary depending on the brand and quality, but it offers a cost-effective upgrade for Cummins engine owners. |

| Warranty | Often comes with a manufacturer's warranty, ensuring quality and providing peace of mind for buyers. |

What You'll Learn

- Preparation: Gather tools, prepare workspace, and inspect kit components for damage

- Fuel Tank: Disconnect old fuel lines, attach new lines to tank, and secure connections

- Engine Connections: Route lines to engine, connect to injectors, and ensure proper alignment

- Testing: Start engine, check for leaks, and verify fuel flow to all cylinders

- Final Adjustments: Tighten connections, clean up, and ensure all components are functioning properly

Preparation: Gather tools, prepare workspace, and inspect kit components for damage

Before you begin the installation process, it's crucial to prepare and gather the necessary tools and materials to ensure a smooth and efficient job. Here's a step-by-step guide to the preparation phase:

Gathering Tools and Materials: Start by collecting all the tools required for the installation. This includes basic hand tools such as wrenches, screwdrivers, and pliers. You might also need a fuel line cutter or a utility knife for precise cuts. Additionally, ensure you have the appropriate safety gear, such as gloves and safety goggles, to protect yourself during the process. It is recommended to have a torque wrench to ensure accurate tightening of bolts and nuts.

Workspace Preparation: Choose a well-lit and spacious area for your work. A clean and organized workspace is essential to avoid any potential hazards. Clear any clutter or obstacles that might interfere with your installation. Ensure you have a stable surface to work on, preferably a workbench or a flat table. If you're working under a vehicle, make sure it is securely elevated and stabilized to prevent any accidents.

Inspecting the Kit Components: Carefully unpack the Big Line Fuel Line Kit and inspect each component for any signs of damage or defects. Check for any missing parts or incorrect items. Verify that all the necessary fittings, hoses, and connectors are present. Look for any visible damage, such as tears, cracks, or kinks in the fuel lines. If any issues are found, contact the supplier or manufacturer to obtain replacements before proceeding. Proper inspection ensures that you have all the required parts and minimizes the risk of errors during installation.

Additionally, familiarize yourself with the kit's instructions and diagrams to understand the layout and connections. This preparation phase is vital to ensure a successful and safe installation process. By gathering the right tools, preparing your workspace, and thoroughly inspecting the kit, you'll be well-prepared to tackle the installation of the Big Line Fuel Line Kit on your 00 Cummins engine.

Fuel Line Valves: Direction Matters for Effective Shut-Off

You may want to see also

Fuel Tank: Disconnect old fuel lines, attach new lines to tank, and secure connections

When replacing the fuel lines on your 00 Cummins engine, a crucial step is connecting the new lines to the fuel tank. Here's a step-by-step guide to ensure a secure and reliable installation:

- Prepare the Fuel Tank: Begin by draining any remaining fuel from the tank. This is essential for safety and to prevent spills during the installation process. Use a fuel pump primer or a similar tool to ensure the lines are primed and ready for fuel.

- Disconnect Old Lines: Carefully disconnect the old fuel lines from the fuel tank. Locate the lines that connect to the tank's inlet and outlet ports. These lines will be secured with clamps or fittings. Gently pull the lines away from the tank, taking note of the positions of the connections.

- Attach New Lines: Now, it's time to connect the new Big Line fuel lines. Start by attaching the inlet line to the appropriate port on the fuel tank. Ensure a snug fit and secure it with the provided clamp or fitting. Repeat this process for the outlet line, connecting it to the other port on the tank. Make sure the lines are positioned to allow for easy access during future maintenance.

- Secure Connections: Tighten all connections securely but be careful not to overtighten. Use the appropriate tools to ensure a firm bond. Check that all fittings are tight and there are no leaks. It's crucial to double-check these connections as any leaks could lead to engine performance issues.

- Final Checks: After securing the connections, double-check the fuel tank for any signs of leakage. Inspect the lines for any kinks or damage. Ensure that the fuel tank is properly grounded to prevent static electricity buildup, which could damage the new lines.

By following these steps, you'll ensure a proper and secure connection of the new fuel lines to the tank, contributing to a reliable and efficient fuel system in your 00 Cummins engine. Remember, taking the time to do this right will pay off in the long run with improved engine performance and longevity.

Can Fuel Oil Lines Safely Run Under Your Floor?

You may want to see also

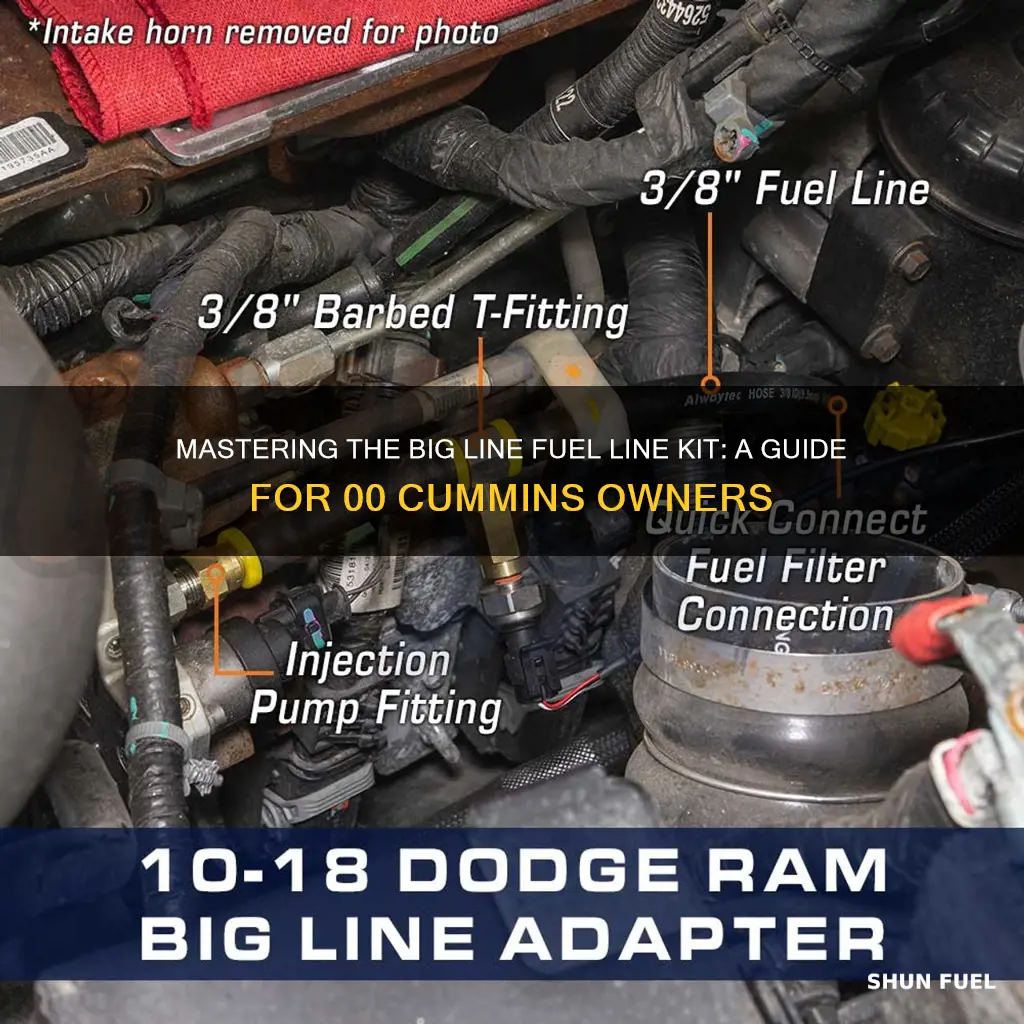

Engine Connections: Route lines to engine, connect to injectors, and ensure proper alignment

When installing the Big Line Fuel Line Kit on a 00 Cummins engine, the engine connections are a crucial step to ensure optimal performance and reliability. Here's a detailed guide on how to approach this part of the installation process:

Routing the Fuel Lines: Begin by carefully examining the engine bay and identifying the optimal path for the fuel lines. The goal is to route the lines in a way that minimizes bends and twists, as sharp angles can restrict fuel flow and potentially cause issues. Typically, the fuel lines should be positioned to run alongside the engine block, utilizing the available space and following the natural contours of the engine bay. Ensure that the lines are not too close to any moving parts or components that could interfere with their movement.

Connecting to the Injectors: The next step is to connect the fuel lines to the injectors. Locate the fuel injectors, which are usually positioned near the engine's intake manifold. Carefully thread one end of each fuel line onto the corresponding injector's fuel rail or mounting bracket. Tighten the connections securely, but be mindful not to overtighten, as this can damage the threads or the fuel lines. It is essential to maintain a tight seal to prevent any fuel leaks. After connecting, double-check that the lines are properly aligned and there are no kinks or obstructions.

Ensuring Proper Alignment: Alignment is critical to the performance and longevity of the fuel system. Once the lines are connected to the injectors, verify that they are straight and aligned with the engine's structure. Any sharp bends or twists at this stage can lead to long-term issues. Use fuel line supports or brackets to maintain the lines' shape and prevent excessive movement. Ensure that the fuel lines are not rubbing against any engine components, as this can cause damage over time. Proper alignment also allows for easy access during future maintenance, making it simpler to inspect and replace the lines if needed.

Take your time during this process, as precision is key. Double-checking connections and alignments will help prevent potential problems down the line. If you encounter any challenges or have doubts about the installation, consulting the kit's instructions or seeking guidance from an experienced mechanic is always a good idea.

Rubber Hose for Carb Fuel Line: A Practical Guide

You may want to see also

Testing: Start engine, check for leaks, and verify fuel flow to all cylinders

After installing the Big Line Fuel Line Kit on your 00 Cummins engine, it's crucial to conduct a thorough testing procedure to ensure everything is functioning correctly and there are no leaks. Here's a step-by-step guide on how to test the system:

Starting the Engine: Begin by starting the engine and allowing it to idle. This initial check is essential to observe any immediate issues. Pay close attention to any unusual noises or vibrations, as these could indicate potential problems. Let the engine run for a few minutes to reach its operating temperature, as this will provide a more accurate assessment.

Leak Detection: The next critical step is to inspect the engine for any leaks. Turn the engine off and locate the fuel lines, particularly the areas where the new kit was installed. Visually inspect the lines for any signs of fuel leakage. You can also use a soapy water solution to create a foam and carefully spray it around the connections and joints. If there are any leaks, they will be indicated by bubbles forming on the surface. Address any leaks immediately, as they can lead to serious engine issues.

Fuel Flow Verification: To verify that the fuel is flowing correctly to all cylinders, you'll need to check the engine's performance. Start by monitoring the engine's idle speed and stability. A well-functioning fuel system should provide a smooth and consistent idle. Then, gradually increase the engine speed and load to ensure that fuel is reaching all cylinders. You can use a scan tool to monitor the engine's data, looking for any abnormal fuel pressure or flow readings. If the engine responds as expected, with no hesitation or misfires, it confirms that the fuel flow is optimal.

Additionally, you can perform a load test by applying additional stress to the engine, such as using a dyno or driving the vehicle at high speeds. This will help identify any potential fuel delivery issues under real-world conditions. If the engine maintains its performance and there are no unusual symptoms, your Big Line Fuel Line Kit installation is likely successful.

Remember, proper testing is vital to ensure the longevity and reliability of your Cummins engine. By following these steps, you can identify and rectify any potential issues, ensuring a smooth and efficient fuel delivery system.

Fuel Line Freeze: A Guide to Winter Car Care

You may want to see also

Final Adjustments: Tighten connections, clean up, and ensure all components are functioning properly

After completing the installation of the Big Line Fuel Line Kit for your 00 Cummins engine, it's crucial to perform a series of final adjustments to ensure optimal performance and longevity. Here's a step-by-step guide to help you through this process:

Tighten Connections: Begin by checking all connections and fittings for tightness. Use a wrench or socket to ensure they are securely fastened. Pay close attention to the fuel lines, as proper tension is essential to prevent leaks. Tighten any loose fittings, but be careful not to over-tighten, as this can damage the lines or cause strain on the connections. Look for any signs of damage or wear, especially around the fittings, and replace any compromised parts.

Inspect for Leaks: With the connections tightened, start the engine and let it run. Observe for any signs of fuel leaks, which could indicate improper installation or damaged lines. Check under the vehicle and around the engine bay for any fuel residue or stains. If you notice any leaks, carefully inspect the connections and lines to identify the source. Tighten or replace any faulty connections to ensure a secure and leak-free system.

Clean and Organize: Give your engine bay a thorough cleaning to remove any dirt, debris, or fuel residue. This step is essential for maintaining a clean and professional appearance, as well as ensuring that no contaminants interfere with the fuel system's performance. Use a mild detergent and water solution to clean the engine and fuel lines. Rinse thoroughly to remove any cleaning agent, and then dry the area to prevent water spots. Organize the fuel lines and connections, ensuring they are neatly routed and not obstructing any other components.

Test and Functionality Check: Once the engine has cooled down, perform a comprehensive test of all fuel system components. Check the fuel pressure using a gauge to ensure it meets the manufacturer's specifications. Verify that the fuel pump is functioning correctly and delivering fuel to the engine as expected. Listen for any unusual noises and inspect for any signs of excessive vibration, which could indicate misalignment or loose connections. Ensure that all sensors and controls are responding accurately, providing real-time data to the engine's computer.

Final Inspection: Conduct a final visual inspection of the entire fuel line kit installation. Check for any signs of damage, cracks, or deterioration in the lines, especially in areas that experience the most stress or movement. Inspect the fittings and connections again, ensuring they are intact and secure. Verify that all components are functioning as intended, and make any necessary adjustments or replacements to guarantee optimal performance.

By following these final adjustments, you'll ensure that your 00 Cummins engine's fuel system is reliable, efficient, and ready for optimal performance. Remember, proper maintenance and attention to detail during the installation process will contribute to a longer-lasting and trouble-free fuel system.

Fuel vs. Oil: Automotive Fluids Demystified

You may want to see also

Frequently asked questions

Before you begin the installation, ensure you have the necessary tools such as a fuel line cutter, crimping tool, and various sizes of fuel line connectors. It's also crucial to have a clean workspace and the appropriate safety gear, including gloves and safety goggles. Prepare the fuel by running the engine for a while to ensure it's hot, making it easier to connect the lines.

Start by locating the existing fuel lines and marking their positions. Cut the old lines and disconnect them from the engine and fuel tank. Now, you can connect the new Big Line Fuel Line Kit. Use the appropriate connectors for the engine and tank, ensuring a tight fit. Remember to bleed the fuel system to remove any air bubbles after the installation.

Yes, regular maintenance is essential to keep the fuel system in top shape. Check the fuel lines for any signs of wear or damage periodically. Keep the fuel tank and lines clean to prevent contamination. It's also a good practice to use a fuel stabilizer in the tank to ensure the fuel remains fresh and the system operates efficiently.