Installing a fuel gauge on your car can be a straightforward process, but it requires careful attention to detail and adherence to safety guidelines. This guide will provide a step-by-step approach to help you successfully install a fuel gauge, ensuring your vehicle's fuel levels are accurately monitored. We'll cover the necessary tools, safety precautions, and the installation process, ensuring you have the knowledge to complete the task efficiently and effectively.

What You'll Learn

- Preparation: Gather tools, gauge, and wiring harness. Ensure car is off and parked on a level surface

- Locate the Gauge Mounting Position: Identify the best location for the gauge, considering visibility and accessibility

- Connect Wiring: Match gauge wiring colors to car's harness, ensuring correct polarity

- Secure the Gauge: Mount the gauge securely using screws or adhesive, following manufacturer's instructions

- Test and Calibrate: Turn on the car, check gauge functionality, and calibrate if necessary

Preparation: Gather tools, gauge, and wiring harness. Ensure car is off and parked on a level surface

Before you begin the installation process, it's crucial to gather all the necessary tools, components, and ensure you have a safe and controlled environment. Start by collecting the following items: a fuel gauge, a wiring harness, a set of screwdrivers (both flat and Phillips head), a wrench or socket set, a wire stripper, and a soldering iron (if you plan to solder the connections). These tools will be essential for a successful and secure installation.

Next, locate the fuel gauge and inspect it for any damage or defects. Ensure that it is compatible with your vehicle's make and model. Check the wiring harness as well; it should be in good condition and free from any signs of wear or damage. If you notice any issues with the gauge or harness, it might be best to source new parts to avoid complications during the installation.

Once you have all the necessary components, it's time to prepare your workspace. Park your car on a level surface, preferably in a well-ventilated area, and ensure it is turned off. This step is crucial for safety and to avoid any potential hazards. Make sure the car's engine is completely cooled down to prevent any heat-related issues during the installation.

With the car in a safe position, you can now proceed to the next step, which is connecting the fuel gauge to the wiring harness. Carefully follow the instructions provided with the gauge and harness, as the wiring process may vary depending on the specific model. Typically, you'll need to match the gauge's wiring to the corresponding terminals on the harness, ensuring a proper connection.

Before finalizing the installation, double-check all connections to ensure they are secure and properly insulated. Test the fuel gauge by starting the car and checking if the gauge reads the fuel level accurately. If everything is functioning correctly, you've successfully installed the fuel gauge, providing you with real-time fuel level information while driving.

Hydrogen Car Fuel Costs: A Comprehensive Guide to Pricing

You may want to see also

Locate the Gauge Mounting Position: Identify the best location for the gauge, considering visibility and accessibility

When installing a fuel gauge on your car, the first crucial step is to determine the optimal location for the gauge itself. This decision will significantly impact the functionality and usability of the gauge. The primary considerations are visibility and accessibility. You want the gauge to be easily visible to the driver, allowing for quick and accurate monitoring of the fuel level. At the same time, it should be conveniently located to facilitate quick adjustments or troubleshooting if needed.

A common and practical placement is within the instrument cluster, which is the central display area in the dashboard. This position ensures the gauge is directly in the driver's line of sight, providing a clear view of the fuel level without distracting the driver from the road. The instrument cluster is typically designed to accommodate various gauges and displays, making it a suitable choice for fuel gauge installation.

Another option is to mount the gauge in the center console or below the steering wheel. This placement offers good visibility and accessibility, especially if the gauge is designed with a slightly tilted or angled view to accommodate the driver's line of sight. However, it's important to ensure that the gauge is not obstructed by any controls or buttons, maintaining a clear and unobstructed view for the driver.

If you prefer a more discreet or less obtrusive installation, you might consider mounting the gauge in the glove box or under the dashboard, closer to the driver's side. While this may provide good visibility, it might require some additional wiring and may not be as easily accessible for quick adjustments.

Ultimately, the best location will depend on your specific vehicle and personal preferences. It's essential to measure and mark the desired position accurately before proceeding with the installation to ensure a proper fit and optimal visibility.

Gas Cap Mystery: Unlocking the Fuel Door's Secret

You may want to see also

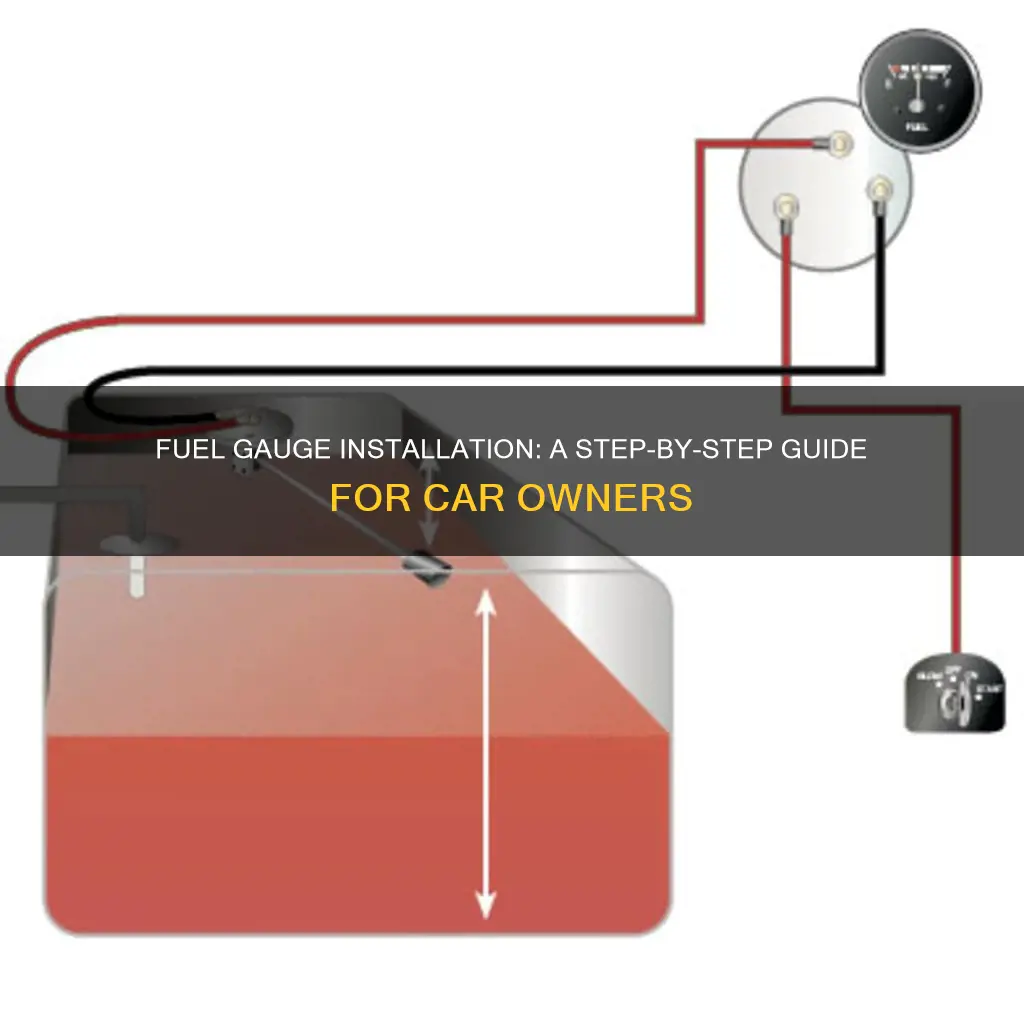

Connect Wiring: Match gauge wiring colors to car's harness, ensuring correct polarity

When installing a fuel gauge in your car, proper wiring connections are crucial to ensure accurate readings and prevent any potential issues. The first step is to familiarize yourself with the wiring colors and their corresponding functions in your vehicle's harness. Most modern cars use a standardized color-coding system for wiring, making it easier to identify the correct connections. Typically, the harness will have a set of wires with specific colors, each representing a particular gauge or sensor. For instance, black or brown wires often signify ground or power, while red or orange wires are commonly used for fuel level sensors.

To begin the wiring process, locate the fuel gauge sender unit and its corresponding wiring harness. This unit is usually connected to the fuel tank and sends electrical signals based on the fuel level. Carefully inspect the wiring colors and match them with the appropriate terminals on the gauge. Ensure that you connect the ground wire (often black or brown) to the ground terminal on the gauge and the power wire (usually red or orange) to the power input. The polarity of these connections is essential, so double-check that the wires are inserted correctly.

Next, identify the wiring harness that connects the fuel gauge to the dashboard. This harness will have wires that need to be matched with the gauge's terminals. Compare the colors of the wires in the harness with the gauge's wiring diagram or the vehicle's service manual. Connect the ground wire from the harness to the ground terminal on the gauge, and the power wire to the power input. Pay close attention to the polarity, as connecting the wires incorrectly could result in a non-functional gauge or even damage the gauge's internal components.

After ensuring the correct wiring connections, test the fuel gauge to verify its functionality. Start the vehicle's engine and check if the gauge responds accurately to changes in fuel level. If everything is connected correctly, the gauge should display the fuel level as expected. If you encounter any issues, such as the gauge not moving or displaying incorrect information, double-check the wiring connections and ensure that all wires are securely attached.

Remember, proper wiring is essential for the reliable operation of your fuel gauge. Taking the time to match the wiring colors and ensure correct polarity will help you avoid potential problems and ensure that your fuel gauge provides accurate readings, giving you peace of mind while driving. Always refer to the vehicle's manual or seek professional assistance if you're unsure about any wiring connections.

Unleash the Power: Top Fuel Funny Car Horsepower Revealed

You may want to see also

Secure the Gauge: Mount the gauge securely using screws or adhesive, following manufacturer's instructions

When installing a fuel gauge, ensuring it is securely mounted is crucial for accurate readings and the overall safety of your vehicle. Here's a step-by-step guide on how to achieve this:

Step 1: Choose the Right Location

Select a suitable position for your fuel gauge, typically near the dashboard or instrument cluster. Consider the ease of access and visibility for the driver. Ensure the chosen spot is free from direct impact or vibration, as this can affect the gauge's performance and longevity.

Step 2: Prepare the Mounting Surface

Clean the designated area on the dashboard or the instrument panel. Remove any dirt, dust, or debris to ensure a strong bond. If using screws, make sure the surface is smooth and free of any protruding edges that might interfere with the gauge's installation.

Step 3: Secure with Screws

If your fuel gauge comes with screws, follow the manufacturer's instructions for mounting. Typically, you'll need to align the holes on the gauge with the corresponding holes on the dashboard. Insert the screws through the holes and tighten them securely. Ensure the gauge is firmly attached and cannot be easily shaken or moved.

Step 4: Adhesive Mounting (Optional)

Some fuel gauges might come with adhesive pads or double-sided tape for a screw-less installation. If so, carefully follow the manufacturer's guidelines. Clean the surface and apply the adhesive, ensuring it is firmly pressed against the dashboard. Allow the adhesive to set according to the instructions provided. This method provides a seamless and discreet look.

Step 5: Final Adjustments

After securing the gauge, double-check its alignment and positioning. Ensure it is level and centered within the instrument cluster. Adjust the gauge's sensitivity and calibration settings according to the manufacturer's recommendations to ensure accurate fuel level readings.

Remember, always refer to the specific instructions provided by the fuel gauge manufacturer for the most accurate and safe installation process. Properly securing the gauge will contribute to a reliable and long-lasting addition to your vehicle's dashboard.

Car Fuel Filter Cleaning: A DIY Guide

You may want to see also

Test and Calibrate: Turn on the car, check gauge functionality, and calibrate if necessary

Once you've installed the fuel gauge, it's crucial to test and calibrate it to ensure accurate fuel level readings. Here's a step-by-step guide to help you through this process:

Step 1: Turn on the Car and Check Gauge Functionality

Start by turning on your car's ignition. Observe the fuel gauge's behavior. It should start displaying the fuel level, which might be at the 'empty' mark initially. If the gauge doesn't move or shows an incorrect reading, there might be an issue with the installation or the gauge itself. In such cases, you may need to inspect the connections and ensure they are secure and properly seated.

Step 2: Calibration

Calibration is essential to ensure the fuel gauge provides accurate readings. Here's how you can calibrate it:

- Full Tank Test: Fill your car's fuel tank completely and note the initial fuel level reading on the gauge. Start the engine and drive the car until the fuel level drops to the desired level (e.g., until the 'low fuel' warning light comes on). Then, stop the car and check the fuel gauge reading. It should match the actual fuel consumed. If there's a discrepancy, you might need to adjust the calibration.

- Empty Tank Test: Similarly, drain the fuel tank completely (if possible) and note the initial reading. Refill the tank and drive the car until the fuel level reaches the desired point, then check the gauge. Again, there should be a match between the gauge and the actual fuel level. If not, you may need to calibrate the gauge.

Troubleshooting:

- If the gauge readings consistently deviate from the actual fuel level, you might need to adjust the calibration settings. This often involves using a specialized tool or software provided by the manufacturer.

- Ensure that the fuel gauge is properly aligned with the fuel tank's sending unit. Misalignment can lead to inaccurate readings.

Step 3: Verify Accuracy

After calibration, regularly check the fuel gauge's accuracy by performing the full tank and empty tank tests periodically. This will help you identify any potential issues early on and ensure the gauge provides reliable information.

Remember, proper testing and calibration are vital to getting the most out of your newly installed fuel gauge. It ensures that you have accurate fuel level information, helping you manage your vehicle's fuel efficiency and maintenance effectively.

Running Your Car: Fuel Pump's Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

To install a fuel gauge, you will typically need a fuel gauge sender, a gauge itself, wiring harnesses, and basic hand tools like screwdrivers and wire cutters. It's also a good idea to have a multimeter for testing electrical connections.

It depends on the specific make and model of your car. Some vehicles allow for in-dash installation, where you can fit the new gauge into the existing dashboard opening. However, for many cars, you will need to remove the old gauge and dashboard trim to access the wiring and install the new gauge.

Start by identifying the correct color-coded wires for the fuel level sensor and the gauge. Typically, you'll have a black wire for power, a brown or red wire for the sensor signal, and a yellow or white wire for ground. Connect the sensor to the fuel tank and then run the wires through the dashboard to the gauge, ensuring you secure them with the appropriate clips or connectors.

Yes, testing is crucial. After connecting the wiring, use a multimeter to check for continuity and ensure the gauge is functioning correctly. Also, test the sensor by filling the tank with fuel and observing the gauge's response to confirm it accurately reflects the fuel level.

While it is possible to install a fuel gauge yourself, especially if you have some mechanical experience, it can be complex, especially for older or more intricate vehicle models. If you're unsure or uncomfortable with the process, it's recommended to seek professional assistance to ensure a proper and safe installation.