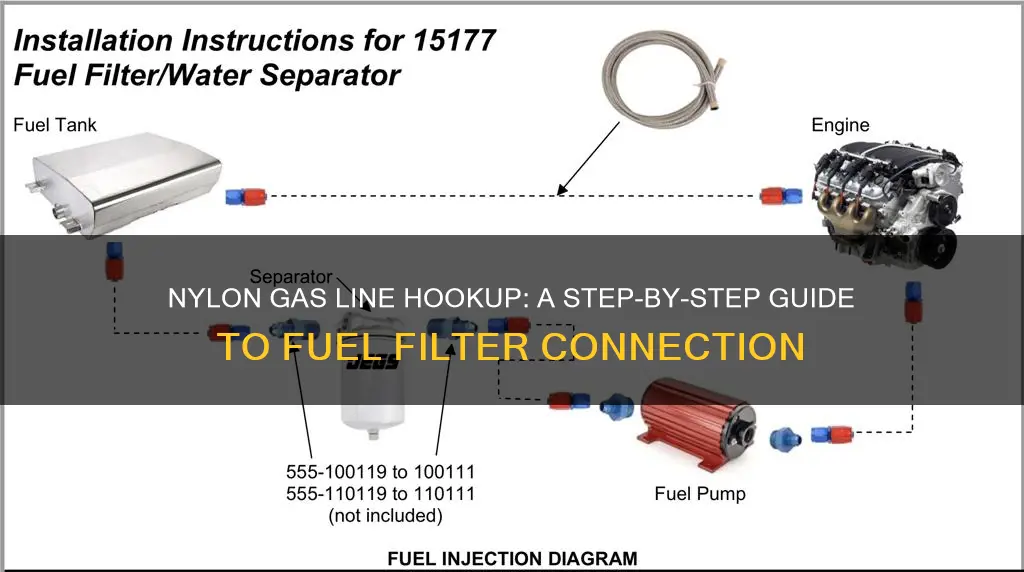

Hooking up a nylon gas line to a fuel filter is a crucial step in ensuring your vehicle's engine receives a steady supply of clean fuel. This process involves connecting the gas line from the fuel tank to the filter, which acts as a barrier to trap contaminants and ensure optimal engine performance. By following a few simple steps, you can securely attach the nylon gas line to the fuel filter, ensuring a reliable and efficient fuel system. This guide will provide a step-by-step approach to make the connection, ensuring your vehicle's engine operates smoothly and efficiently.

| Characteristics | Values |

|---|---|

| Material | Nylon |

| Purpose | Connecting to a fuel filter |

| Application | Gas lines |

| Process | Hooking up involves threading the nylon line onto the fuel filter's port and securing it with a ferrule or clamp |

| Compatibility | Ensure the nylon line is compatible with the fuel filter's specifications and the type of fuel being used |

| Safety | Properly secure the connection to prevent fuel leaks and ensure a tight seal |

| Maintenance | Regularly inspect the connection for any signs of damage or wear and replace if necessary |

| Advantages | Nylon lines are flexible, lightweight, and resistant to fuel degradation |

| Disadvantages | May require specialized tools for installation |

What You'll Learn

- Prepare Tools: Gather necessary tools: wrench, gas line connectors, and cleaning supplies

- Inspect Gas Line: Check for damage, kinks, or leaks before connecting to fuel filter

- Connect Gas Line: Tighten connectors securely, ensuring a tight seal to prevent gas leaks

- Test for Leaks: Spray soapy water around connections to identify any potential leaks

- Secure Gas Line: Use clamps or brackets to fasten the gas line to the fuel filter securely

Prepare Tools: Gather necessary tools: wrench, gas line connectors, and cleaning supplies

Before you begin the process of connecting a nylon gas line to a fuel filter, it's crucial to ensure you have all the necessary tools and supplies. This preparation will make the task easier and more efficient. Here's a detailed guide on what you need to gather:

Wrench: A wrench is an essential tool for any plumbing or fuel system work. You'll need a wrench that fits the size of the gas line connectors you are using. Common sizes include 1/4-inch, 3/8-inch, and 1/2-inch. Make sure it is adjustable or have a set of different sizes to accommodate various connections. Wrenches are used to tighten and loosen fittings, ensuring a secure and leak-free connection.

Gas Line Connectors: These connectors are specifically designed for joining gas lines and should be compatible with the nylon material. Look for connectors that are rated for fuel applications to ensure they can handle the pressure and temperature changes associated with gasoline. Common types include compression fittings, quick-connect fittings, and barbed fittings. Ensure you have the appropriate size and type for your gas line and fuel filter setup.

Cleaning Supplies: Cleaning the work area and the fuel filter is essential to prevent contamination and ensure a proper connection. Gather some cleaning supplies such as:

- Solvent: A suitable solvent, like gasoline or a fuel-safe cleaner, to dissolve any dirt, grease, or old fuel residue.

- Brushes: Soft-bristled brushes can be used to scrub away any debris or contaminants from the gas line and fuel filter.

- Rags or Cloths: Have some clean rags or cloths ready for wiping down surfaces and removing any residue.

- Air Hose or Blowgun: An air hose or blowgun can be used to blow away any loose particles or solvent vapor, ensuring a clean work environment.

Having these tools and supplies prepared will make the process of connecting the nylon gas line to the fuel filter much smoother. It ensures that you have everything readily available, allowing you to work efficiently and effectively while maintaining a safe and clean work area.

Is Nylon Suitable for Fuel Lines? Unraveling the Truth

You may want to see also

Inspect Gas Line: Check for damage, kinks, or leaks before connecting to fuel filter

Before you begin the process of connecting the nylon gas line to the fuel filter, it is crucial to thoroughly inspect the gas line for any potential issues. This step is essential to ensure the safety and proper functioning of your fuel system. Start by examining the gas line for any visible signs of damage, such as cracks, punctures, or tears. Look for any areas where the line might have been compromised, especially at the points where it connects to the fuel filter and other components. Inspect the entire length of the line, paying close attention to any bends or kinks. Kinks in the line can restrict fuel flow and potentially cause damage over time. Ensure that the line is straight and free from any sharp bends that might lead to stress points.

Check for any signs of corrosion or deterioration, especially if the line has been exposed to harsh weather conditions or chemicals. Corroded lines can develop small holes or leaks, which can lead to fuel leaks and potential safety hazards. If you notice any damage, it is best to replace the affected section of the gas line to ensure a secure connection. Additionally, look for any signs of leaks by applying a small amount of soapy water to the line and observing for any bubbles. Even a small leak can be a serious issue, so address any potential problems immediately.

When inspecting the gas line, also check for any loose connections or fittings. Ensure that all connectors are tightened securely to prevent fuel leakage. You can use a wrench to tighten the fittings, but be careful not to overtighten, as this can also cause damage. It is a good practice to carry out this inspection regularly, especially if you have recently worked on the fuel system or if the vehicle is older. Regular maintenance helps identify and rectify potential issues before they become major problems.

If you find any issues during the inspection, such as significant damage or persistent leaks, it is advisable to consult a professional mechanic or automotive specialist. They can provide expert advice and ensure that the gas line is safely and correctly connected to the fuel filter. Remember, proper inspection and maintenance of the gas line are critical to preventing fuel-related accidents and ensuring the longevity of your vehicle's fuel system.

The Ultimate Guide to Choosing Lubricant for Fuel Line Installation

You may want to see also

Connect Gas Line: Tighten connectors securely, ensuring a tight seal to prevent gas leaks

When connecting a nylon gas line to a fuel filter, ensuring a secure and leak-free attachment is crucial for the safe operation of your vehicle. Here's a step-by-step guide to help you achieve this:

Start by ensuring you have the right tools and materials. You'll need the nylon gas line, a fuel filter adapter (if required), and a set of wrenches or pliers. It's essential to use the correct size and type of connectors for your specific gas line and filter. Measure and cut the nylon gas line to the appropriate length, leaving a few extra inches for flexibility.

Now, focus on the connector attachment. Take the nylon gas line and align it with the fuel filter's inlet port. Insert the connector onto the gas line, ensuring it is fully seated and aligned with the port. Use your wrench or pliers to tighten the connector securely. Apply firm pressure and turn it clockwise until it is snug, but be careful not to overtighten, as this can damage the gas line. A tight seal is critical to prevent gas leaks, so take your time and ensure it is secure.

Check for any signs of leakage around the connector. You can use a soapy water solution to test for leaks. If no bubbles appear, it indicates a successful seal. If you notice any leaks, carefully tighten the connector further, being mindful of not over-tightening.

Remember, a well-connected gas line is essential for the efficient operation of your vehicle's fuel system. Always follow manufacturer guidelines and use the correct tools to ensure a professional-grade installation. Regularly inspect your connections for any signs of wear or damage, especially if you've had any previous issues with gas leaks.

Locating the Fuel Line: A 2006 325i BMW Guide

You may want to see also

Test for Leaks: Spray soapy water around connections to identify any potential leaks

When connecting a nylon gas line to a fuel filter, it's crucial to ensure a tight and secure fit to prevent any potential leaks. One of the most effective ways to verify the integrity of these connections is by conducting a simple yet crucial test: the soapy water leak test. This test is a quick and easy method to identify any potential issues before you start using the system.

Here's a step-by-step guide on how to perform this test:

- Gather the Materials: You'll need a few simple items for this test. First, prepare a bucket or large container filled with soapy water. The soap is essential because it creates a visible lather that will make any leaks stand out. You'll also need a spray bottle or a small squirt gun to apply the soapy water.

- Prepare the Connections: Before you begin, ensure that the nylon gas line is properly connected to the fuel filter. If it's a new installation, double-check that all fittings are tightened correctly. If it's an existing setup, you might want to clean the connections to remove any dirt or debris that could interfere with the test.

- Spray and Observe: Start by spraying a gentle stream of soapy water around each connection point. Pay close attention to the areas where the nylon gas line connects to the fuel filter and any other fittings or valves. The soapy water will create a lather, and if there's a leak, you'll see bubbles forming around the connection. Even a small leak can be detected this way.

- Inspect Thoroughly: Take your time to inspect all the connections. Leaks can occur at any point, so be thorough. Look for any signs of water entering the system where it shouldn't, as even a tiny gap can lead to significant issues over time. If you notice any bubbles forming, it indicates a potential leak, and you should address it immediately.

- Address Leaks: If you find any leaks, it's essential to fix them before using the system. Tighten connections, replace damaged fittings, or seek professional help if the leak is significant. Properly sealing the connections will ensure the safety and efficiency of your fuel system.

By following this simple test, you can ensure that your nylon gas line and fuel filter are securely connected and free from leaks, providing a safe and reliable fuel supply for your vehicle or equipment. It's a critical step in the process of hooking up the gas line to the fuel filter, ensuring that your setup is both functional and safe.

Mobile Mechanics: Can They Drain Fuel Lines?

You may want to see also

Secure Gas Line: Use clamps or brackets to fasten the gas line to the fuel filter securely

When connecting a nylon gas line to a fuel filter, ensuring a secure and reliable attachment is crucial to prevent leaks and ensure the safe operation of your vehicle. One effective method to achieve this is by using clamps or brackets specifically designed for this purpose. Here's a step-by-step guide on how to secure the gas line using these components:

Start by locating the fuel filter in your vehicle's engine compartment. It is typically a cylindrical or rectangular component with connections for the gas line and other fuel system components. Identify the correct port or fitting on the fuel filter where the gas line will be attached. Clean the fuel filter and the gas line connections to ensure a proper seal. This step is essential to remove any dirt or debris that might interfere with the connection.

Next, prepare the gas line by cutting it to the appropriate length. Ensure that the cut is clean and smooth to facilitate a secure connection. Slide the gas line onto the fuel filter fitting until it is fully inserted. The nylon gas line should fit snugly over the fitting, providing a good initial seal. Now, it's time to secure the connection using clamps or brackets.

For clamps, choose a size that fits the diameter of your gas line. Tighten the clamp firmly around the gas line and the fuel filter fitting. Ensure that the clamp is secure but not overly tight, as this can restrict fuel flow. Clamps provide a reliable and adjustable hold, allowing you to position the gas line as needed. Alternatively, brackets offer a more permanent solution. Mount the bracket onto the fuel filter housing, ensuring it is positioned to support the gas line at the desired angle. Secure the gas line to the bracket using the appropriate fasteners. Brackets are especially useful when you want to maintain a specific orientation for the gas line.

Once the gas line is securely attached to the fuel filter using clamps or brackets, double-check the connection for any signs of leaks. Apply a small amount of fuel line sealant to the connection if necessary, especially if you're using clamps. This additional step can provide extra protection against leaks. After ensuring a secure and leak-free connection, start the vehicle and check for any unusual noises or vibrations. Properly secured gas lines contribute to a smooth and efficient fuel supply, ensuring your vehicle operates optimally.

Unraveling the Mystery: Understanding Fuel Pump Line Requirements

You may want to see also

Frequently asked questions

Nylon gas lines are commonly used for fuel filtration systems due to their flexibility, durability, and resistance to fuel-related chemicals. They provide a reliable and cost-effective solution for transporting fuel from the tank to the filter and then to the engine.

Connecting the nylon gas line to the fuel filter is a straightforward process. Start by ensuring the fuel line is clean and free of any debris. Then, slip the male end of the nylon line over the female port on the fuel filter, pushing it on until it is securely attached. Use a fuel line clamp to hold the connection in place and ensure a tight seal.

Yes, you will need a few essential tools to make the connection. A fuel line cutter or a pair of sharp scissors will help you trim the nylon line to the desired length. A fuel line clamp or ferrule is necessary to secure the line to the filter and create a leak-free seal. It is also recommended to have a fuel line primer or tape to ensure a tight connection, especially if the line is not pre-primed.

It is important to choose the right size and type of nylon gas line for your specific application. Consider the fuel filter's specifications and the diameter of the existing fuel lines in your vehicle. Using the correct size ensures a proper fit and allows for efficient fuel flow. Additionally, opt for a high-quality nylon line from a reputable manufacturer to ensure longevity and reliability.